Impeller for turbine

a technology for turbines and impellers, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of difficult to provide impellers at a low cost, difficult to efficiently convert the impulsive force of working gas into rotational force, and high cost of the impellers manufactured in this way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

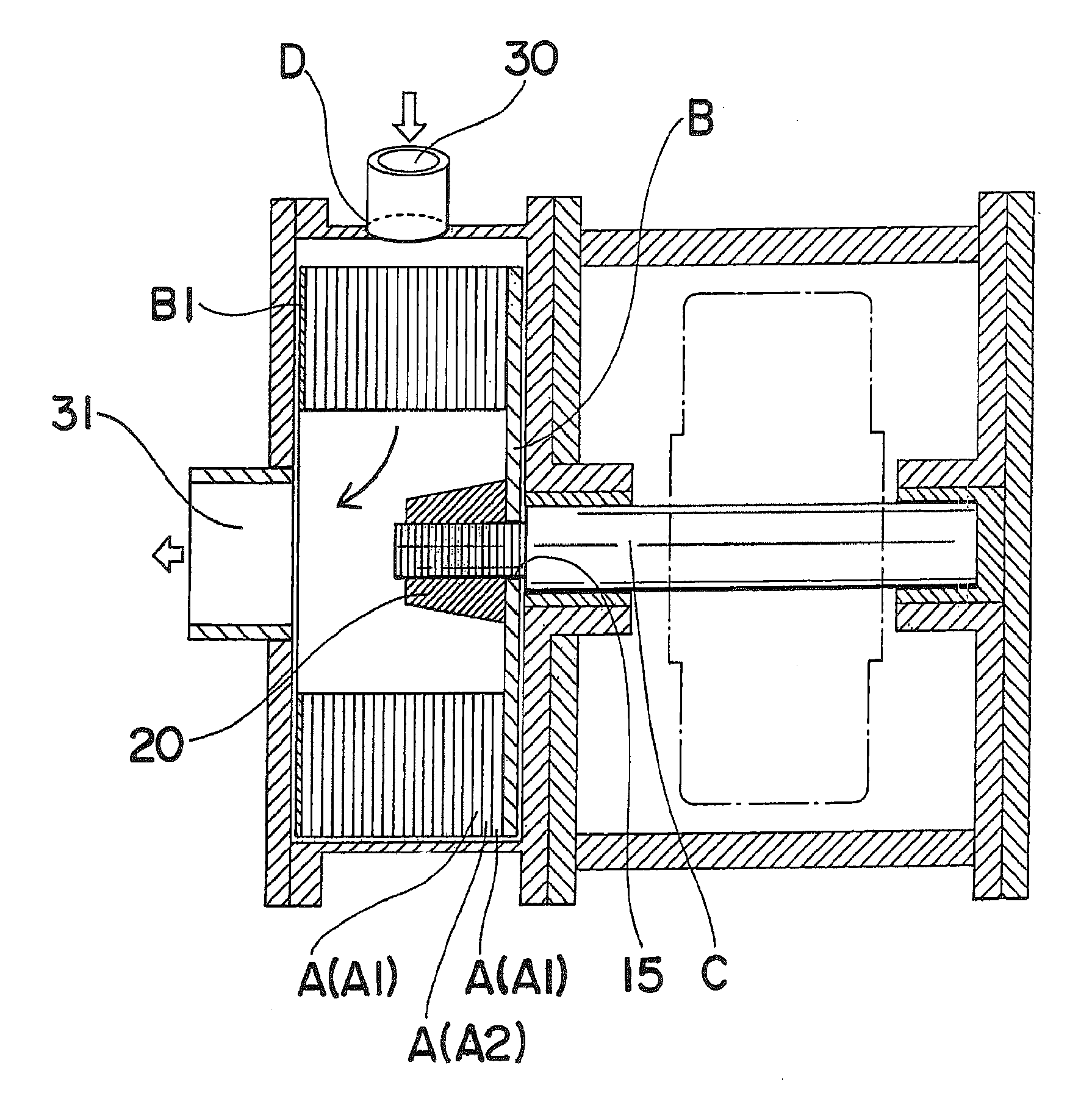

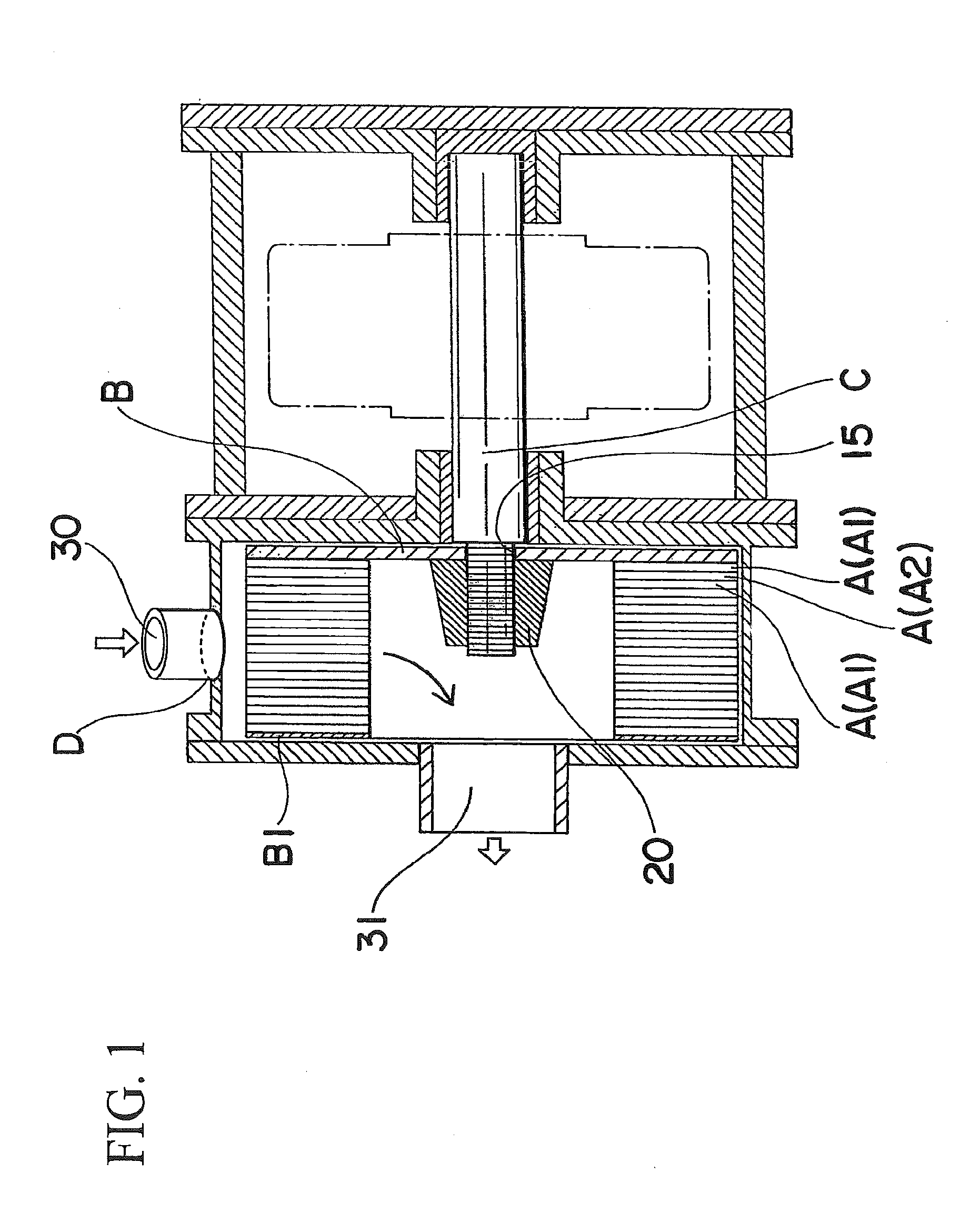

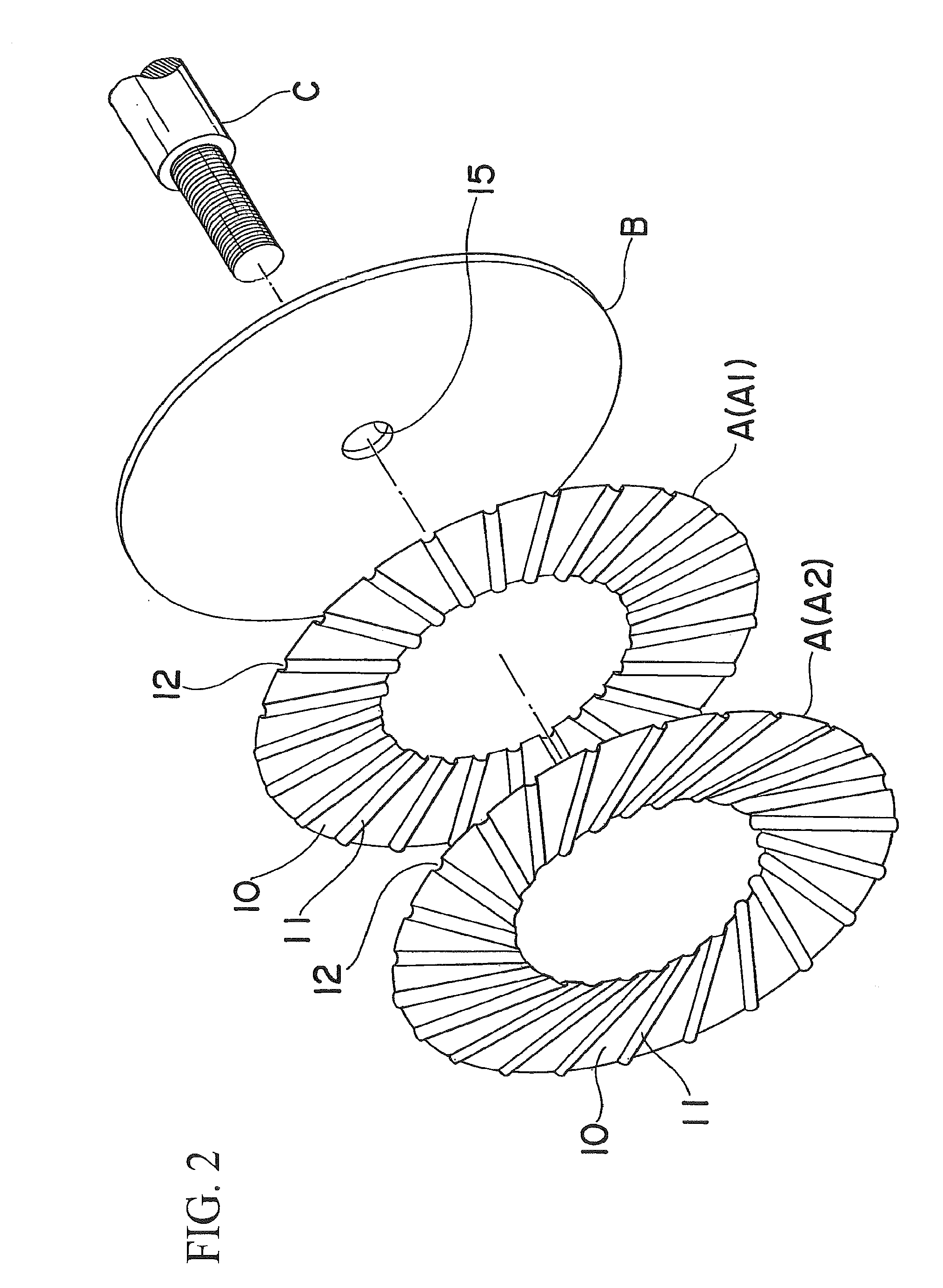

[0050]The disk blade A which is used in the impeller for a turbine is constituted by, for example, a metallic (for example, stainless steel) disk having a relatively thin annular disk shape and excellent corrosion resistance. Further, the disk blade is configured such that a number of pressed vane portions 11 are provided at the disk by a single (or, a plurality is also acceptable) press working and also a number of pressed vane portions 11 project from one surface side of the disk. Furthermore, the pressed vane portions 11 are formed from the inner circumferential edge to the outer circumferential edge of the disk. Also, a portion of the disk, in which the pressed vane portions 11 are not formed by the press working, becomes the basal portion 10, the inside of the projected pressed vane portion 11 becomes the recessed space 12, and the most protruded ridge portion of the pressed vane portion 11 becomes the projecting rear portion 11a.

[0051]Further, two or more types of disk blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com