Method and apparatus for determining proper curing of pipe liners using distributed temperature sensing

a temperature sensing and temperature sensing technology, applied in the direction of instruments, heat measurement, mechanical control devices, etc., can solve the problems of affecting the operation requiring replacement or repair, and starting to leak or fail structurally, etc., and achieving the effect of avoiding the failure of the entire lining operation, and avoiding the failure of the whole lining operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

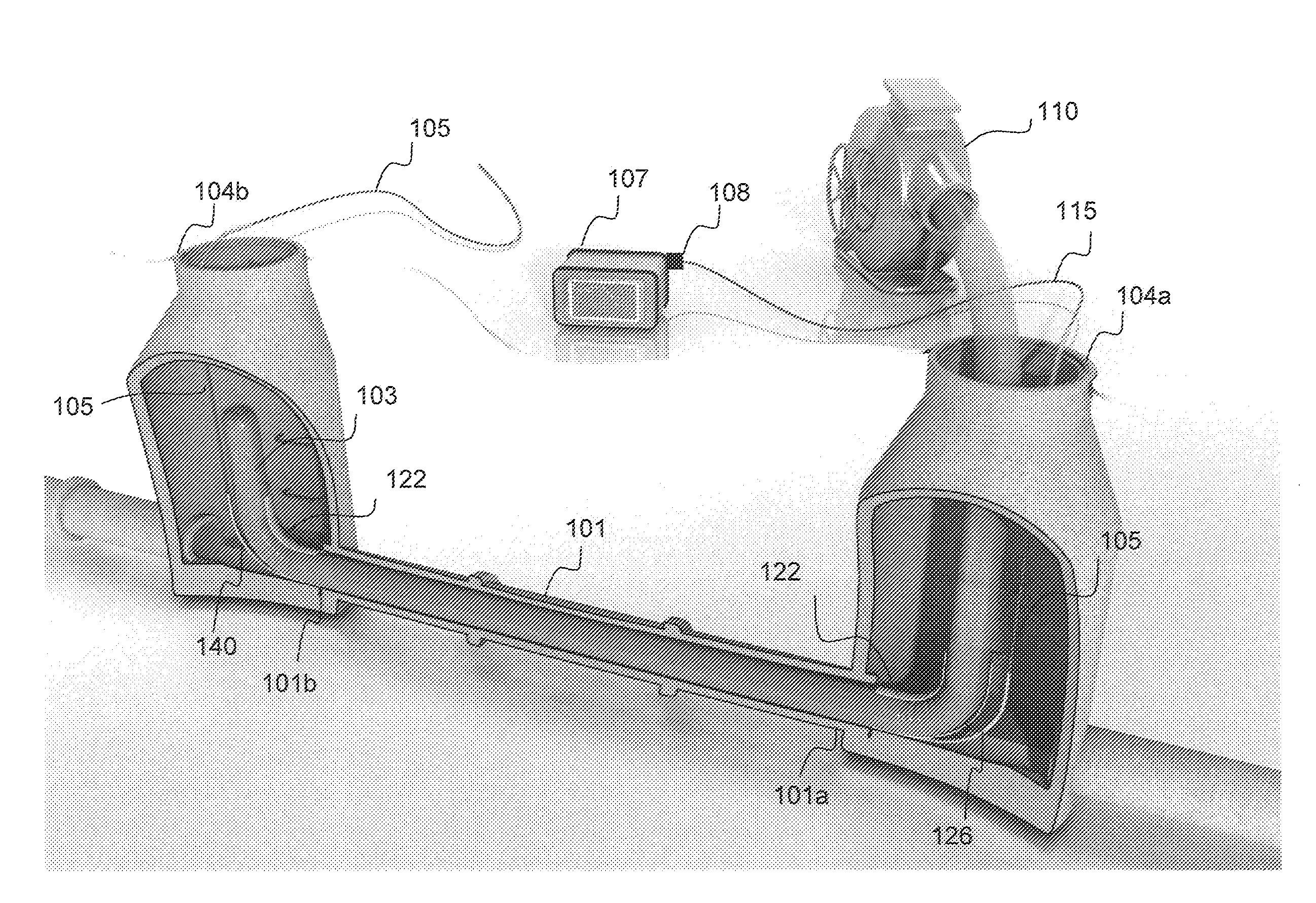

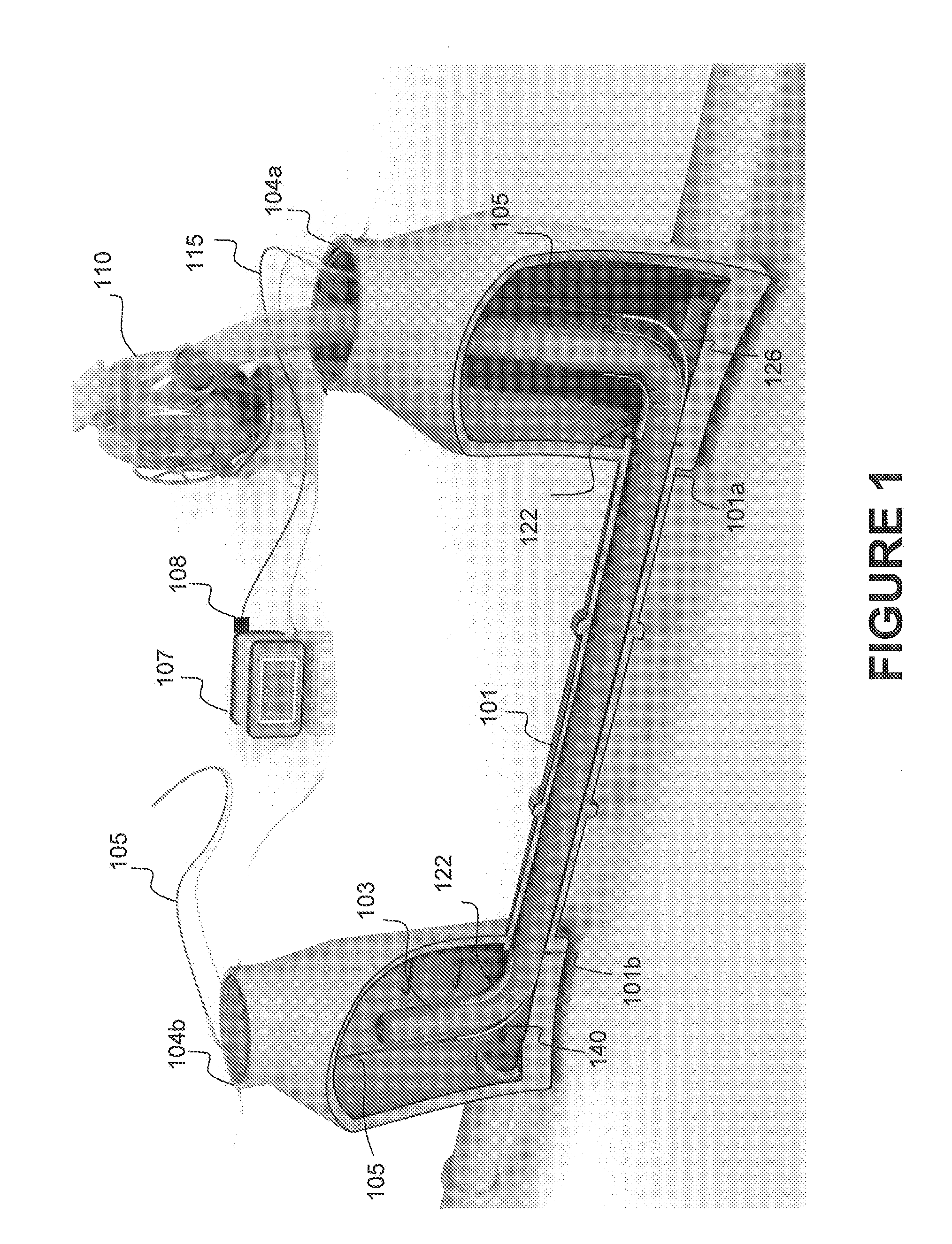

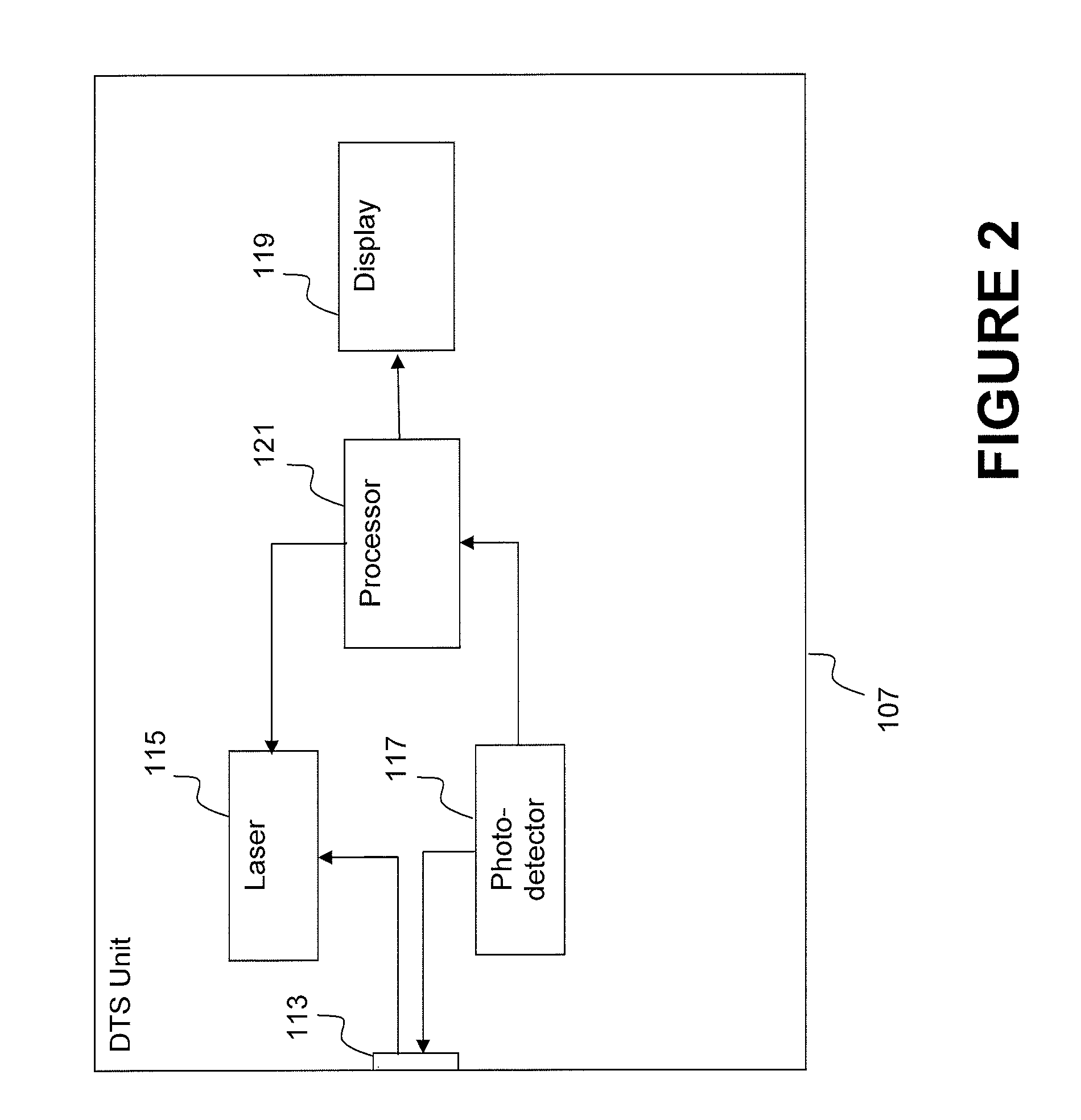

[0018]FIG. 1 is a schematic diagram of a pipe segment in the process of being lined in accordance with the principles of the present invention and showing the various components involved in the practice of the present invention. FIG. 1 shows the process near an end stage so as to illustrate all of the components involved. Particularly, a segment of pipe 101, such as sewer pipe, that is in need to repair is disposed underground and is accessible only at discrete points adjacent manholes 104a, 104b in the street, e.g., commonly spaced apart approximately 360-400 feet in the United States. Accordingly, a 360-400 foot long sock of cured-in-place pipe liner 103 is provided for lining the pipe 101. Before the liner 103 is placed in the pipe 101, an optical fiber cable 105 is placed in the pipe 101. Preferably, the optical fiber cable is longer than the actual pipe segment so as to provide at least approximately ten meters of extra cable at the far end and any extra cable needed at the nea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com