Catheter delivery system

a catheter and delivery system technology, applied in the field of catheter delivery methods and equipment, can solve problems such as accidental perforation of surrounding walls, patient discomfort, and buckling of the catheter, and achieve the effects of avoiding buckling, avoiding buckling, and avoiding buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]While several variations of the present invention have been illustrated by way of example in particular embodiments, it is apparent that further embodiments could be developed within the spirit and scope of the present invention, or the inventive concept thereof. However, it is to be expressly understood that such modifications and adaptations are within the spirit and scope of the present invention, and are inclusive, but not limited to the following appended claims as set forth.

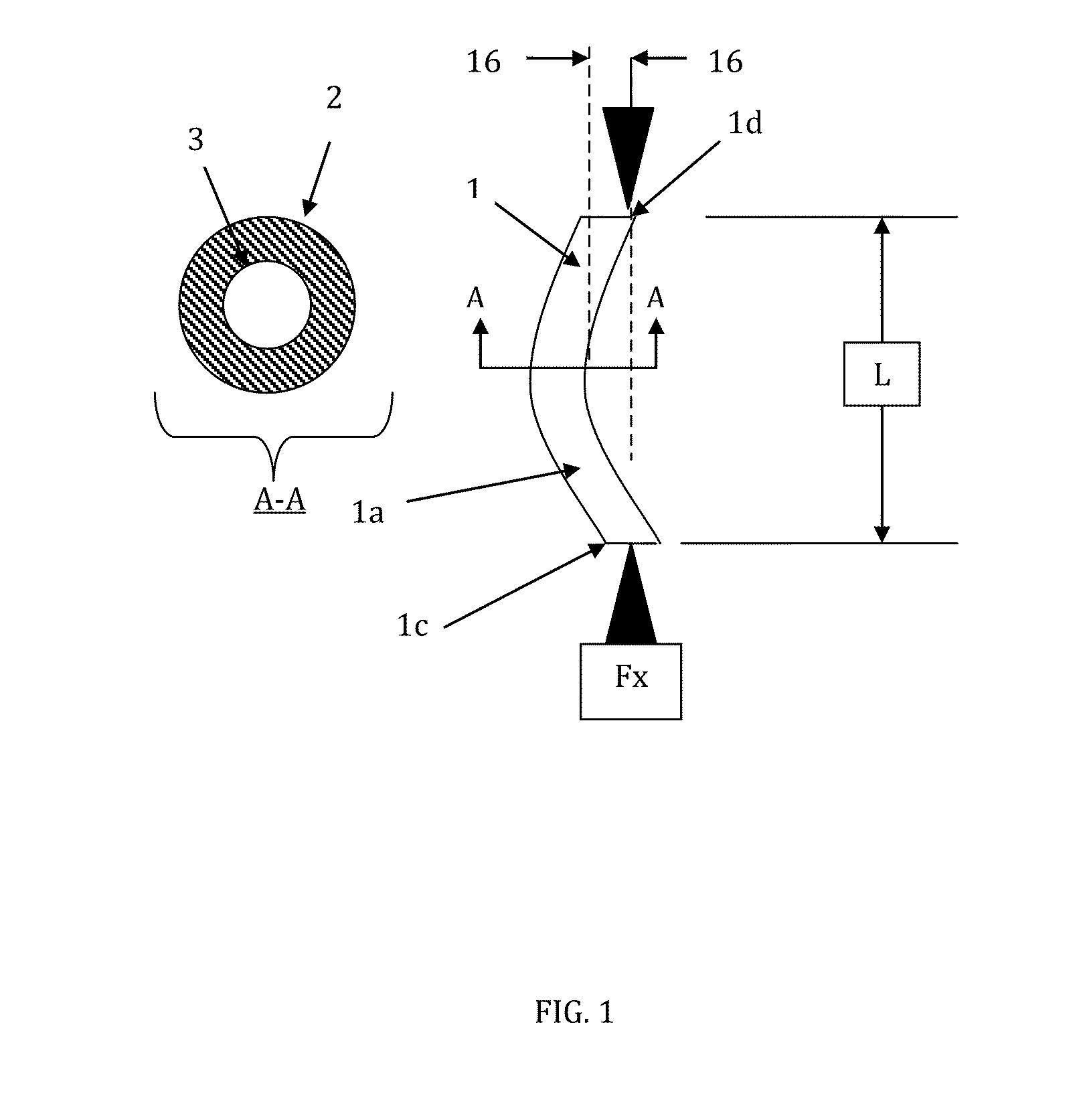

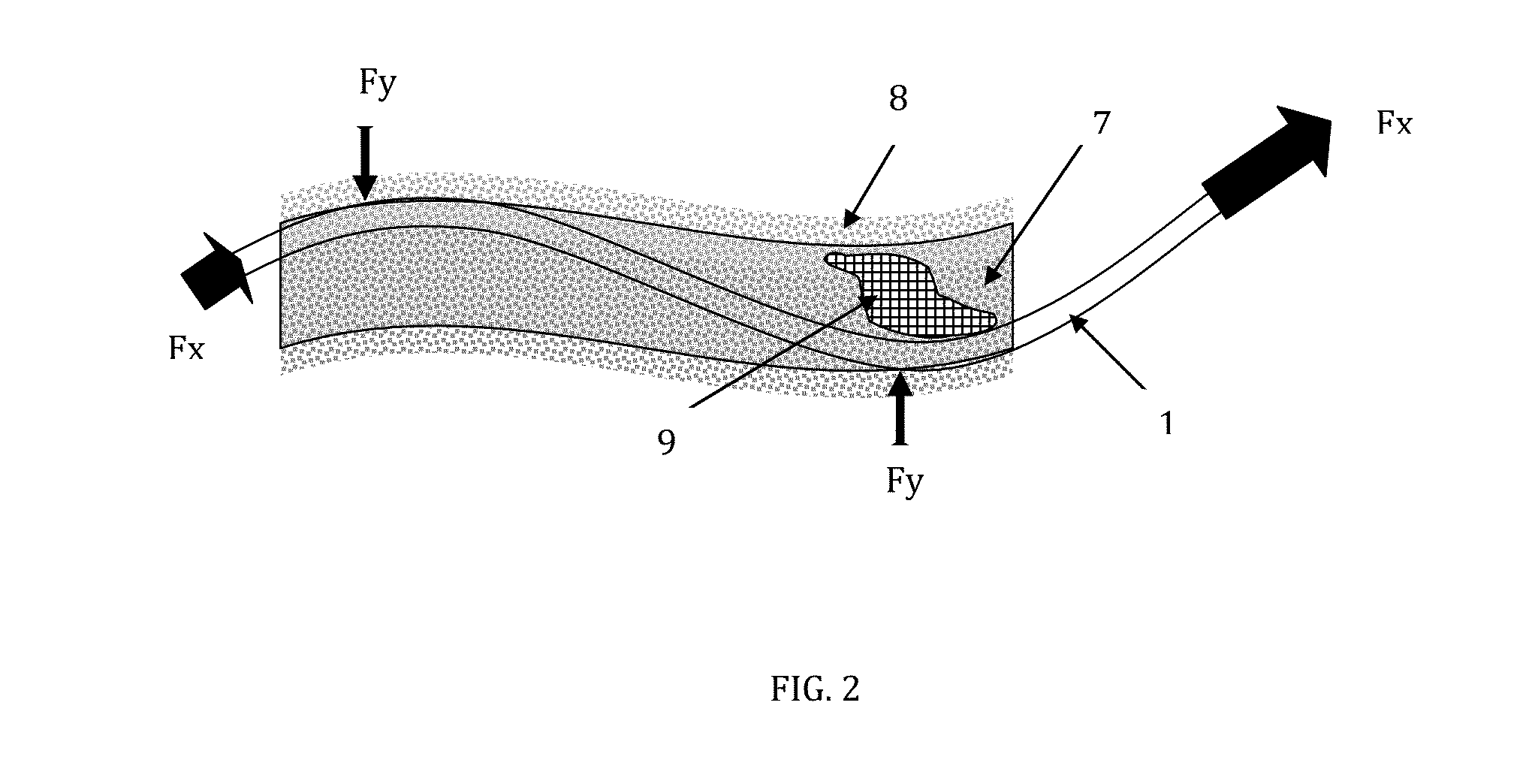

[0042]The subject invention is a novel method for delivery of catheters and stents to anatomical sites that prevents buckling of the device due to applied axial force.

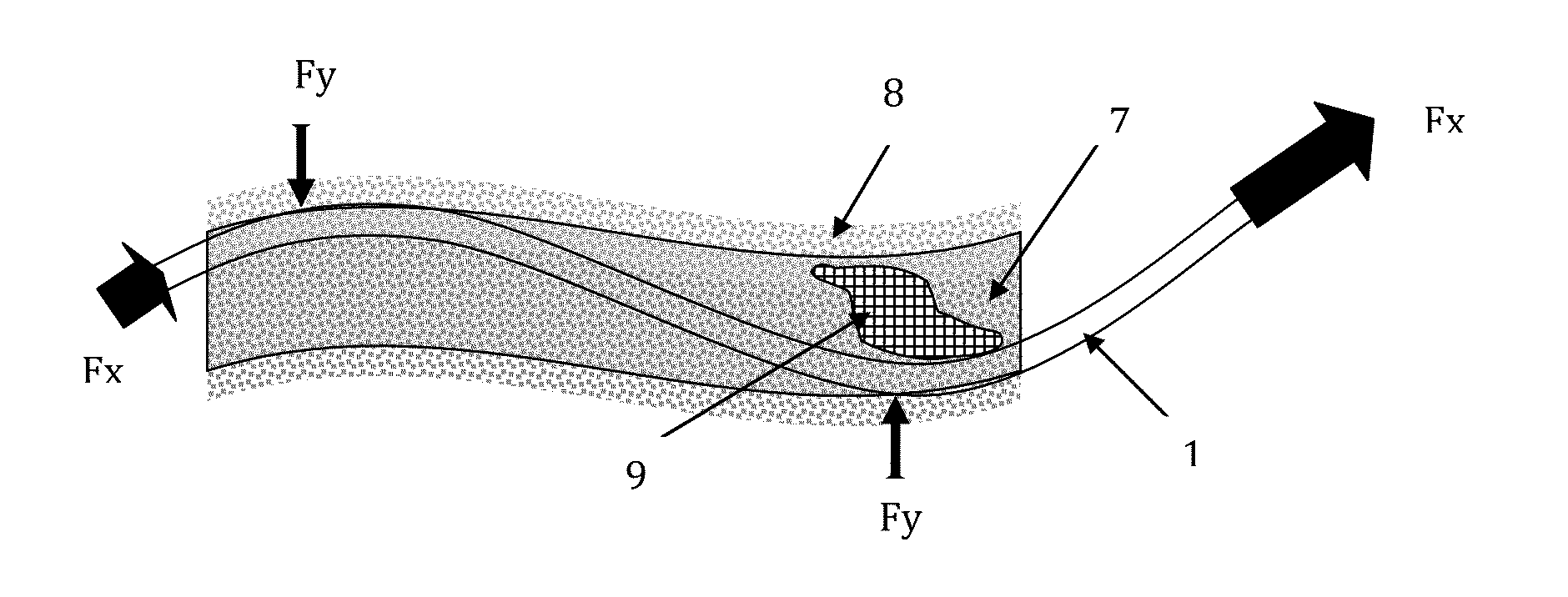

[0043]FIG. 1 is a diagram illustrating a top view and a cross-sectional view of a catheter or stent (1) with simple column catheter shaft (1a) with a given length (L). An axial force (Fx) may be applied to either the proximal end (1c) of catheter (1) by a physician, the distal end (1d) by an anatomical obstruction, or both when the physi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com