Exhaust purification system of internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

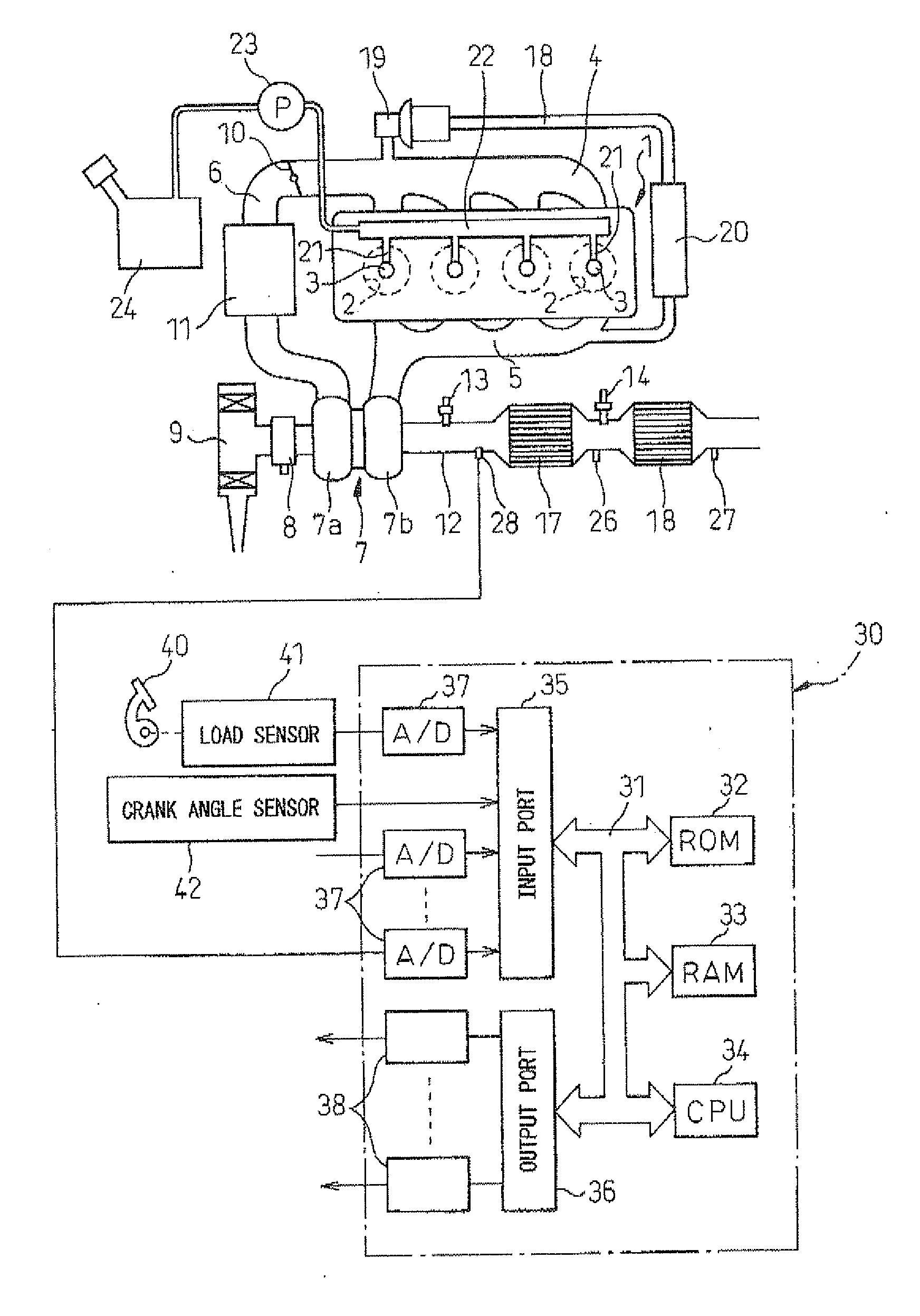

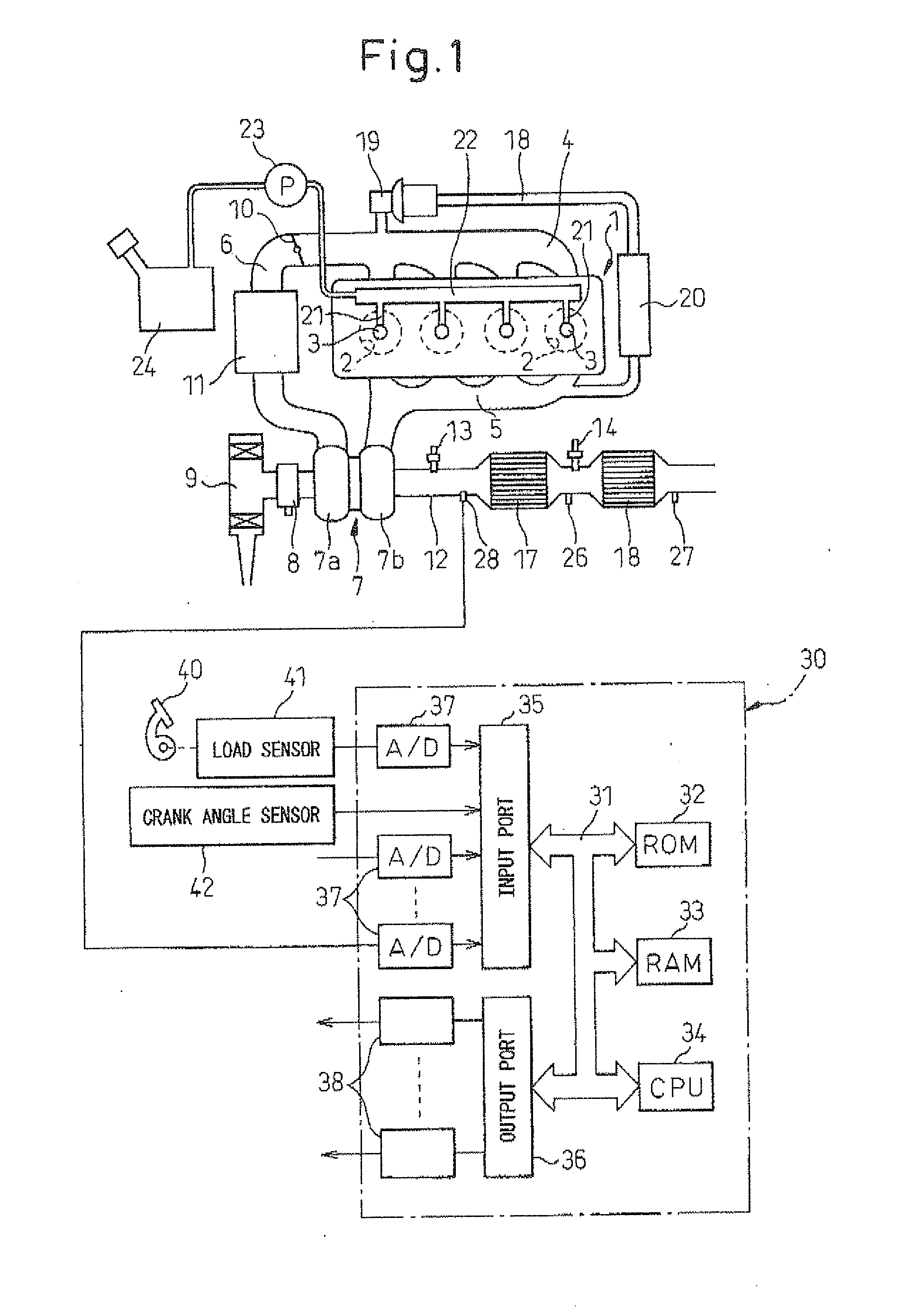

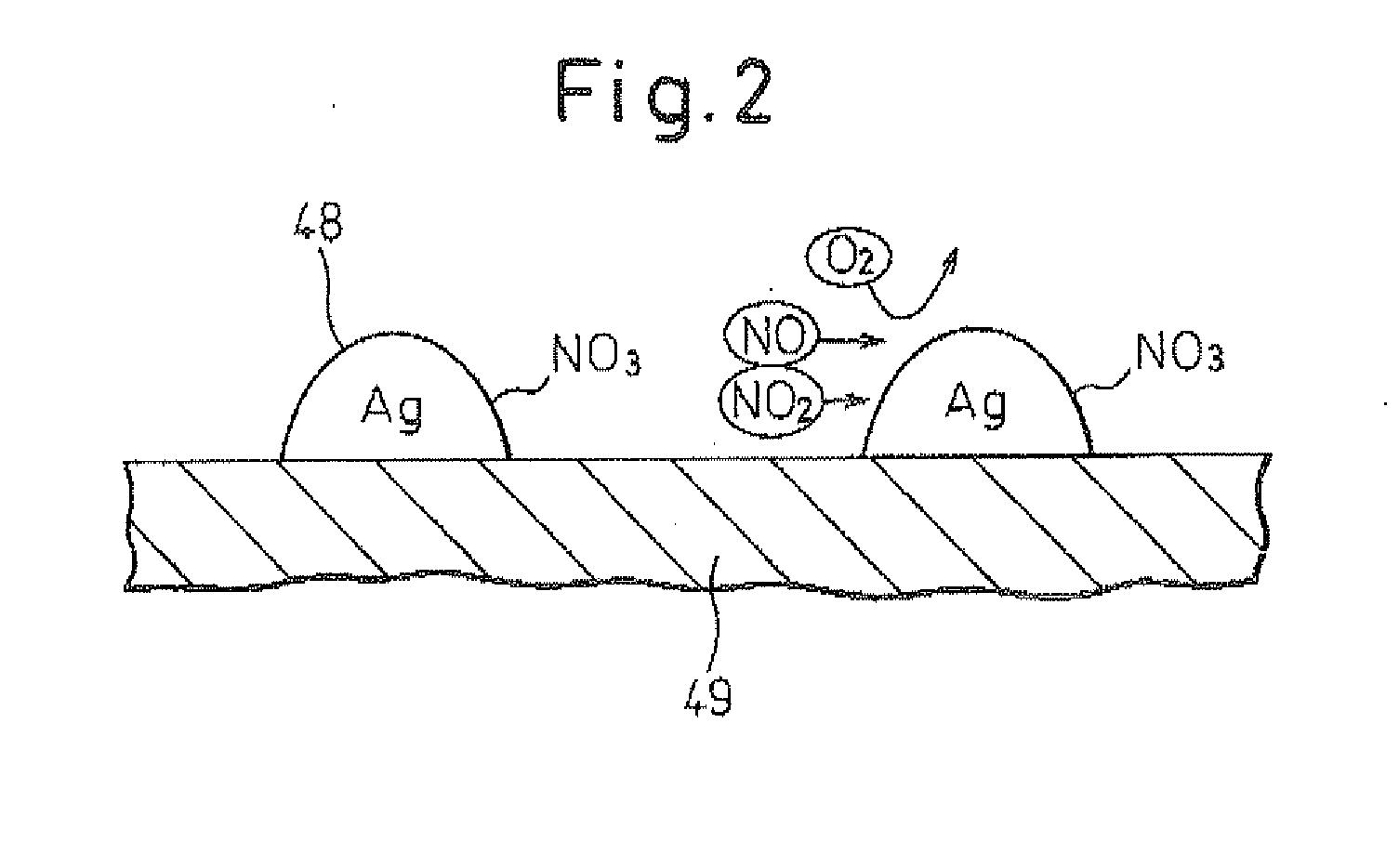

[0032]Referring to FIG. 1 to FIG. 14, an exhaust purification system of an internal, combustion engine in a first embodiment will be explained.

[0033]FIG. 1 is an overall view of an internal combustion engine in the present embodiment. In the present embodiment, the explanation will be made taking as an example a compression ignition type diesel, engine. The internal combustion engine is provided with an engine body 1. Further, the internal combustion engine is provided with an exhaust purification system. The engine body 1 includes cylinders constituted by combustion chambers 2, electronically controlled fuel injectors 3 for injecting fuel to the respective combustion chambers 2, an intake manifold 4, and an exhaust manifold 5.

[0034]The intake manifold 4 is connected through an intake duct 6 to an outlet of a compressor 7a of an exhaust turbocharger 7. An inlet of the compressor 7a is connected through an intake air detector 8 to an air cleaner 9. Inside the intake duct 6, a throttl...

second embodiment

[0097]Referring to FIG. 1 and FIG. 15 to FIG. 18, an exhaust purification system of an internal combustion engine in a second embodiment can be explained. The configuration of the exhaust purification system of an internal combustion engine in the present embodiment is similar to the exhaust purification system in the first embodiment. Referring to FIG. 1, the NOX selective reduction catalyst 17 is arranged in the engine exhaust passage, while the three-way catalyst 18 is arranged downstream of the NOX selective reduction catalyst 17.

[0098]FIG. 15 shows a graph explaining the relationship between the air-fuel ratio of the exhaust gas flowing into the NOX selective reduction catalyst and the NOX amount which is desorbed from the NOX selective reduction catalyst. The inventors discovered that in the slightly lean region near the stoichiometric air-fuel ratio in the region where the air-fuel ratio of the inflowing exhaust gas is lean, the absorbed NOX is desorbed, so the NOX purificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com