Multi-evaporation system

a multi-evaporation system and evaporation system technology, applied in the field of multi-evaporation systems, can solve the problems of deteriorating cooling efficiency of air, difficult to control the flow, and inability to efficiently evaporate refrigerant, and achieve the effect of efficiently evaporating refrigerant, reducing the length of the refrigerant passage, and efficient evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]

10: compressor11: condenser20: expanding means31: inlet port32a~32n: first to Nth discharging part33: inlet passage34a~34n: first to Nth outlet passage35: expanding part before branching35a~35n: first to Nth expanding parts40: evaporator41~4N: first to Nth evaporating part60: blower70: detecting means

BEST MODE

[0041]Hereinafter, the embodiments of the present invention will be described in detail with reference to accompanying drawings.

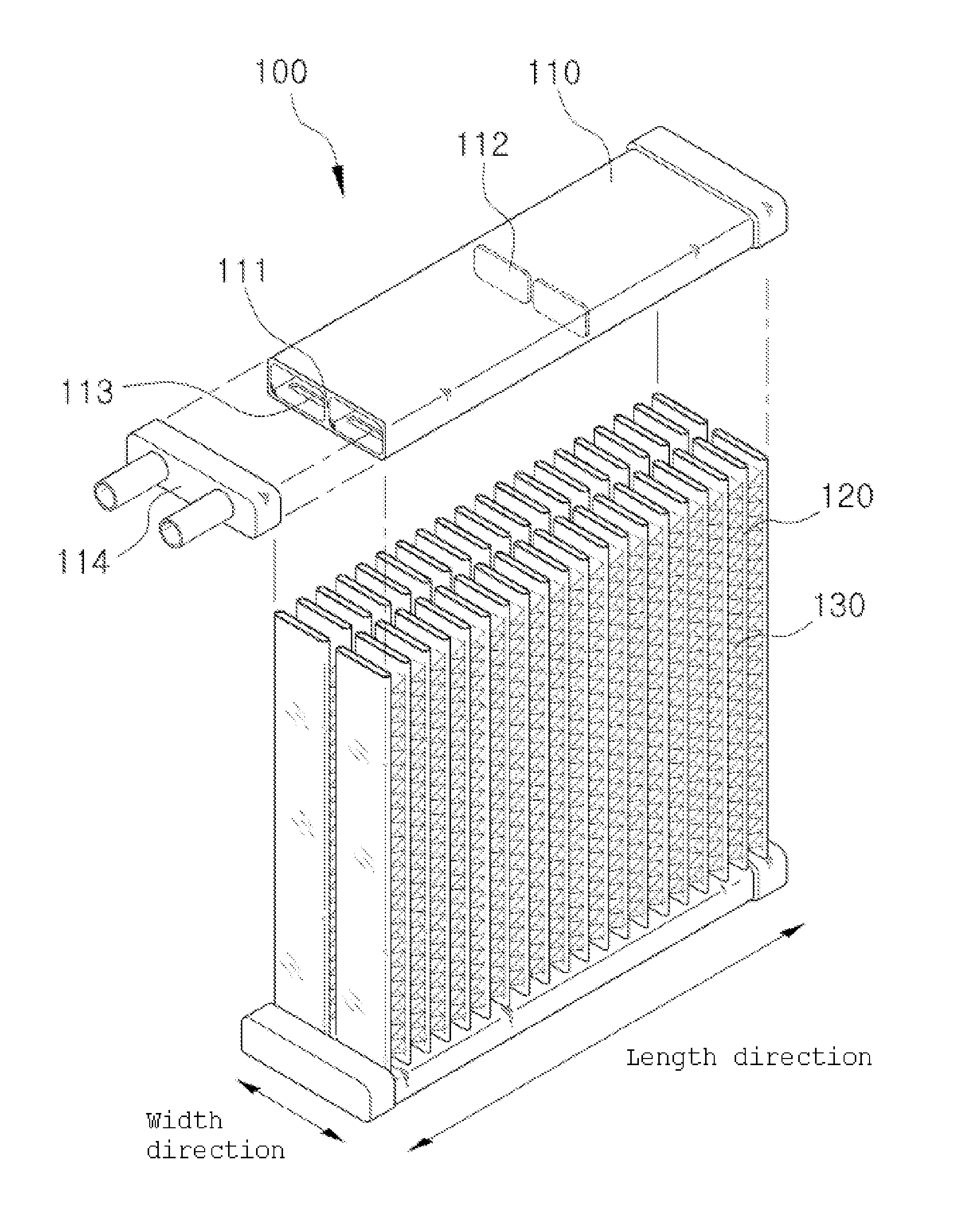

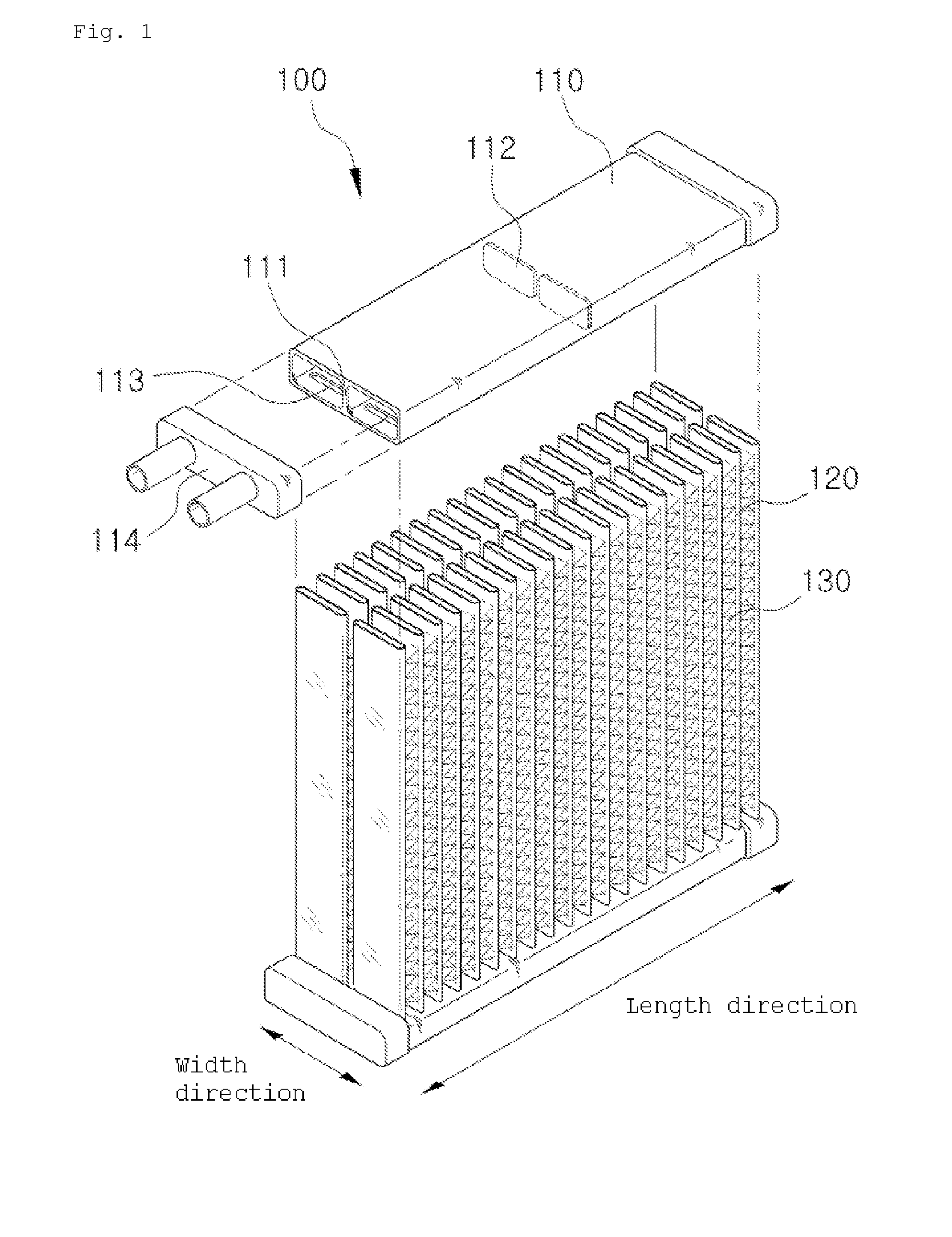

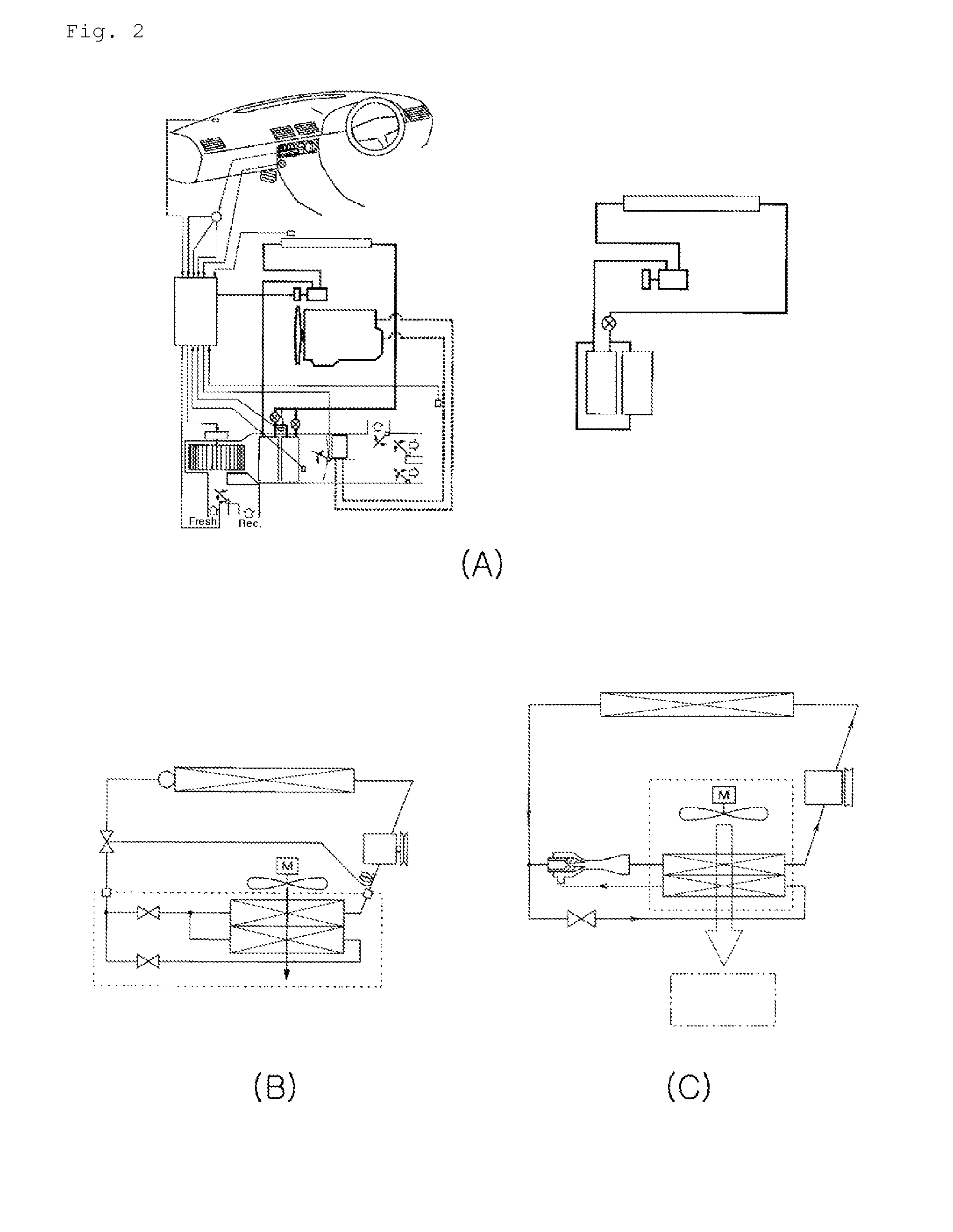

[0042]FIG. 3 is a view of a multi-evaporation system in accordance with the present invention. Like a general air-conditioning system, the multi-evaporation system of the present invention includes a compressor 10 which sucks and compresses refrigerant; a condenser 20 which condenses the refrigerant compressed in the compressor 10; an expanding means 30 which throttles the refrigerant condensed in the condenser 20; and an evaporator 40 which evaporates the refrigerant throttled in the expanding means 30. As shown in FIG. 3, the refrigerant discha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap