Leaf collecting and hauling tarpaulin

a technology for hauling tarpaulin and leaves, applied in the field of material handling devices, can solve the problems of long storage package, inconvenient moving, and inconvenient transportation, and achieve the effect of convenient hauling and better conforming to the contour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

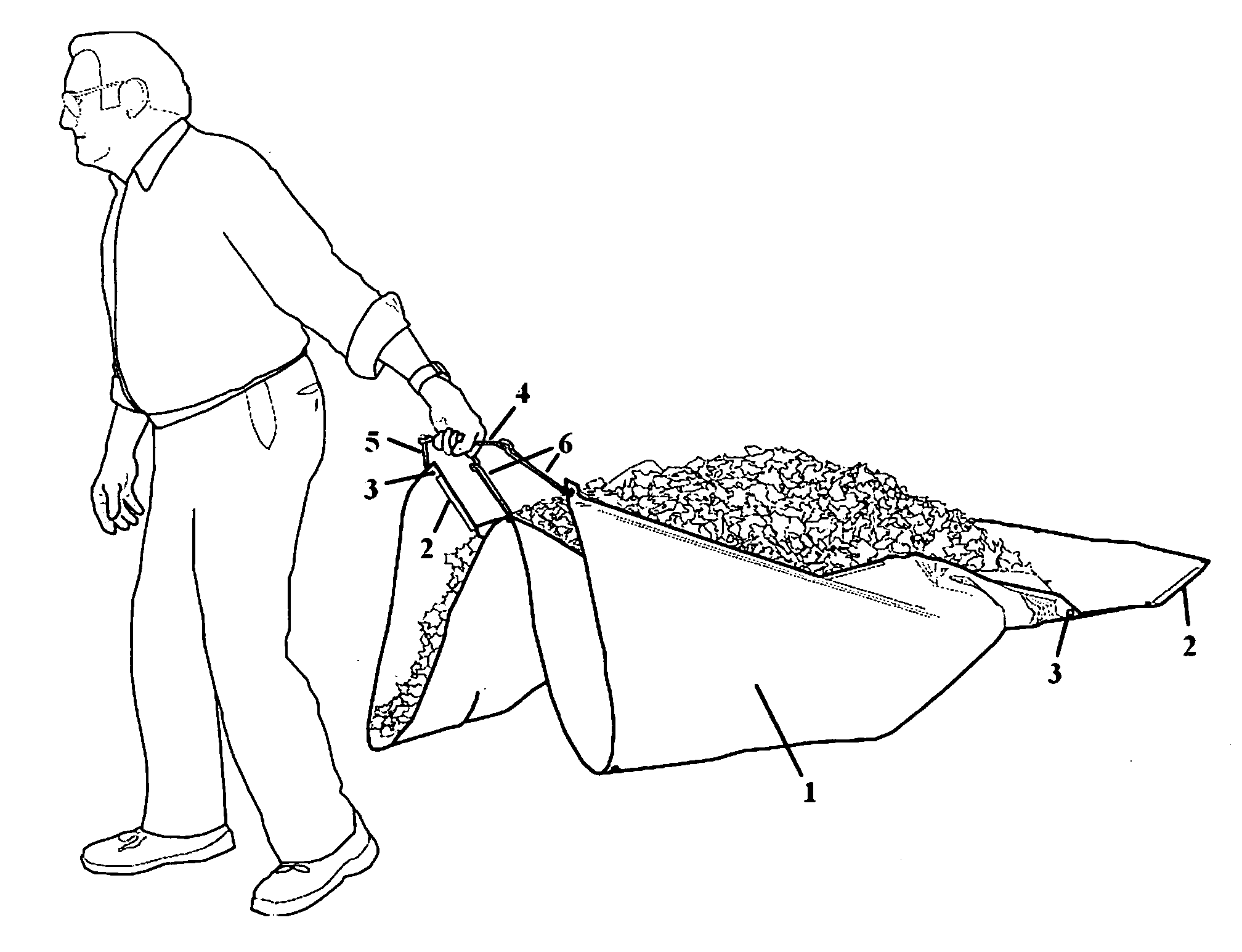

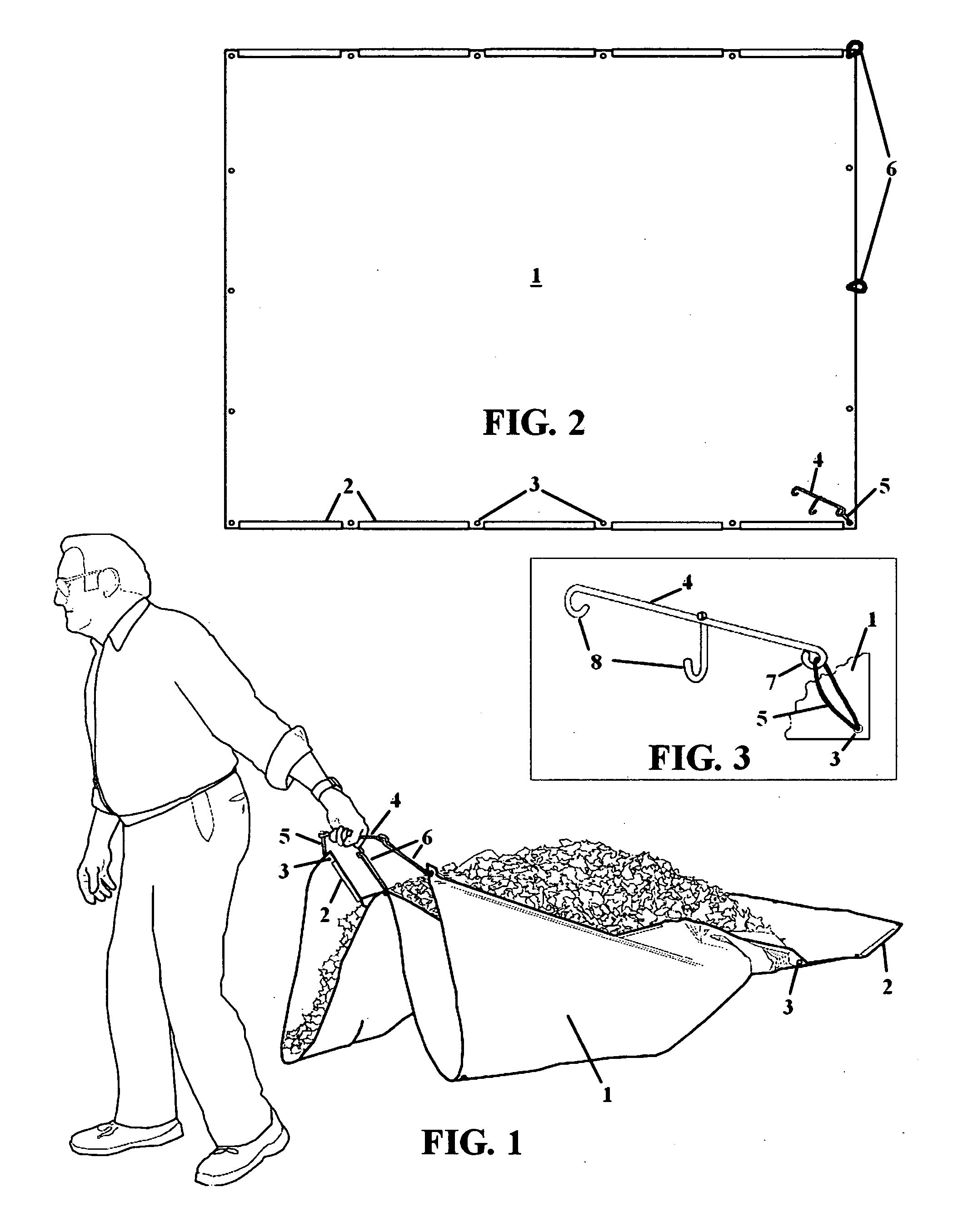

[0008]FIG. 1 shows the lawn tarpaulin 1 full of leaves being transported, and showing the manner in which the partially stiffened edges enclose the load. The tarpaulin material may be made of any strong flexible material preferably having a smooth surface to facilitate dragging over the ground and emptying the contents. The size of the tarpaulin has a practical limitation based on the weight Of the contents to be hauled and emptied. For hauling leaves and other lawn debris an 8′×10′ tarpaulin is about right allowing an average person to handle it easily.

[0009]In FIG. 2 the overall placement of the parts of the preferred embodiment of lawn tarpaulin 1 is shown. The stiffening / weighting elements 2 are place along two parallel edges of the tarpaulin, leaving a short distance between them to allow limited flexibility of the edges. They may be of any composition that provides the necessary strength and weight. For the prototype they consisted of strips of sheet metal folded over the tarp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com