Electrically conductive yarn with reduced torsions

a technology of torsions and conductive yarns, applied in the field of electrically conductive yarns, can solve the problems of failure of yarns and yarns may no longer provide the function of heating elements in e, and achieve the effects of increasing reducing the life expectancy of applications comprising yarns, and affecting the flexlife of yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

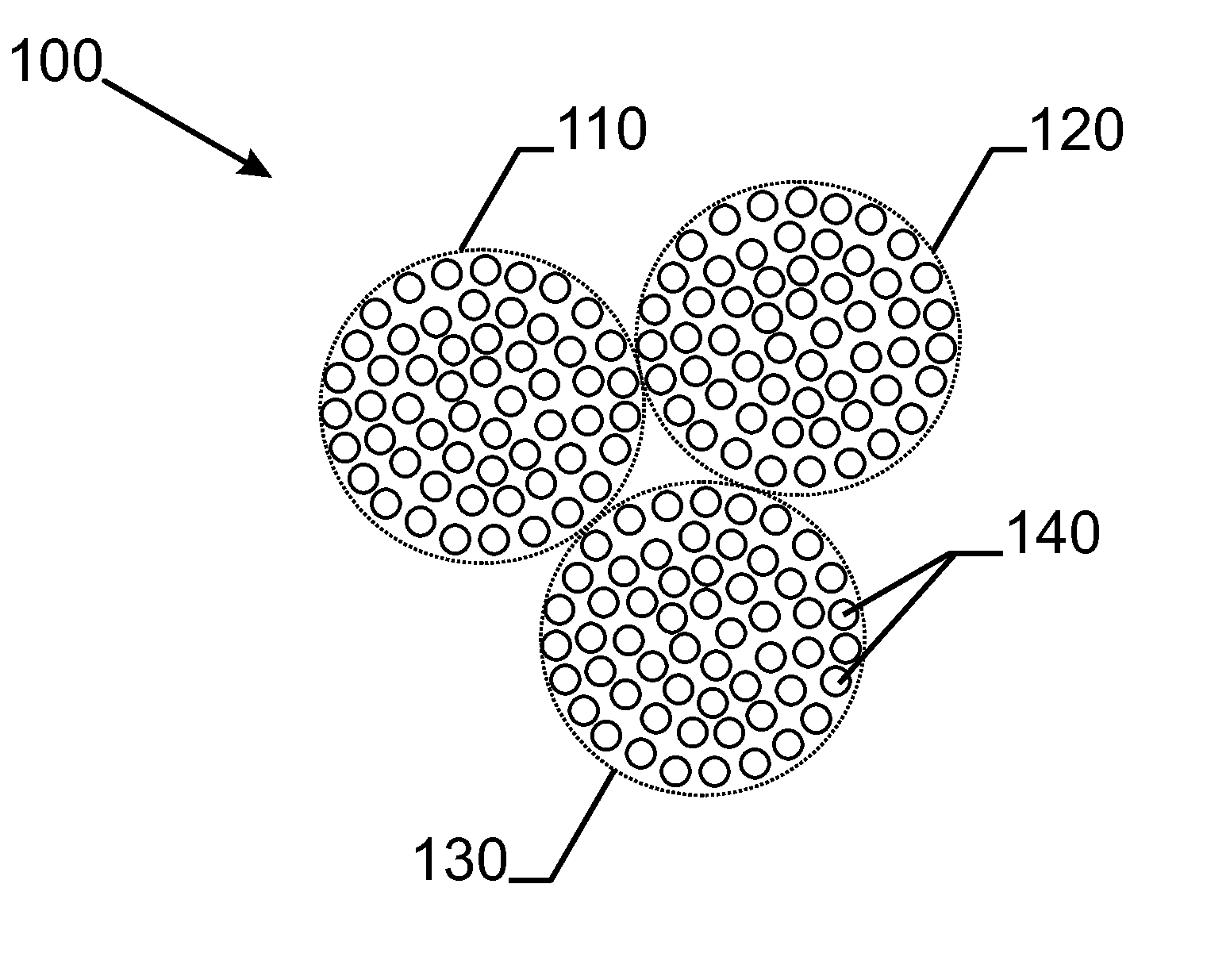

[0023]Yarns according to the present invention comprise one or more bundles of metal fibres, each bundle comprising at least 30 metal fibres. FIG. 1 schematically depicts a cross-sectional view of a yarn 100 according to the present invention. The yarn 100 comprises three bundles 110, 120 and 130 each comprising more than 30 metal fibres 140.

[0024]In the present invention, metal is to be understood as encompassing both metals and metal alloys (such as stainless steel) or compositions. As an example, the metal fibres as applied in the present invention may comprise a stainless steel core enclosed by copper or a copper alloy. Alternatively, the metal fibres as applied in a yarn according to the present invention may have a copper core surrounded by a stainless steel mantle. Such fibres provide improved electrical properties combined with the corrosion and oxidation resistance of stainless steel. Said stainless steel is preferable chosen out of AISI 300 series such as AISI 302, 304, 31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| equivalent diameter | aaaaa | aaaaa |

| equivalent diameter | aaaaa | aaaaa |

| equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com