Device and method for distributing residual air in pasty masses, in particular for the production of sausages

a technology of residual air and air mass, which is applied in the field of devices and methods for distributing residual air in pasty masses, can solve the problems of pressure increase in front of the device and higher pressure loss in the flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

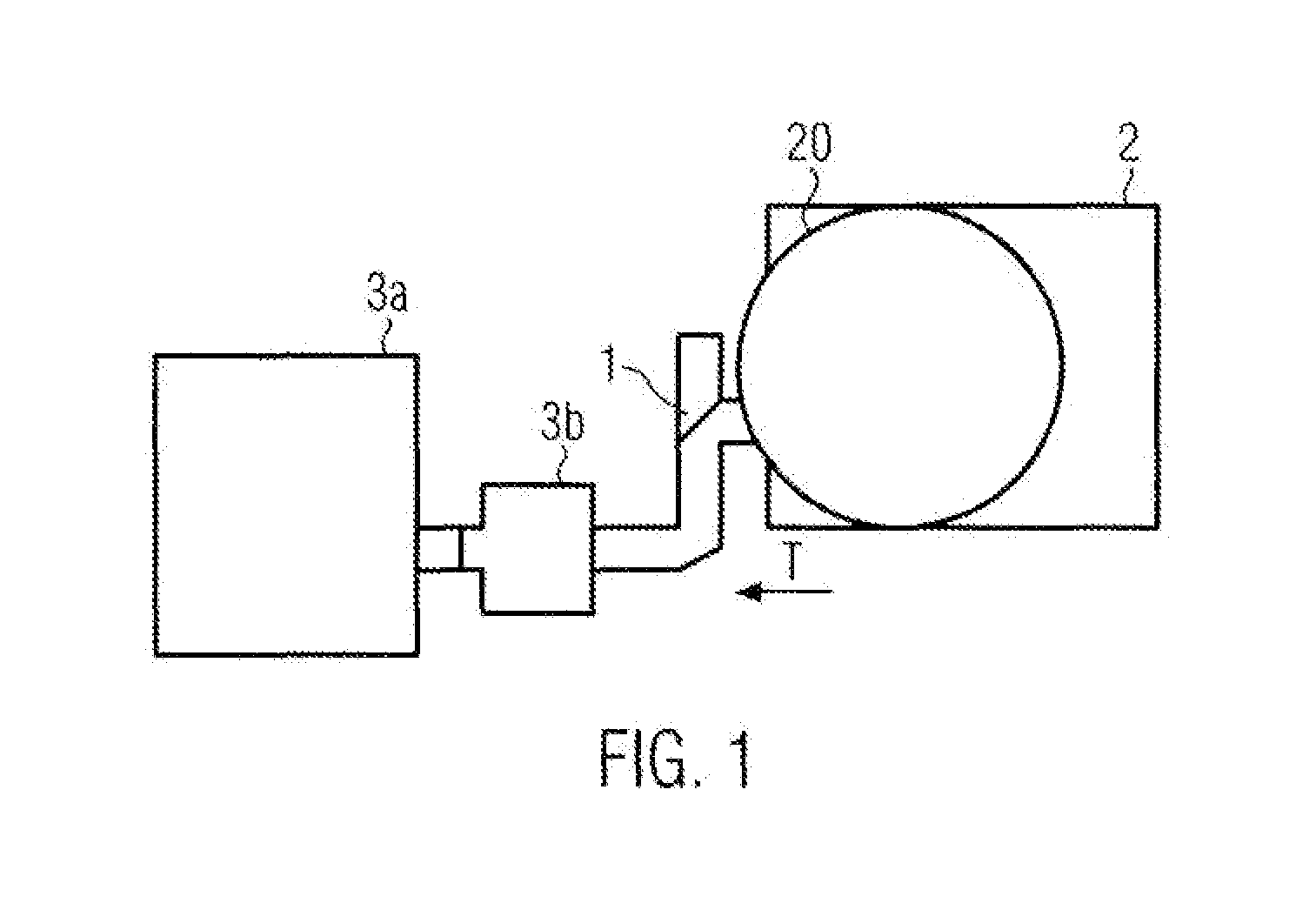

[0049]FIG. 1 shows the principal construction of a filling line with a device 1 for distributing residual air in a pasty mass according to the present disclosure. Here, the filling line comprises a filling machine 2, in particular a vacuum filler, which comprises, as is schematically shown, a feed hopper 20 via which product is fed to a not represented conveyor system, for example in the form of a vane pump. Via the conveyor system, the pasty mass is fed to the device 1 downstream of the conveyor system seen in the direction of transport T, for distributing residual air. In the device 1, the pasty mass is deflected and thoroughly mixed thereby. In the process, the residual air in the pasty mass can distribute uniformly. The pasty mass is then further fed in the direction of transport T to an attachment 3. Such an attachment can comprise, for example, a metal detector 3b and an automatic clipper 3a, or it can also be embodied, for example, in the form of a filling tube. The device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com