Exhaust heat recovery for engine heating and exhaust cooling

a technology of exhaust heat recovery and engine heating, applied in the field of heat exchange, can solve the problems of viscous energy loss, higher emissions, energy loss, etc., and achieve the effects of reducing energy loss, reducing heat loss in the combustion chamber, and reducing engine pumping loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

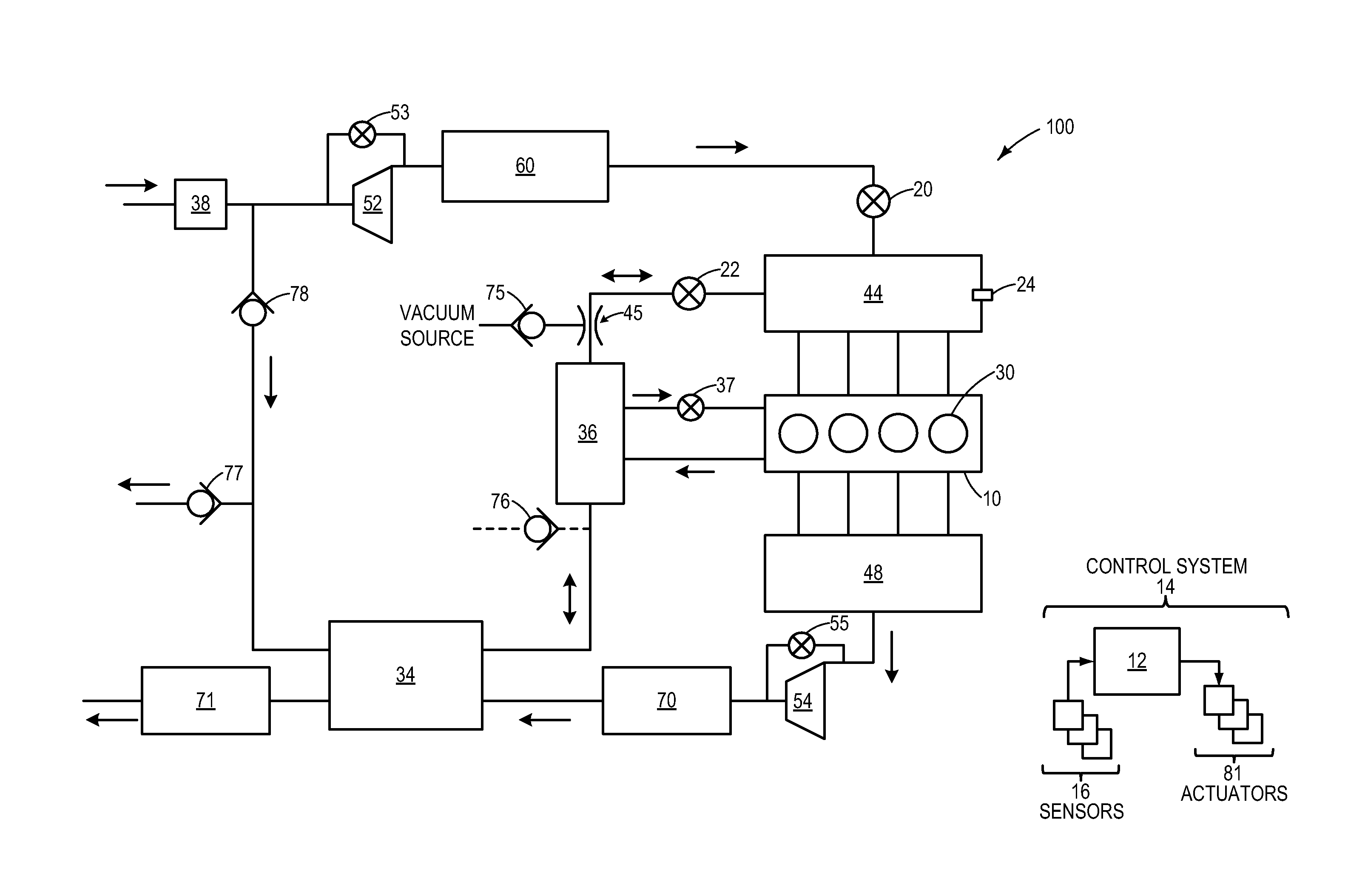

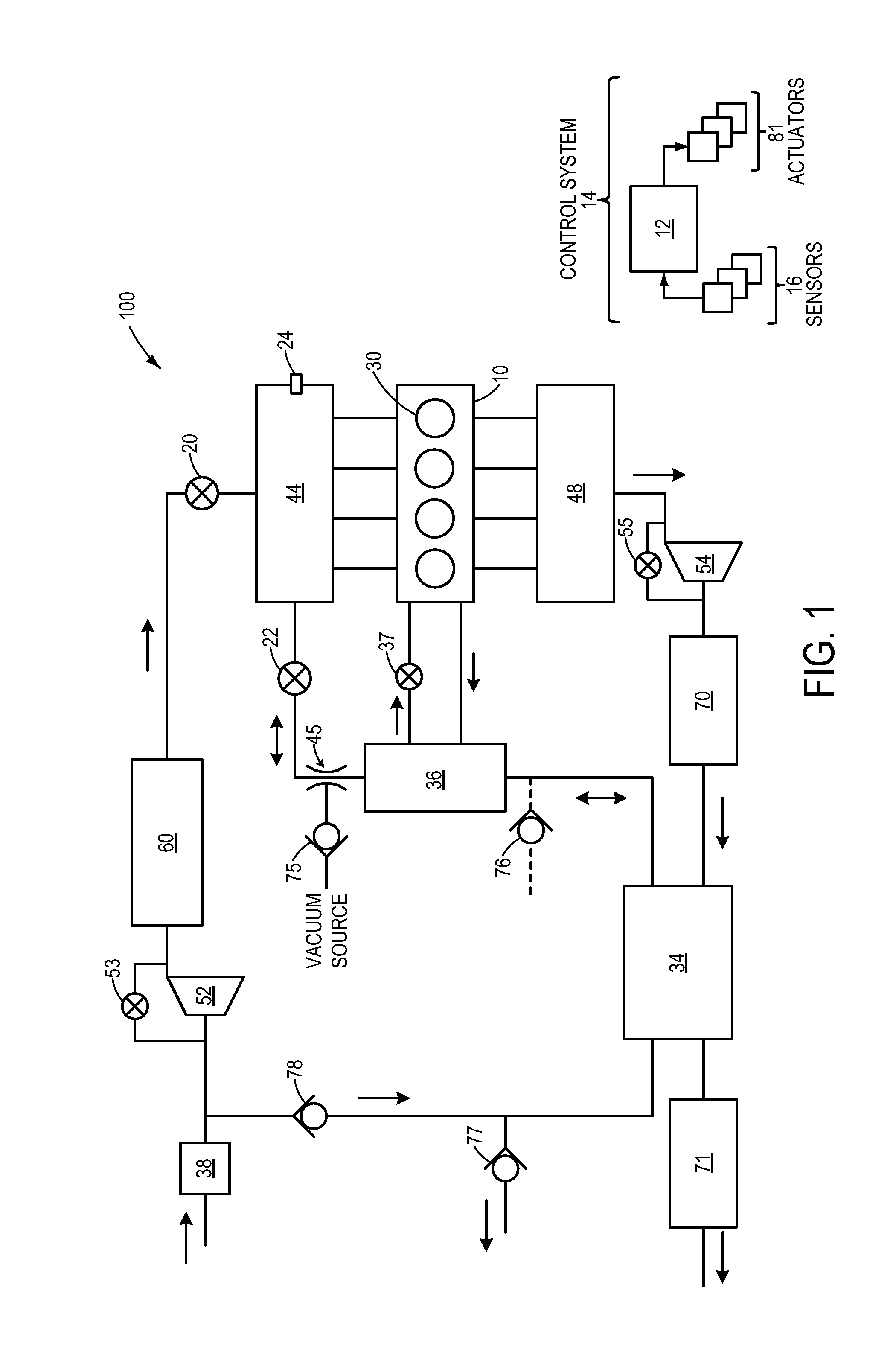

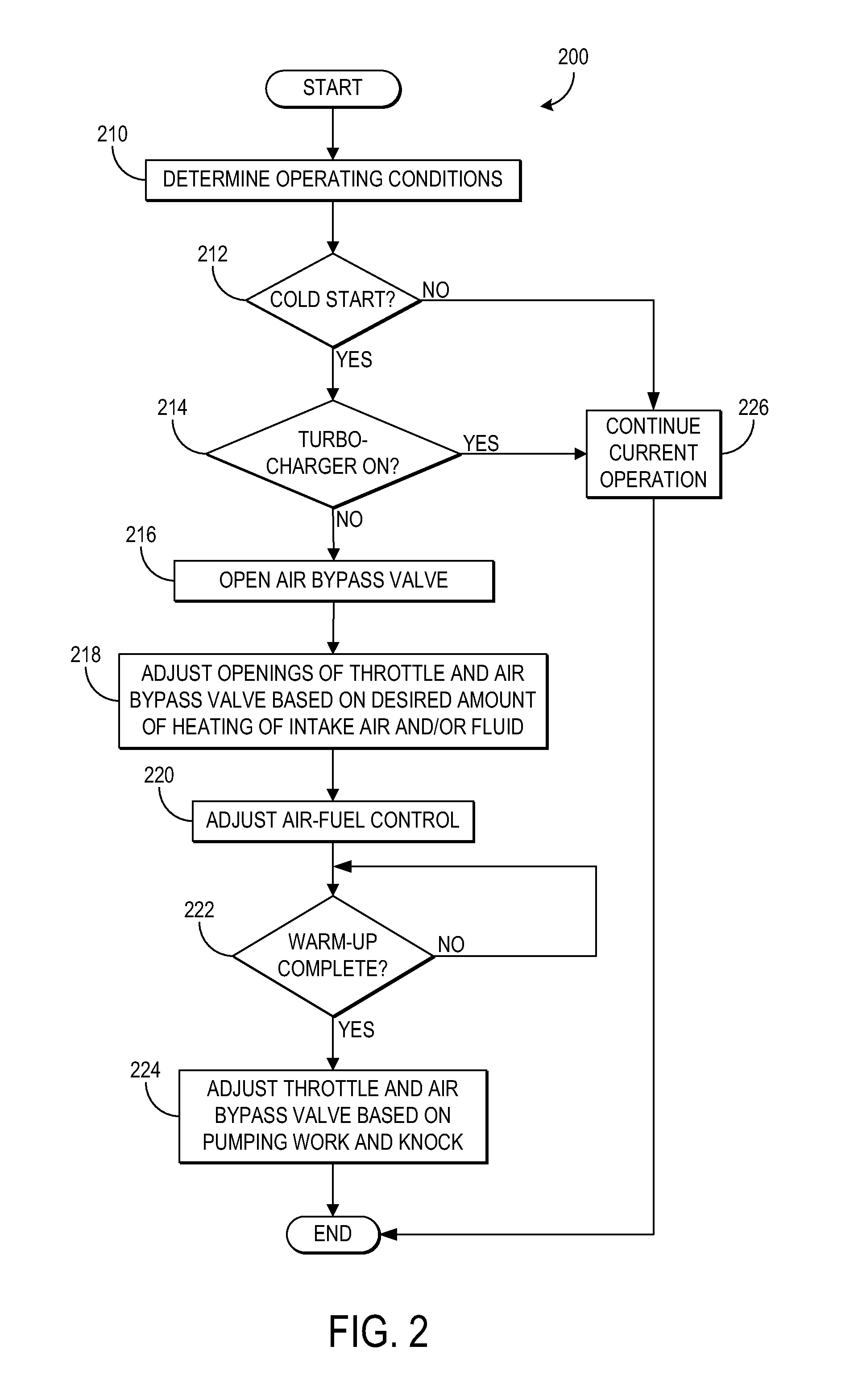

[0011]The following description relates to systems and methods for heating an engine in a vehicle during a cold start. In one example, intake air flowing in a first direction may be heated through a heat exchange with exhaust gas via a gas-to-gas heat exchanger. The heated intake air may subsequently undergo a second heat exchange with a powertrain fluid (e.g., engine oil, transmission fluid, etc.) via a gas-to-liquid heat exchanger such that the powertrain fluid is heated. As such, viscous energy losses due to relatively cold fluid may be reduced, and combustion chamber heat loss and pumping losses are also reduced due to the heated intake air. Furthermore, in another example, when pumping loss reduction and powertrain fluid heating are not desired, but exhaust cooling is desired, intake air may flow through the heat exchangers in a second direction such that the exhaust is cooled for exhaust catalyst cooling, for example.

[0012]FIG. 1 shows a schematic diagram of vehicle system 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com