Lavatory System with Overflow Prevention and Other Features

a technology of overflow prevention and lavatory system, which is applied in the field of lavatory system with overflow prevention and other features, can solve the problems of reducing the comfort of use, reducing the efficiency of use, and reducing the force of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]The present invention and the various features and advantageous details thereof are explained more fully with reference to the non-limiting embodiments described in detail in the following description.

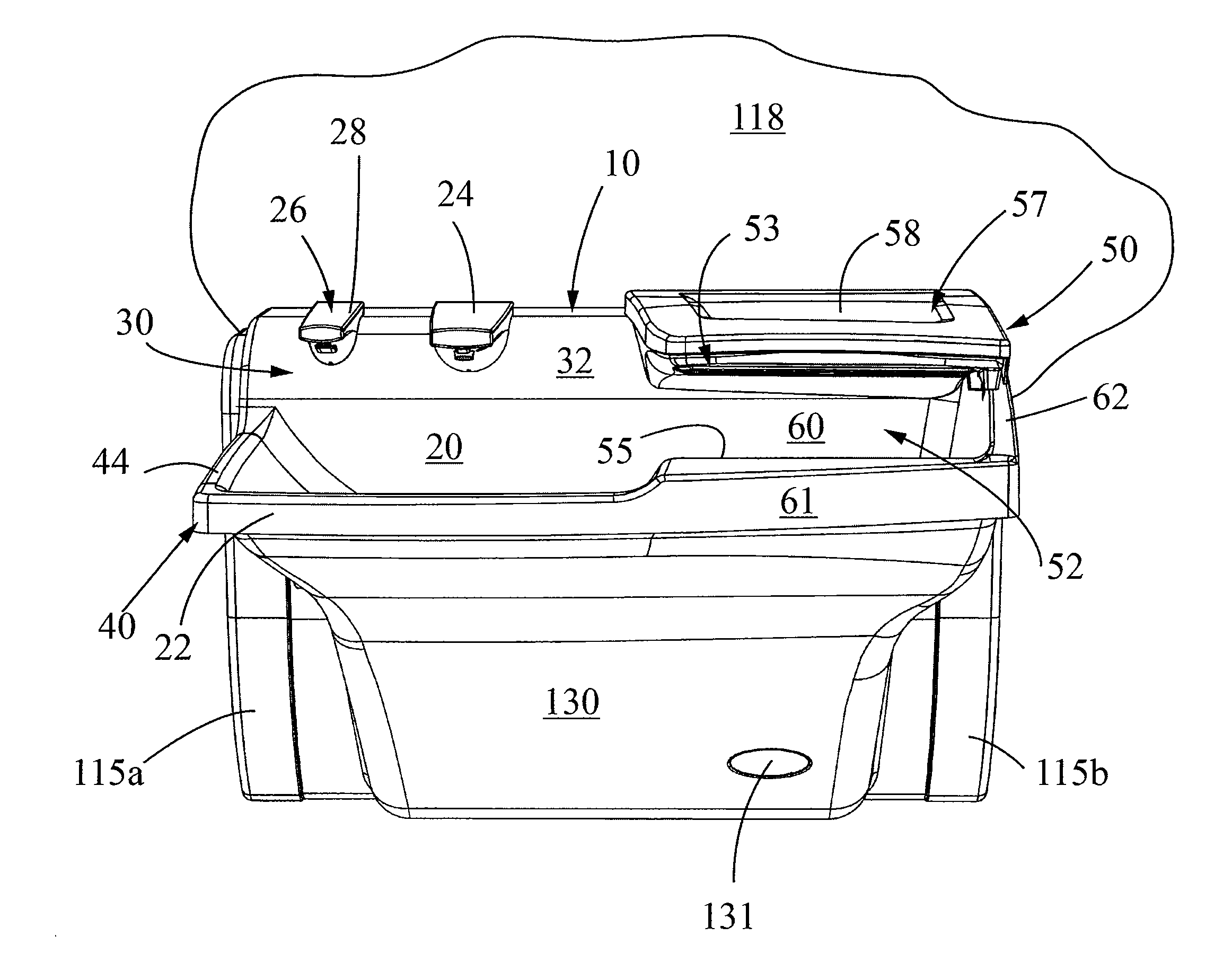

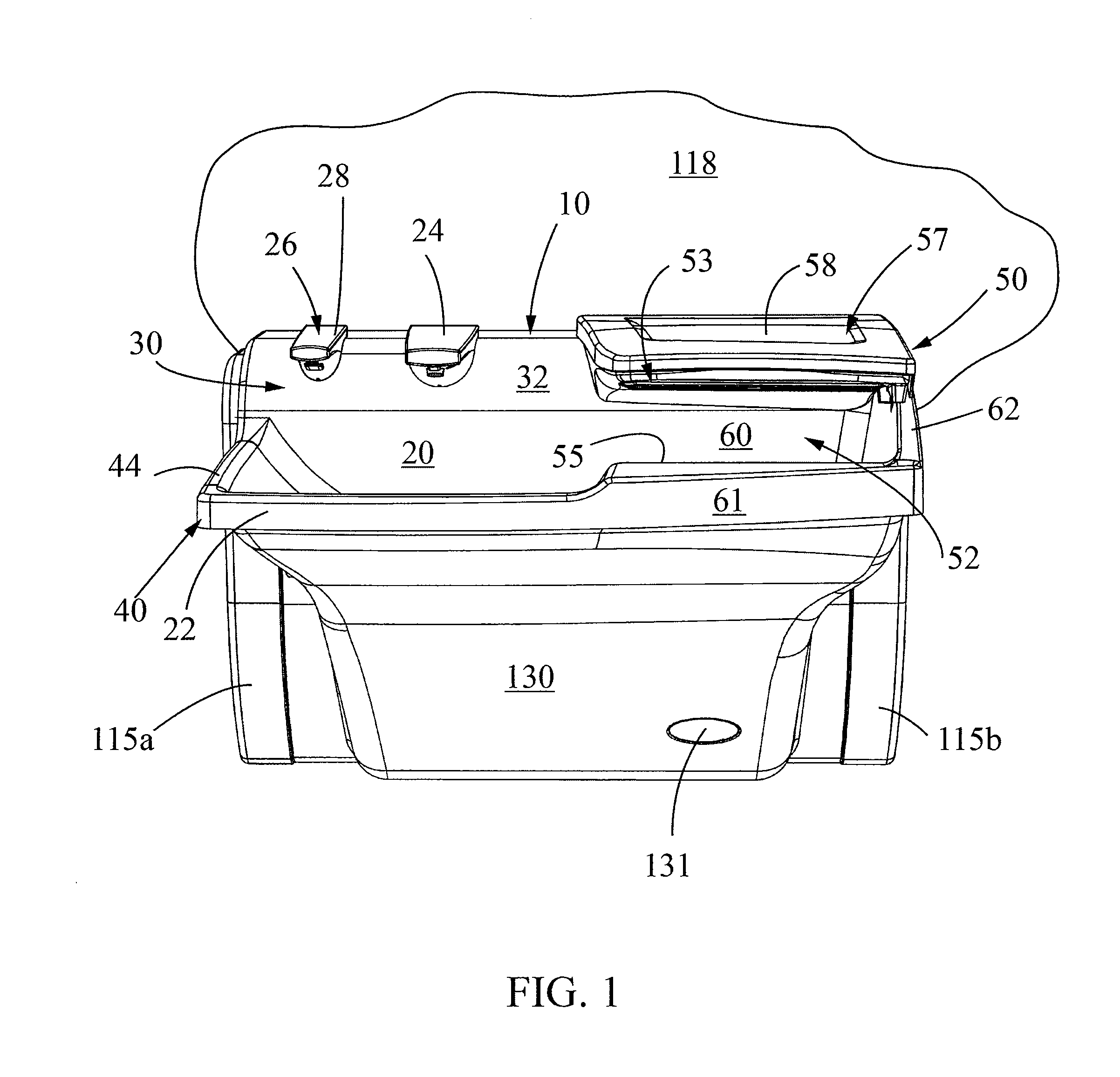

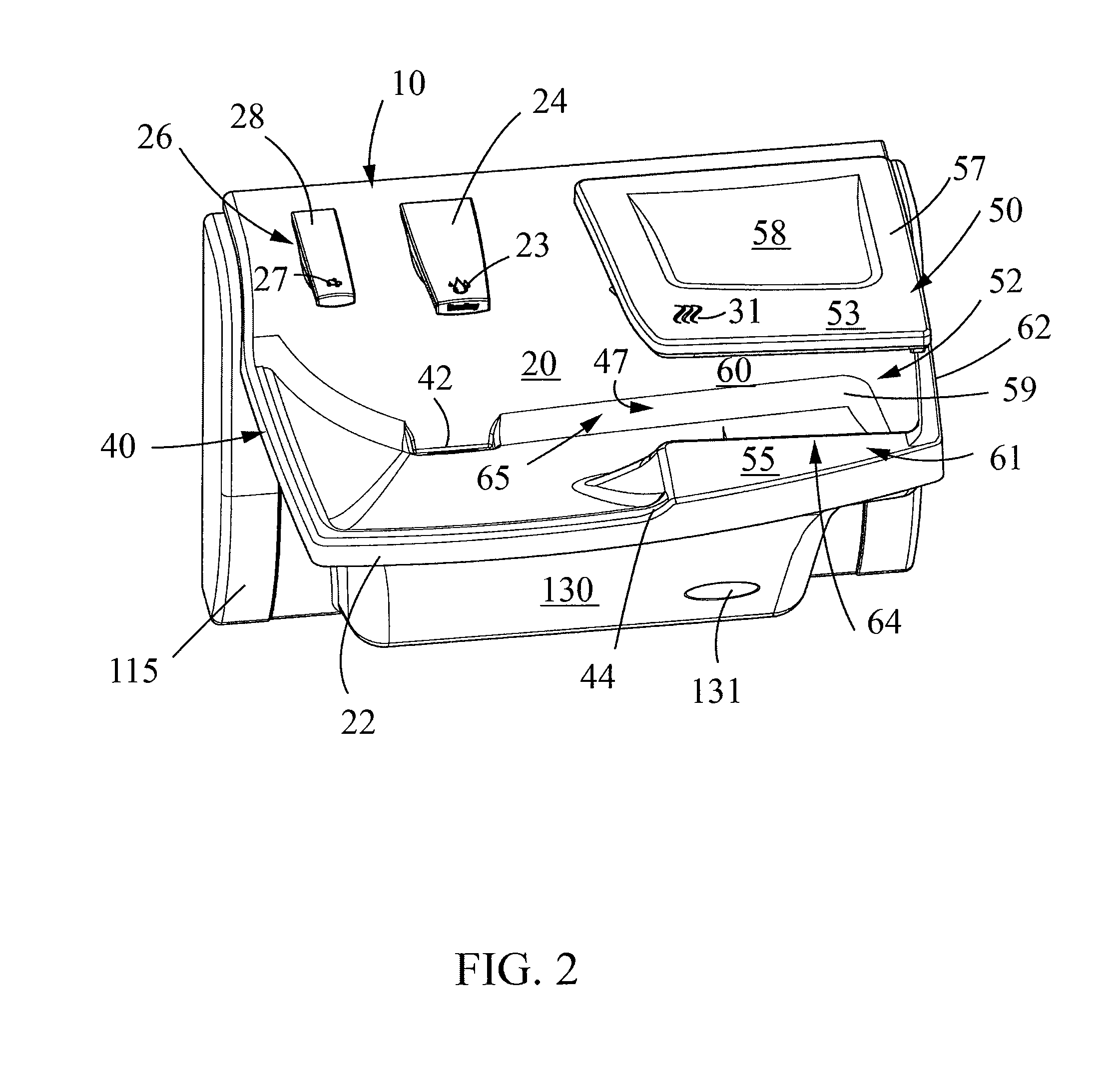

[0059]Now turning generally to FIGS. 1-24, the present invention is directed generally to a lavatory system 10. The lavatory system 10, preferably, has a wash basin 20, including a wash basin wall 22. As shown in FIGS. 1-4, faucet 24 is provided within the wash basin 20. The faucet 24 may include indicia etched thereon such as a water droplet symbol or a faucet light 23 for directing a user. Such etched indicia may be particularly helpful to a user that has poor eyesight. The faucet 24 may also include a sensor located behind a sensor window 25 which automatically engages a faucet control to provide water to the user. The faucet 24 is connected to plumbing to provide hot and / or cold water to the faucet. Preferably, the water is provided at a comfortable temperature for the user's...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com