Enhanced service life bolt

a service life and bolt technology, applied in the field of enhanced service life bolts and improved bolt design for firearms, can solve the problems of increasing the wear and tear of the bolt lugs, and generating relatively high temperatures and pressures within the firearm during use, so as to achieve enhanced life and strengthen the tensile strength of materials. the effect of li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

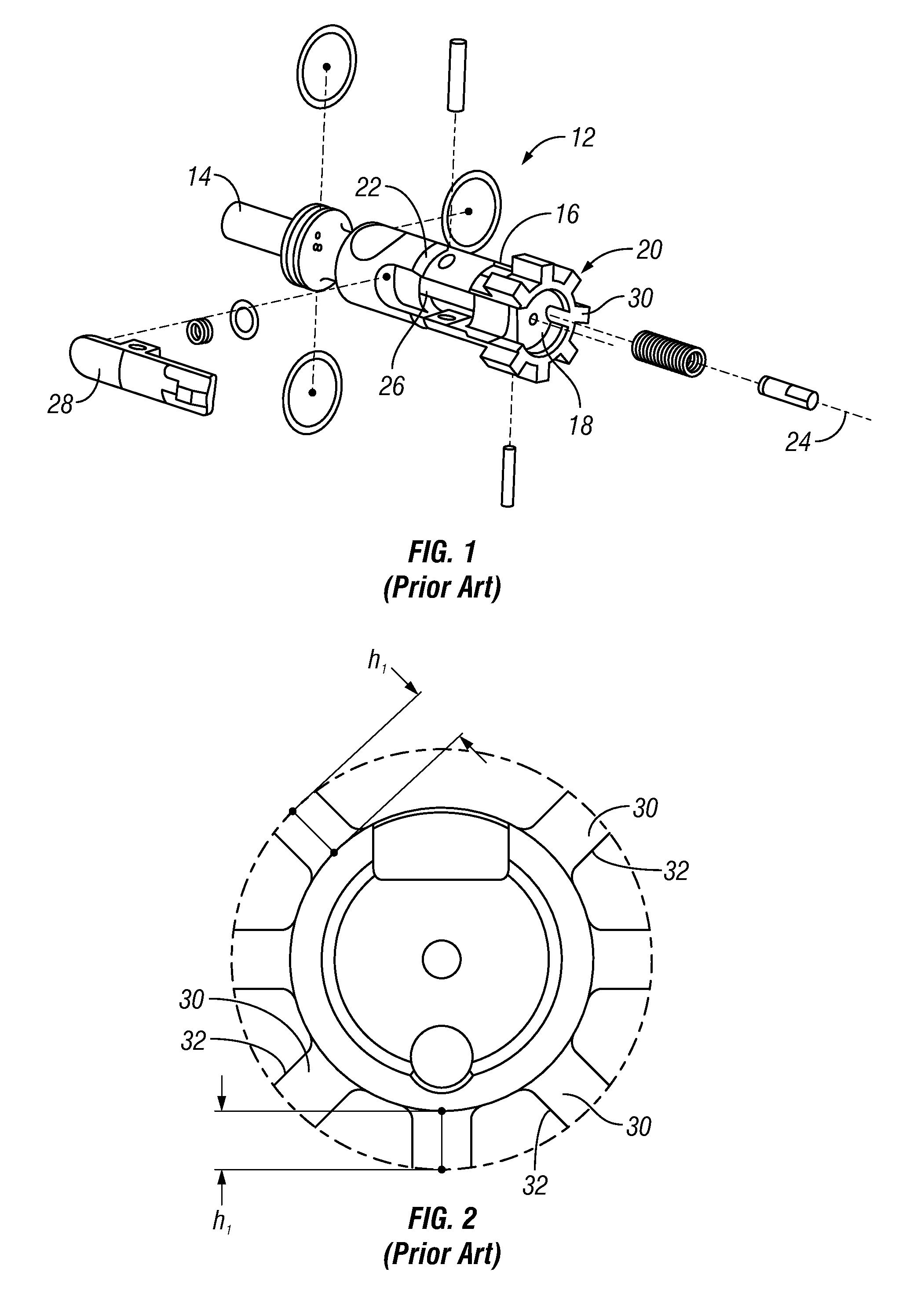

[0017]Referring to FIG. 1, a prior art bolt design for the M4 / M16 family of rifles is shown. The bolt 12 has a proximal end 14, a distal end 16 terminating in bolt face 18 surrounded by an integral bolt head 20 and an integral cylindrical portion 22 disposed between the proximal end 14 and the distal end 16 along a longitudinal axis or bolt centerline 24. The bolt 12 also has a longitudinal opening 26 in the integral cylindrical portion 22 to receive an extractor 28.

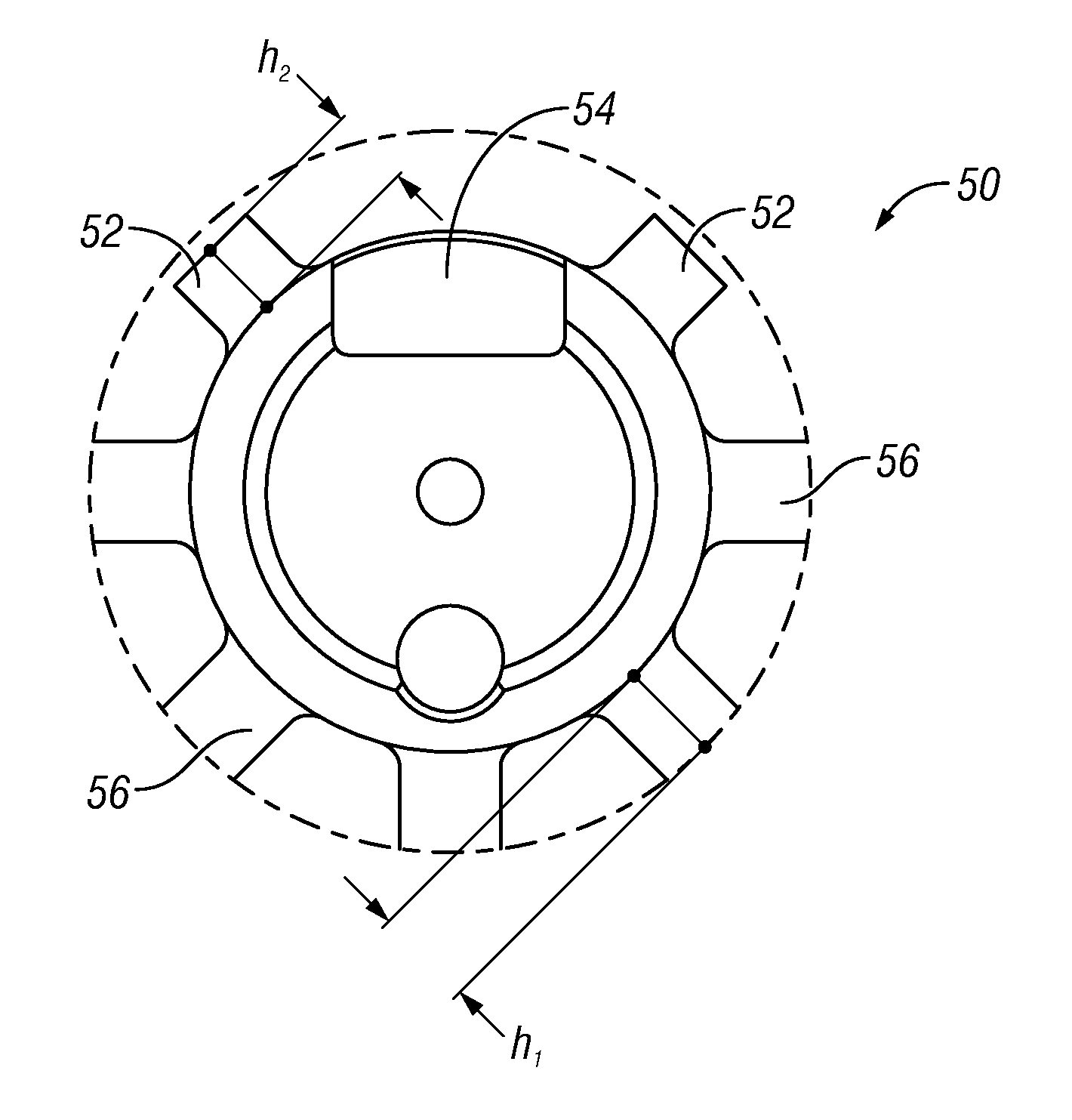

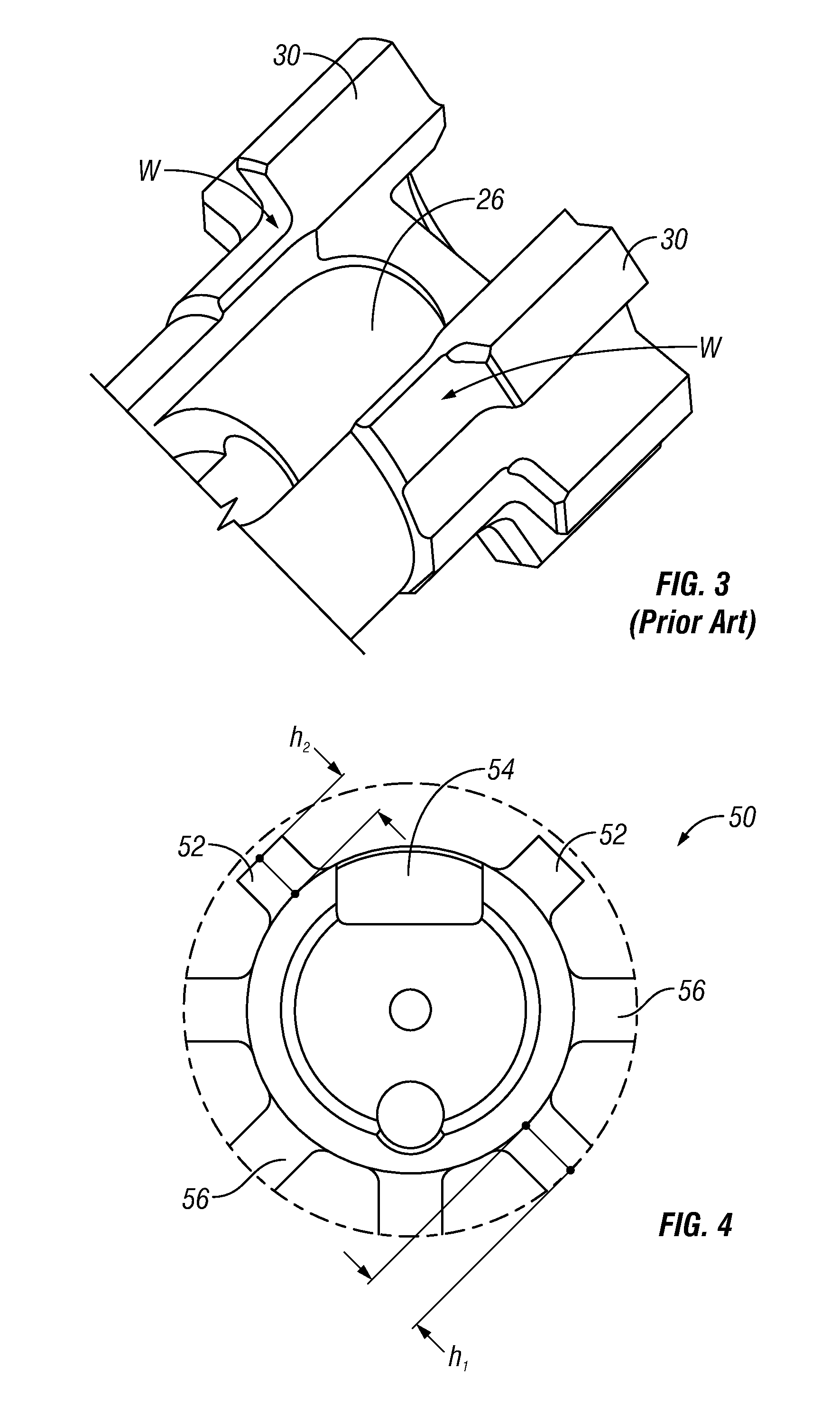

[0018]As shown in FIG. 2, the bolt head 20 has a plurality of bolt lugs 30 with walls 32 extending integrally and radially outward therefrom. This prior art bolt design employs seven (7) lugs 30 to lock the bolt with the barrel extension during the firing of each round of ammunition. Each locking lug 30 is symmetrical and is substantially the same in terms of dimensional specifications. In addition, as further shown in FIG. 2, each locking lug is spaced the same distance, and extends outward the same distance, from the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com