Finishing machine

a technology for finishing machines and belts, applied in the direction of grinding machines, grinding machine components, construction, etc., can solve the problems of time-consuming and difficult to move, and achieve the effect of reducing labor intensity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

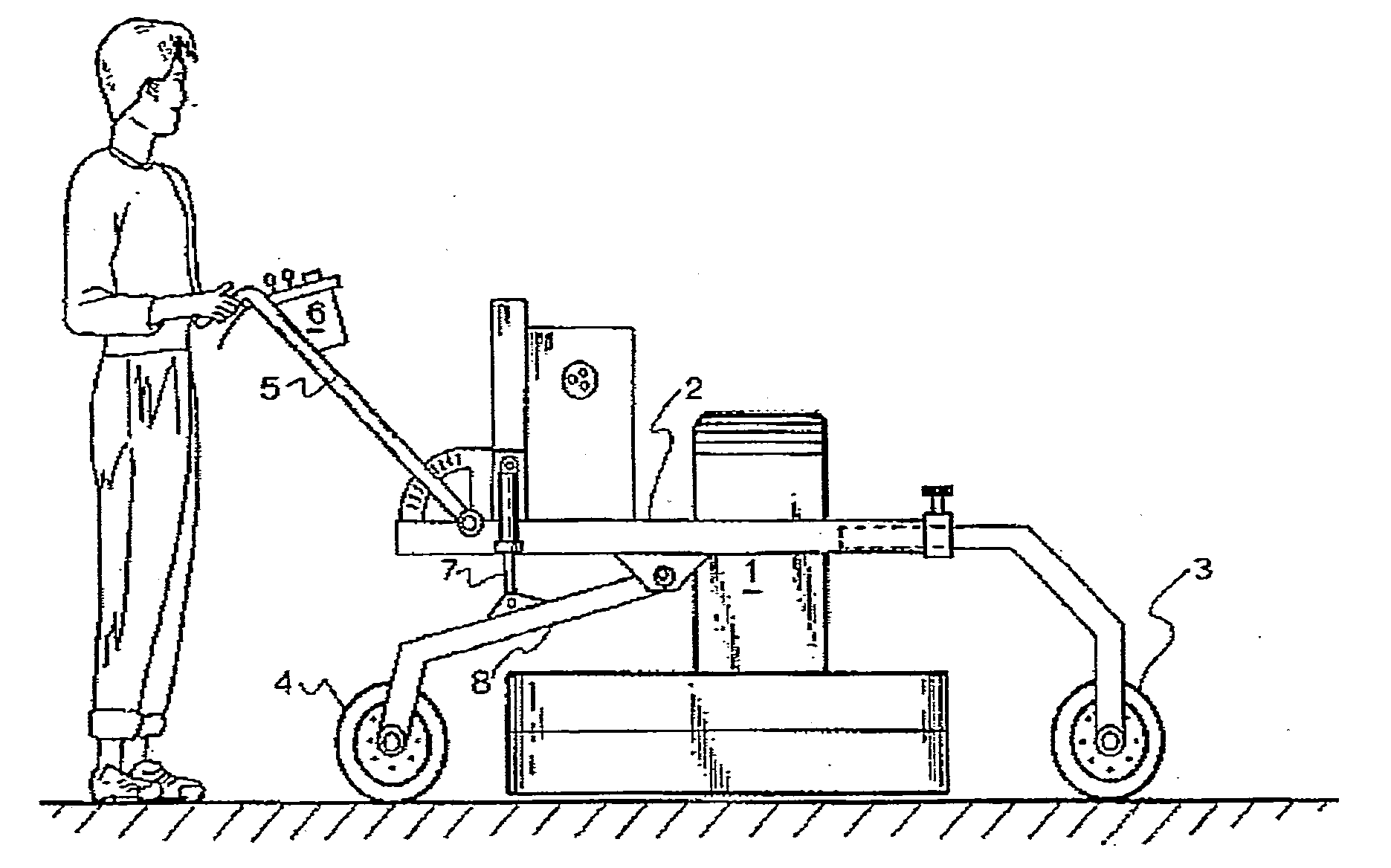

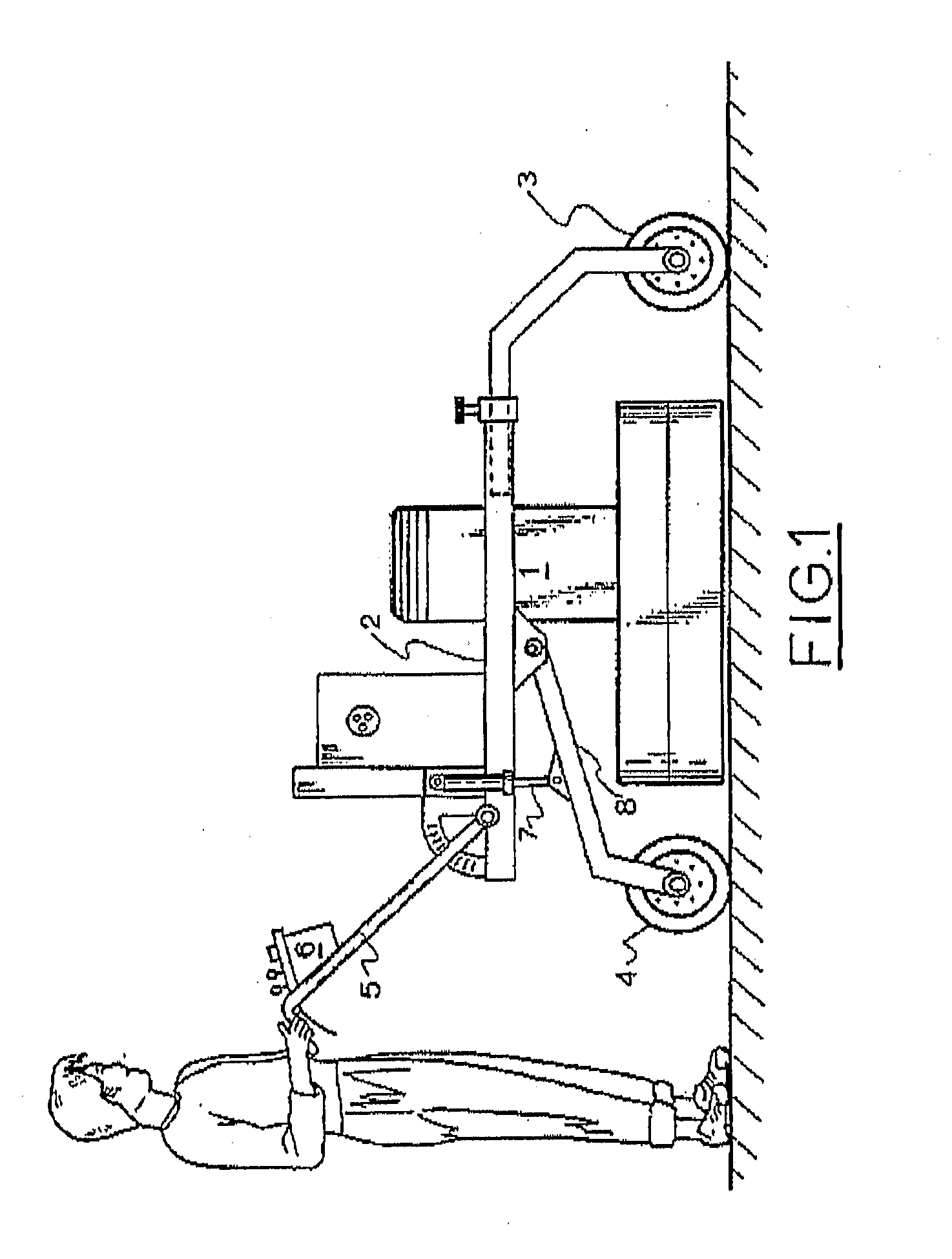

FIG. 1 illustrates an operator using a finishing machine which has motor 1 mounted on frame 2 with removable front wheels 3 and adjustable rear wheels 4. Handles 5 have a control box 6 mounted within reach of the operator. As well as switching the machine on and off box 6 controls height adjustment by operating hydraulic cylinder 7 to rotate rear wheel strut 8 up or down. Accordingly when not in use strut 8 is lowered and the machine can be easily wheeled to another location.

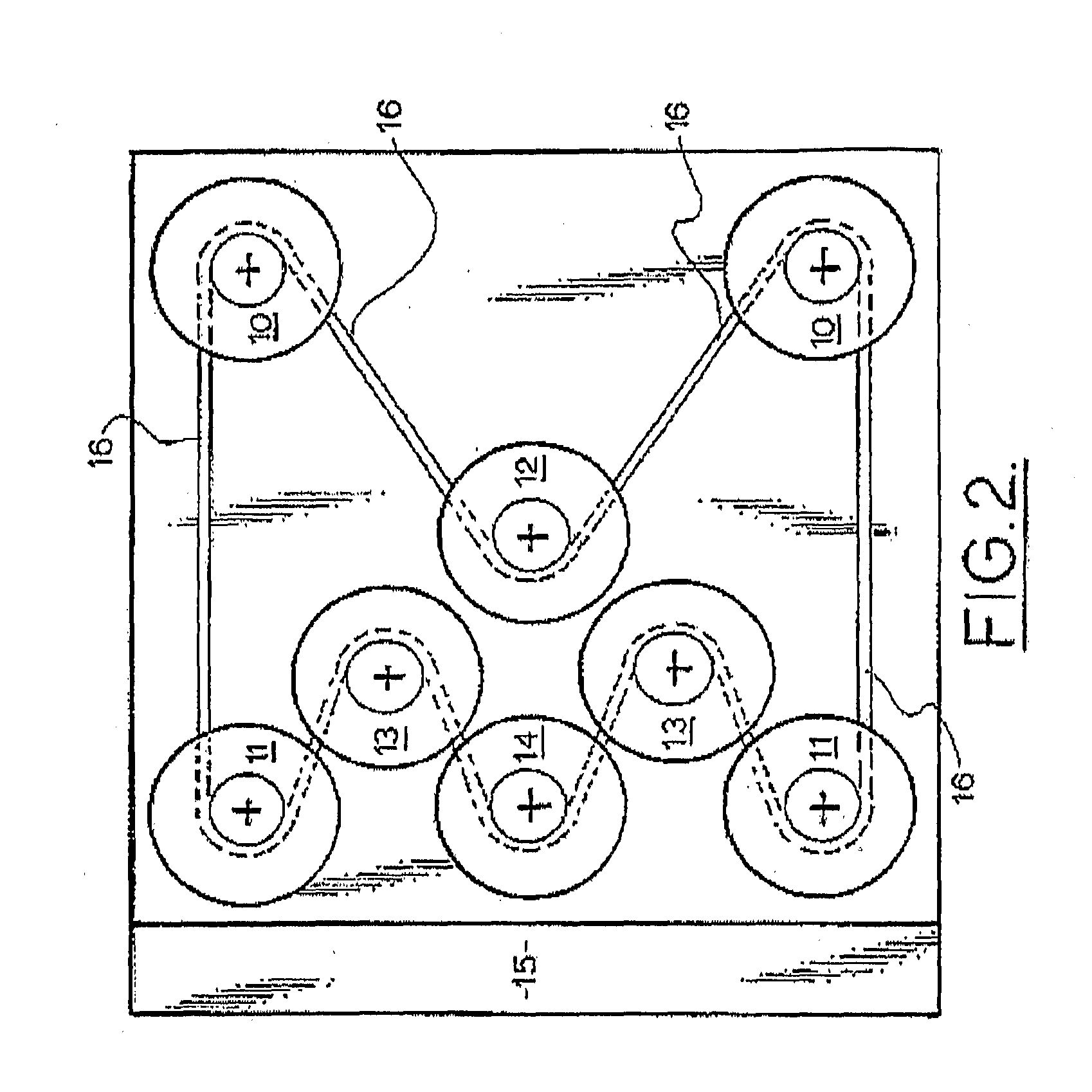

FIG. 2 shows the configuration of grinding head assemblies with a pair 10 at the front corners, a pair 11 at the rear corners, one 12 in the centre and a pair 13 between the centre and the rear corners. The assembly 14 midway between the rear corners does not have a grinding head but is a fan which impels dust into a vacuum manifold 15 at the rear of the assemblies.

Motor 1 drives assembly 12 through a direct drive flexible coupling (not shown) and assembly 12 drives assemblies 10, 11, 13 and 14 via serpentine be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com