Floating Structure

a floating structure and structure technology, applied in waterborne vessels, special-purpose vessels, vehicles, etc., can solve the problems of long working period for double-hull change, high construction cost, and oil pollution of rivers and oceans, and achieve the effect of reducing construction costs and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

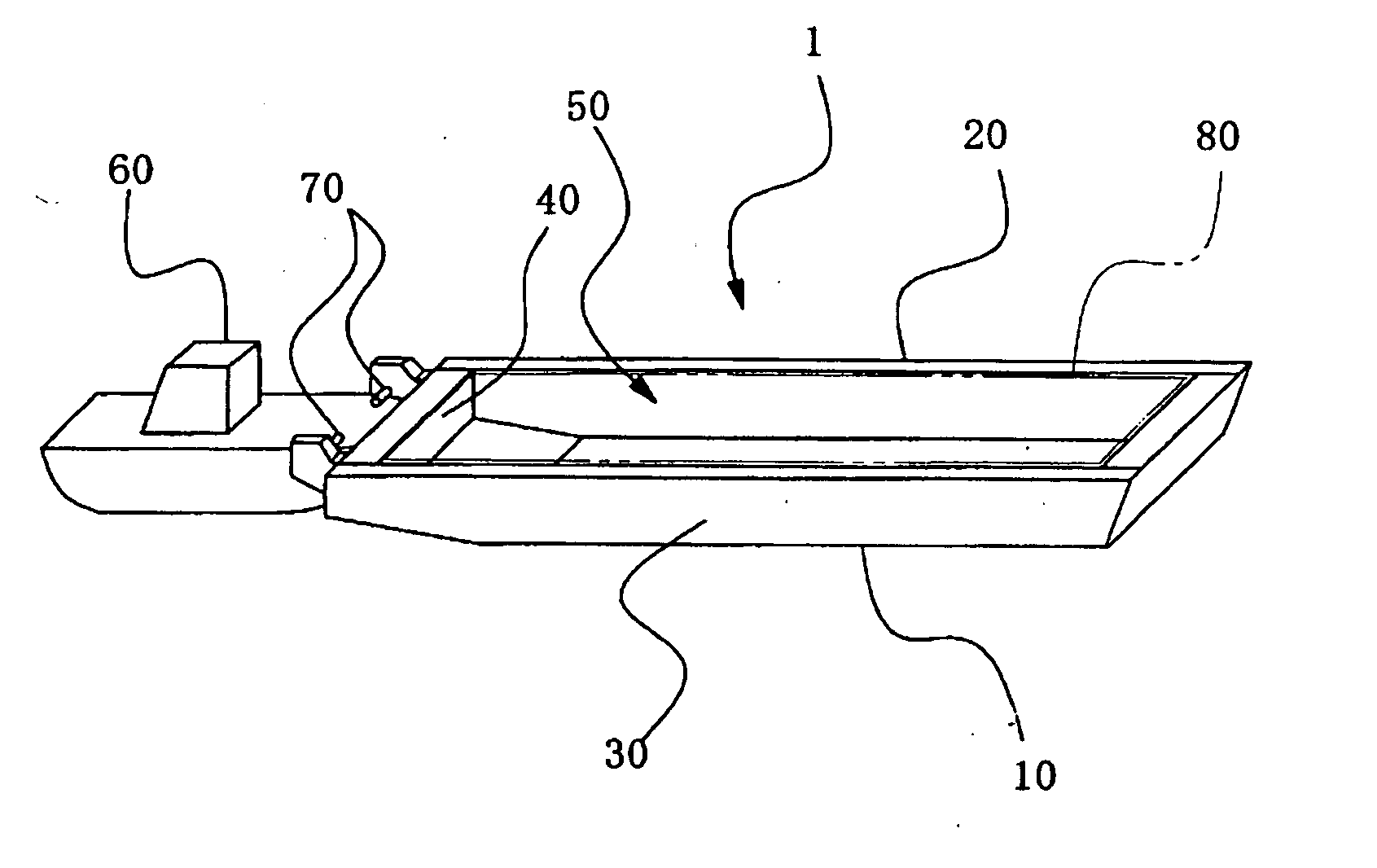

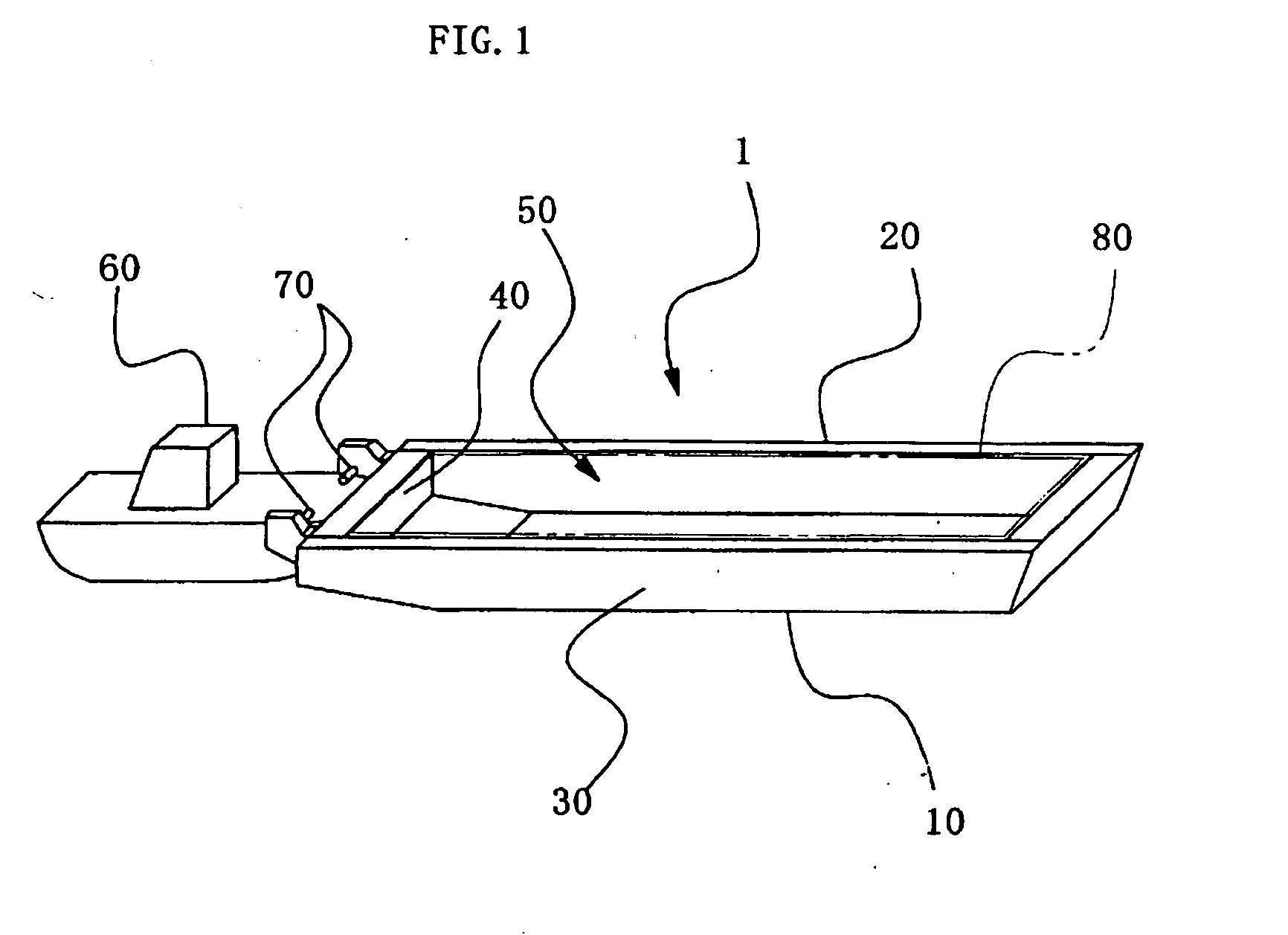

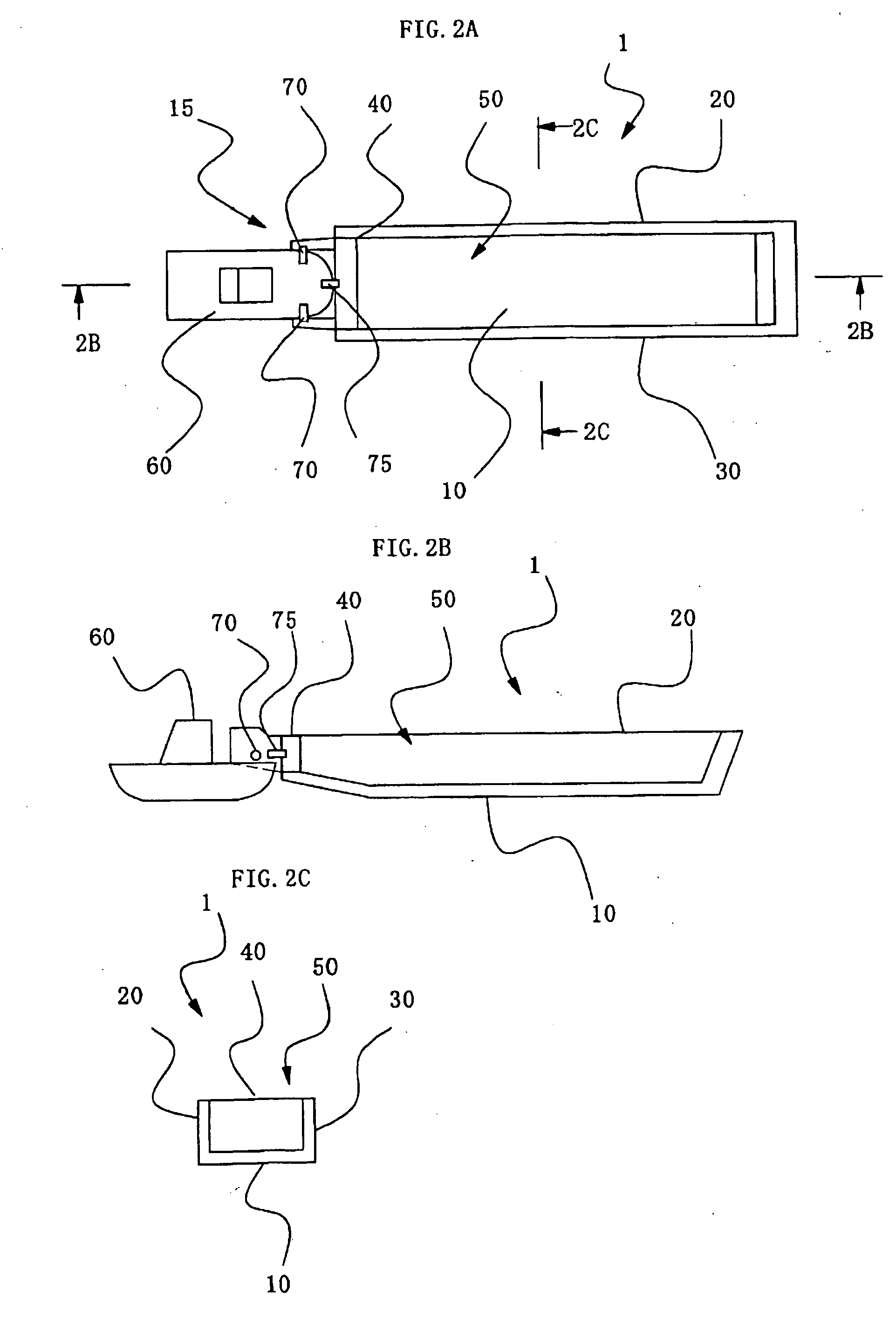

[0032]FIG. 1 illustrates the floating structure that lies in one execution form of this invention, FIG. 2A illustrates a plan of the floating structure that lies in one execution form of this invention, FIG. 2B illustrates a longitudinal section of the floating structure that lies in FIG. 2A, FIG. 2C illustrates a cross sectional side view of the floating structure that lies in FIG. 2A. Floating structure 1 that lies this invention as shown in FIGS. 1,2A,2B,2C, possesses the hull structure made of steel that can endure hydraulic pressure under the water line, and gives necessary rust prevention painting, etc. This floating structure 1 has central tank 10 where a front wall and the bottom of a structure are composed, wing tank 20 where a left wall is composed, wing tank 30 where a right wall is composed, and gate 40 that composes a rear wall.

[0033]Central tank 10 has the floating body of the abbreviation box shape of the size of extent in which the oil tanker and oil barge of single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com