Method of and apparatus for winding a lengthy rubber material

a technology of long rubber and winding rod, which is applied in the directions of thin material handling, transportation and packaging, filament handling, etc., can solve the problems of large weight, elongation and cut, and small storage amount, so as to increase the quantity of long rubber material as wound, prevent excessive bonding of rubber material, and increase the effect of conveyance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]A mode for carrying out the invention will be described below on the basis of an embodiment shown in the drawings.

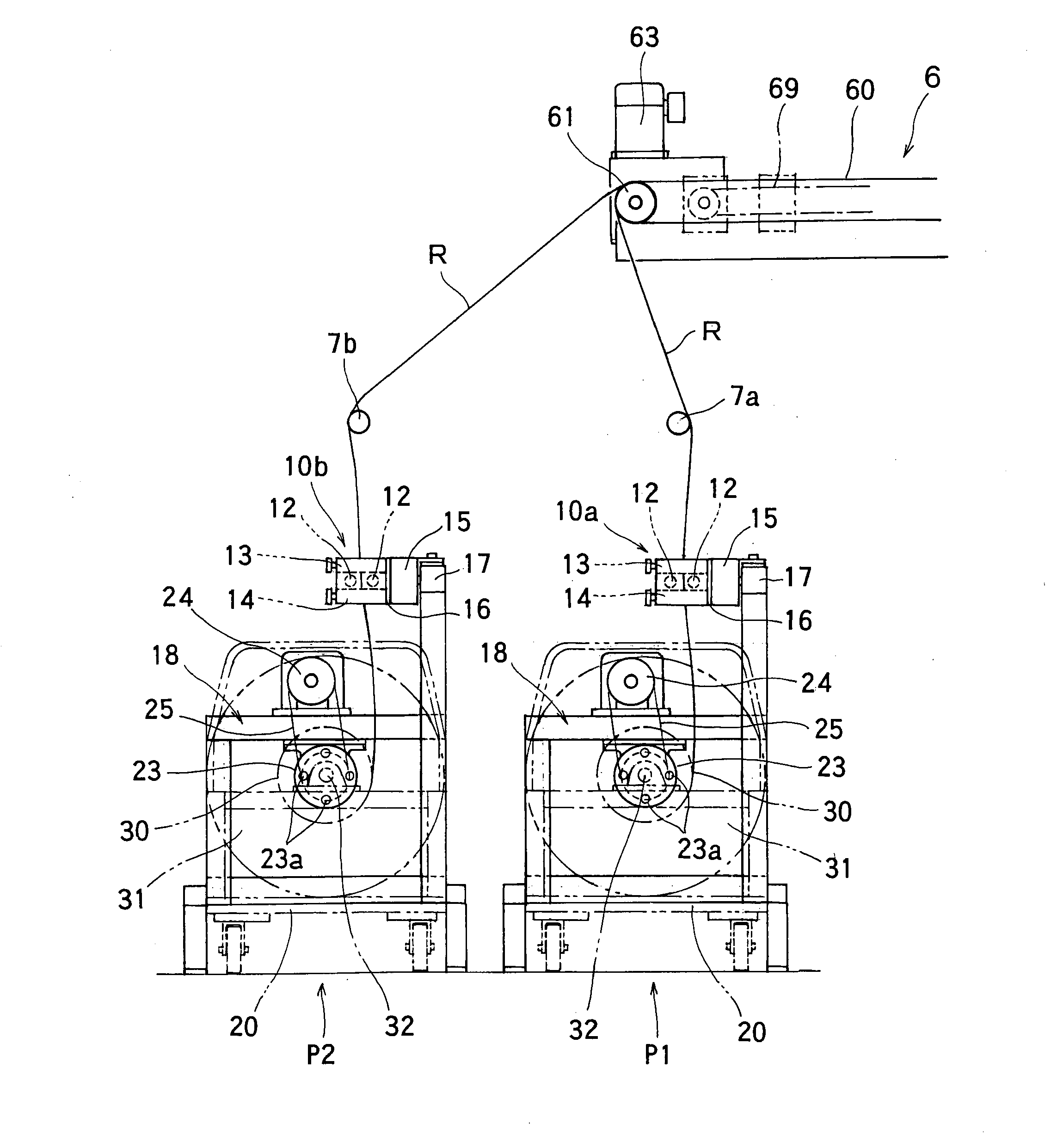

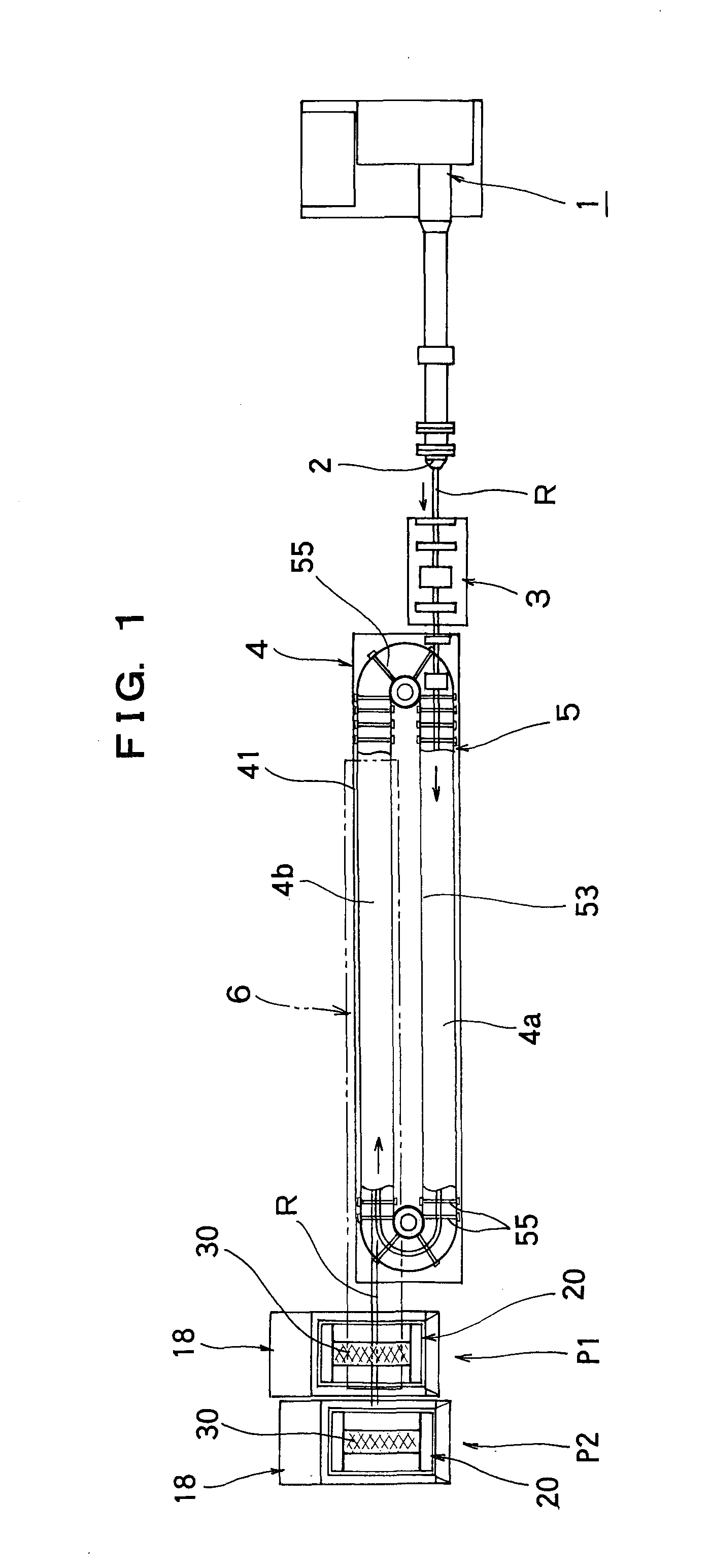

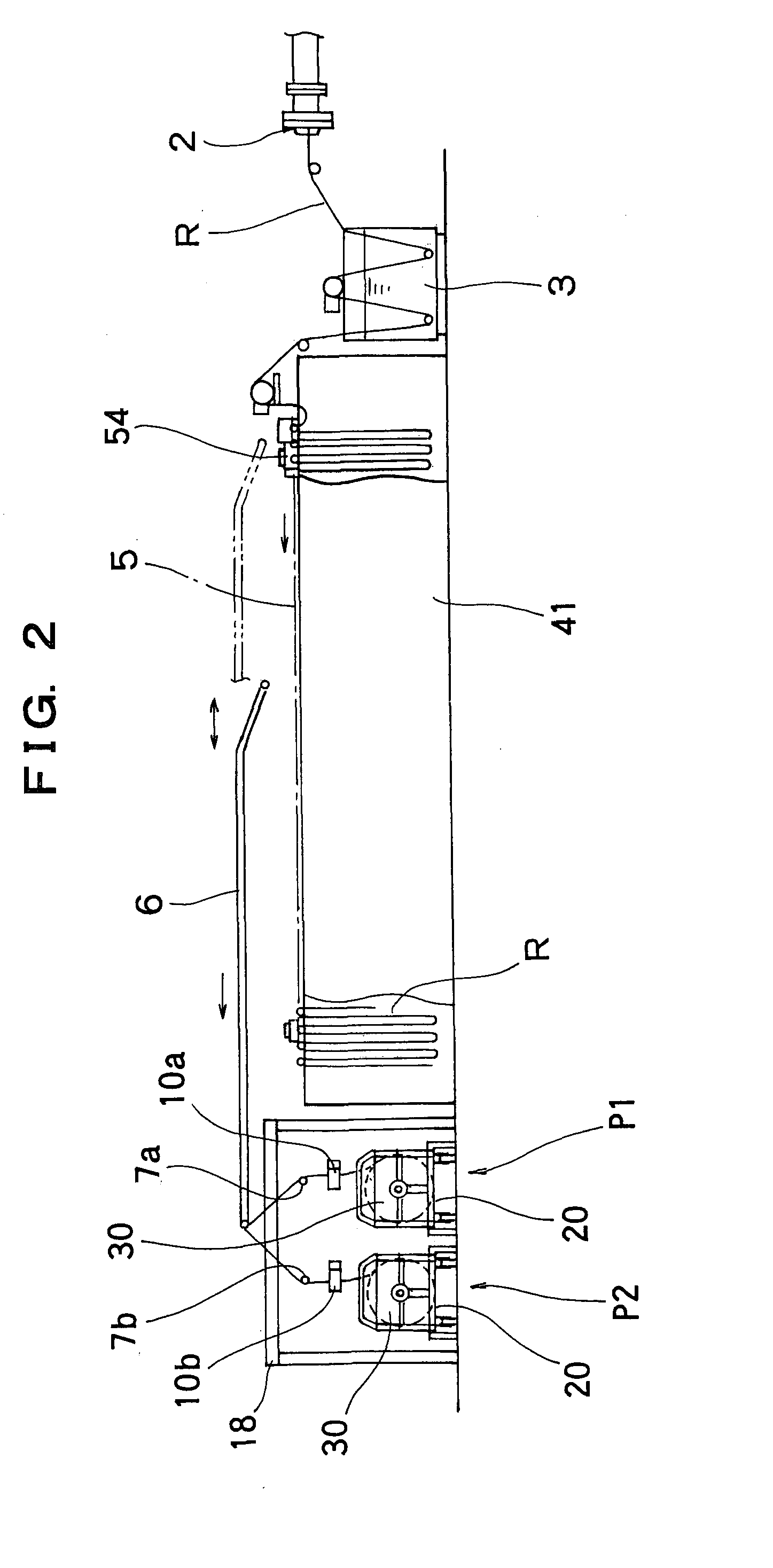

[0025]FIG. 1 is a schematic, plan view showing the outline of the production equipment of a lengthy rubber material, which includes a winding apparatus of the invention and FIG. 2 is a schematic, side view showing the equipment. FIG. 3 is a schematic, plan view showing a drying apparatus of the equipment, FIGS. 4 and 5 are cross sectional views showing a part of the drying apparatus, FIG. 6 is a schematic, plan view showing a conveyor device of the equipment, FIG. 7 is a schematic, side view showing the conveyor device, and FIG. 8 is a schematic, cross sectional view illustrating the telescopic function of the conveyor device. FIG. 9 is a plan view showing, in enlarged scale, a main portion of a winding apparatus. FIGS. 10 and 11 are a side view and a front view in enlarged scale. FIG. 12 is a plan view showing a traverse guide and FIGS. 13 and 14, respectively, ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com