Protective glove and method of manufacturing the same

a technology of protective gloves and gloves, which is applied in the field of gloves, can solve the problems of liquids and gases that cannot penetrate the seams of gloves, severe burns, and injury to the wearer, and achieve the effects of improving the cut and penetration strength of gloves, adding comfort and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

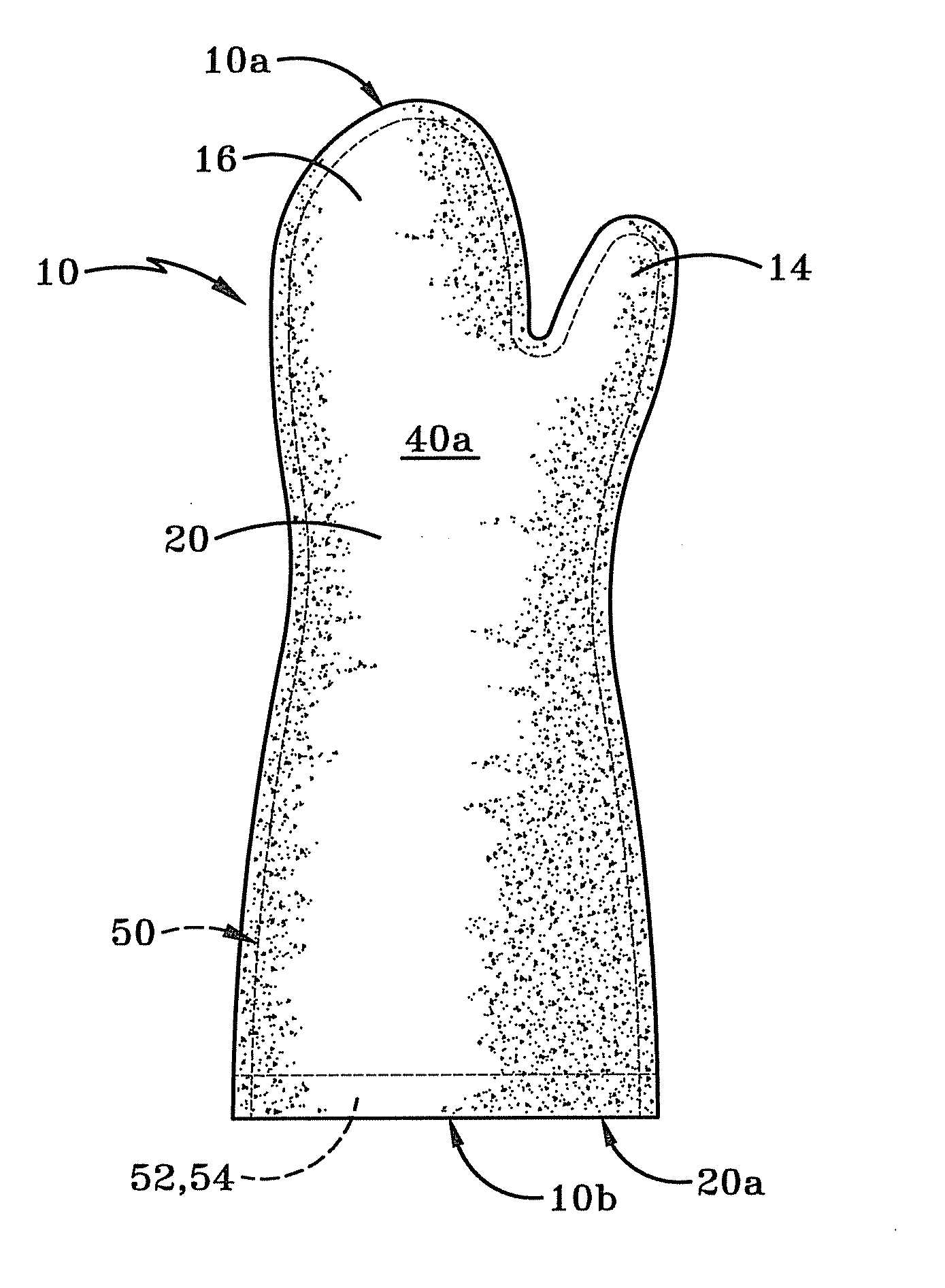

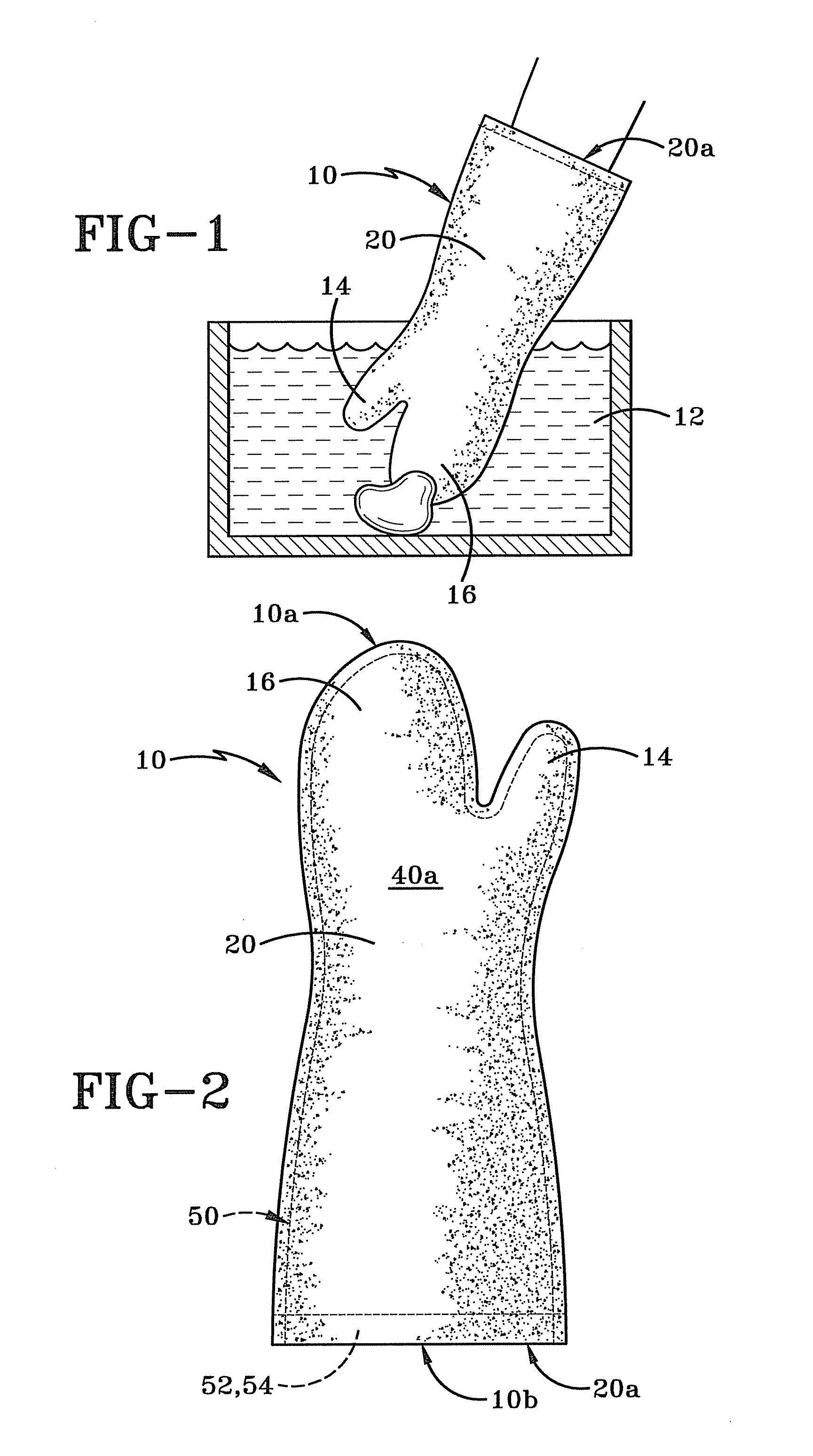

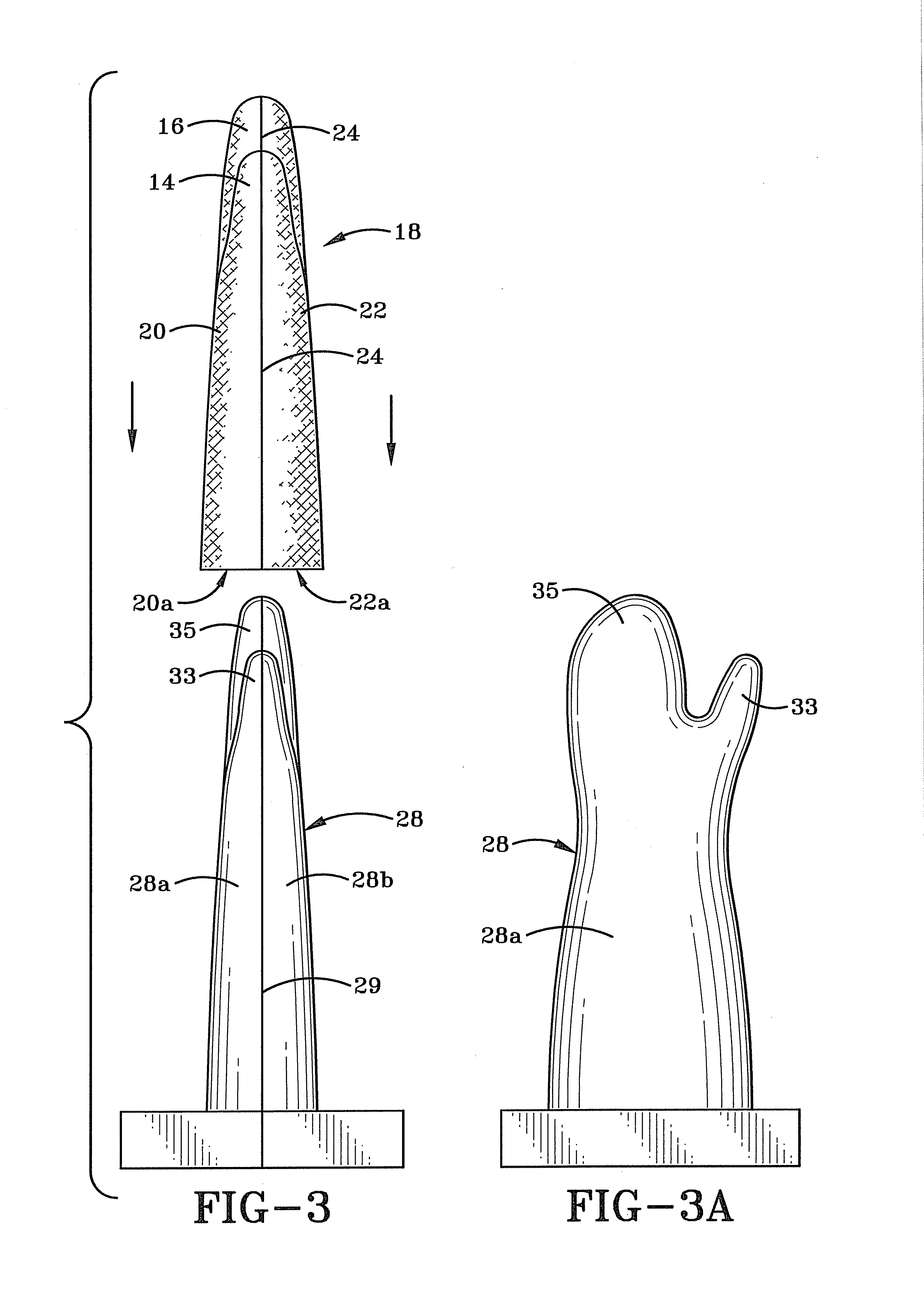

Referring to FIGS. 1-12, there is shown a protective glove in accordance with the present invention and generally indicated at 10. FIGS. 1, 2 and 12 show various details of the structure of glove 10. FIGS. 3-11a illustrate how glove 10 is manufactured and how the process constructs the structure of glove 10. FIG. 11a illustrates an alternative structure for the glove in accordance with the present invention.

Glove 10 as illustrated herein is of a mitt style and includes a thumb region 14 and a single finger region 16 that would cover and protect all four of the wearer's fingers together. It will be understood that if it is desirable to protect the wearer's fingers in a different manner, that glove could alternatively include a thumb region and two, three or four finger regions. These alternative versions of the glove are not illustrated herein but are considered to fall within the spirit and scope of the present invention.

As indicated previously, glove 10 is designed for applications...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| temperature resistant | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com