Smoking Article

a technology of smoking articles and cigarettes, applied in the field of smoking articles, can solve the problems of increased smoke delivery for equivalent puff volumes, no longer providing a low resistance path in the tube, and loss of action, so as to reduce the pressure differential, increase the ventilation level, and reduce the effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

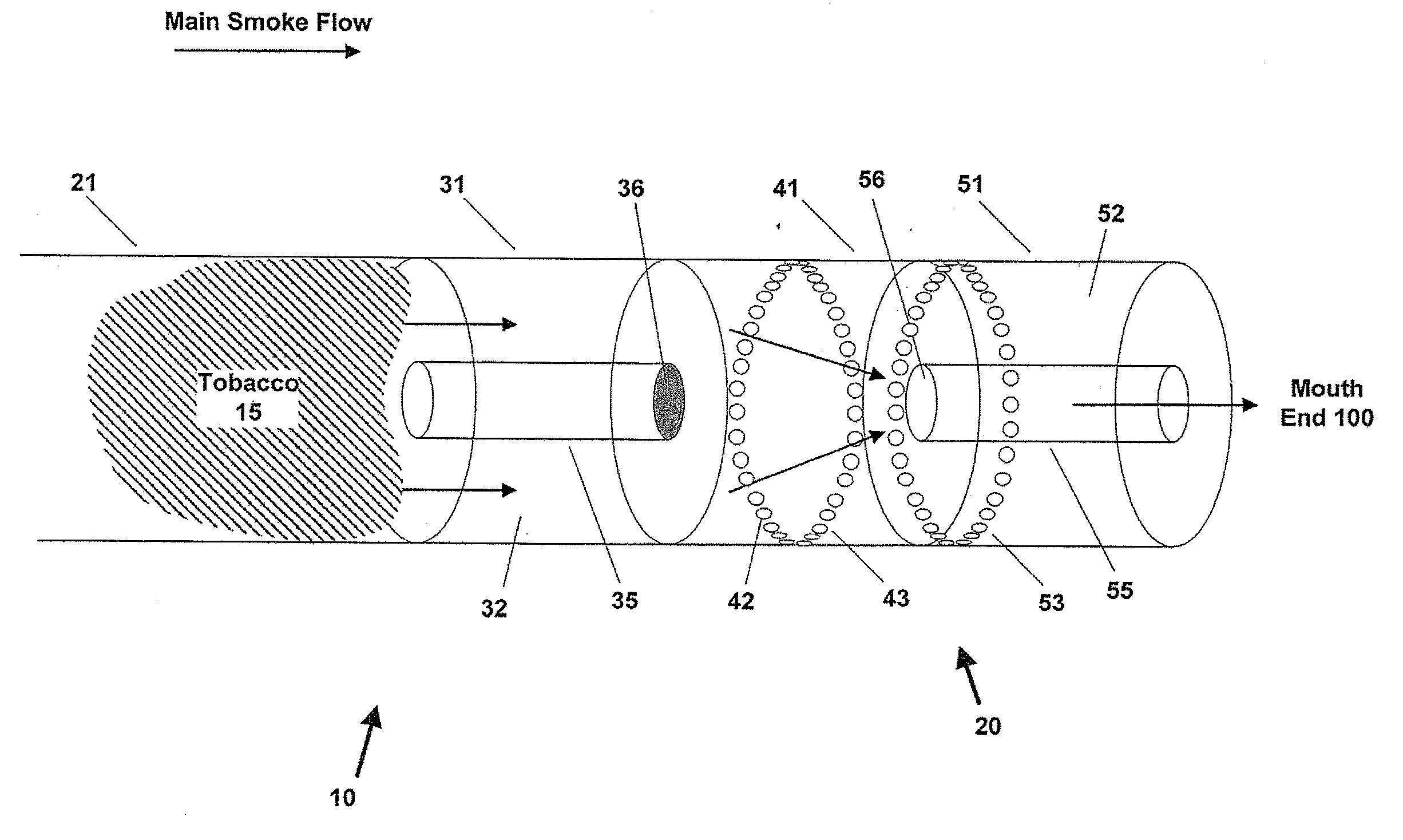

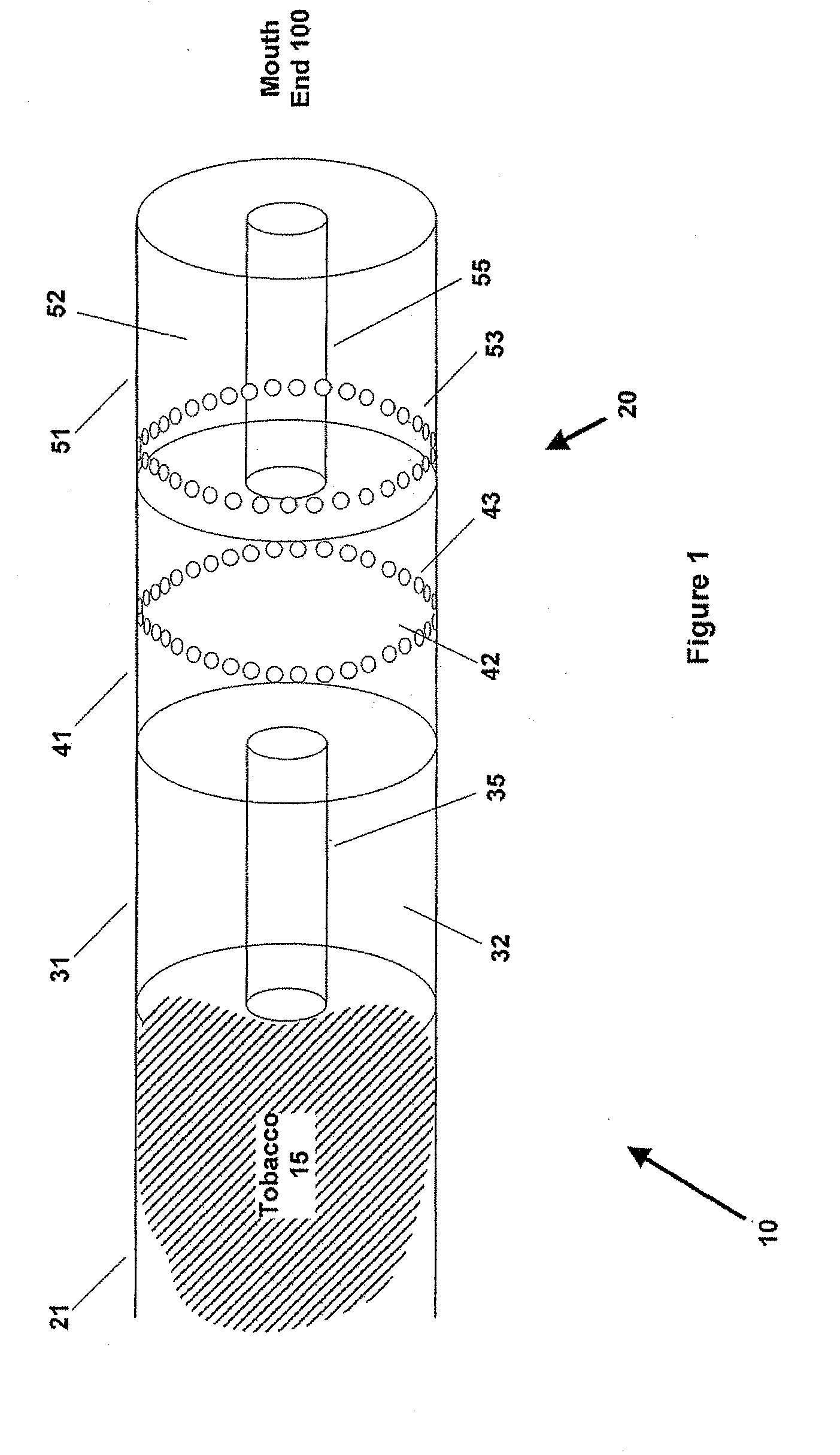

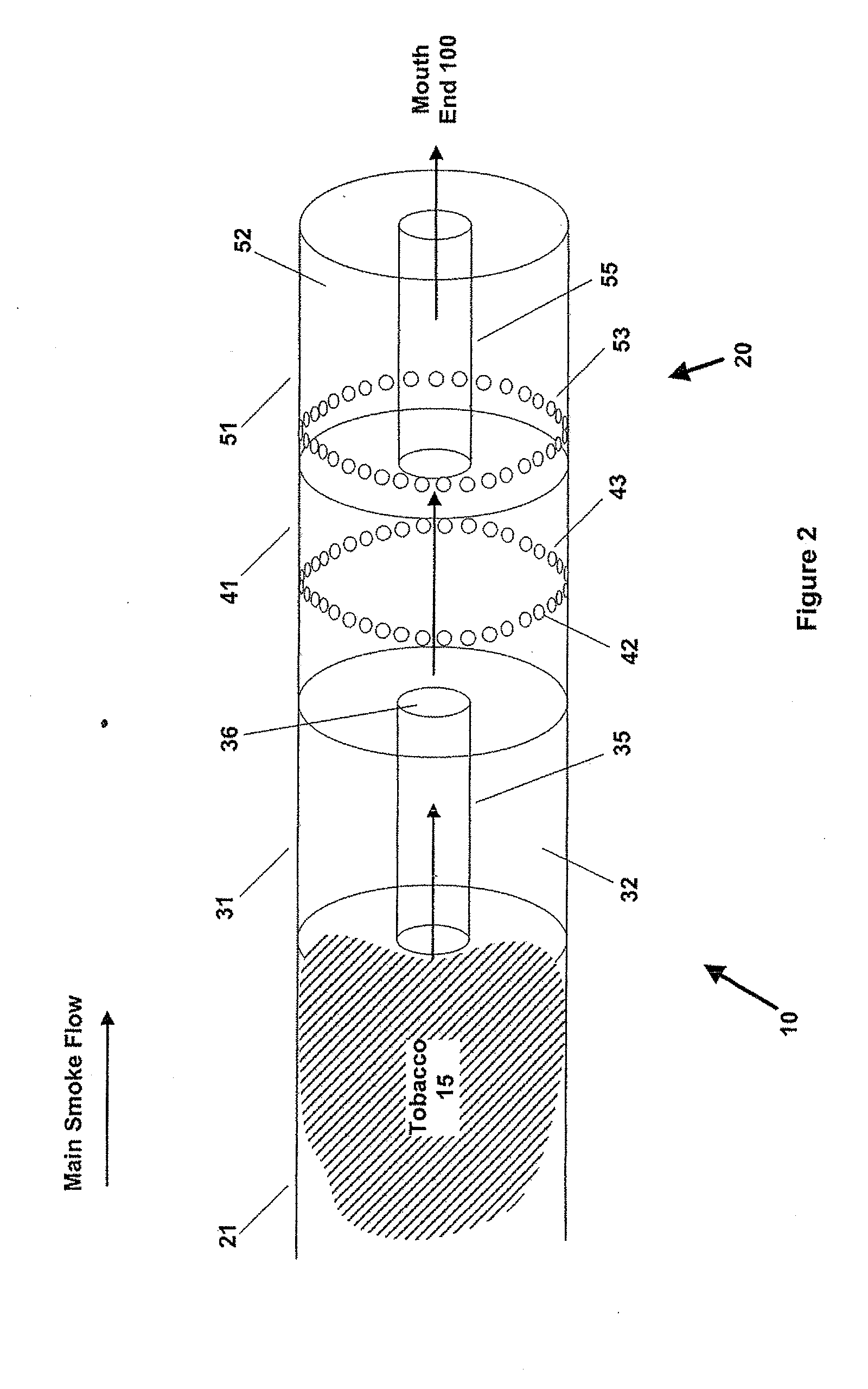

[0020]FIG. 1 is the schematic illustration of a cigarette 10 in accordance with one embodiment of the invention. Cigarette 10 has a generally cylindrical shape, and comprises a tobacco rod 15 (only shown partly in FIG. 1) joined to a filter 20 with an outer wrap 21. The filter is located at the mouth end 100 of the cigarette. The cigarette 10 is lit at the end of the tobacco rod 15 opposite to the mouth end.

[0021]Filter 20 comprises three sections 31, 41, 51 arranged along the cylindrical axis of the cigarette, where each section is cylindrical in shape. Section 31 is adjacent the tobacco rod 15, section 51 is adjacent the mouth end 100, and section 41 is between section 31 and section 51. The configuration of cigarette 10 is therefore determined by a succession of three planes, all perpendicular to the cylindrical axis of the cigarette. The first plane defines the boundary between tobacco rod 15 and the first filter element 31, the second plane defines the boundary between the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com