Heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

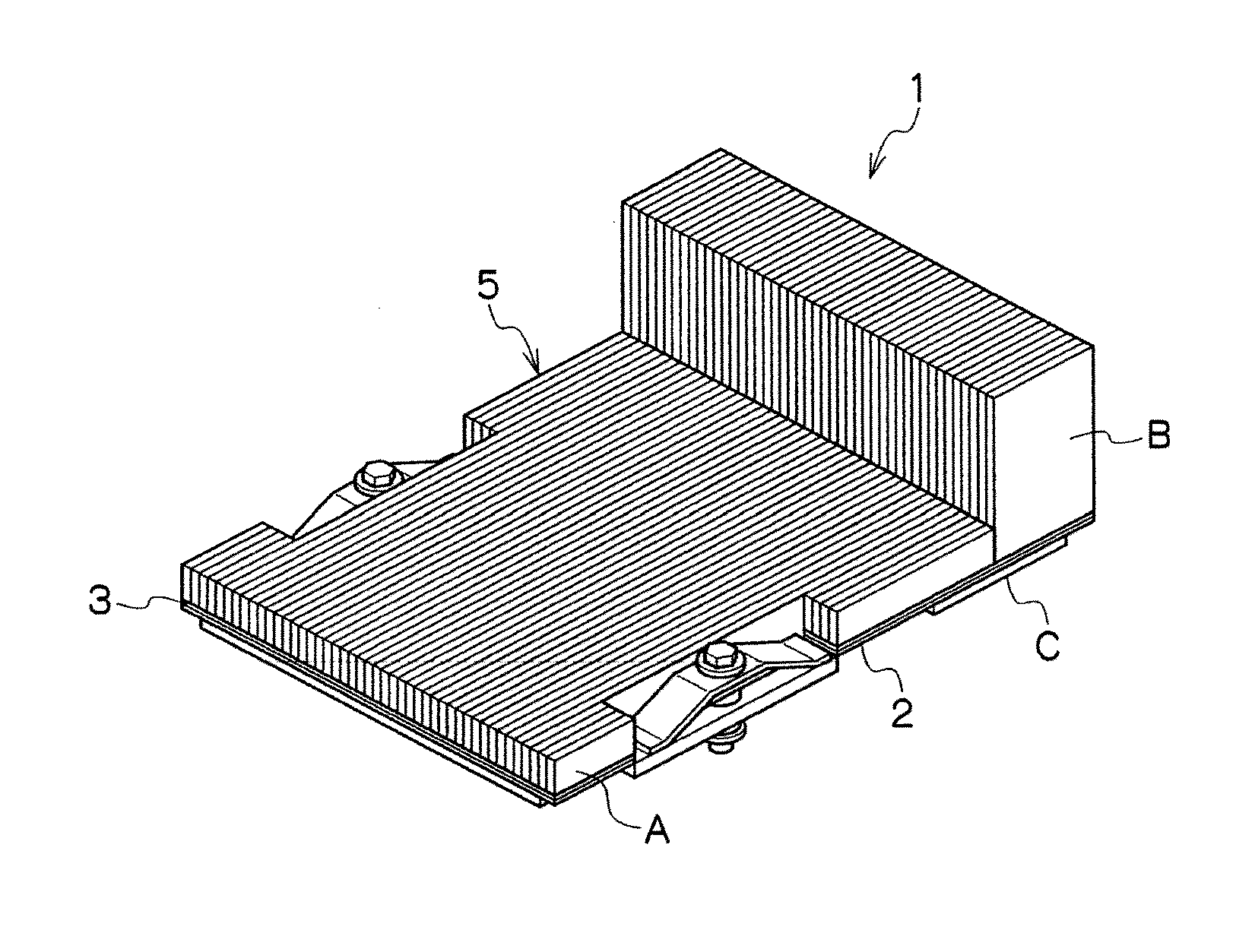

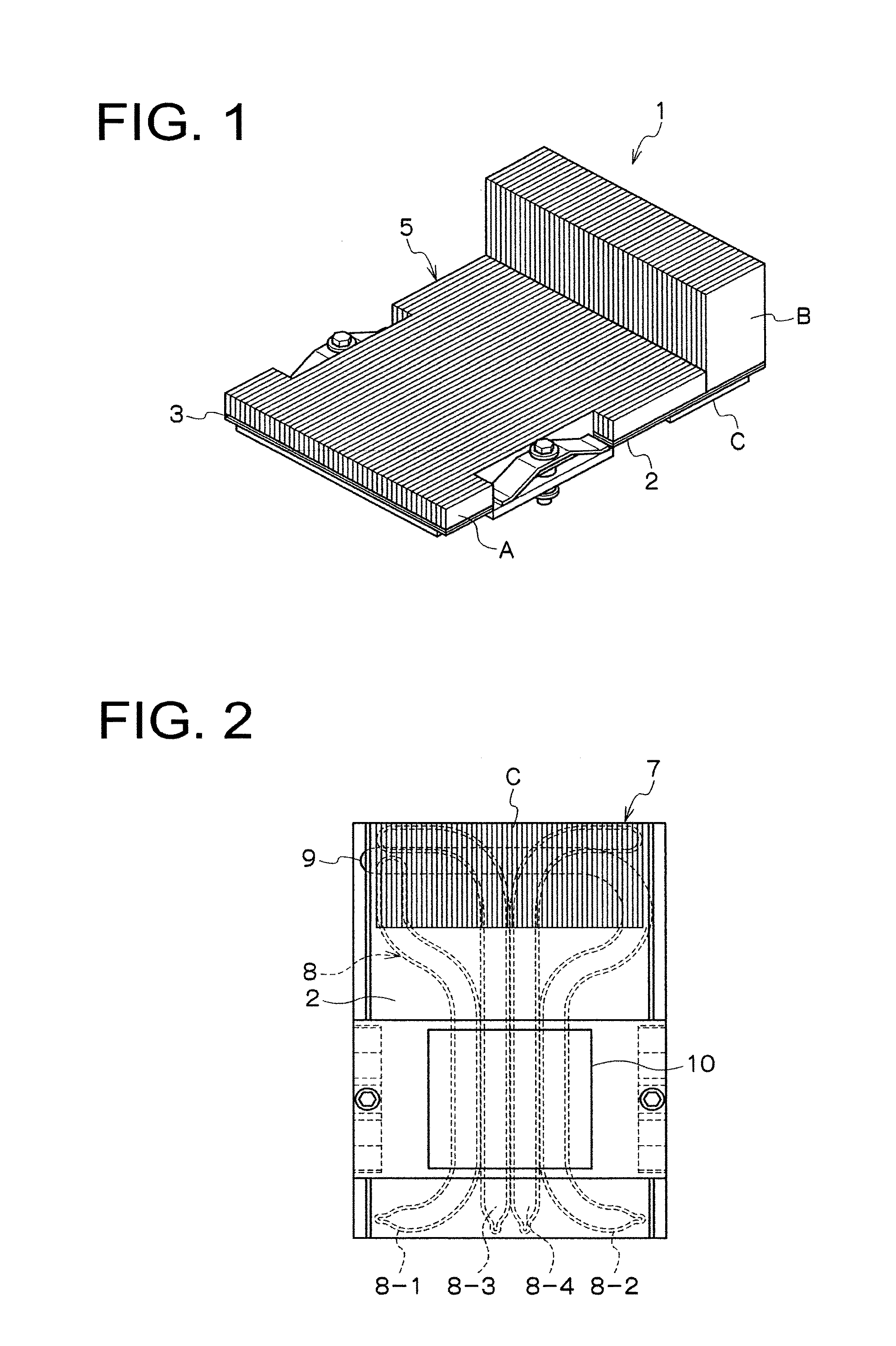

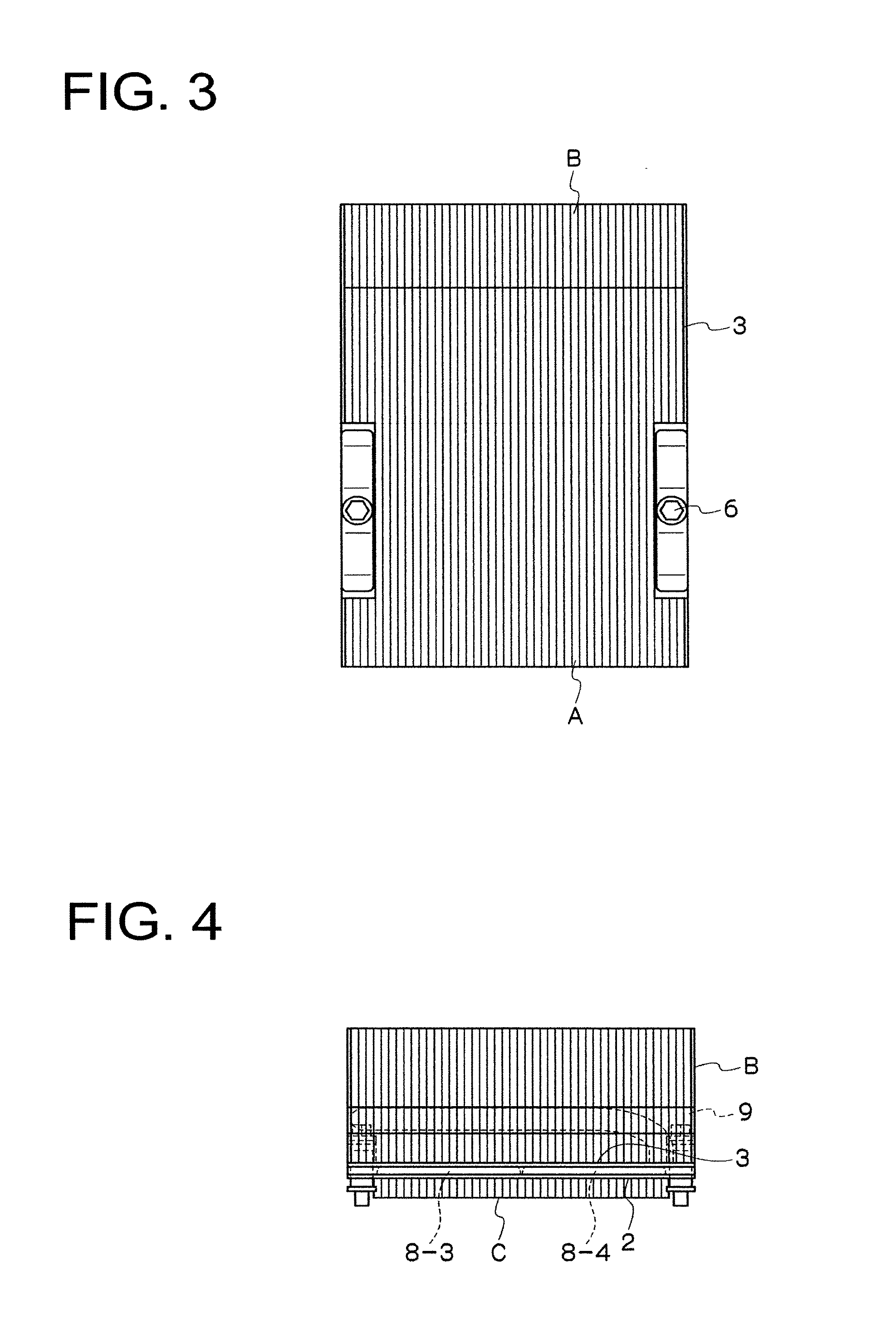

[0036]With reference to the drawings, a heat sink of the present invention will be described below.

[0037]The heat sink according to an embodiment of the present invention has a base plate which has one surface thermally connected to a heat generating component and which has thermally connected thereto a first heat dissipating fin section composed of a thin plate fin; an upper plate which has a second heat dissipating fin section thermally connected to one surface, the second heat dissipating fin section being composed of two kinds of thin plate fins having different heights; and a plurality of heat pipes which are disposed between the other surface of the base plate and the other surface of the upper plate by being thermally connected to the surfaces and which include a heat pipe that has at least a part thereof inserted into a part of the second heat dissipating fin section. The first heat dissipating fin section is preferably connected to the base plate, but may not be connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com