Unitised Building System

a building system and unitary technology, applied in special buildings, building repairs, parking, etc., can solve problems such as inflexibility and limit their application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

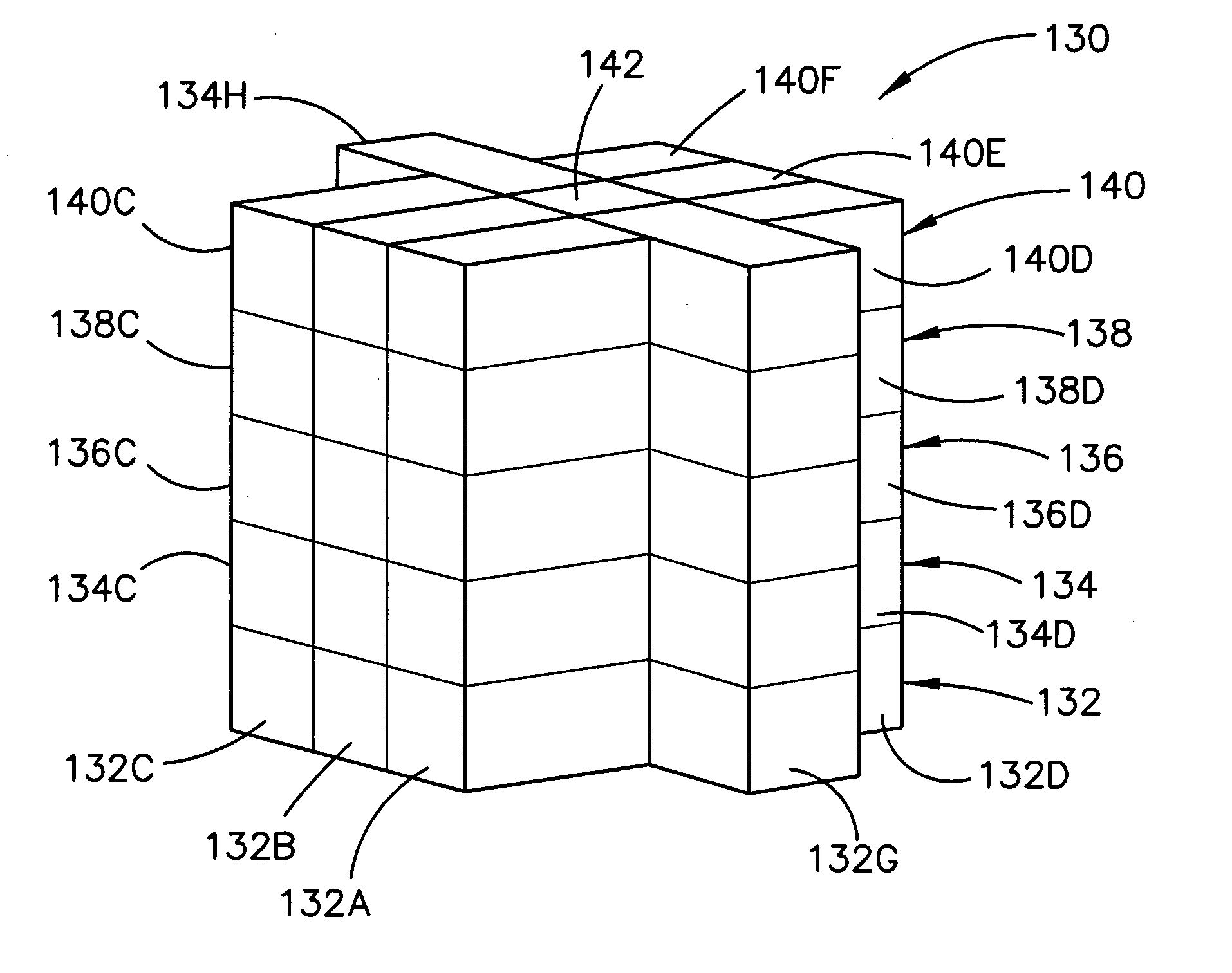

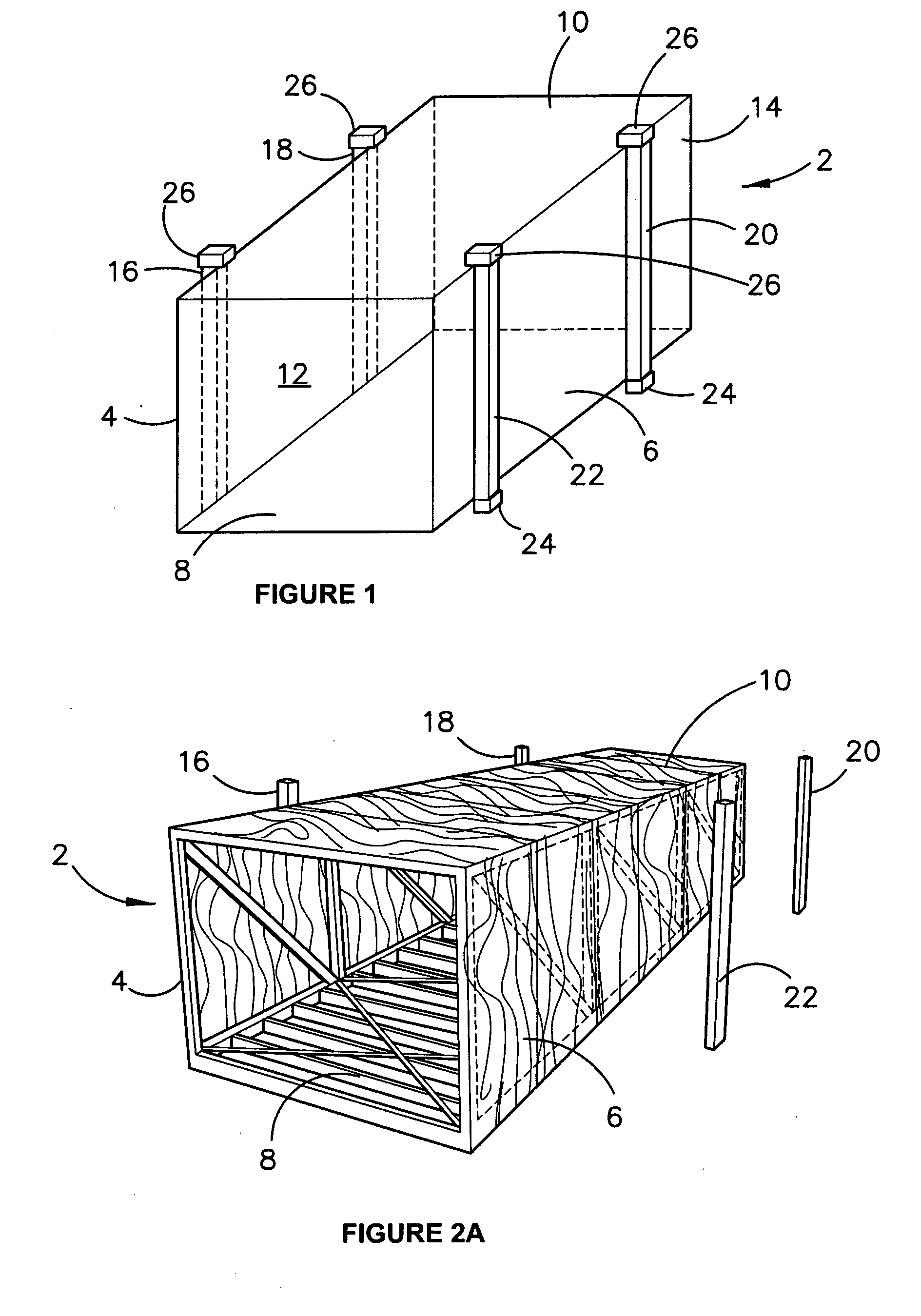

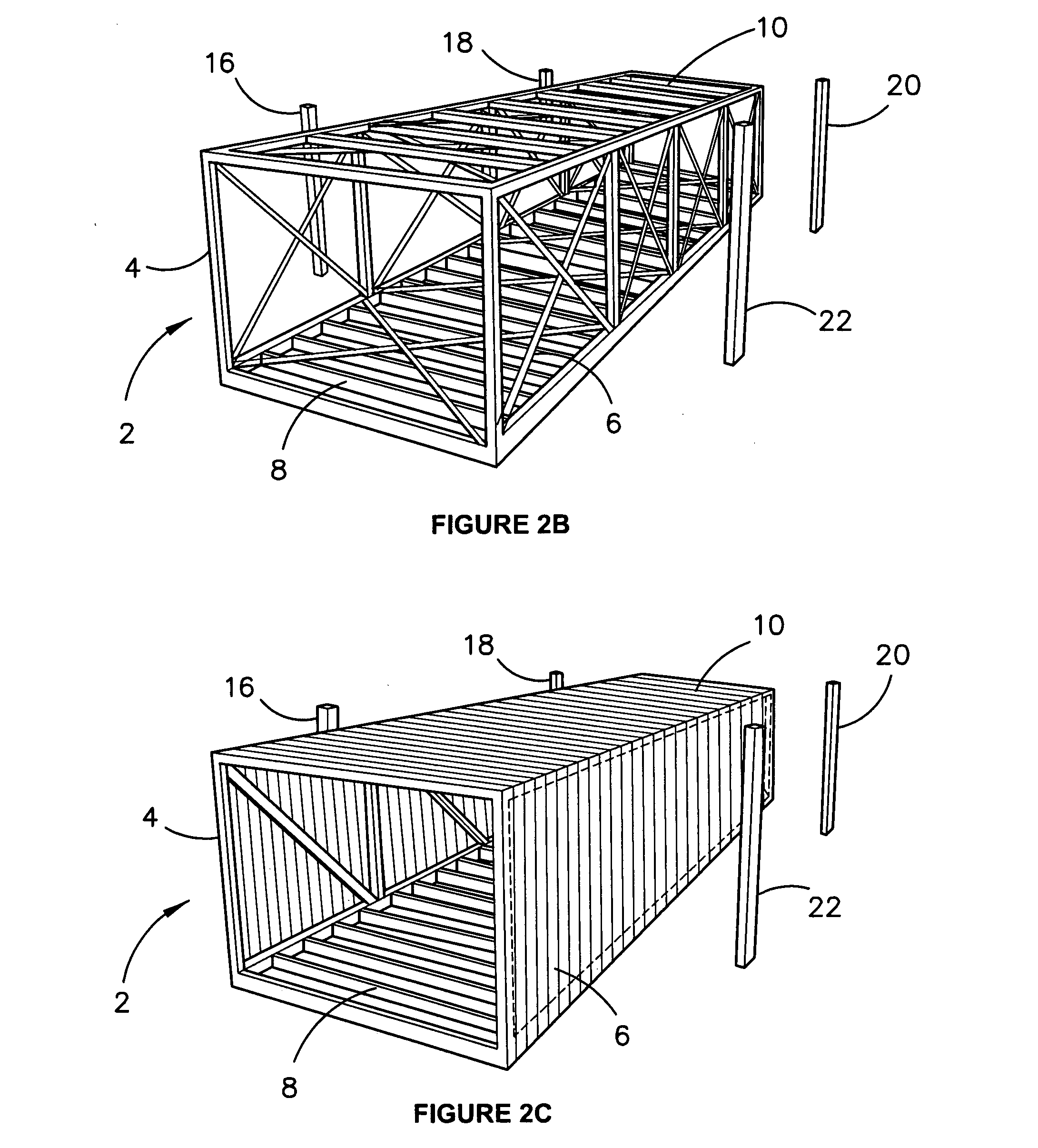

[0196]In broad concept the inventor has realised that the building units per se (which delineates the interior space of the unit) can be considered separately from the structural frame of the unit, when this is implemented in a preferred form this can allow both flexibility of design an improved ease of manufacture.

[0197]In terms of ease of manufacture the building units can be manufactured to relatively relaxed tolerances, say ±20 mm, which is relatively easy to achieve. The structural frame segments can be manufactured to much tighter tolerances, say within ±1 mm so as to provide an accurate framework for the building. The building unit and associated structural frame segments assemblies can then be attached together in a manner that accounts for any inaccuracy in the building unit to form a building unit assembly for assembly into the building which has an accurately positioned structural frame segment attached to it.

[0198]The preferred embodiments provide an independent column s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com