Optical body, window member, fitting, solar shading device, and building

a technology for solar shading and optical bodies, applied in the direction of optical elements, instruments, synthetic resin layered products, etc., can solve the problems of just specular reflection, insufficient shielding ability of pigment layers, and acceleration of phenomena, so as to improve safety, reduce heat generation, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

1. First Embodiment

[Construction of Optical Film]

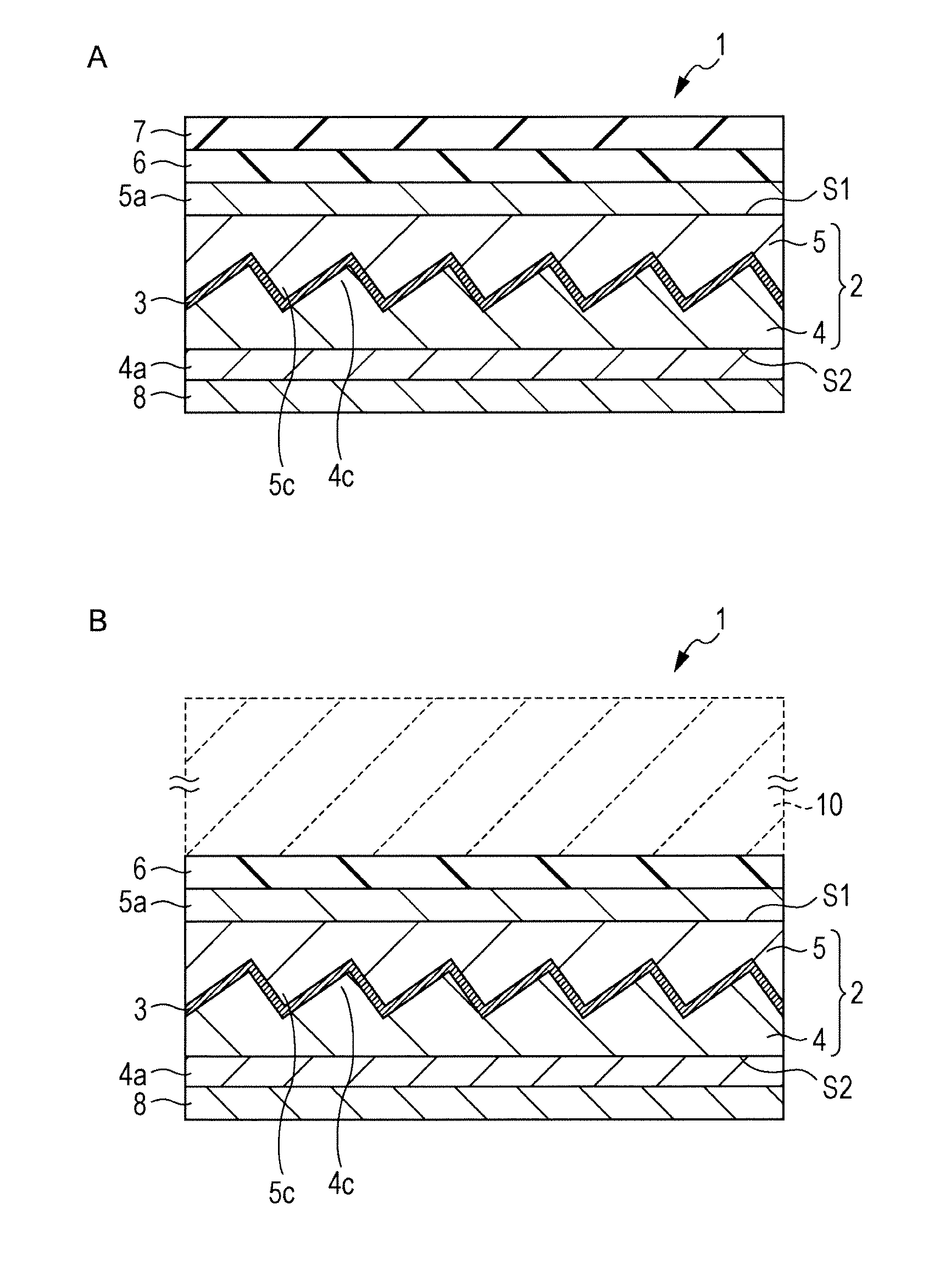

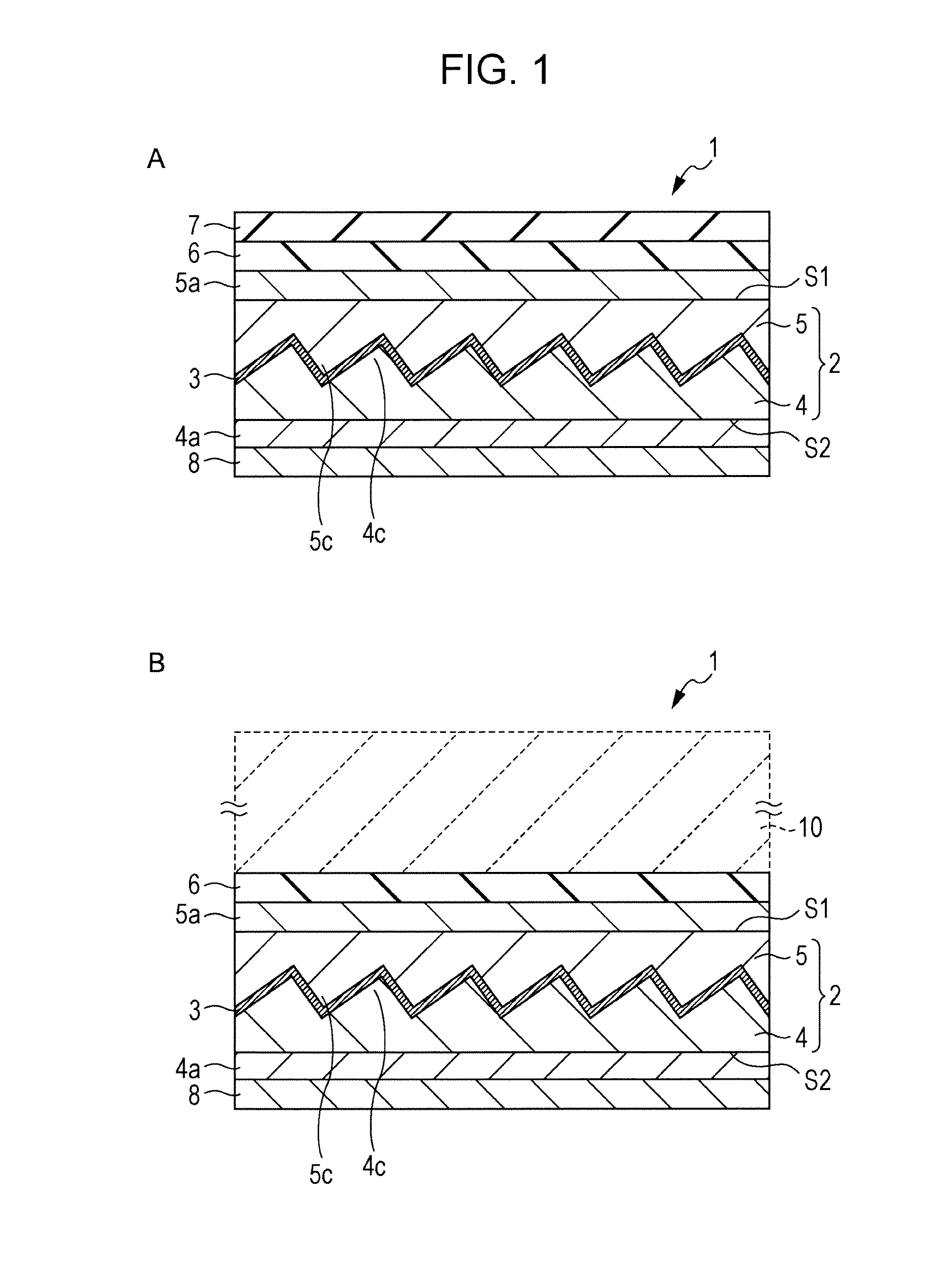

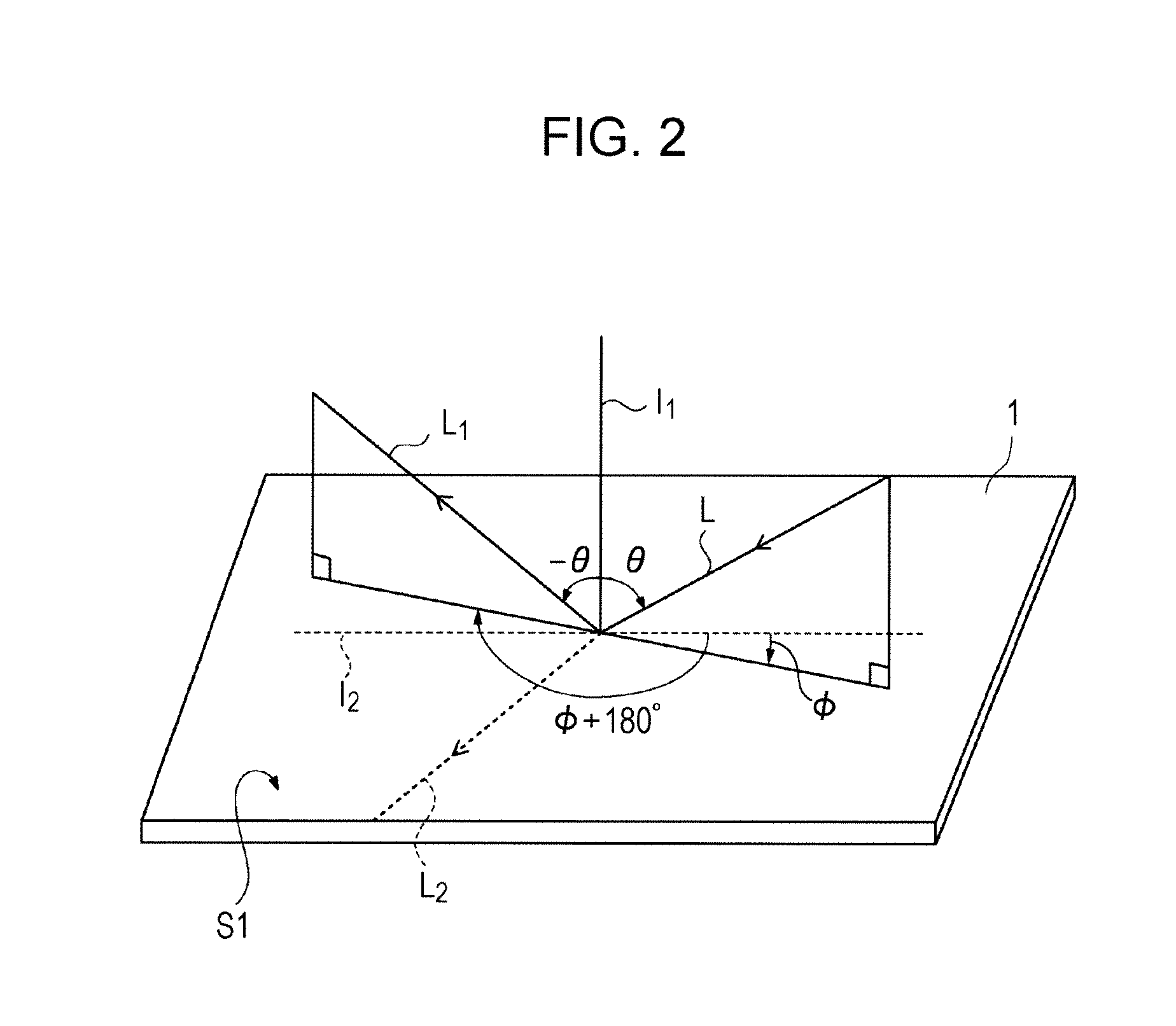

[0068]FIG. 1A is a sectional view illustrating one example of construction of an optical film according to a first embodiment. FIG. 1B is a sectional view illustrating an example in which the optical film according to the first embodiment is affixed to an adherend. An optical film 1 as an optical body is an optical film having the so-called directional reflection property. As illustrated in FIG. 1A, the optical film 1 includes an optical layer 2 having an interface formed therein in a concave-convex shape, and a wavelength selective reflecting layer 3 formed at the interface in the optical layer 2. The optical layer 2 includes a first optical layer 4 having a first surface in a concave-convex shape, and a second optical layer 5 having a second surface in a concave-convex shape. The interface in the optical layer is formed by the first surface and the second surface each having the concave-convex shape, which are arranged to face each ...

first modification

[0172]FIG. 11A is a sectional view illustrating a first modification of the first embodiment. As illustrated in FIG. 11A, an optical film 1 according to the first modification has an incident surface S1 in a concave-convex shape. The concave-convex shape of the incident surface S1 is formed to follow the concave-convex shape of the first optical layer 4, for example, such that positions of top portions of convexes and positions of bottom portions of concaves are aligned between both the concave-convex shapes. The concave-convex shape of the incident surface S1 is preferably gentler than that of the first optical layer 4.

second modification

[0173]FIG. 11B is a sectional view illustrating a second modification of the first embodiment. As illustrated in FIG. 11B, an optical film 1 according to the second modification is formed such that top portions of convexes in the concave-convex surface of the first optical layer 4, on which the wavelength selective reflecting layer 3 is formed, are substantially flush with the incident surface S1 of the first optical layer 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com