Ring generator

a generator and ring technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problem of increasing the temperature of the stator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]It is to be noted that the same references can denote possibly similar, non-identical elements of different embodiments.

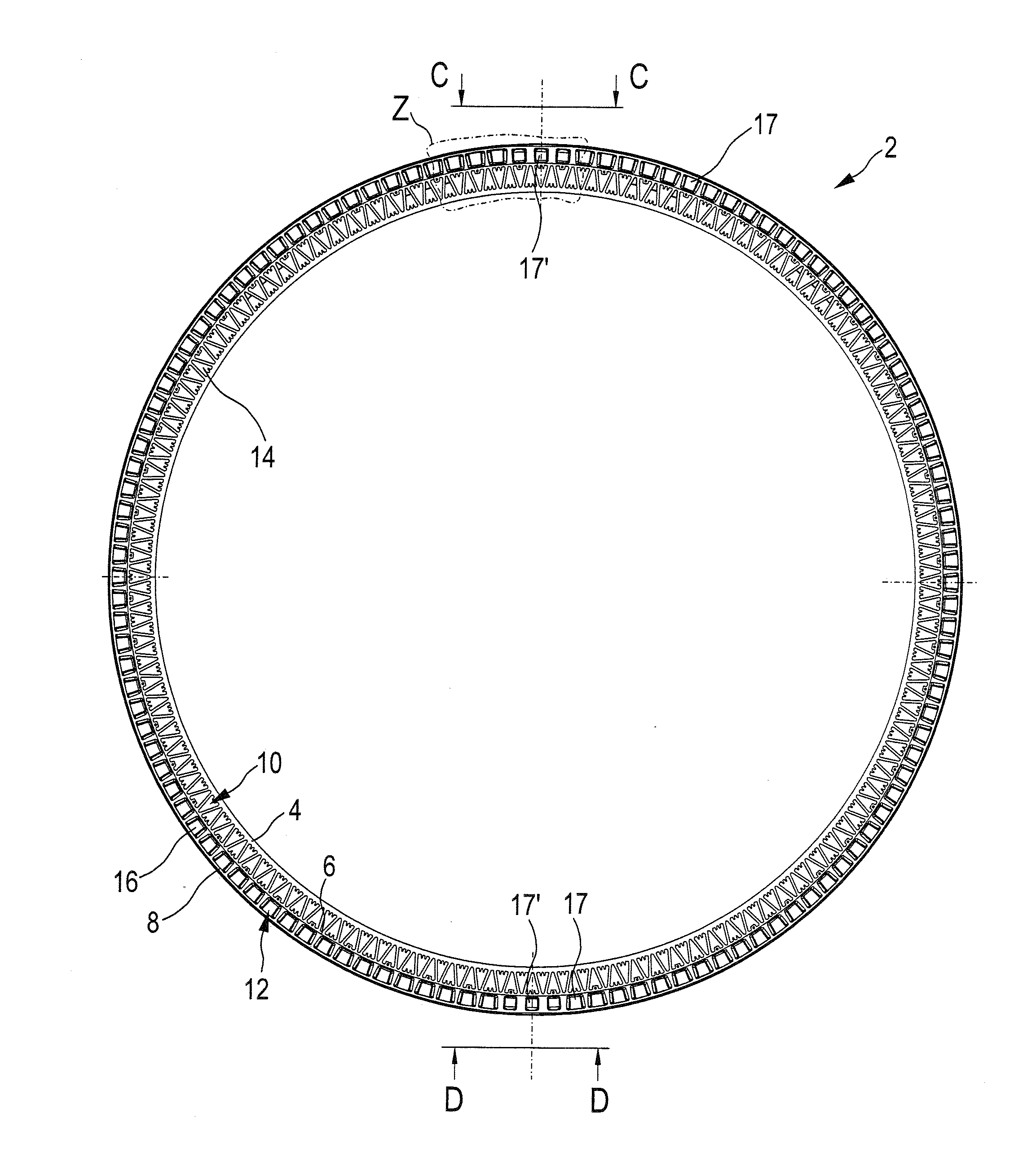

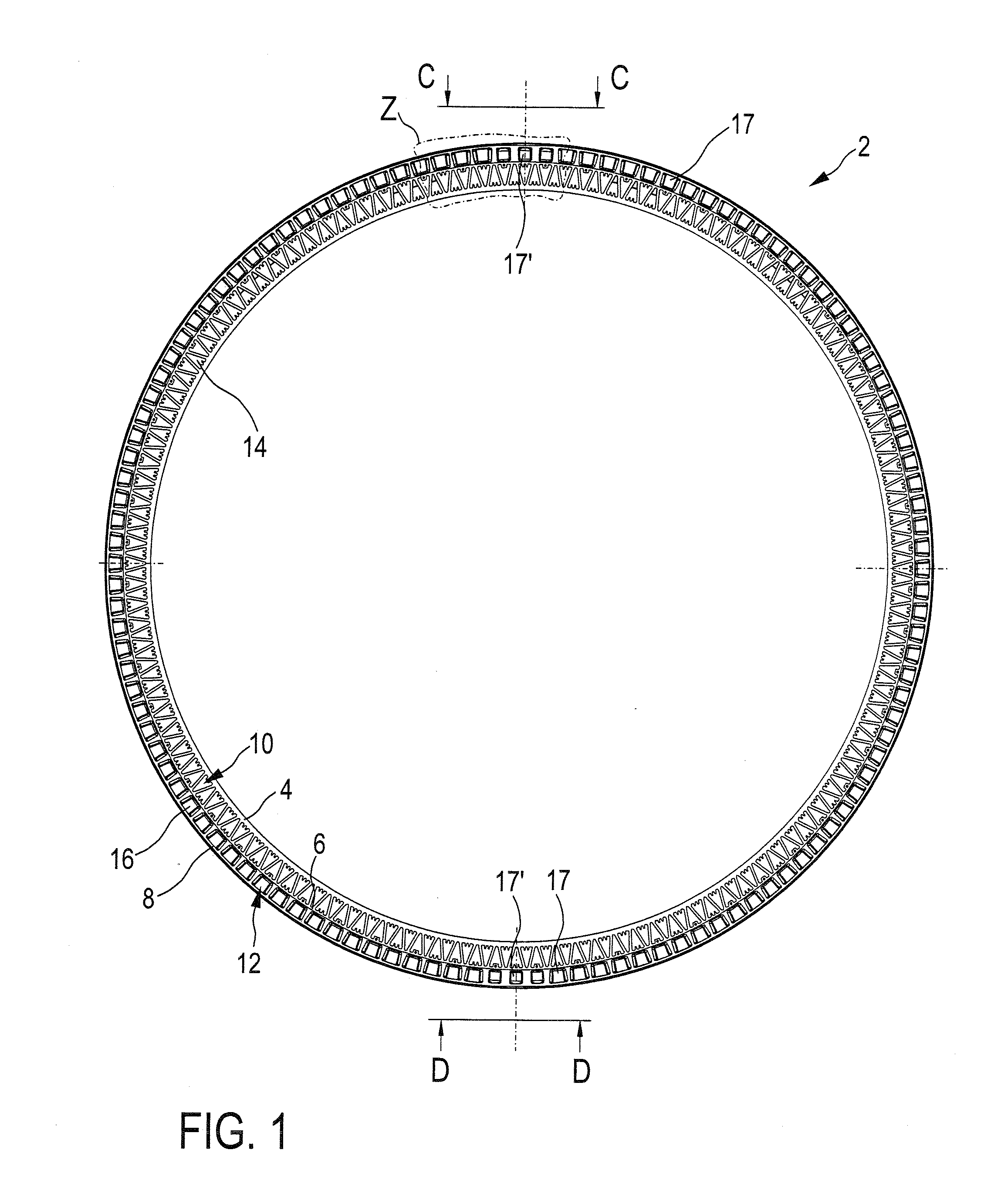

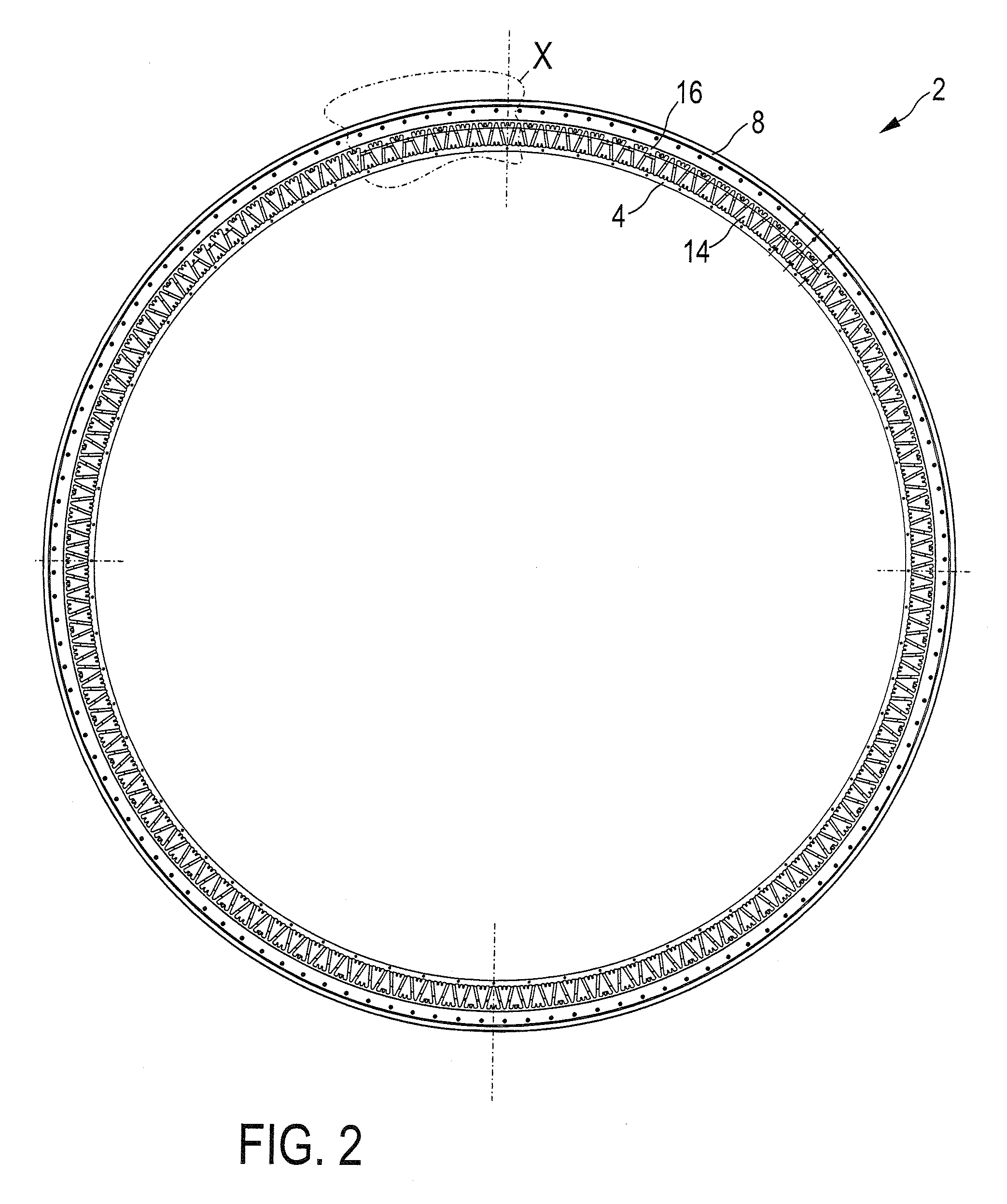

[0070]The stator ring 2 shown in FIG. 1 is of a ring-shaped configuration and forms a part of a ring generator with an internal rotor. The stator ring 2 has an inner carrier ring 4, a central carrier ring 6 and an outer carrier ring 8. Provided between the inner and outer carrier rings 4, 6 is an active cooling portion 10 while a passive cooling portion 12 is provided between the central and outer carrier rings 6, 8. As illustrated, the stator ring 2 is cast in one piece including the inner, central and outer carrier rings 4, 6, 8 and active and passive cooling portions 10, 12, the material used being aluminium.

[0071]The inner, central and outer carrier rings 4, 6, 8 provide for stability and stiffness by virtue of their substantially solid nature. To guide a magnetic field, a suitable magnetically well-conductive laminated core carrying stator windings is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com