Sealed container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

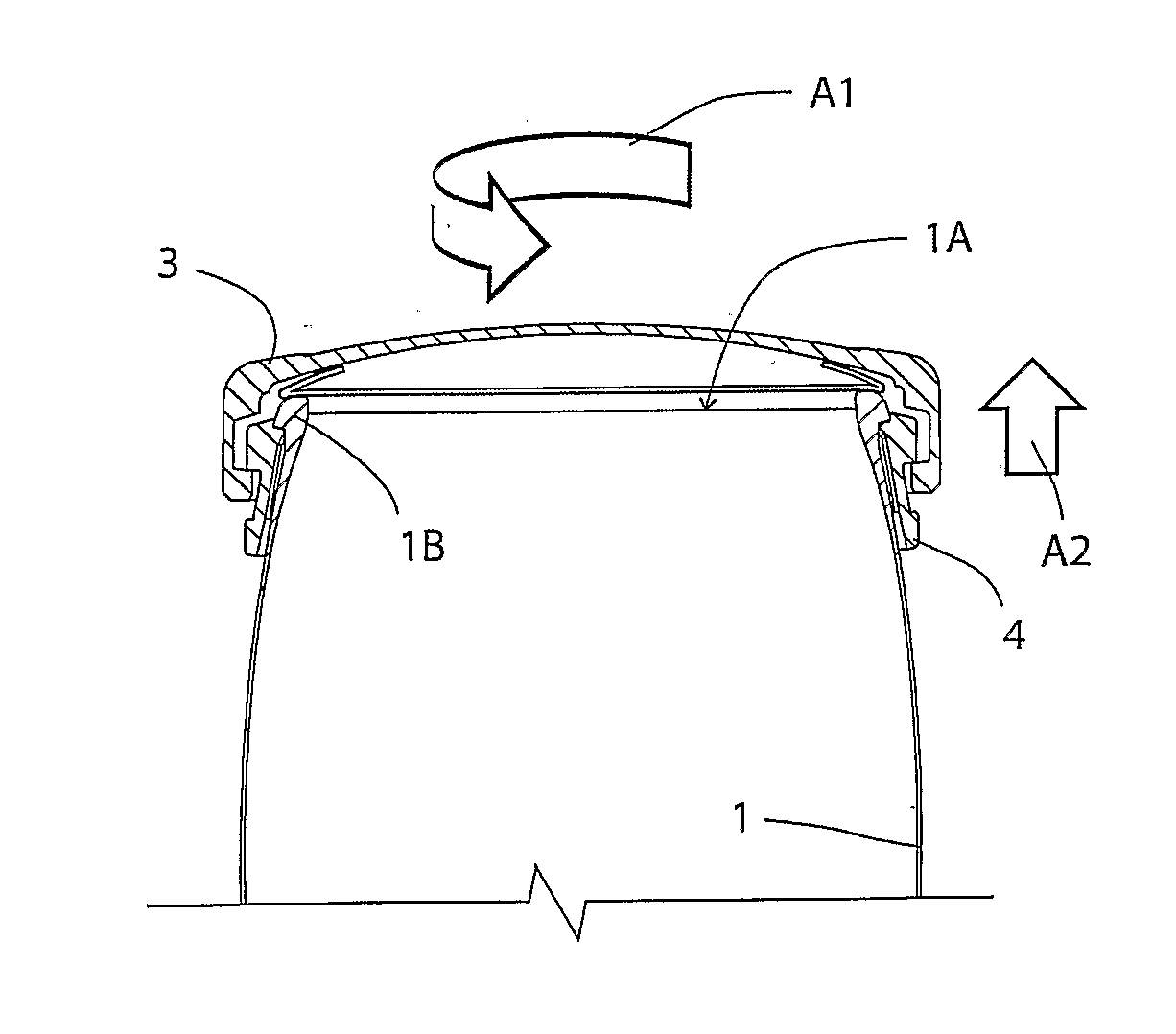

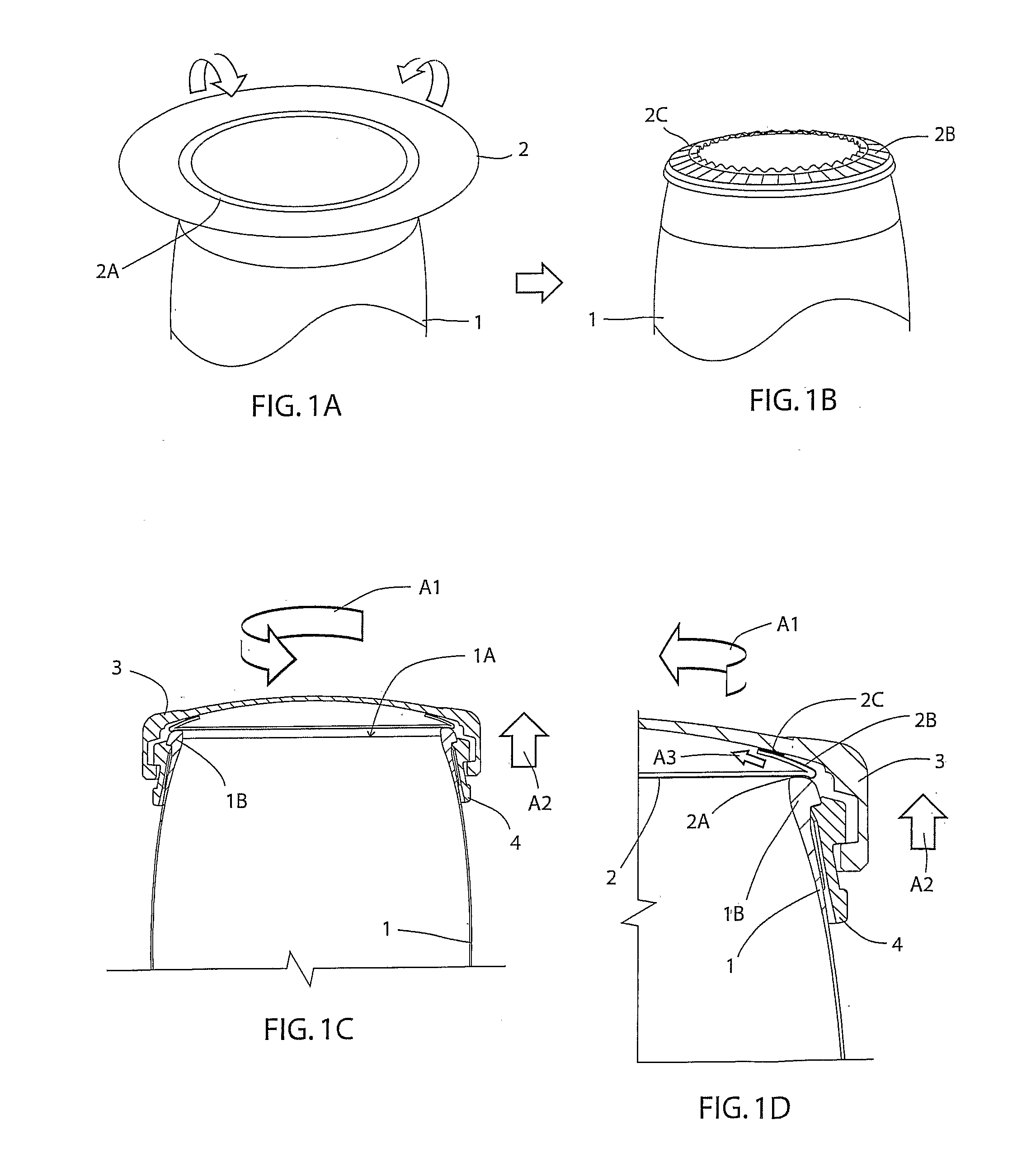

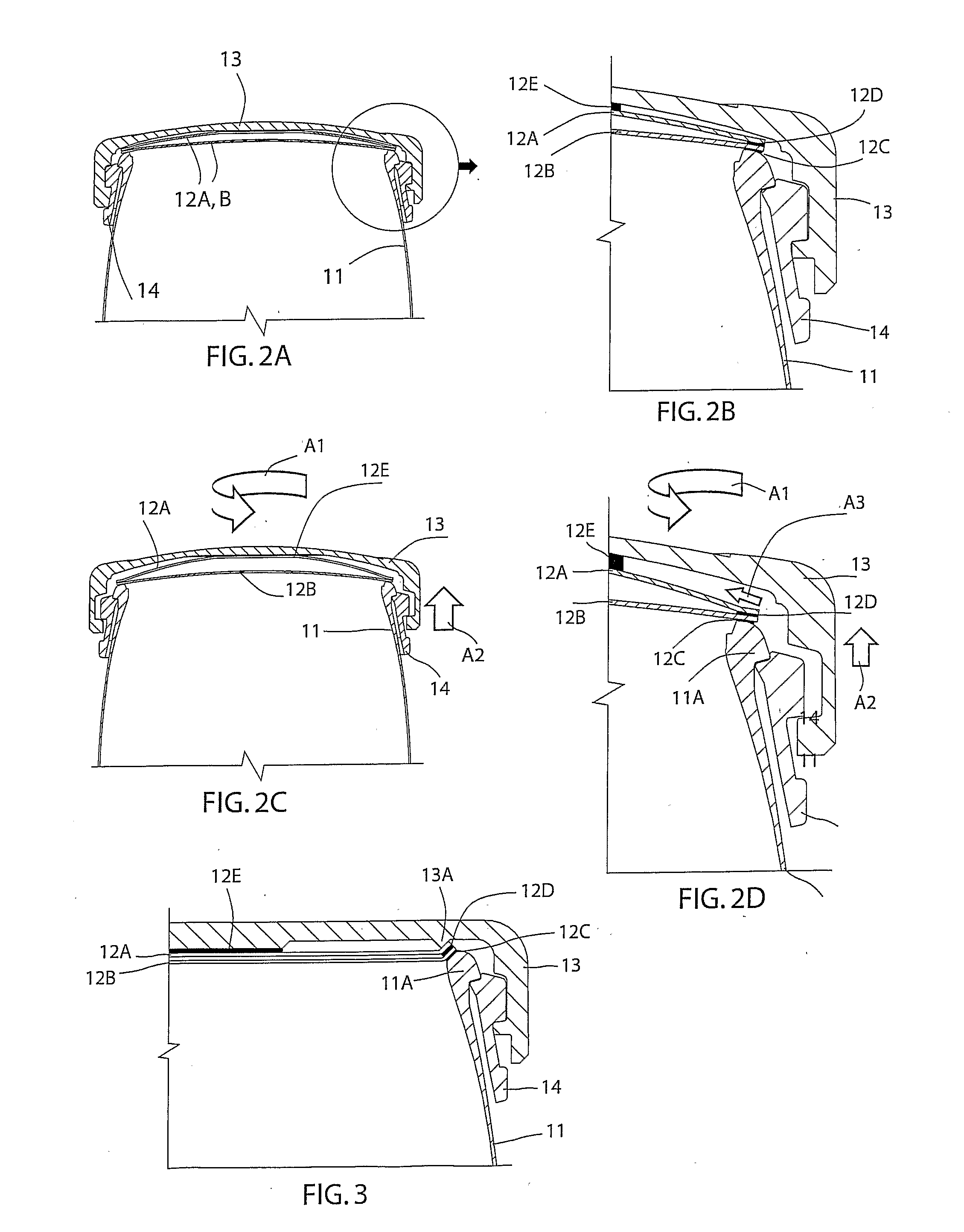

Image

Examples

sixth embodiment

FIGS. 8A-8F illustrate a sixth embodiment which is a further development of that shown in FIG. 3 above.

In this embodiment, a pre-formed foil 52 is mechanically secured to the underside of a cap 53 by engaging apertures 52A in the foil over projections 53A on the underside of the cap 53 and then pressing a securing plate 55 onto the projections 53A so a central portion of the foil is clamped to the underside of the cap 53. Other forms of mechanical connection may be used. The projections 53A may, for example, be hot-studded once the foil 52 is in place so as to enlarge their heads so the foil cannot be removed therefrom. An adhesive connection or welded bond may also be used (as in the embodiments described above).

An annular projection 53B is also provided on the underside of the cap 53 to form a bore seal which fits against the interior of a container body (as described further below).

The foil 52 is preferably, pre-formed so that an outer portion thereof fits around the bore seal 53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com