Lead-free solder alloy, connecting member and a method for its manufacture, and electronic part

a technology of lead-free solder alloy and connecting member, which is applied in the direction of connecting contact member material, soldering apparatus, manufacturing tools, etc., can solve the problems of inadequate adhesion between the heat dissipating member and the package, voids inside the joints, so as to reduce the amount of voids remaining inside the joints, increase the adhesion and bonding strength of the first member and the second member, and reduce the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

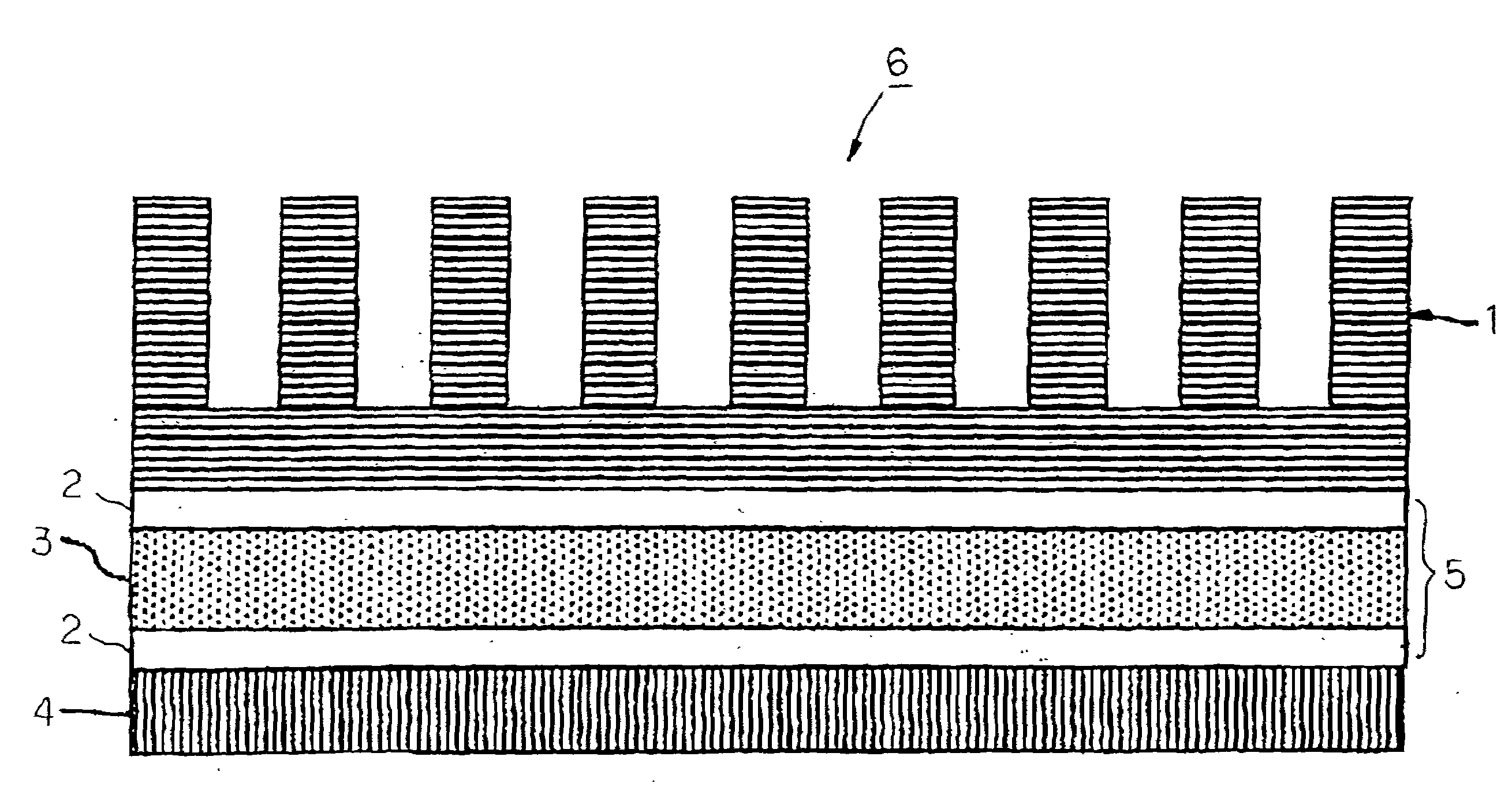

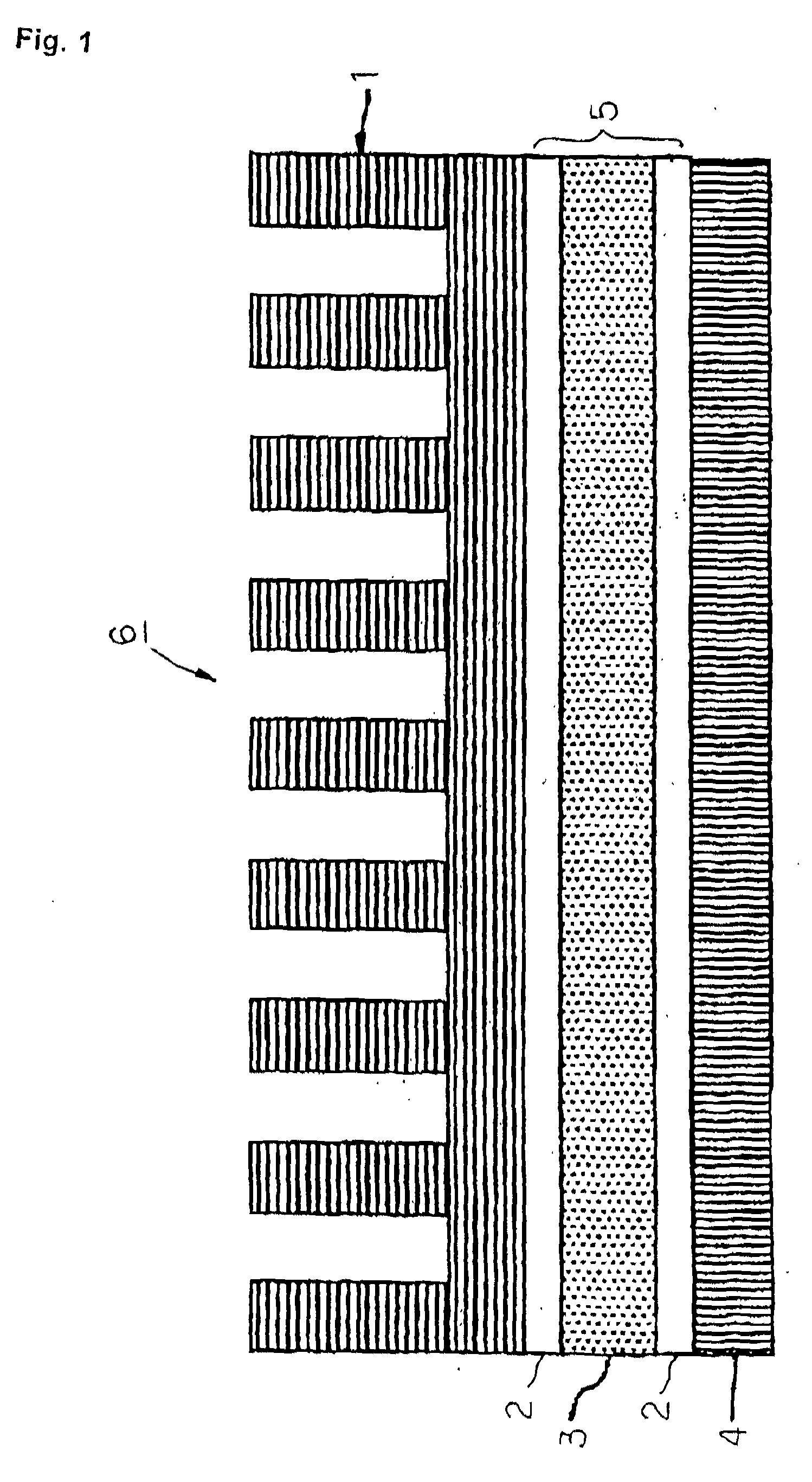

Image

Examples

example 1

[0087]Examples of the present invention are shown in Table 1 and FIG. 3, and comparative examples are shown in Table 1 and FIG. 4.

TABLE 1Melting temperature (° C.)VoidsComposition (mass %)SolidusLiquidusSuit-rateInSnBitemp.temp.ability(%)Example 199.80.10.1157157◯23.9Example 296.930.1145.7152.4◯25.5Example 396.530.5151.4153.5◯31.3Example 497.90.12149.3154.8◯21.2Example 59532144.7150.9◯32.8Example 699.90.10156156.6◯21Example 79730152.9153.7◯27.9Example 899.900.1156.1156.6◯25.6Example 99802149.5152.8◯21.1Comp. 110000157157◯44.6Comp. 29361145.6149◯42.1Comp. 387.9120.1142.1144.6◯39.1Comp. 486122133.4139.8◯59.9Comp. 574.9250.1131.3133◯53.7Comp. 695.90.14140.1150◯40.4Comp. 794.90.15129.7147.2XNDComp. 869.9300.1127129XNDComp. 999.960.040156156.8◯33.4Comp. 1096.53.50152.1153◯44.3Comp. 1199.9600.04156.1156.8◯33.8Comp. 1297.503145.1151.3◯38.5ND: not determined

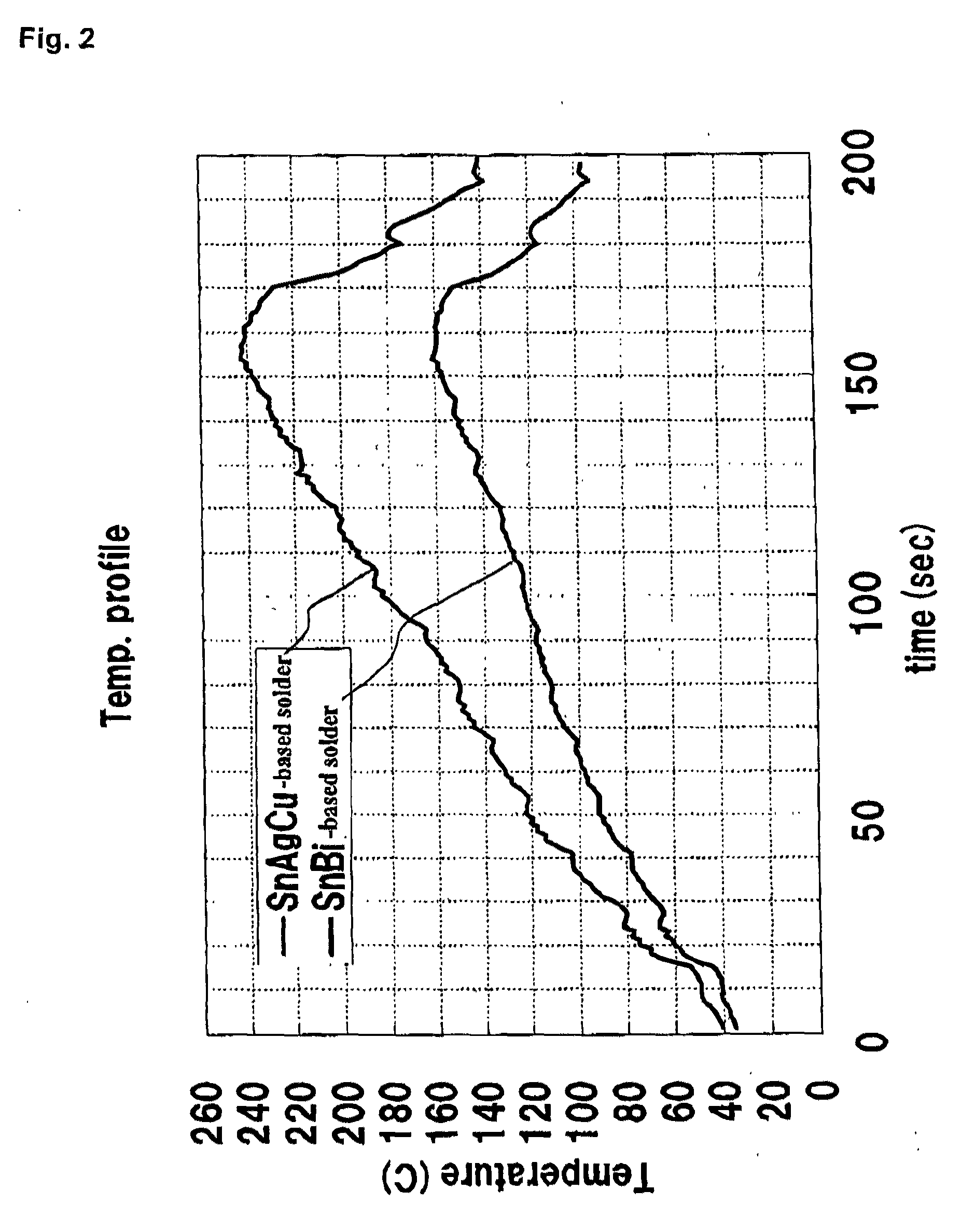

[0088]The melting temperature of the solder was measured using a differential thermal analyzer. The analyzer was a DSC 6200 manufacture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap