Microelectrode array sensor for detection of heavy metals in aqueous solutions

a micro-electrode array and sensor technology, applied in the field of electrochemical detection of heavy metals, can solve the problems of limited sensitivity in terms of surface oxidation and reduction of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

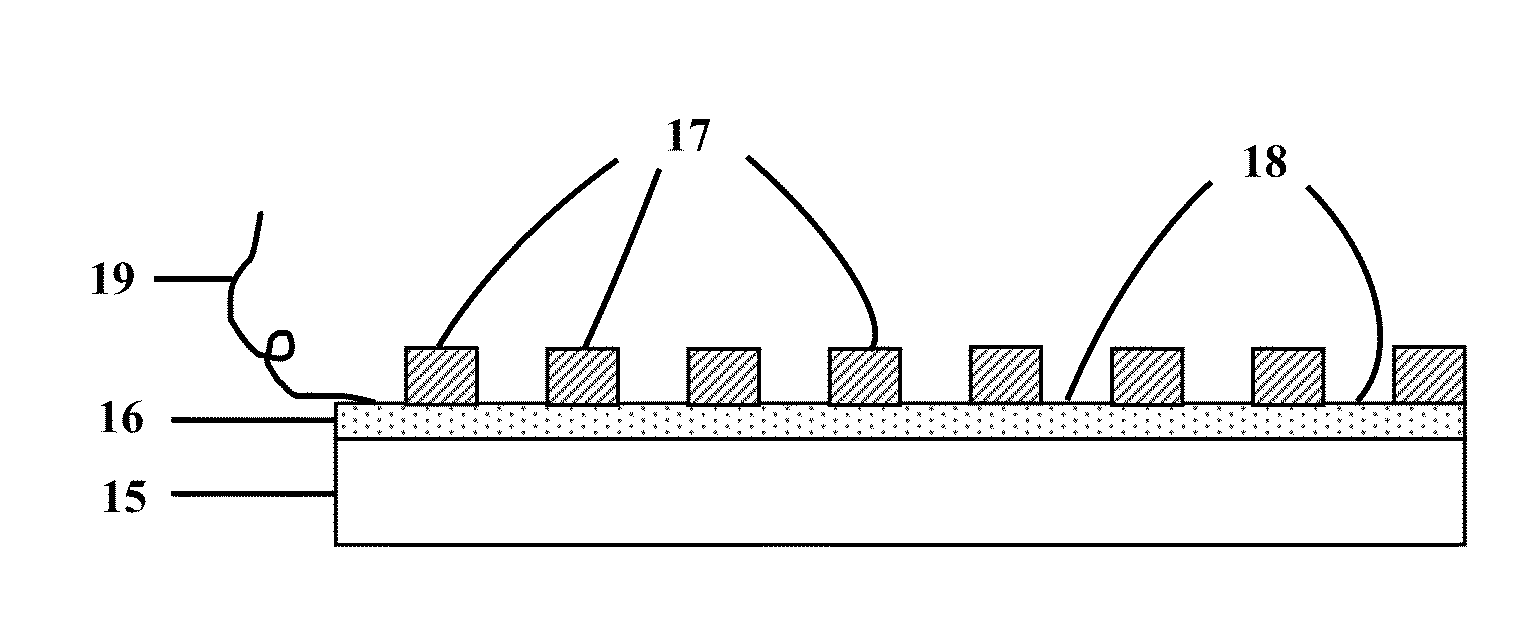

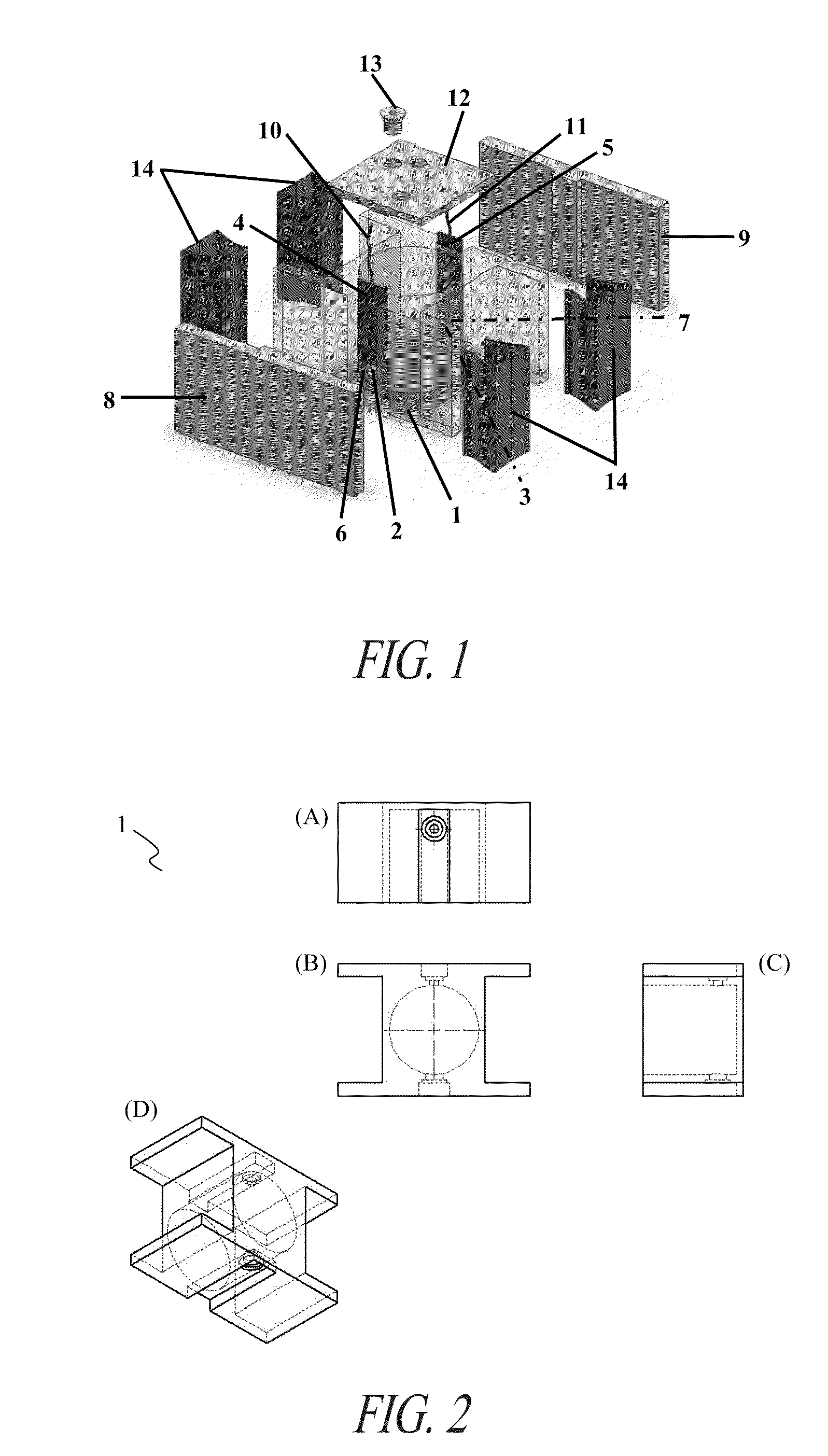

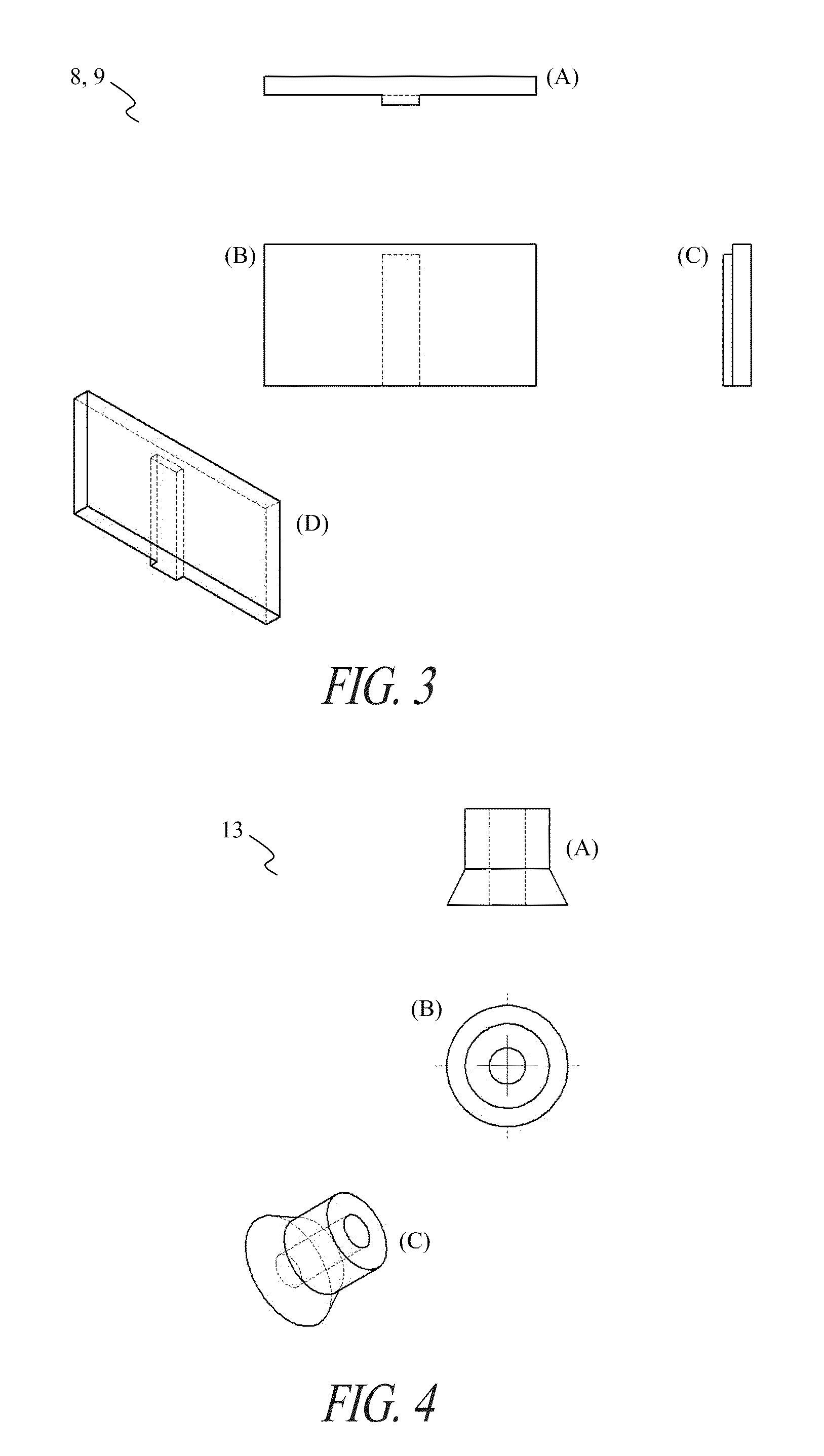

[0027]In a first aspect the present invention refers to a microelectrode array for detecting heavy metals in an aqueous solution. The microelectrode array can comprise a layer of a doped carbon film and a patterning layer arranged on the doped carbon film for defining multiple microelectrodes in the doped carbon film to form the microelectrode array. The dimension, such as size, and shape, and arrangement of each of the multiple microelectrodes can be defined by the dimensions, such as size, and shape, and arrangement of each of the openings in the patterning layer which expose the underlying doped carbon film. Furthermore, the ratio of the maximal width of a microelectrode relative to the shortest distance between the neighboring microelectrodes (center to center) in the microelectrode array is between about 1:1.2 and about 1:6.

[0028]In general, microelectrodes (maximal width of a microelectrode ≦100 μm have significant advantages over conventional macroelectrodes (width of a macro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com