Strapping machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

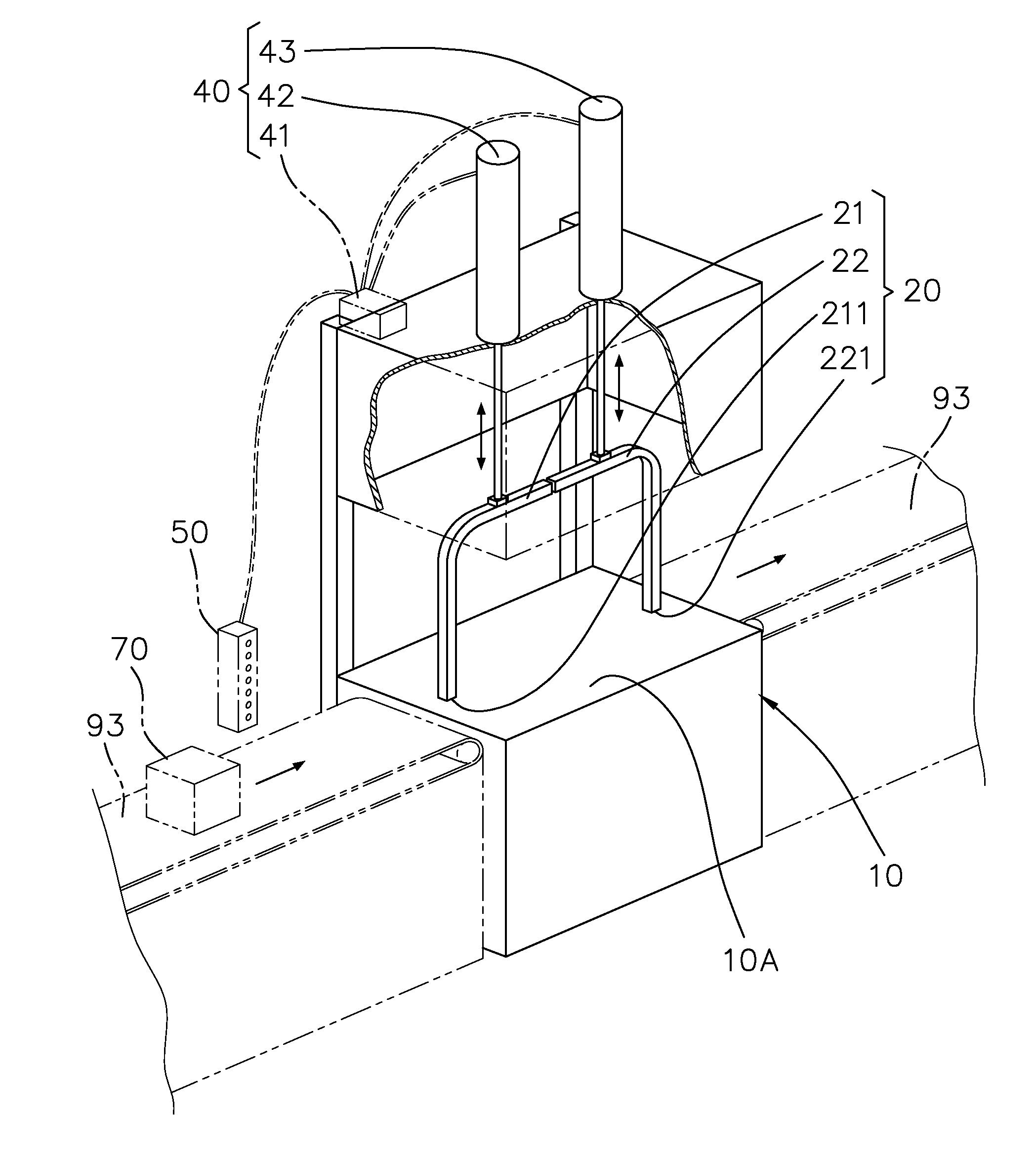

[0034]Referring to FIGS. 7, 8 and 9, the present invention is a strapping machine. It comprises a machine body 10, a strap chute 20, a strap supplying device 30, and a controlling device 40.

[0035]With regard to the machine body 10, it has a working surface 10A, a first hole 11, and a second hole 12.

[0036]The strap chute 20 includes an access guiding portion 21 and an exit guiding portion 22. The access guiding portion 21 has an access hole 211 which is corresponding to the first hole 11. The exit guiding portion 22 has an exit hole 221 which is corresponding to the second hole 12.

[0037]Concerning the strap supplying device 30, it can supply a strap 100 and can perform a strapping work. The strap 100 is supplied into the strap chute 20 via the first hole 11 and the access hole 211 and then is guided out via the exit hole 221 and the second hole 12. After which, the strap 100 is back to the strap supplying device 30 for performing a strapping movement. The strap supplying device 30 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com