Regenerative thermal energy storage apparatus for an adiabatic compressed air energy storage system

a technology of compressed air energy storage and thermal energy storage, which is applied in the direction of mechanical equipment, indirect heat exchangers, machines/engines, etc., can solve the problems of reducing the heat left in the cavern or other compressed air storage componen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

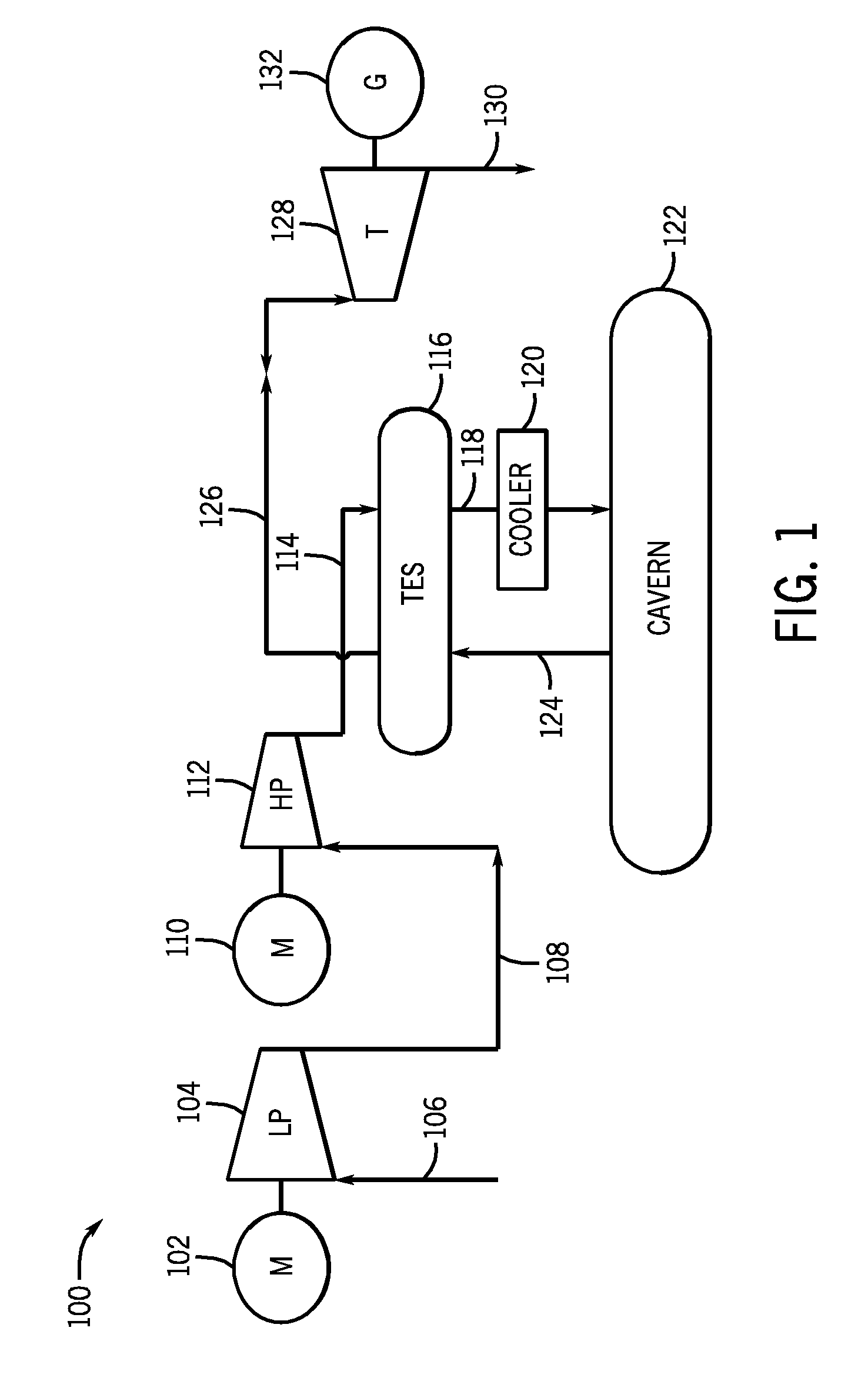

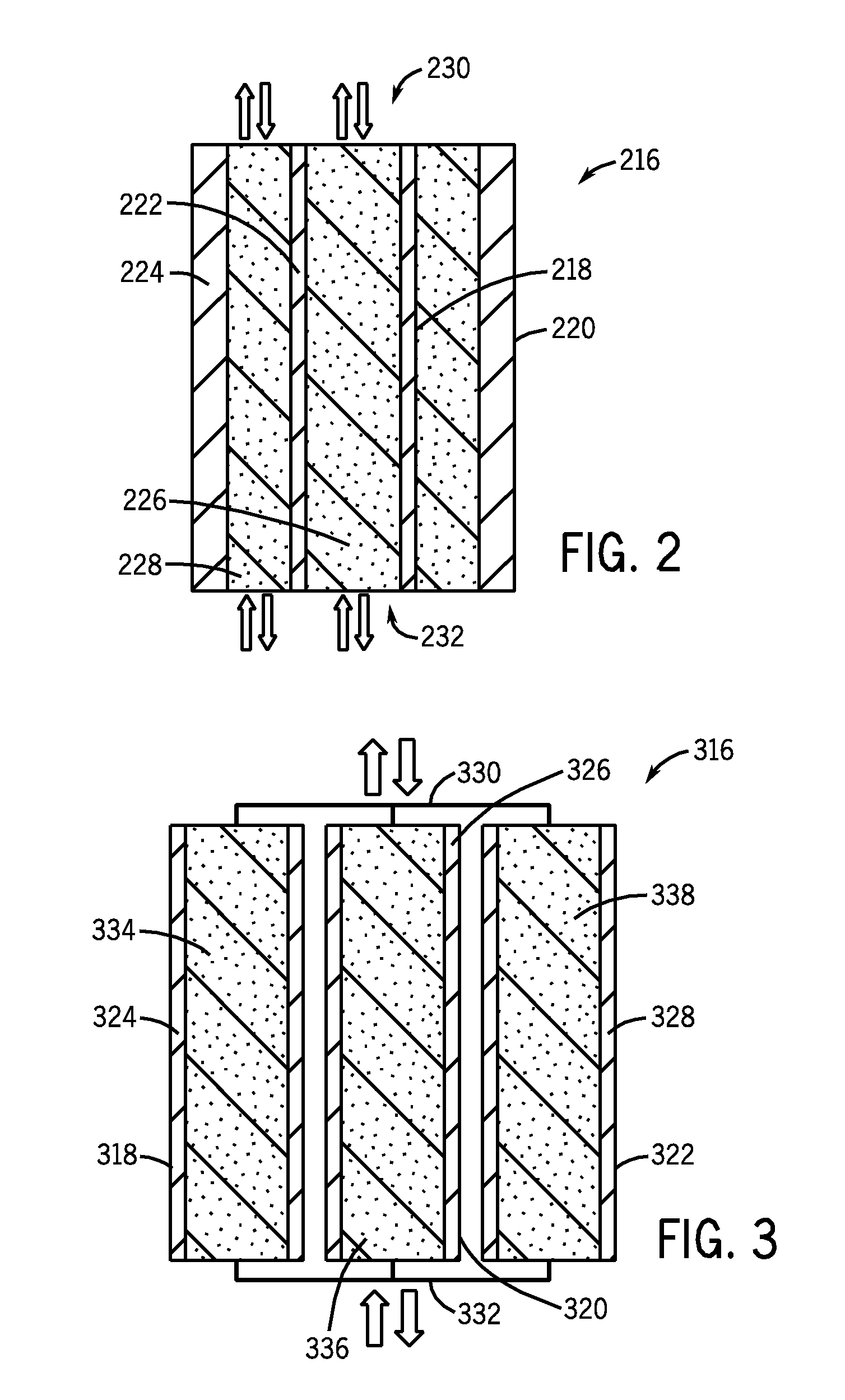

[0021]According to embodiments of the invention, a system is provided that comprises at least one TES unit configured to allow the at least one TES unit to withstand high pressure and temperature fluctuations while maintaining minimal wall thickness.

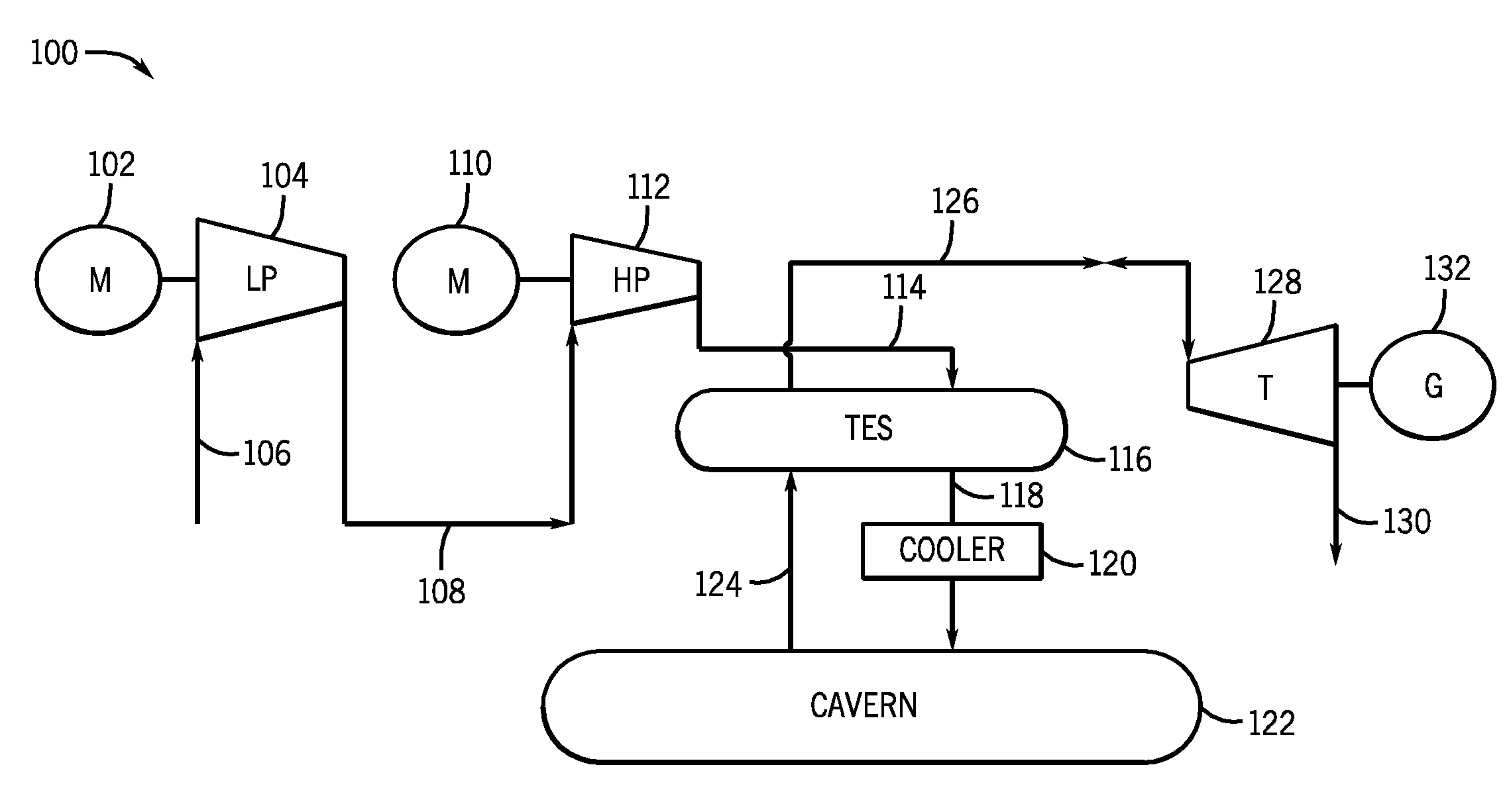

[0022]First, referring to FIG. 1, a schematic arrangement of the primary elements of an ACAES system is shown. ACAES system 100 comprises an electric motor 102 coupled to a low-pressure compressor 104. Electric motor 102 may be electrically powered via conventional means, i.e., the utility grid, during off-peak utility hours. Alternatively, electric motor 102 may be powered by electricity provided via wind farms, solar arrays, or other renewable sources. Electric motor 102 powers low-pressure compressor 104 such that low-pressure compressor 104 pressurizes intake air 106. Pressurized air 108 from low-pressure compressor 104 is then provided to a high-pressure compressor 112 to enable the air to undergo further compression. Similar to low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com