Practice golf ball

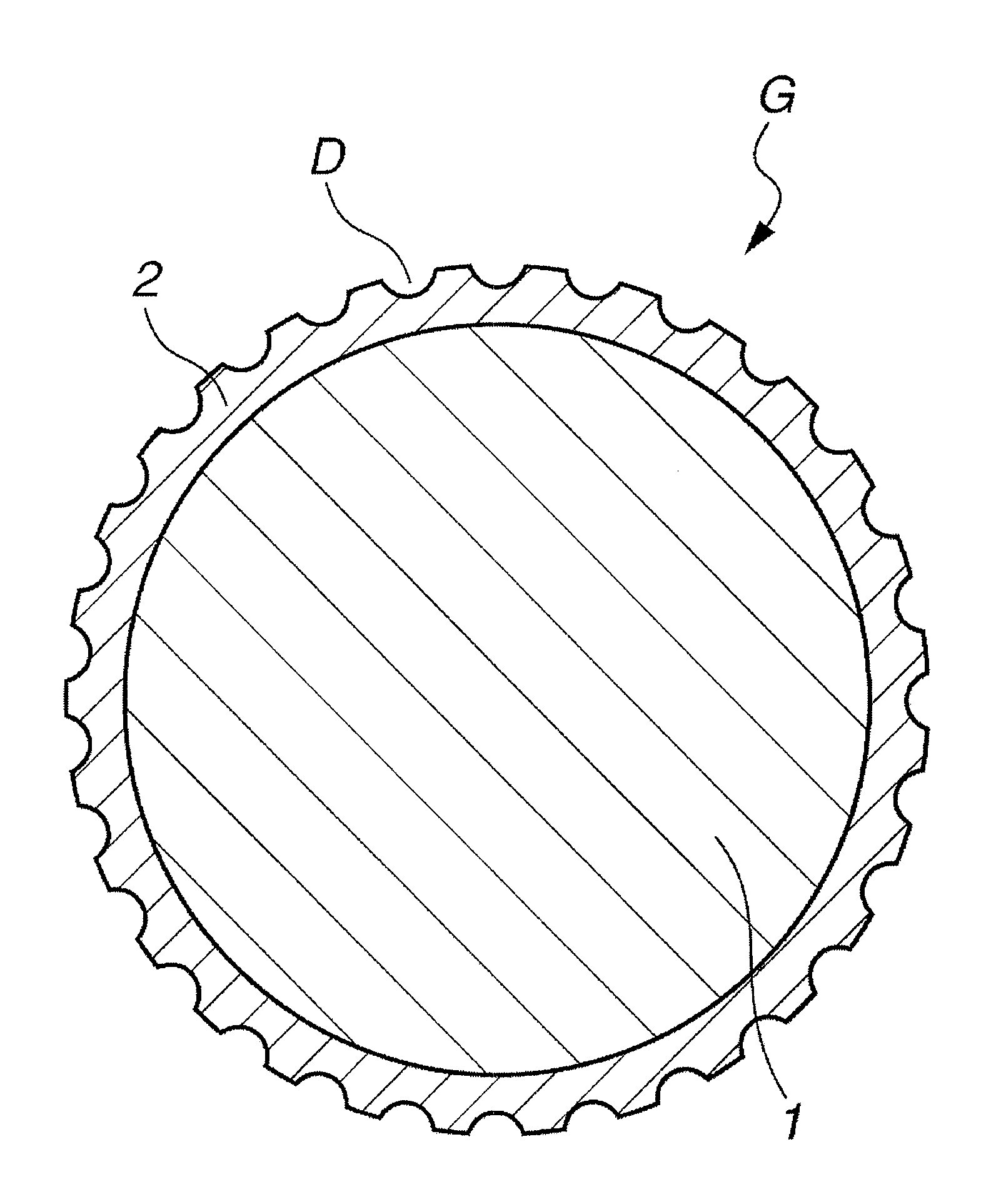

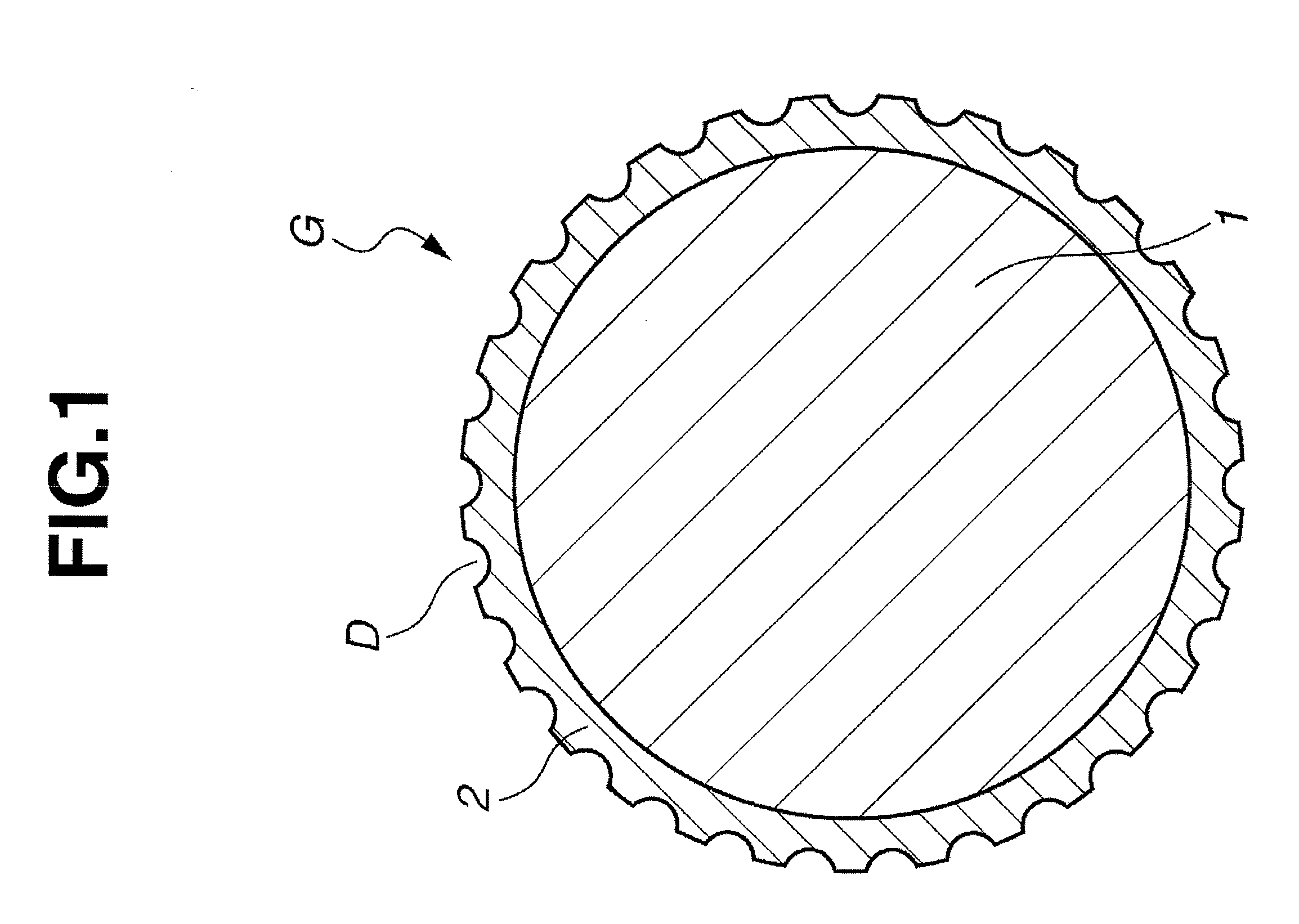

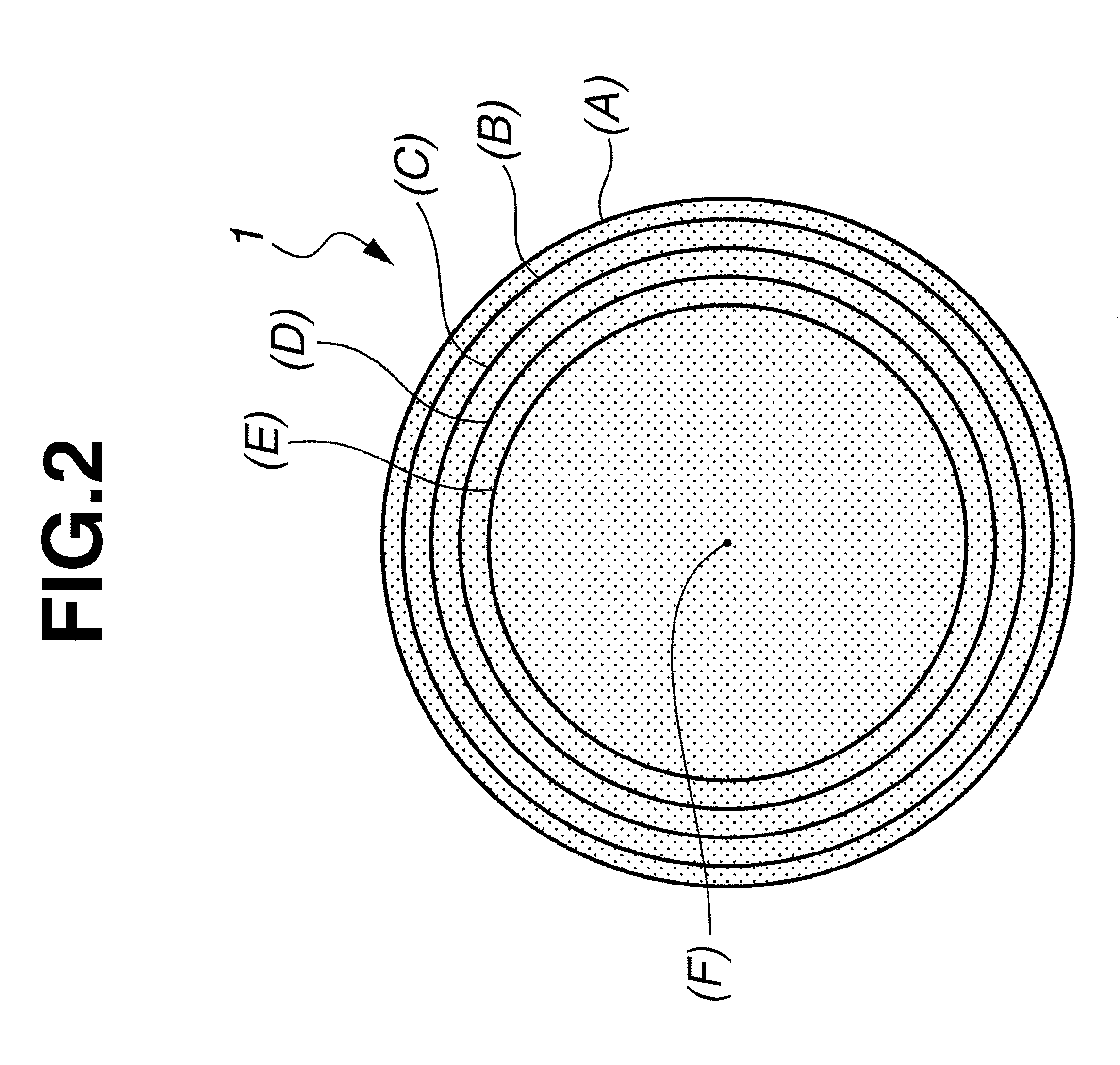

a golf ball and golf technology, applied in the field of golf balls, can solve the problems of difficult to golfers will be unable to take full advantage of the skills acquired through practice, and achieve good ball durability in long-term use at golf driving ranges, etc., to achieve good impact feel, good flight performance, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0114]The following Examples and Comparative Examples are provided to illustrate the invention, and are not intended to limit the scope thereof.

examples 1 to 8

, Comparative Examples 1 to 11

[0115]Rubber materials formulated as shown in Table 1 below were furnished for the fabrication of practice golf balls in the Examples and Comparative Examples. These rubber compositions were suitably mixed using a kneader or roll mill, then vulcanized under the temperature and time conditions in Table 1 to produce solid cores in the respective Examples. Ingredient amounts in the table below are shown in parts by weight.

TABLE 1Type of Core(1)(2)(3)(4)(5)(6)(7)(8)CoreBR015555551006010095formulationIR22002015155BR730100BR5140SBR0202253030Perhexa C-400.60.6(40% dilution)Actual amount0.240.24of additionPercumyl D0.91.10.91.20.80.60.60.8Zinc oxide232322.523.5239.59.523Antioxidant0.20.20.20.20.20.10.10.2Methacrylic acid25.52717291822.5Zinc26methacrylateZinc acrylate26Titanium oxide4VulcanizationTemperature (° C.)170170170170170160160170conditionsTime (minutes)2020202020131330

[0116]Details on the materials used in the core formulations in the above table are pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| specific gravity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com