Bottle stopper

a technology of stopper and stopper body, which is applied in the direction of container preventing decay, liquid handling, application, etc., can solve the problems of economic burden, deterioration of wine, and contact between the oxygen absorbing member and the liquid of wine, so as to prevent deterioration in the quality of the liquid content, prevent deterioration, and absorb oxygen. the effect of safe and stable functioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

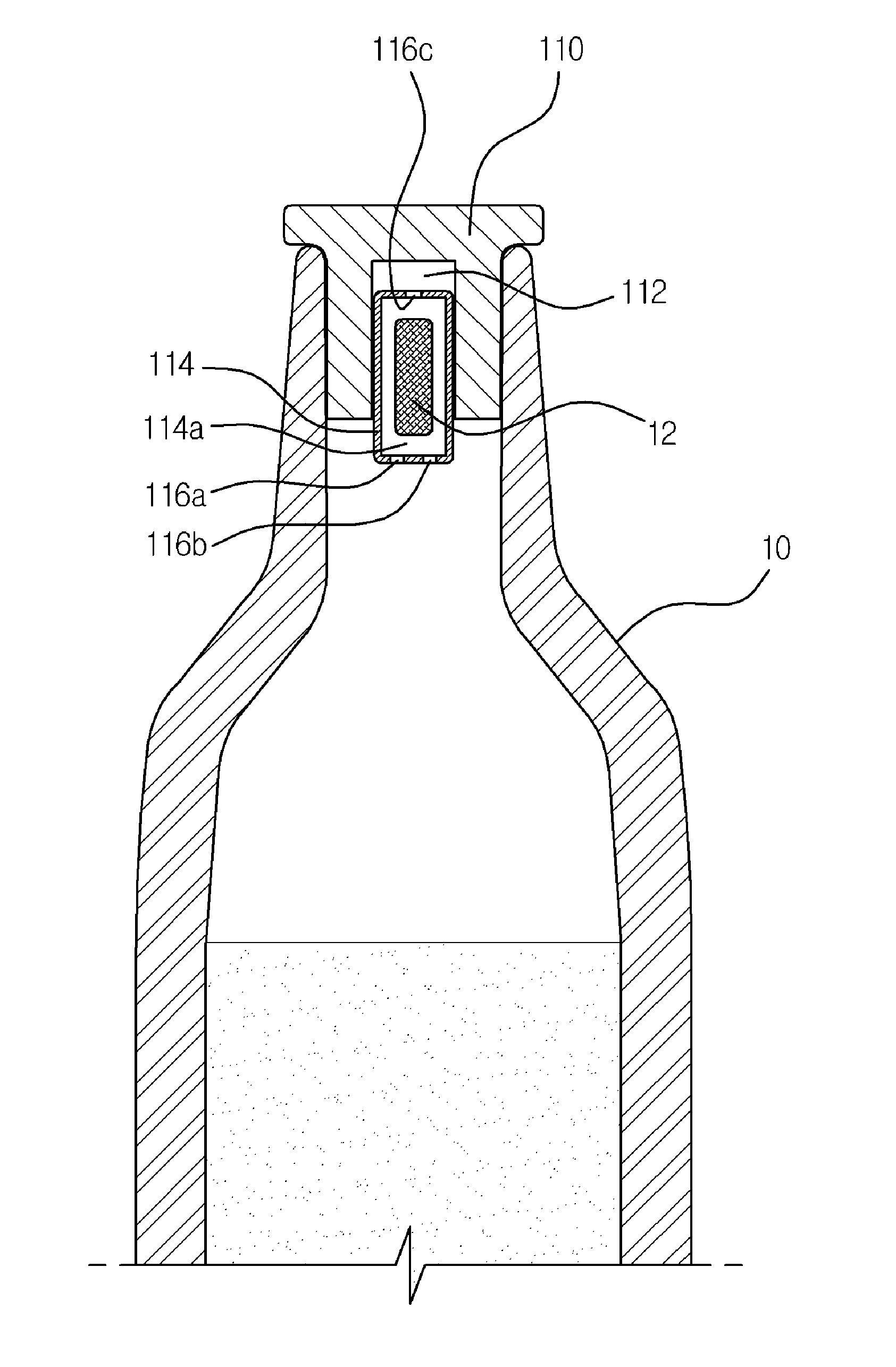

[0020]FIG. 1 is a cross-sectional view illustrating a bottle with a bottle stopper according to the present invention.

[0021]Referring to FIG. 1, the bottle stopper according to a first embodiment of the present invention is used to hermetically re-seal a bottle 10, and is formed to have an outer diameter equal to or smaller than an inner diameter of a mouth part of the bottle 10. The bottle stopper is made of wood or resin, which is not harmful to the human body. The bottle stopper includes a stopper main body 110 shaped so as to be fitted into the mouth part of the bottle 10 by a predetermined depth only.

[0022]As shown in FIG. 1, the stopper main body 110 includes a fitting recessed portion 112 formed therein in such a fashion as to be opened at a lower end thereof so that a cylindrical oxygen absorber accommodating container 114 including an accommodating space portion 114a for accommodating an oxygen absorber 12 therein is fixedly fitted into the fitting recessed portion 112. In ...

second embodiment

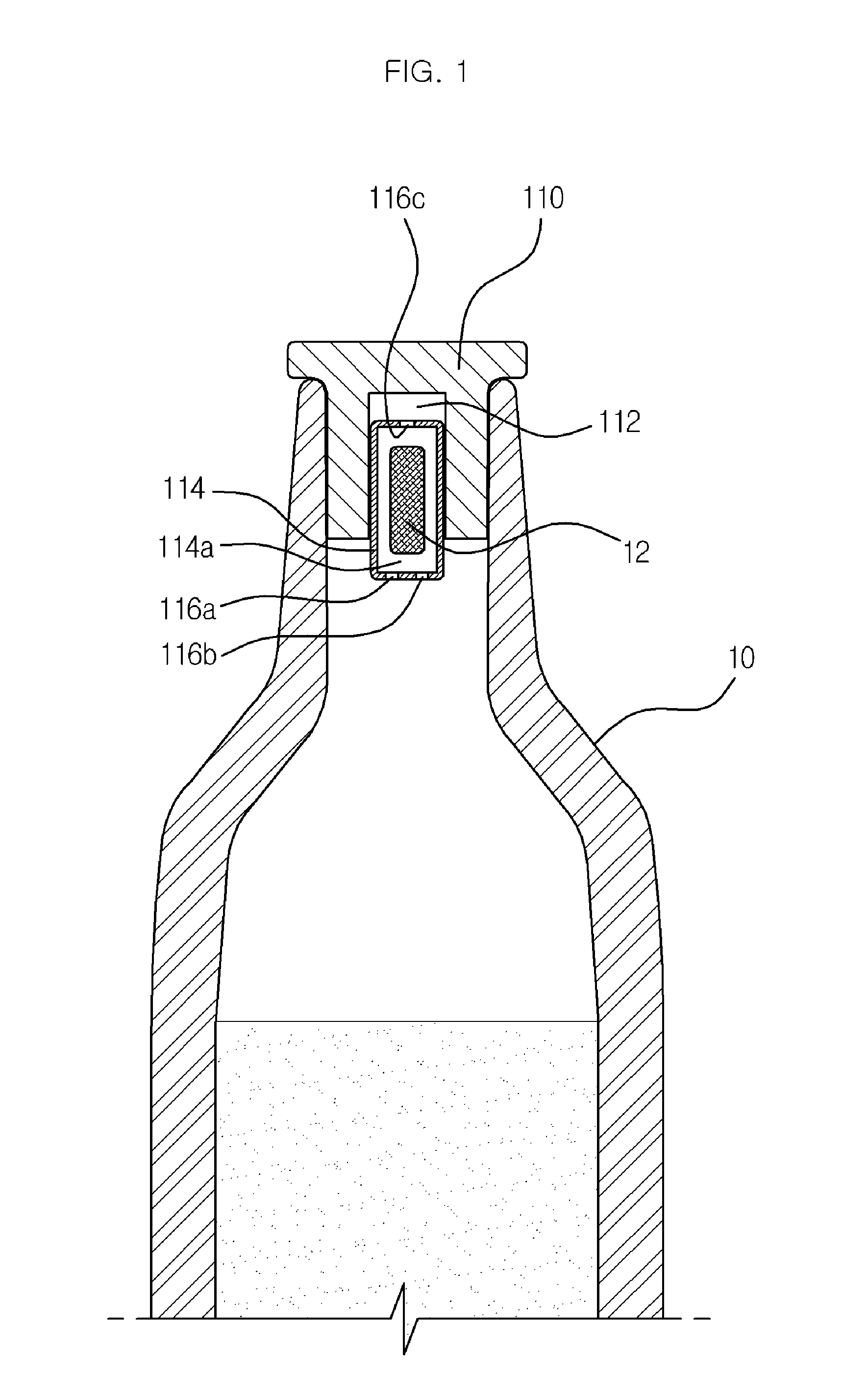

[0026]FIG. 2 is a cross-sectional view illustrating a bottle with a bottle stopper according to the present invention.

[0027]Referring to FIG. 2, the bottle stopper according to the second embodiment of the present invention is different from that according to the first embodiment of the present invention in that retaining steps 118 are protrudingly formed on corresponding engagement portions of an inner circumferential surface of the oxygen absorber accommodating container 114 and an outer circumferential surface of the fitting recessed portion 112, respectively, so that the oxygen absorber accommodating container 114 can be securely fixed to the stopper main body 110 without escaping from the fitting recessed portion 112 by the engagement between the corresponding retaining steps 118. That is, in order for the oxygen absorber accommodating container 114 not to easily escape from the fitting recessed portion 112, the retaining step 118 having a retaining function is formed on corres...

third embodiment

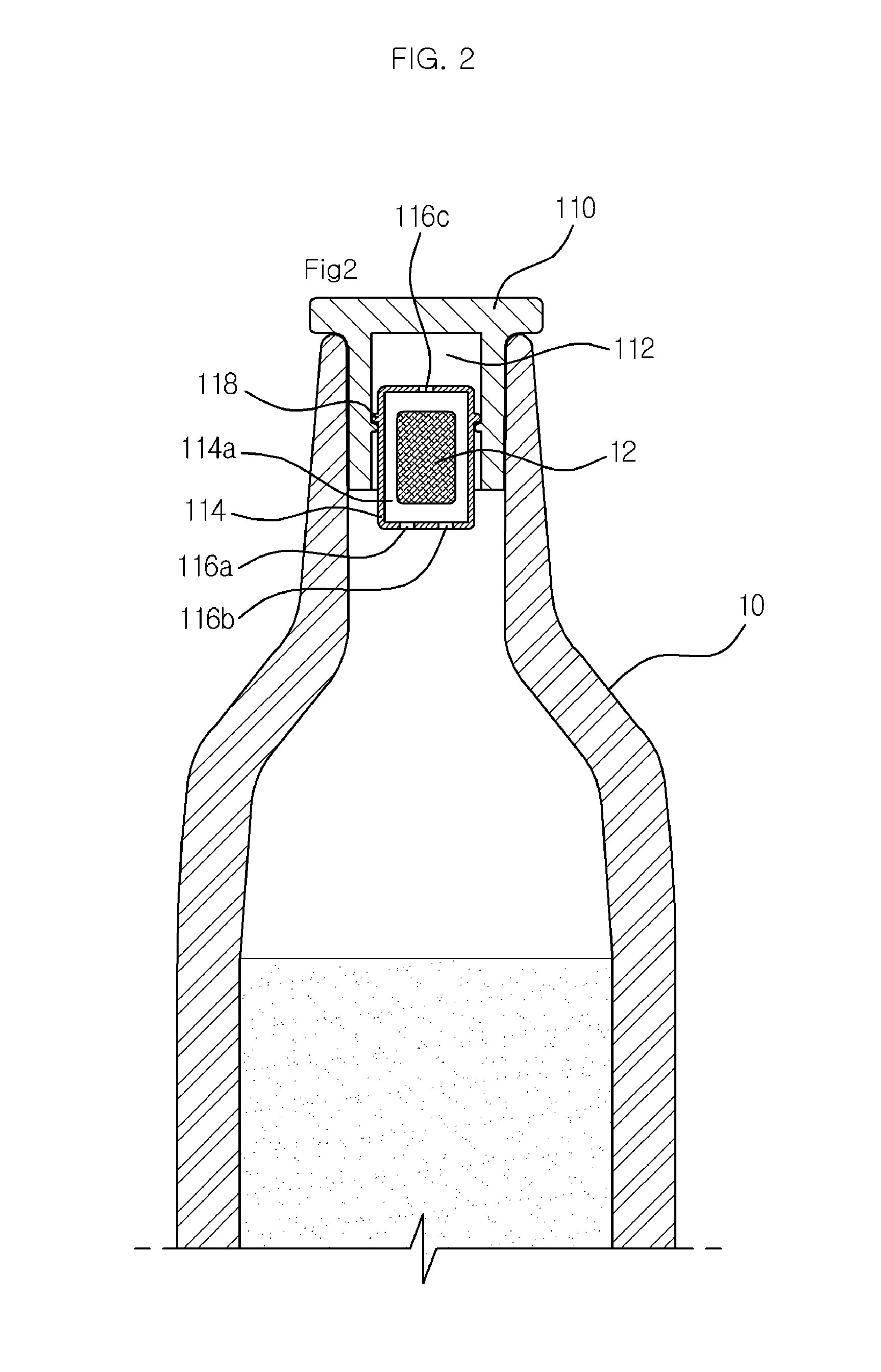

[0028]FIG. 3 is a cross-sectional view illustrating a bottle with a bottle stopper according to the present invention.

[0029]Referring to FIG. 3, the bottle stopper according to the third embodiment of the present invention is also constructed in the same manner as that of the bottle stopper of the first embodiment except that the oxygen absorber is directly accommodated in the bottle stopper.

[0030]In other words, the bottle stopper according to this embodiment includes an oxygen absorber accommodating container 214 provided with an accommodating space portion 214a of a predetermined dimension formed therein in such a fashion as to be opened at a top end thereof only so as to directly accommodate the oxygen absorber 12 in the bottle stopper. The bottle stopper also includes an inner cover 213 separably coupled to an opening of the accommodating space portion 214a of the oxygen absorber accommodating container 214 so as to hermetically seal the opening of the accommodating space porti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com