Laundry Treatment Apparatus Having Heat Pump System

a technology of heat pump and laundry treatment equipment, which is applied in the direction of detergent compounding agent, washing machine with receptacles, cleaning using liquids, etc., to achieve the effect of reducing or zero air conveying power, reducing air circulation speed, and reducing power provided to the blower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

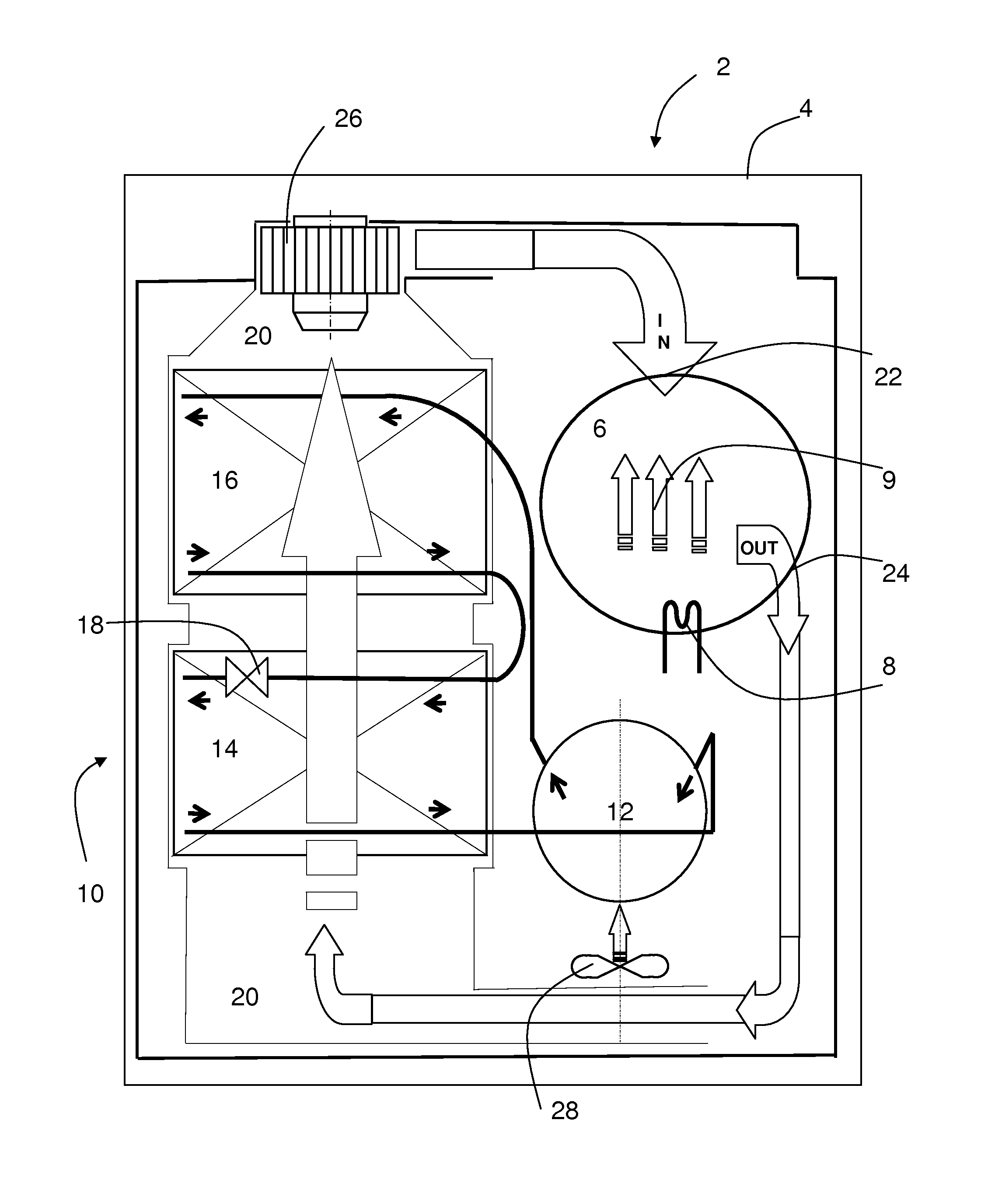

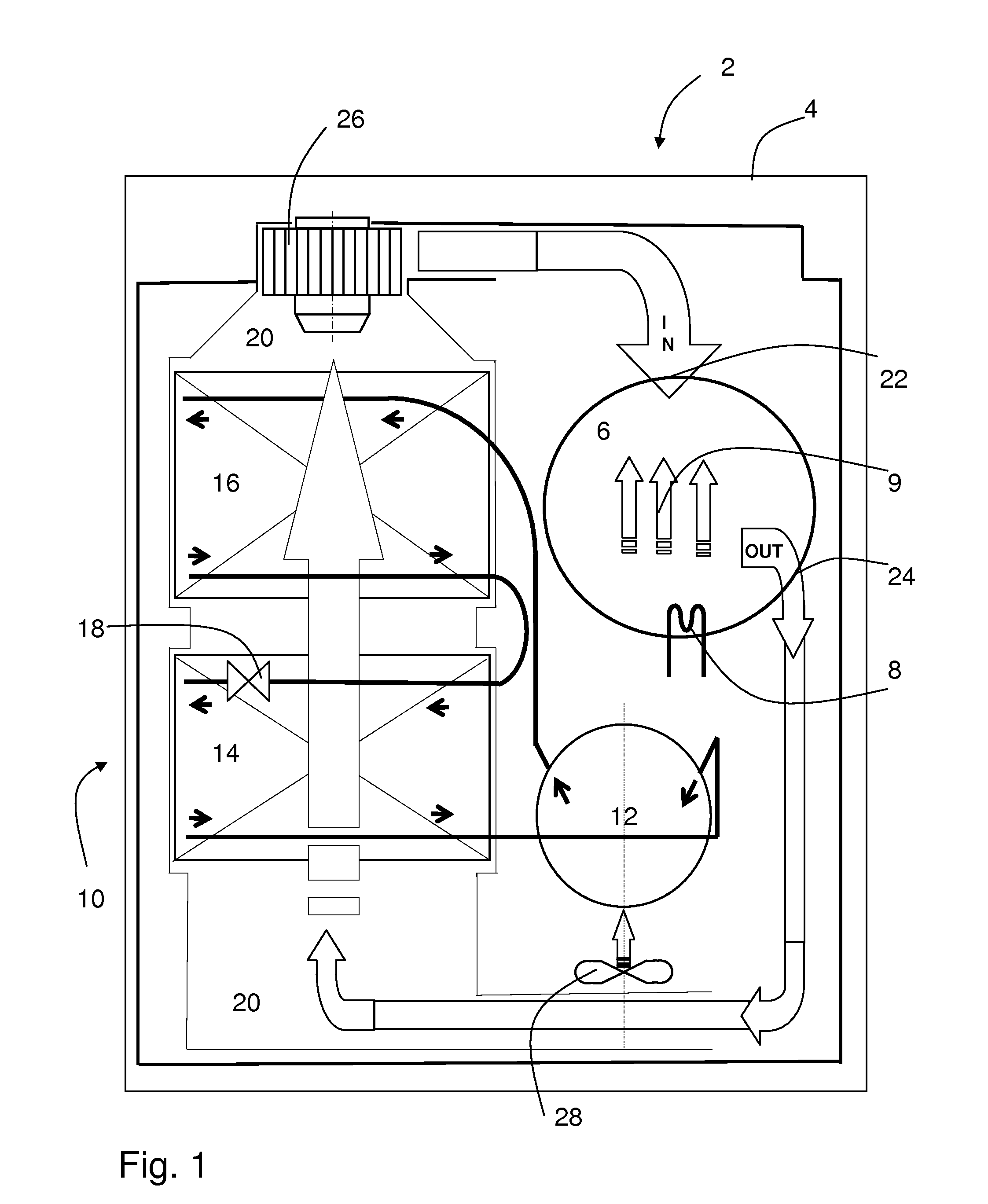

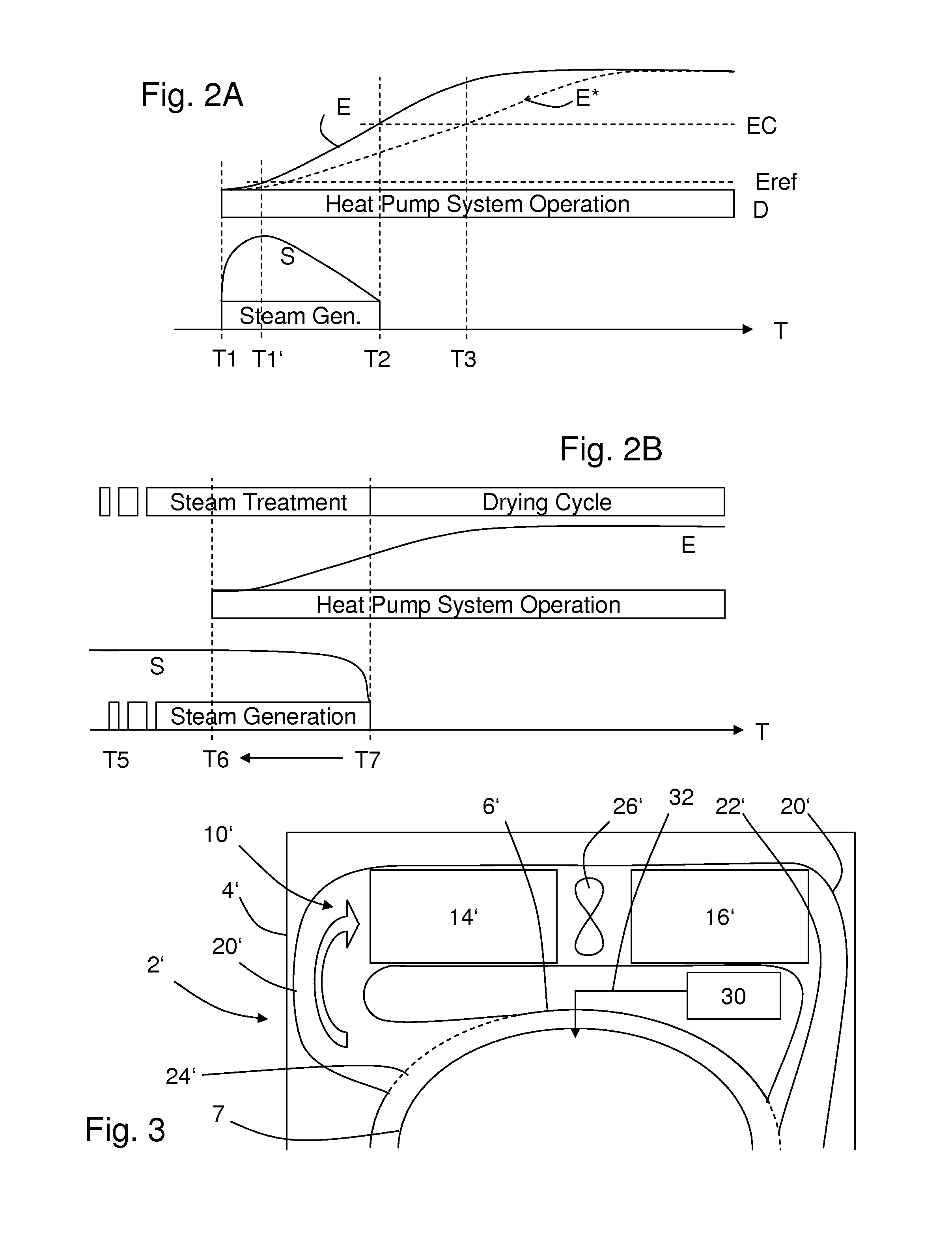

[0042]FIG. 1 is a schematic diagram of a washing machine 2 showing some of the elements relating to the heat pump system 10 used for the drying cycle. The invention can also be implemented in a condenser-type dryer having a heat pump system similar to the one shown with respect to FIG. 3.

[0043]The heat pump system 10 of the washing machine 2 shown in FIG. 1 has a compressor 12, an evaporator 14 and a condenser 16. Compressor 12, evaporator 14 and condenser 16 are connected via coolant liquid or coolant vapour guiding pipes as schematically shown by the respective lines. An expansion valve 18 or capillary is assigned to the evaporator 14. The terms evaporator and condenser are used here in relation to the closed heat pump system 10 and the processes which the coolant liquid undergoes. The heat pump system 10, its pipes and electrical wiring, a tub 6 enclosing a rotatable drum (7 as shown in FIG. 3), a heater 8 and an air circulation channel 20 are all arranged within the case or body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com