Sensor Arrangement for a Vehicle and Corresponding Method for Producing such a Sensor Arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

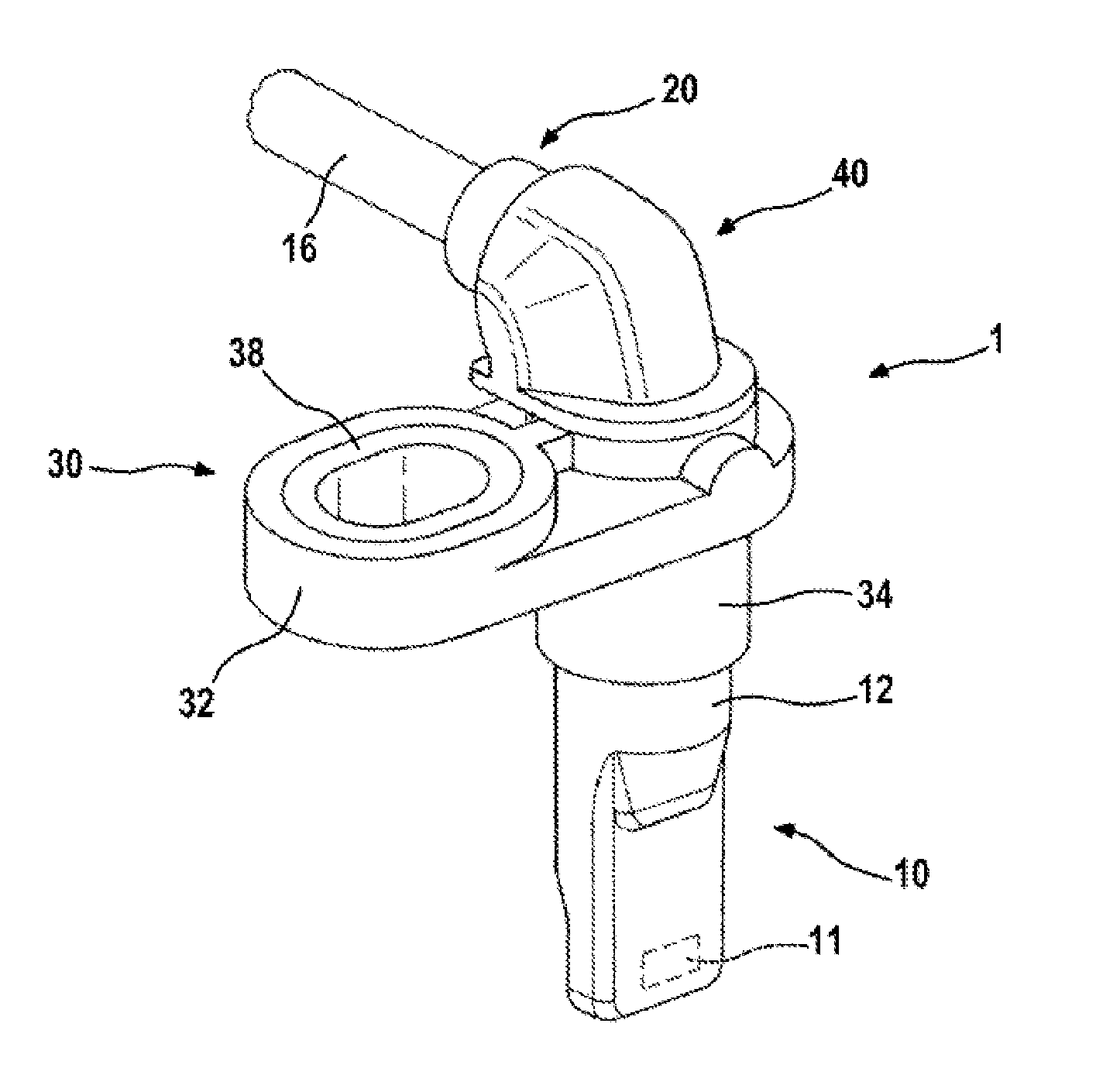

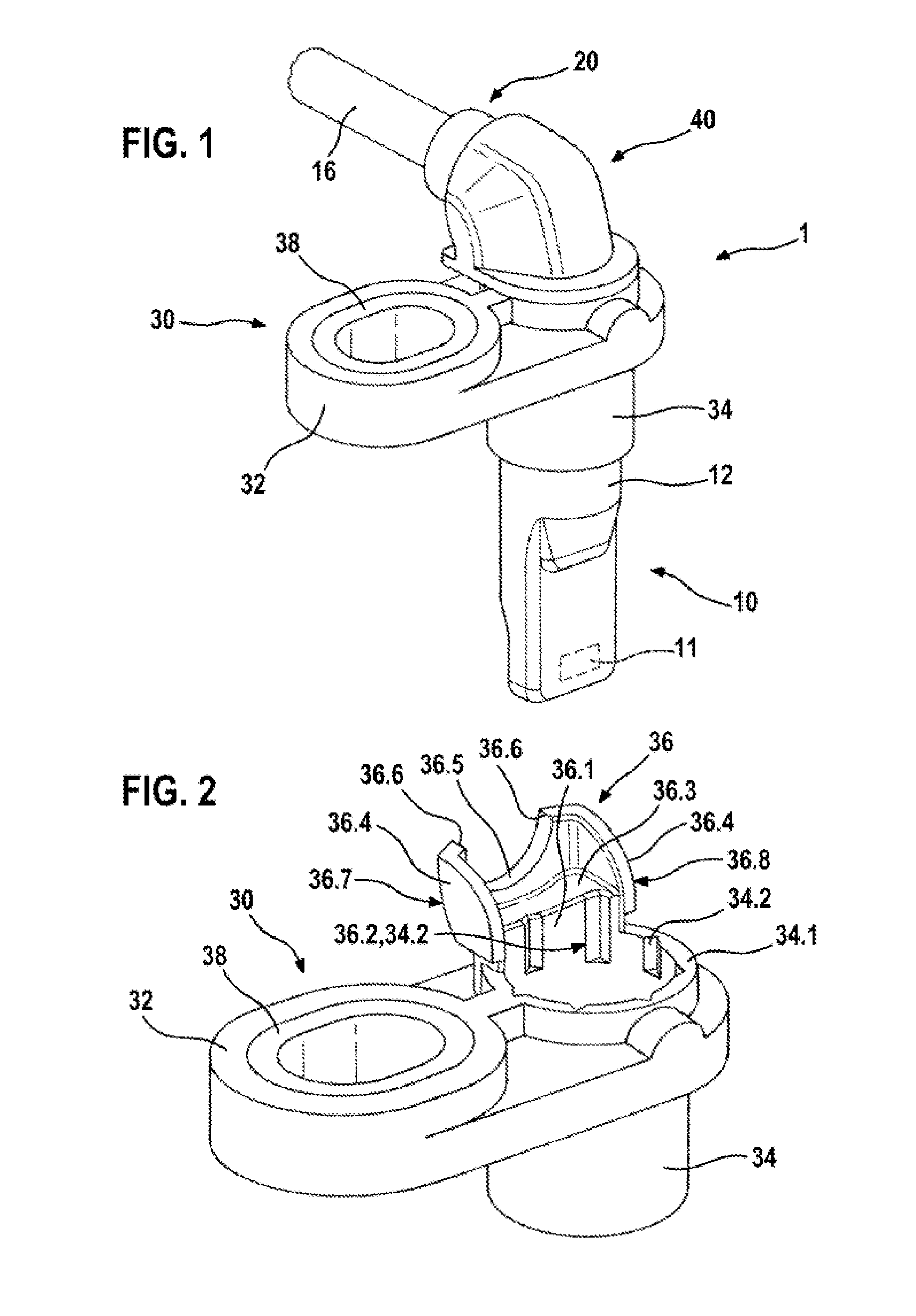

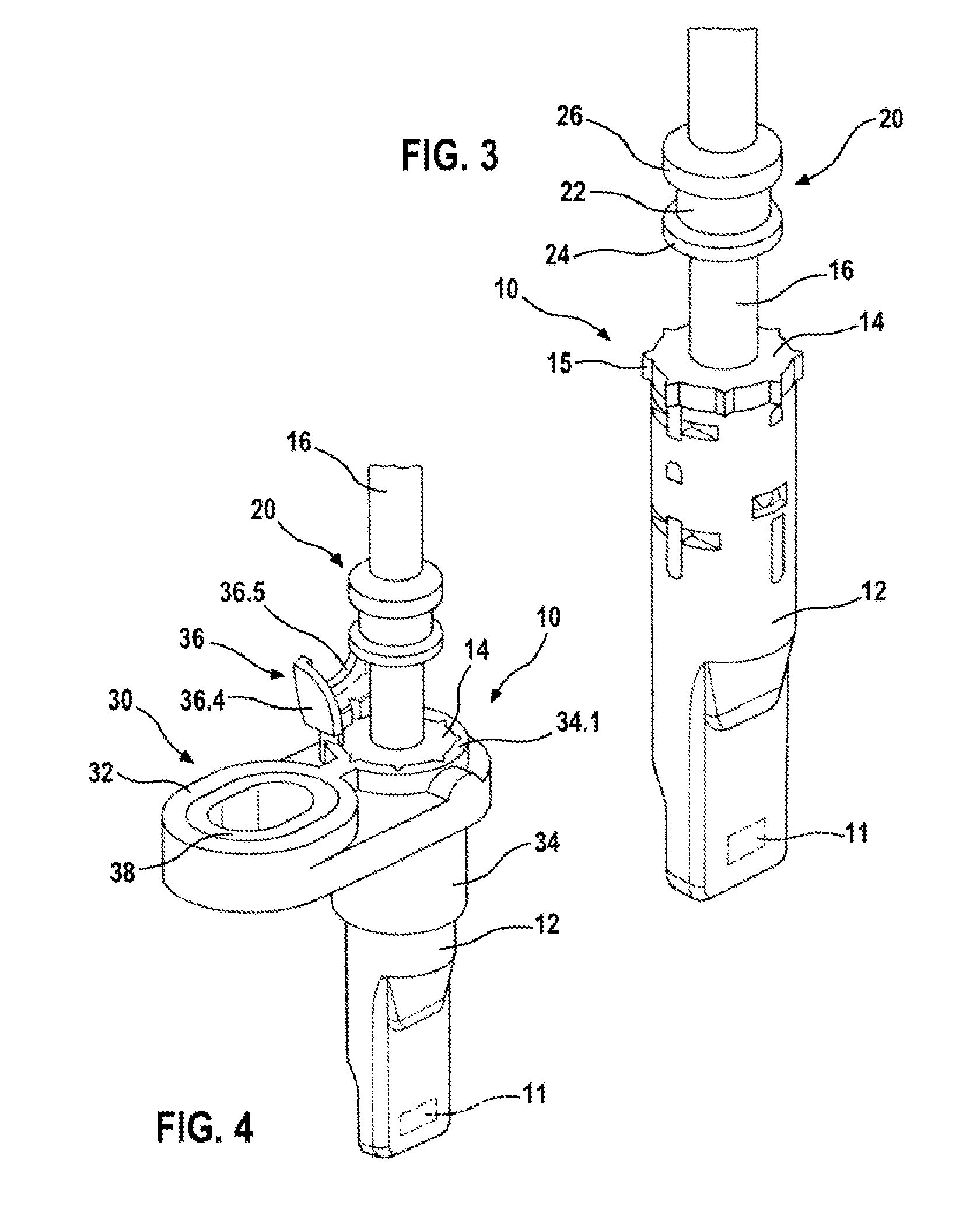

[0023]In the accompanying FIGS. 1 to 10, identical reference symbols denote throughout elements and / or components which carry identical or analogous functions.

[0024]FIG. 1 illustrates a first exemplary embodiment of a sensor arrangement 1 with a sensor element 11 and / or an electrical assembly for detecting and evaluating measurement signals, in particular magnetic field signals, a fastening tab 30, a connecting cable 16 and cap 40. The sensor element 11 and the connecting cable 16 have been at least partially encased with plastic by injection molding in order to form a sensor housing 10. The sensor housing 10 is connected to the fastening tab 30 which comprises a base body 32 with a fastening bush 38 which is arranged to the side of the cable outlet. In addition, the fastening tab 30 comprises an insertion sleeve 34 which is connected to the base body 32 and into which a sensor housing body 12 of the sensor housing 10 is inserted. The sensor housing 10 and the insertion sleeve 34 ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com