Cooling method and cooling system for electronic device

a cooling system and electronic device technology, applied in the field of cooling methods and cooling systems for electronic devices, can solve the problems of system halt, increased head generation of electronic devices, and increased running costs of air-conditioning equipment, so as to prevent dew condensation, reduce the electric power cost of air-conditioning systems, and maintain the effect of natural circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

of the Present Invention

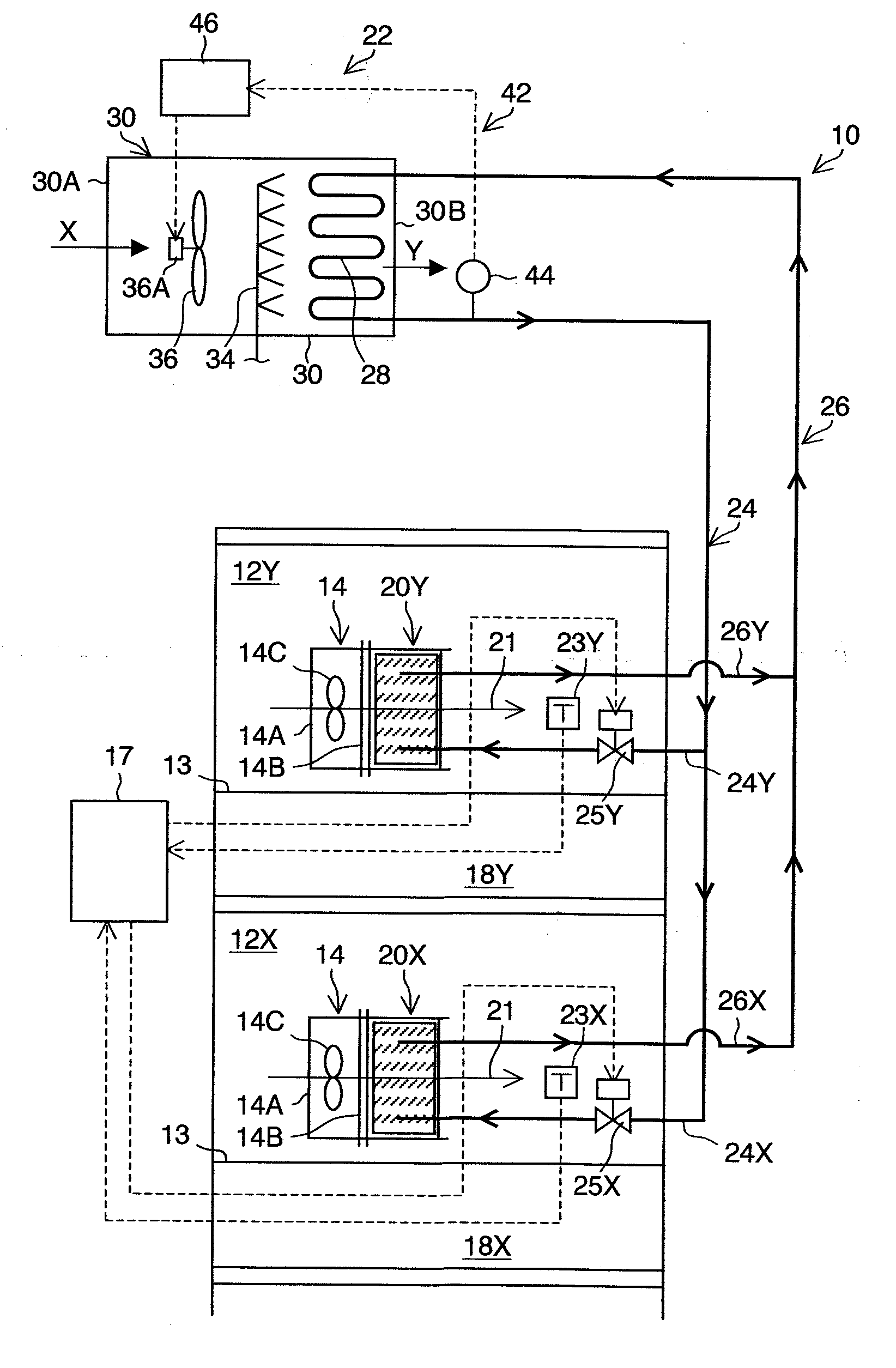

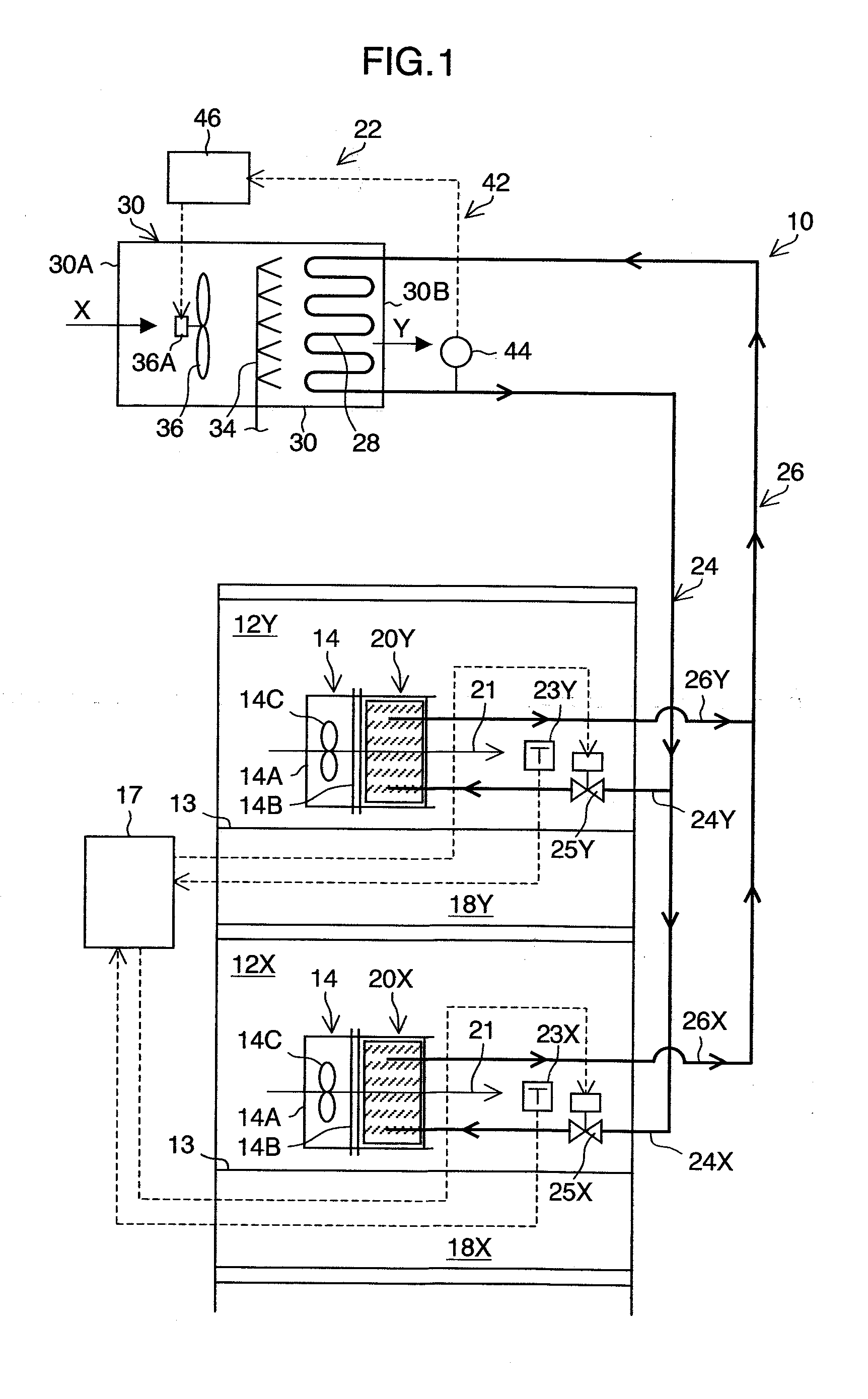

[0082]FIG. 1 is a conceptual diagram illustrating an overall configuration of a first embodiment of a cooling system 10 for an electronic device.

[0083]The cooling system 10 illustrated in FIG. 1 is a system which locally cools the vicinity of a server 14 provided in each of server rooms 12X and 12Y on lower and upper two floors. It should be noted that X attached to reference numeral in the following description designates a member relating to a cooling system on the lower floor, and Y attached to reference numeral in the following description designates a member relating to a cooling system on the upper floor. In addition, in FIG. 1, although one server 14 is illustrated in each of the server rooms 12X and 12Y, in reality, a large number of the servers 14 are placed therein. Further, normally, the servers 14 are stacked on top of one another to be housed in a server rack (not shown), and thus are installed in the server rooms 12X and 12Y.

[0084]The server 14 ...

second embodiment

of the Present Invention

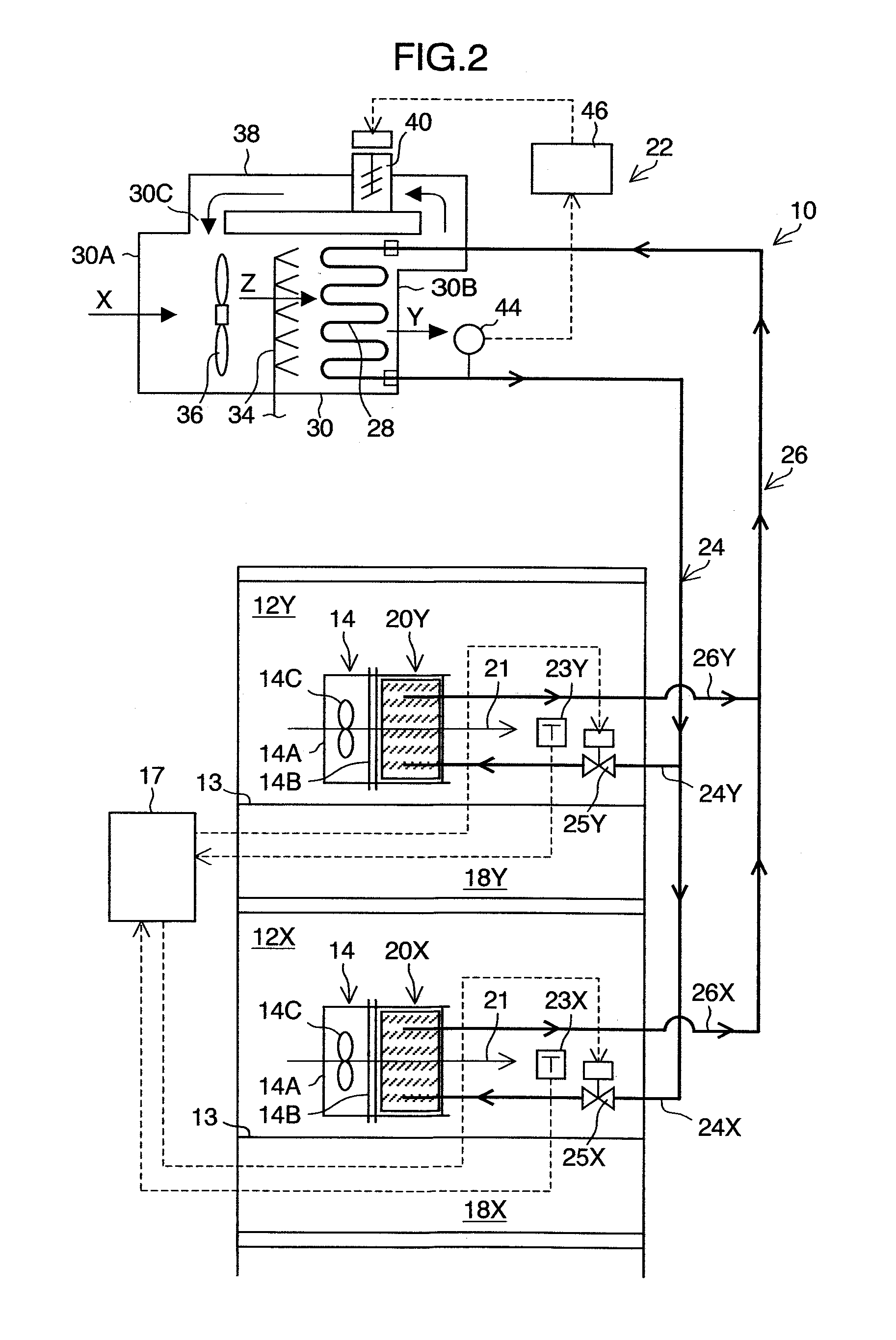

[0110]FIG. 2 is a conceptual diagram illustrating an overall configuration of a second embodiment of the cooling system 10 for the electronic device, and illustrates the case where a circulation duct type cooling tower is provided as the apparatus which condenses the refrigerant gas.

[0111]It should be noted that elements common to those of the first embodiment are denoted by the same reference symbols, and description thereof is omitted.

[0112]As illustrated in FIG. 2 and FIG. 3, a coupling hole 30C is opened on a side surface of the cooling tower main body 30 on the take-in port 30A side, and part of the exhaust port 30B and the coupling hole 30C are coupled to each other by a circulation duct 38. With this configuration, part of the exhaust outside air Y which has an increased temperature and is exhausted from the exhaust port 30B passes through the circulation duct38 to be circulated to the vicinity of the take-in port 30A, and hence the exhaust outside air...

third embodiment

of the Present Invention

[0124]FIG. 4 is a conceptual diagram illustrating an overall configuration of a third embodiment of the cooling system 10 for the electronic device, and illustrates the case where the cooling tower 22 according to each of the first and second embodiments is replaced with a cold water type condenser 48 as the apparatus which condenses the refrigerant gas.

[0125]It should be noted that elements common to those of the first and second embodiments are denoted by the same reference symbols, and description thereof is omitted.

[0126]As illustrated in FIG. 4, the heat exchange coil 28 coupled to the gas piping 26 and the liquid piping 24 and a cold water supply coil 50 coupled to a cold water supply apparatus (not shown) are provided inside of a cold water type condenser main body 49 (casing). Then, the refrigerant gas flowing through the heat exchange coil 28 and cold water flowing through the cold water supply coil 50 exchange heat with each other, so that the refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com