Heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

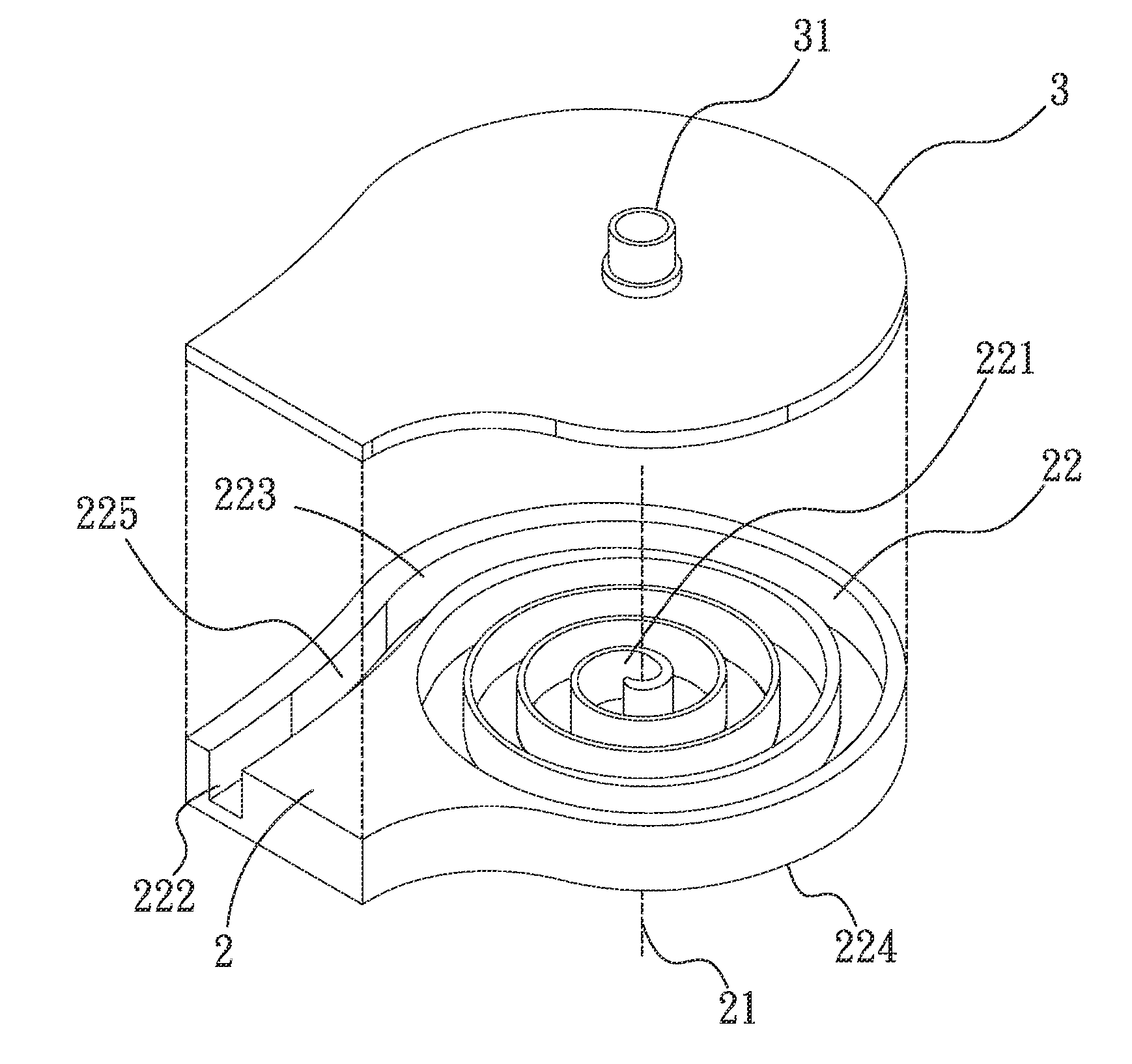

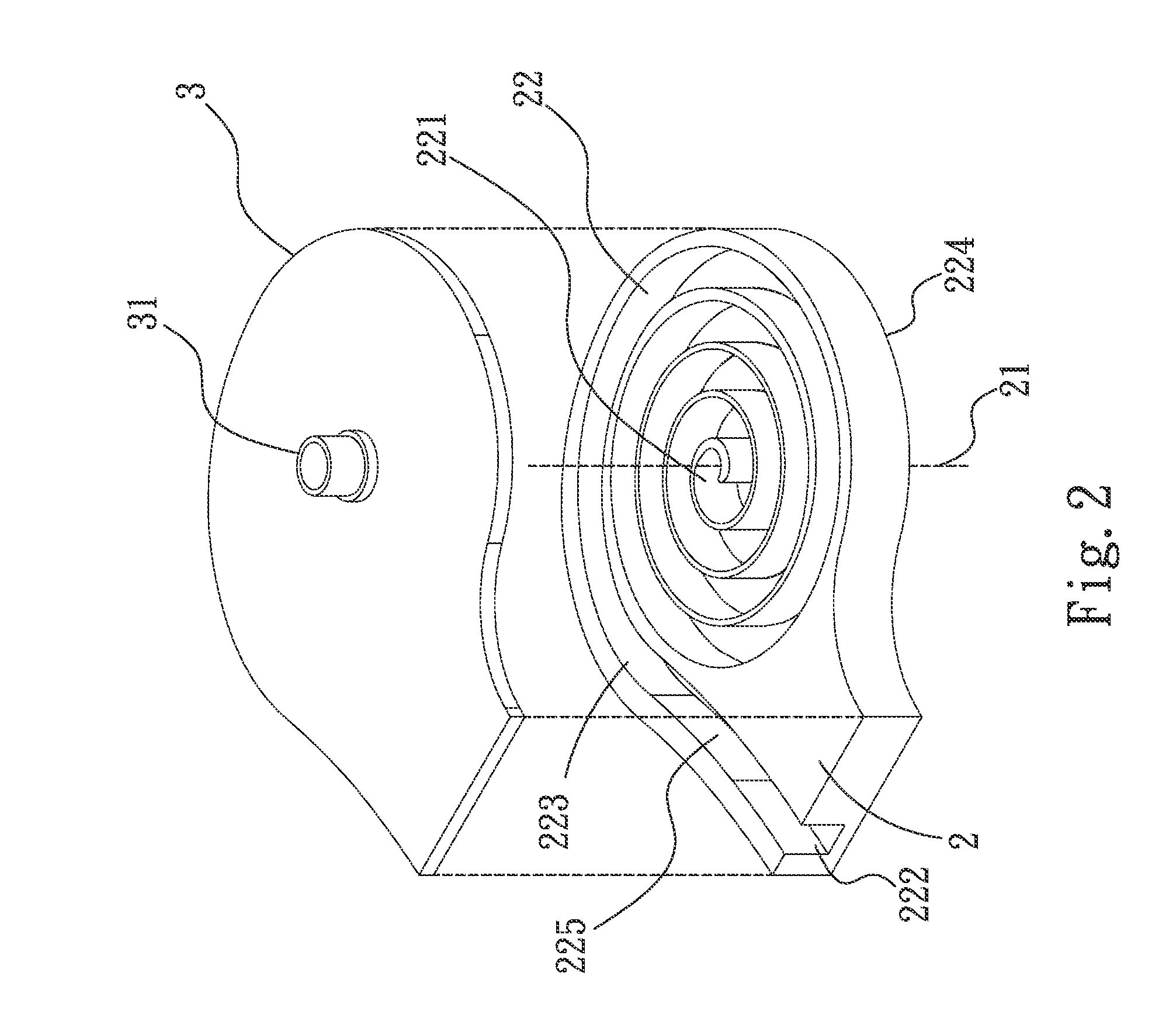

[0037]The present invention is directed to a heat exchanger. The drawings show several preferred embodiments of the present invention. Please refer to FIGS. 2 to 5. The heat exchanger of the present invention includes a body 2 having a center 21 as shown by a dotted axis. A spiral guiding trough 22 extends spirally and outwardly from the center 21 to the outside of the center 21. The radius of the spiral guiding trough 22 increases gradually from the center 21 to the outside of the center 21. In other words, the spiral guiding trough 22 extends spirally toward the inner wall of the body 2, thereby forming a spiral channel (i.e. the spiral guiding trough 22). FIG. 2 shows the spiral guiding trough 22.

[0038]The body 2 further has a first port 221 and a second port 222. The first port 221 is provided in the center 21, and the second port 222 is provided at the outside of the center 21. The first port 221 and the second port 222 are in communication with the spiral guiding trough 22.

[00...

third embodiment

[0047]Please refer to FIGS. 7 to 9, which show the present invention. The third embodiment is substantially the same as the first embodiment, and thus the redundant description is omitted thereto. The only difference between the third embodiment and the first embodiment lies in that the heat exchanger further includes at least one first turbulent unit 4 provided on a wall surface 226 of the spiral guiding trough 22. In the present embodiment, the first turbulent unit 4 is provided on the closed side 224 of the spiral guiding trough 22. The first cover 3 has at least one second turbulent unit 5 facing the open side 223 of the spiral guiding trough 22. Thus, in the present embodiment, the first turbulent unit 4 and the second turbulent unit 5 are provided on the closed side 224 and the open side 223 of the spiral guiding trough 22 respectively. The first turbulent unit 4 and the second turbulent unit 5 are protrusions provided on the closed side 224 and the open side 223 of the spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com