Sealing adapter for well tubing head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

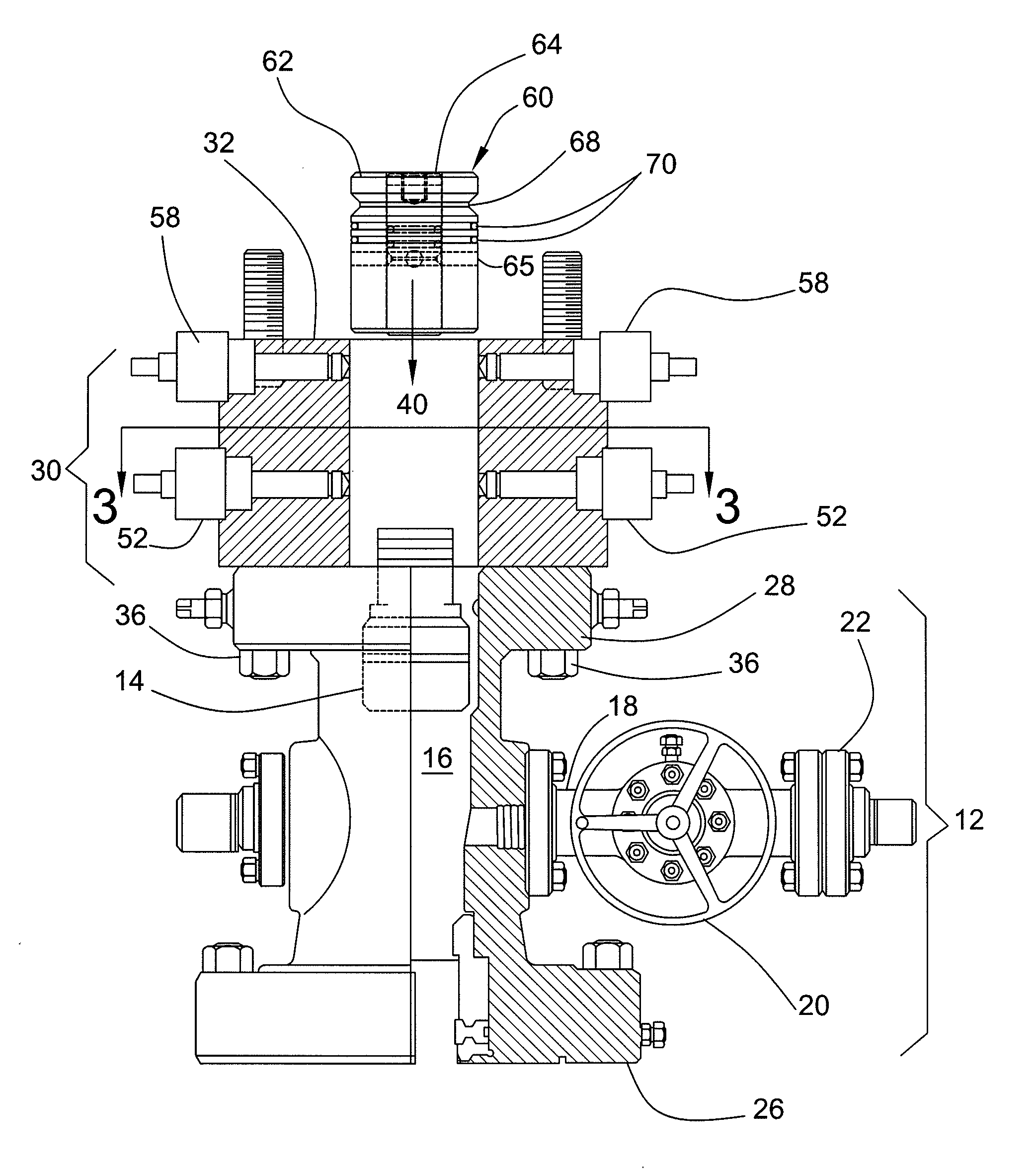

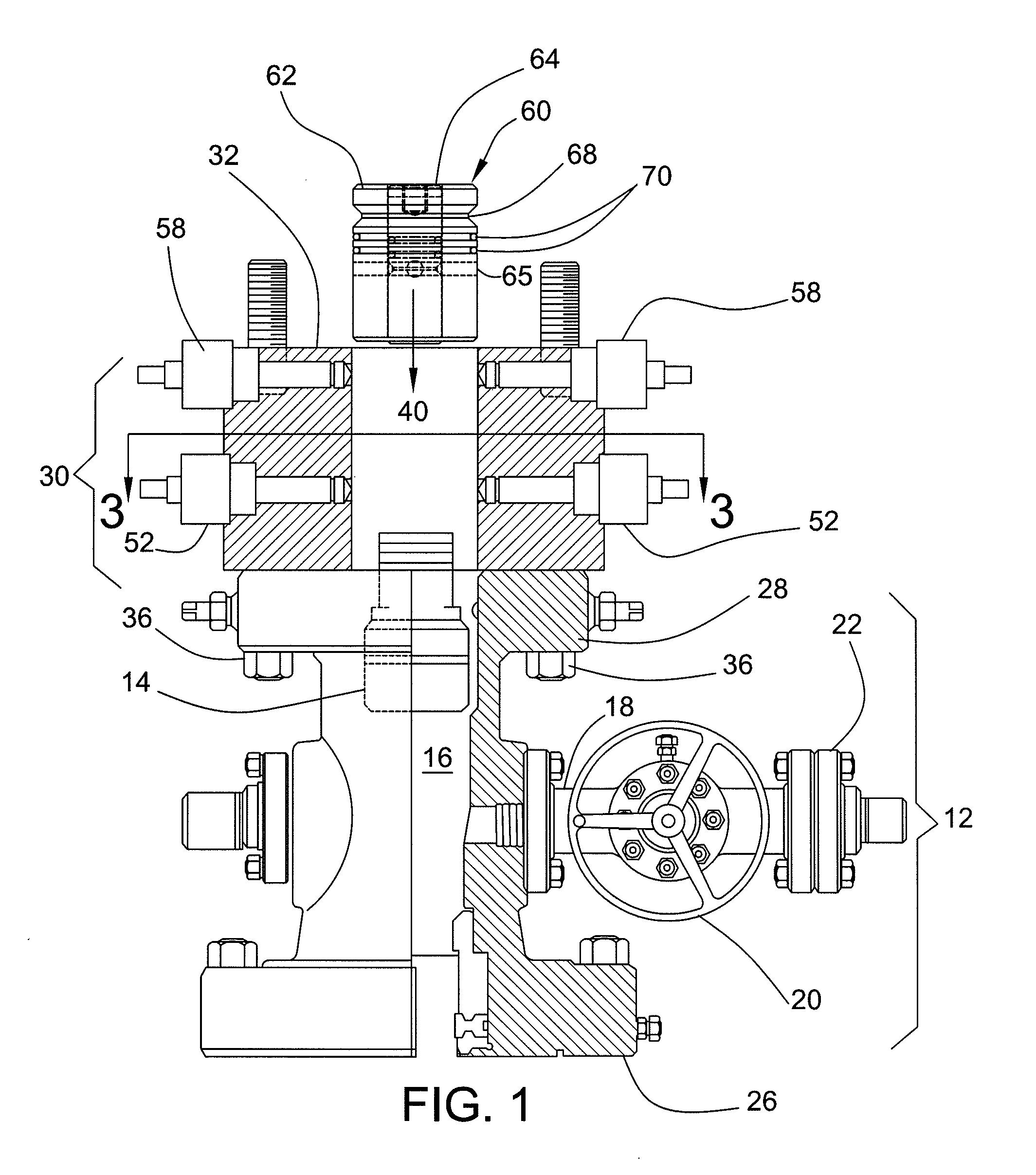

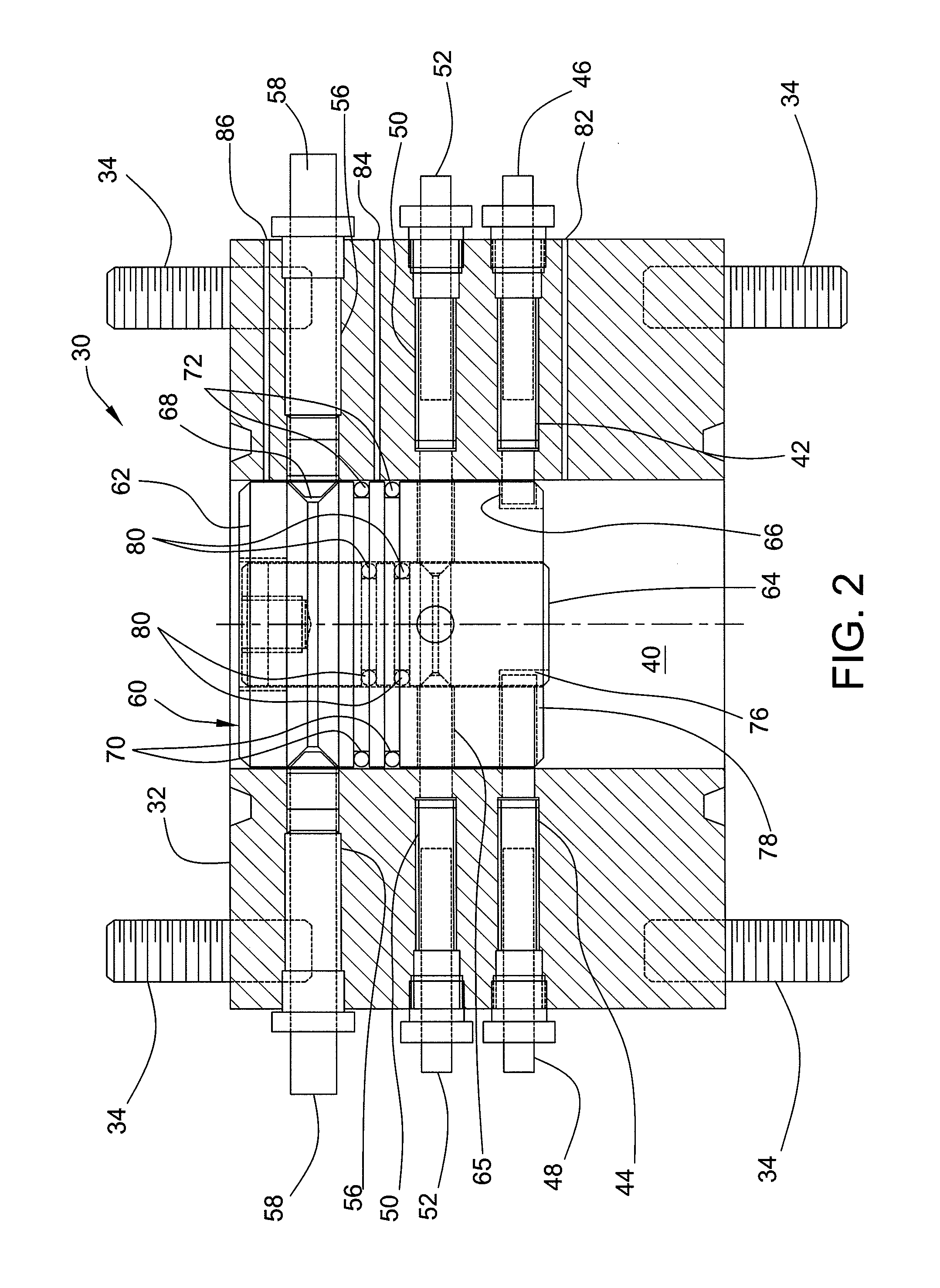

[0013]Reference will now be made to the drawings. To the extent possible, like elements are designated by like reference numerals in the various views. Referring to FIG. 1, a production tubing head 12 (also referred to as a tubing spool) is shown with a tubing hanger 14 in place within the axial bore 16 of the tubing head 12. In practice, the tubing head 12 is operatively connected to a well casing (not shown) in a manner as will be well known to those of skill in the art. As shown, the tubing head 12 may include a connection leg 18 for attachment of fracturing equipment or the like. In the illustrated exemplary arrangement, the connection leg 18 may be sealed by use of an isolation valve 20 and a flange seal 22. Thus, the tubing hanger 14 in combination with the isolation valve 20 and the flange seal 22 act to provide primary sealing of the production tubing head 12. However, other primary sealing arrangements may be used if desired.

[0014]In a typical arrangement, the production tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com