Cross Groove Type Constant Velocity Joint with Composite Groove Patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

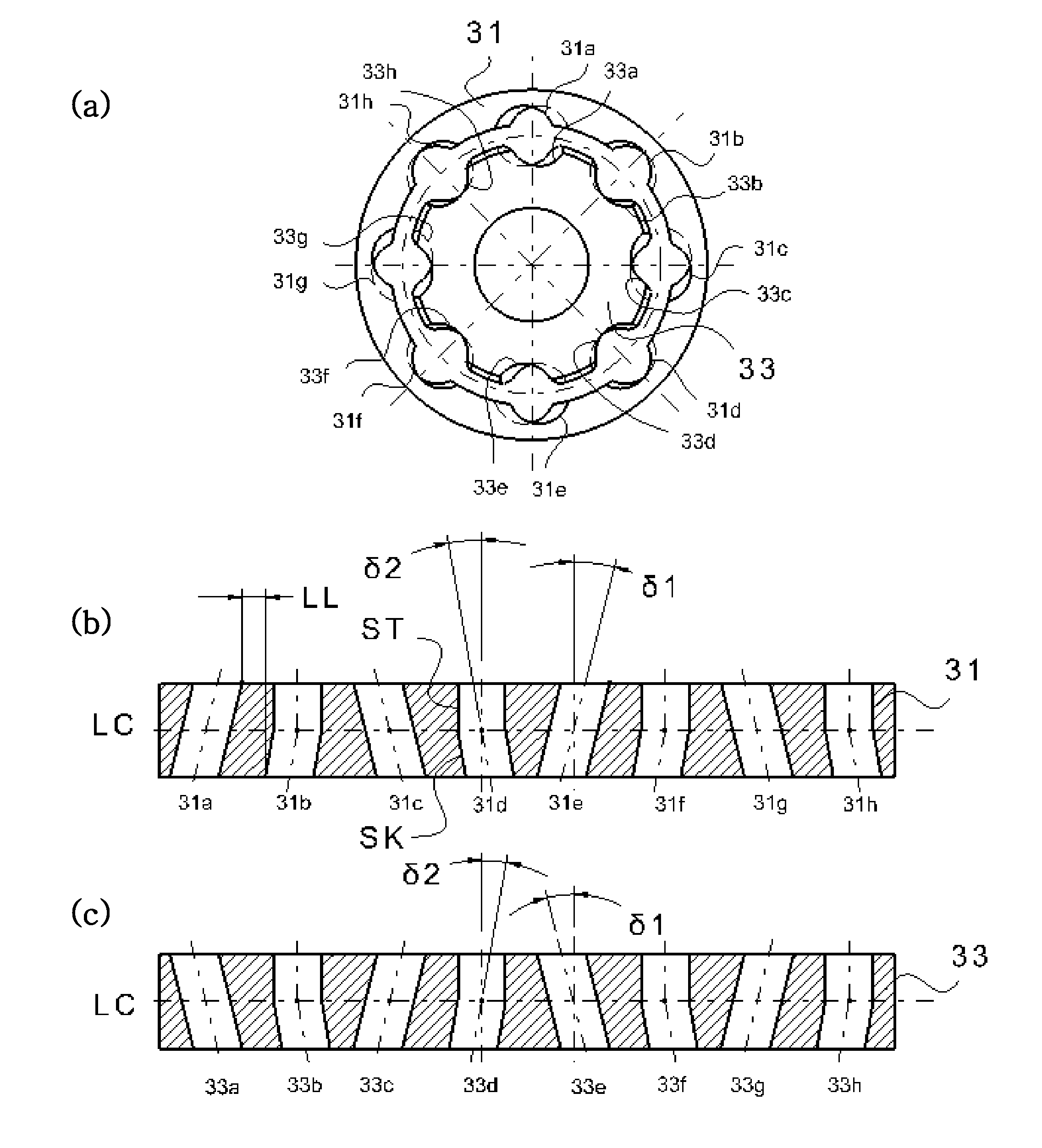

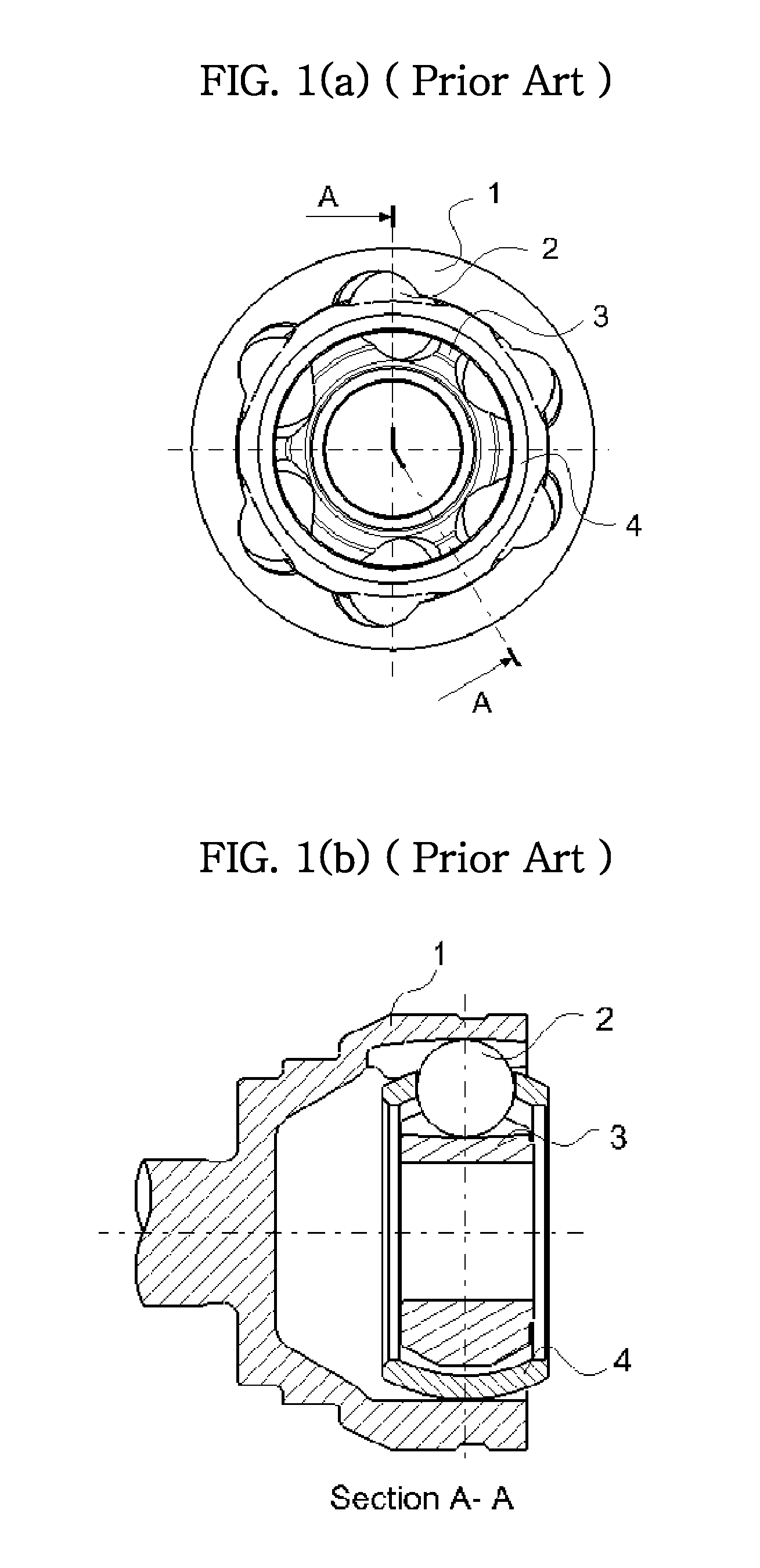

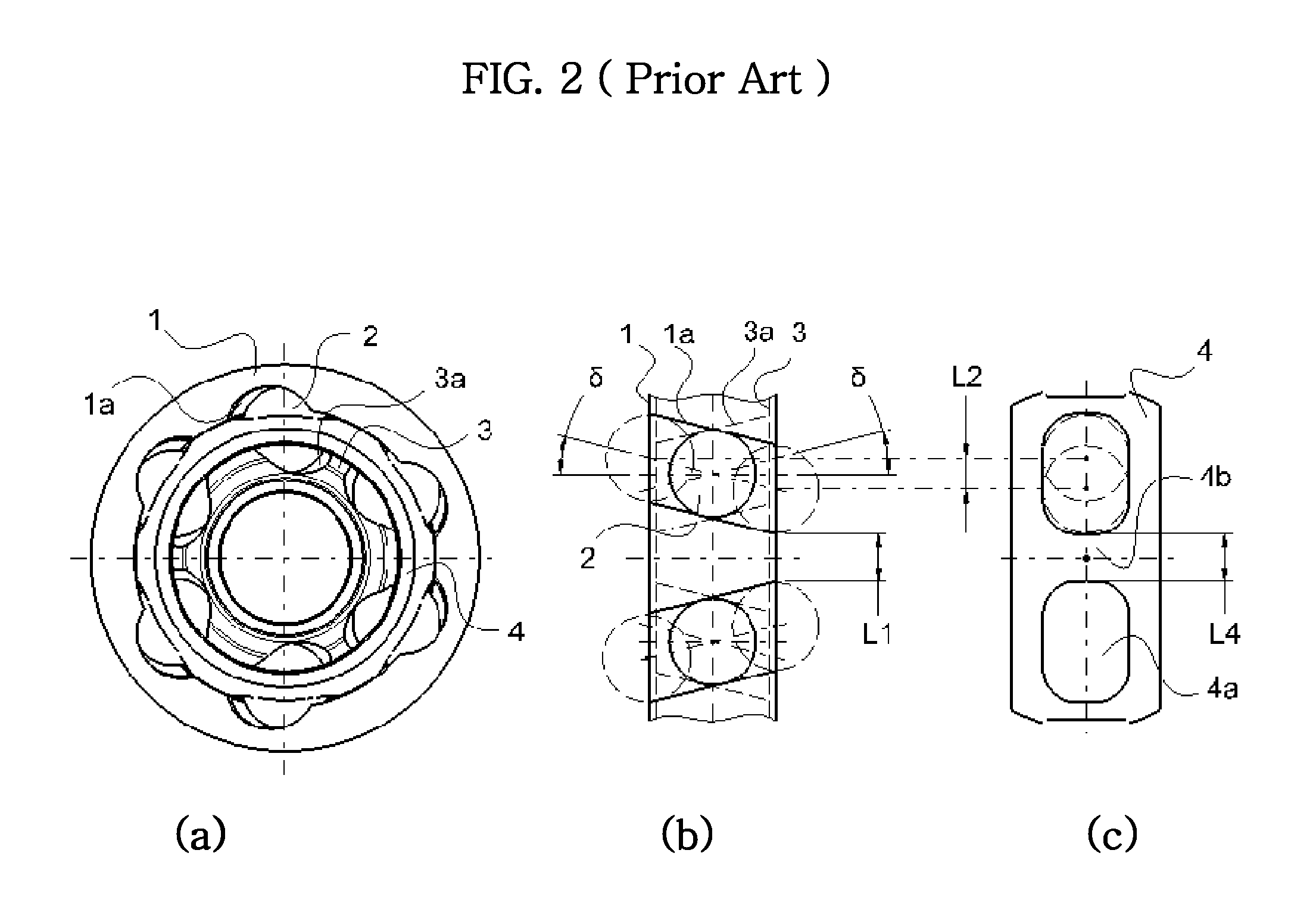

[0031]The present invention will be explained and illustrated below in association with several embodiments to be described later, in particular, the cross groove joint of eight ball type. However, it is noted that the present invention is not limited to the eight ball type joint, but is applicable to the cross groove joint of any ball type, for example, having six, eight, ten, or more balls.

[0032]Referring to FIGS. 5-10 of the drawings, the cross groove type constant velocity joints of the present invention are described herein in details with several exemplary or preferred embodiments thereof. However, the following descriptions of such embodiments are intended primarily for illustrating the principles and exemplary constructions of the constant velocity joints of the present invention, and the present invention is not specifically limited to these exemplary embodiments. Thus, one skilled in the art can appreciate or recognize that various modifications and substitutions can be ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com