Offset igniter assembly

a technology of offset igniter and assembly, which is applied in the direction of gaseous heating fuel, combustion types, domestic stoves or ranges, etc., can solve the problems of increasing cost and complexity, and the optimal location of hot surface ignition devices may not be the same,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]While methods and apparatuses are herein described in the context of a gas-fired cooktop, as set forth more fully below, it is contemplated that the herein described methods and apparatuses may find utility in other applications, including, but not limited to, gas heater devices, gas ovens, gas kilns, gas-fired meat smoker devices, and gas barbecues. In addition, the principles and teachings set forth herein may find equal applicability to combustion burners for a variety of combustible fuels. The description hereinbelow is therefore set forth only by way of illustration rather than limitation.

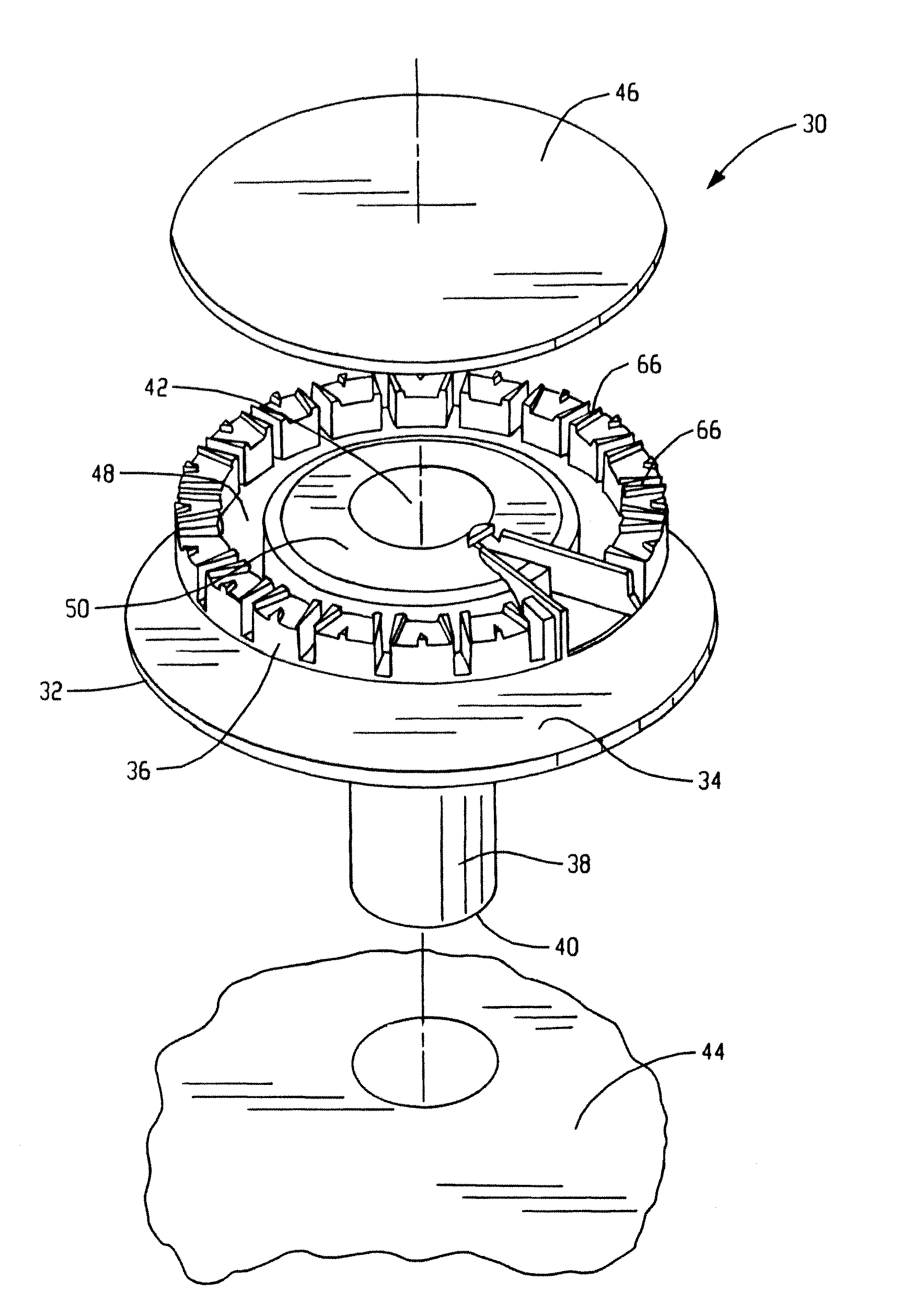

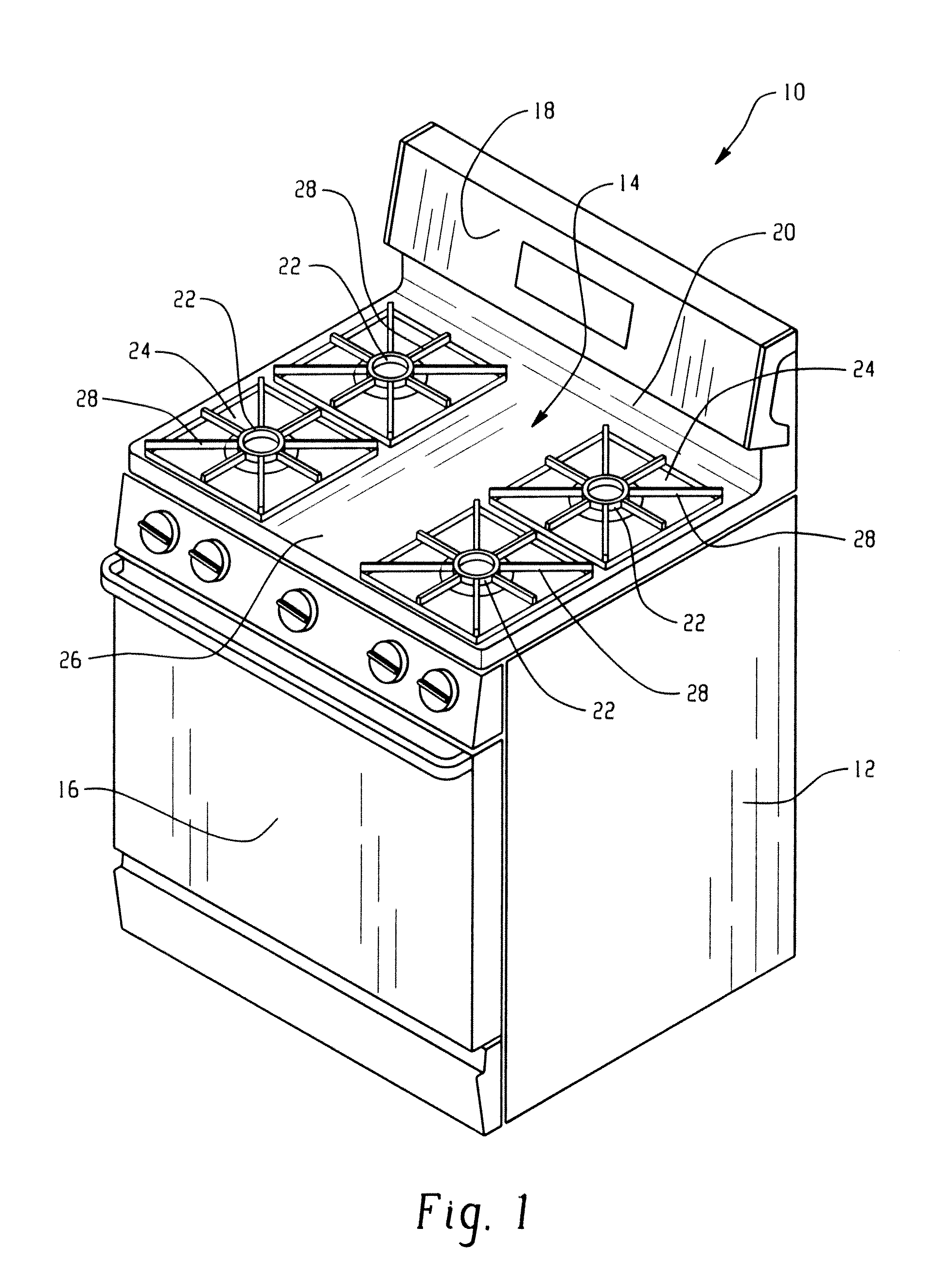

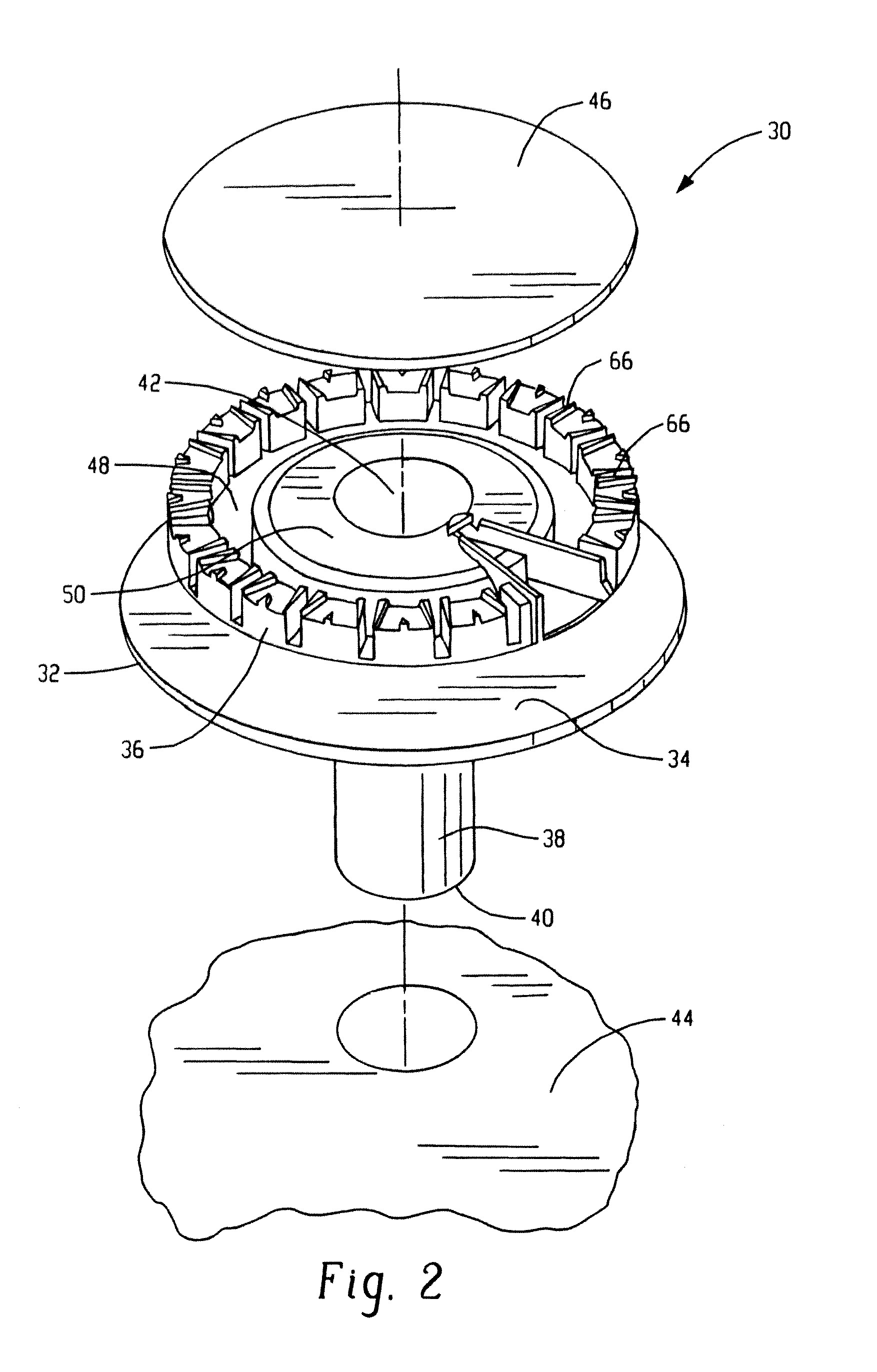

[0017]FIG. 1 illustrates an exemplary free standing gas range in which the herein described methods and apparatuses may be practiced. Range 10 includes an outer body or cabinet that incorporates a cooktop shown here as a generally rectangular cooktop 14. An oven, not shown, is positioned below cooktop 14 and has a front-opening access door 16. A range backsplash 18 extends upward of a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com