Patents

Literature

44results about How to "Great gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

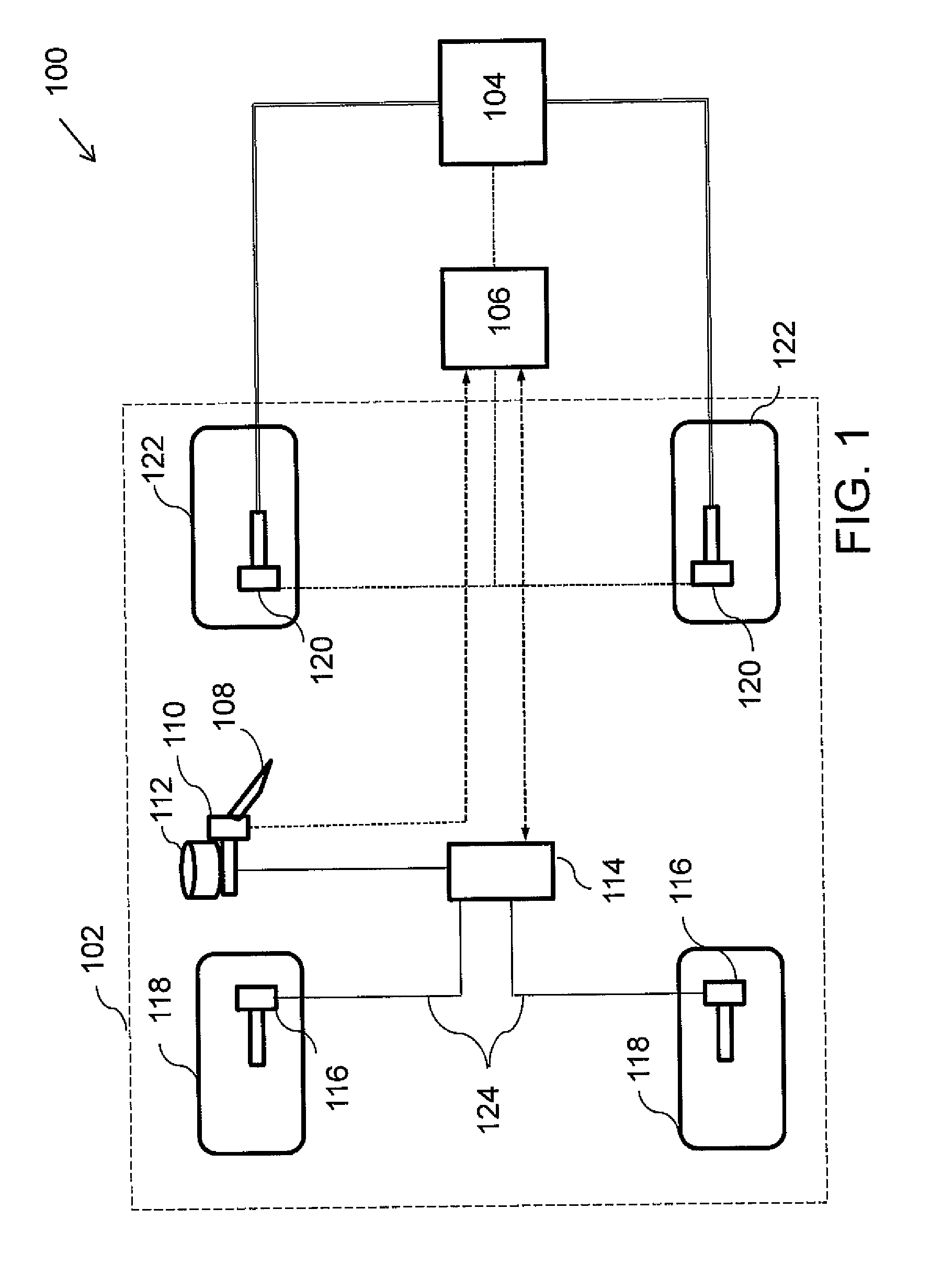

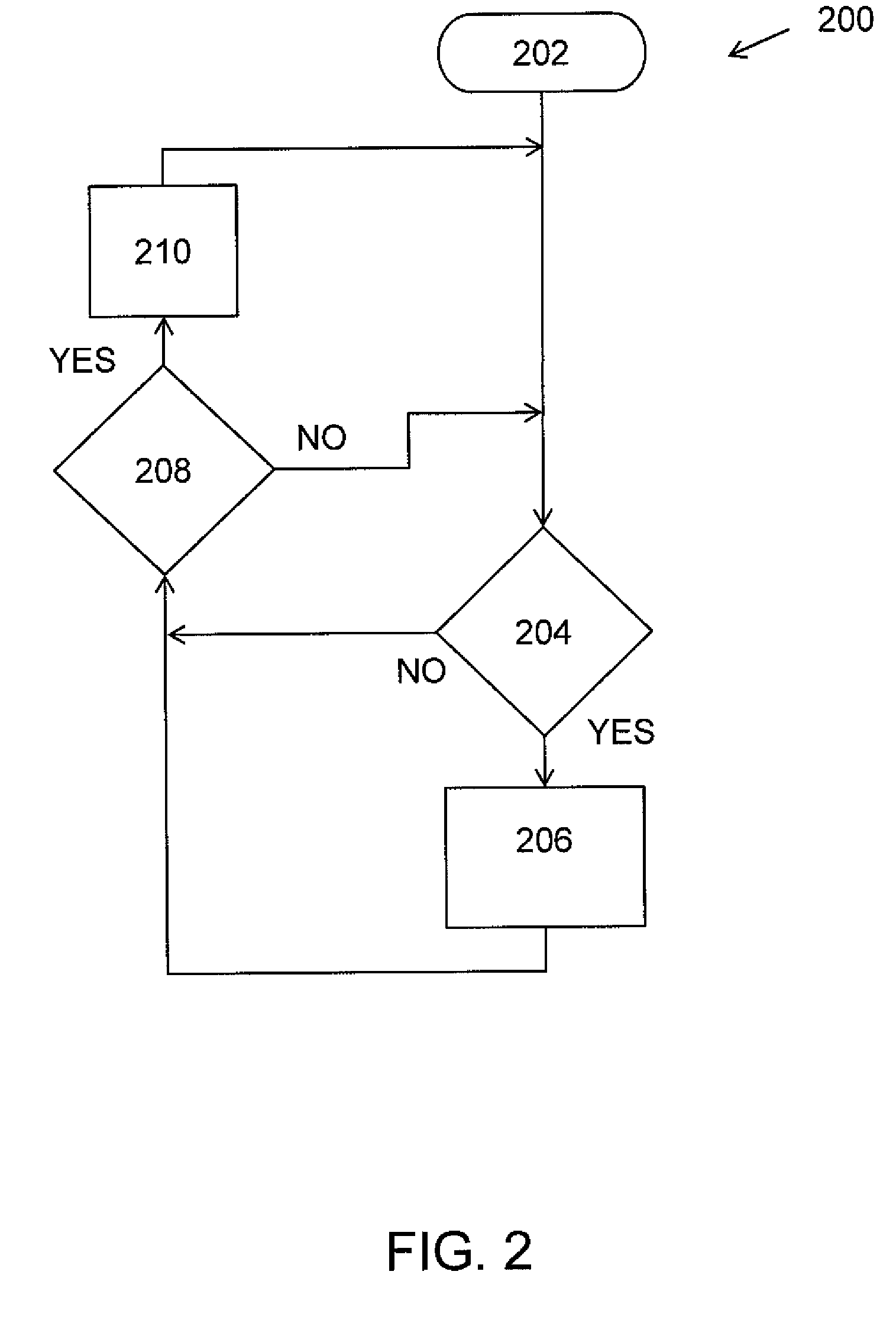

Regenerative Braking System for a Hybrid Electric Vehicle and a Corresponding Method

ActiveUS20130076113A1Cost-effective and reliableIncreased braking torqueHybrid vehiclesSpeed controllerElectricityBrake torque

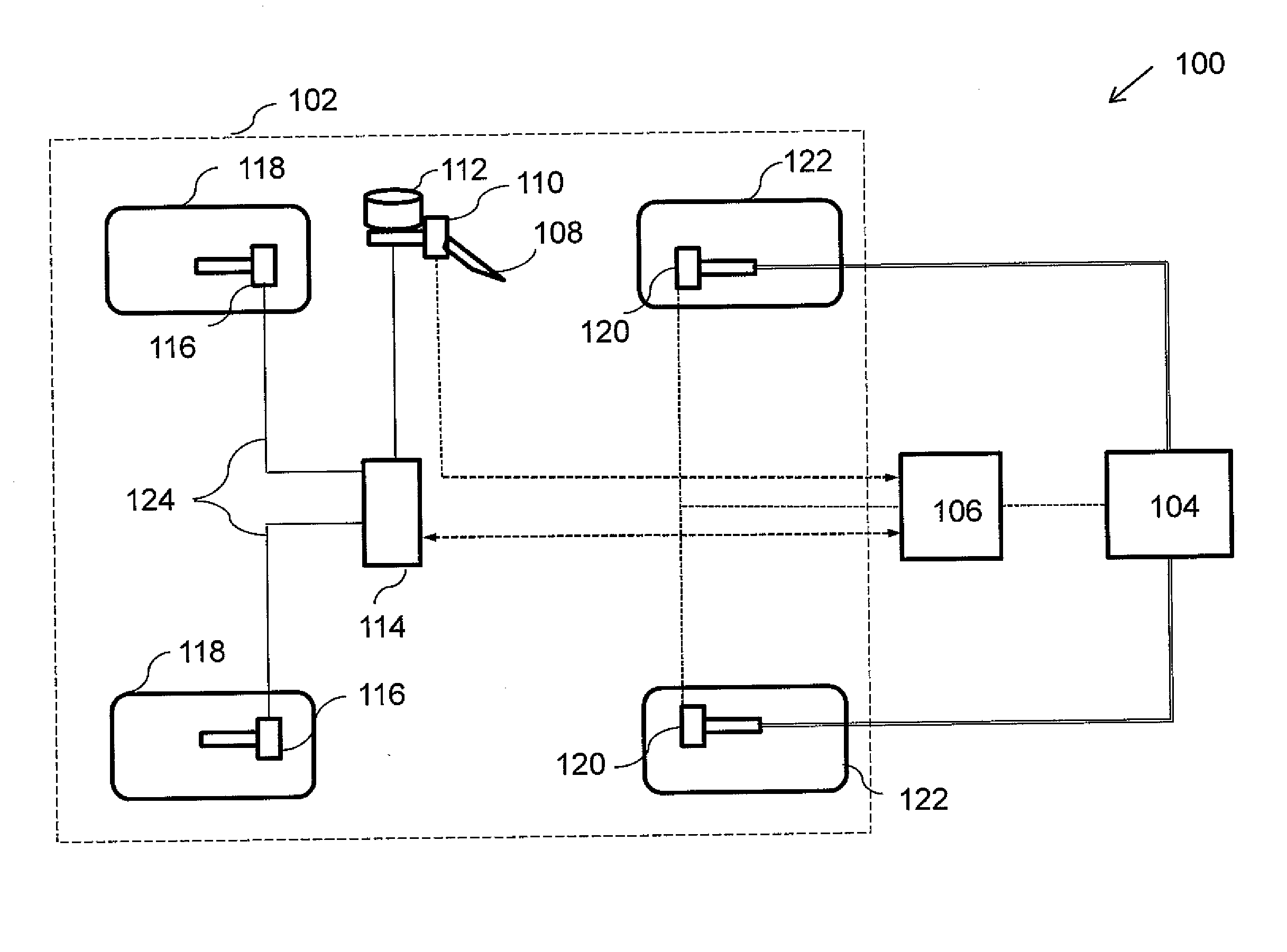

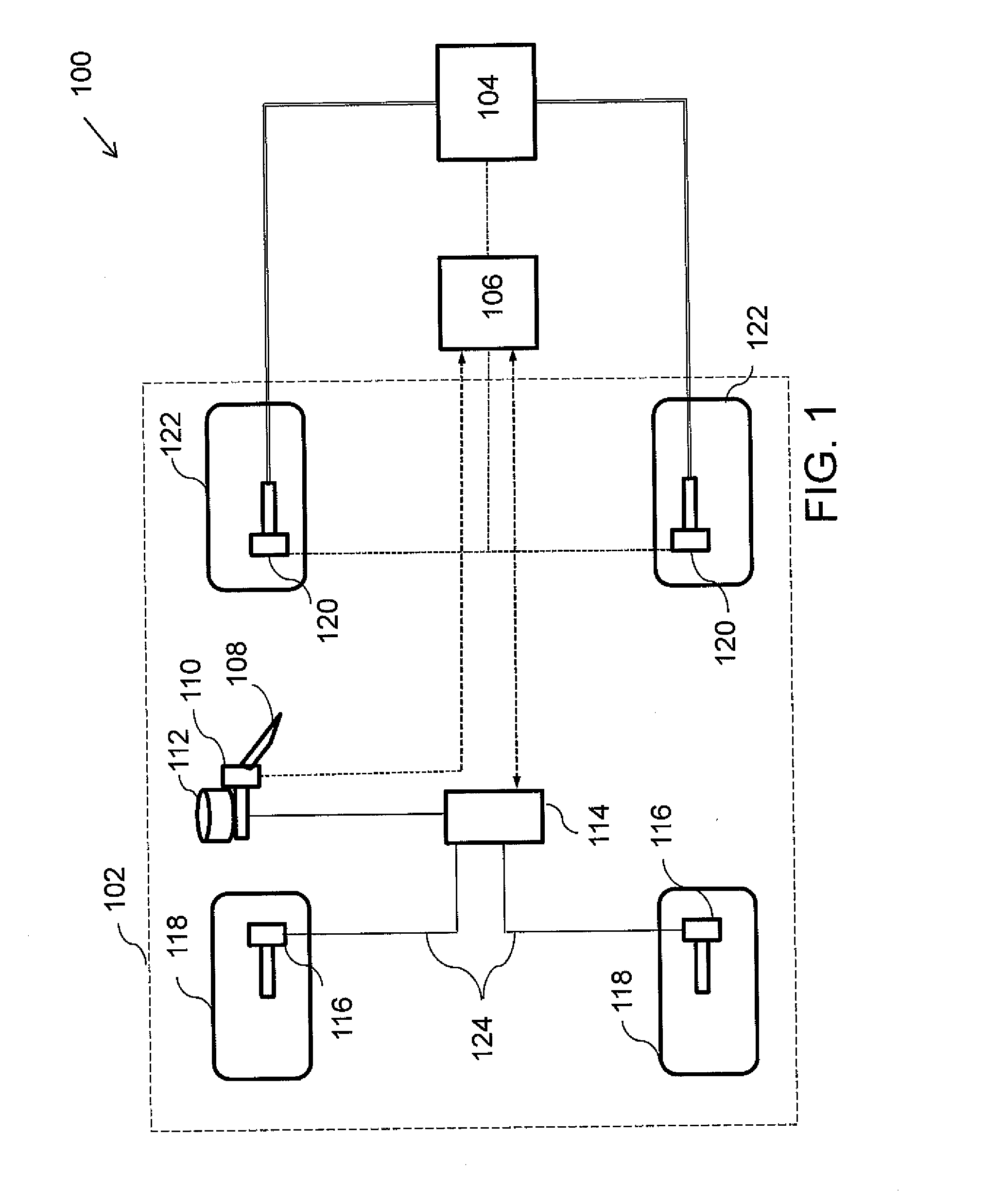

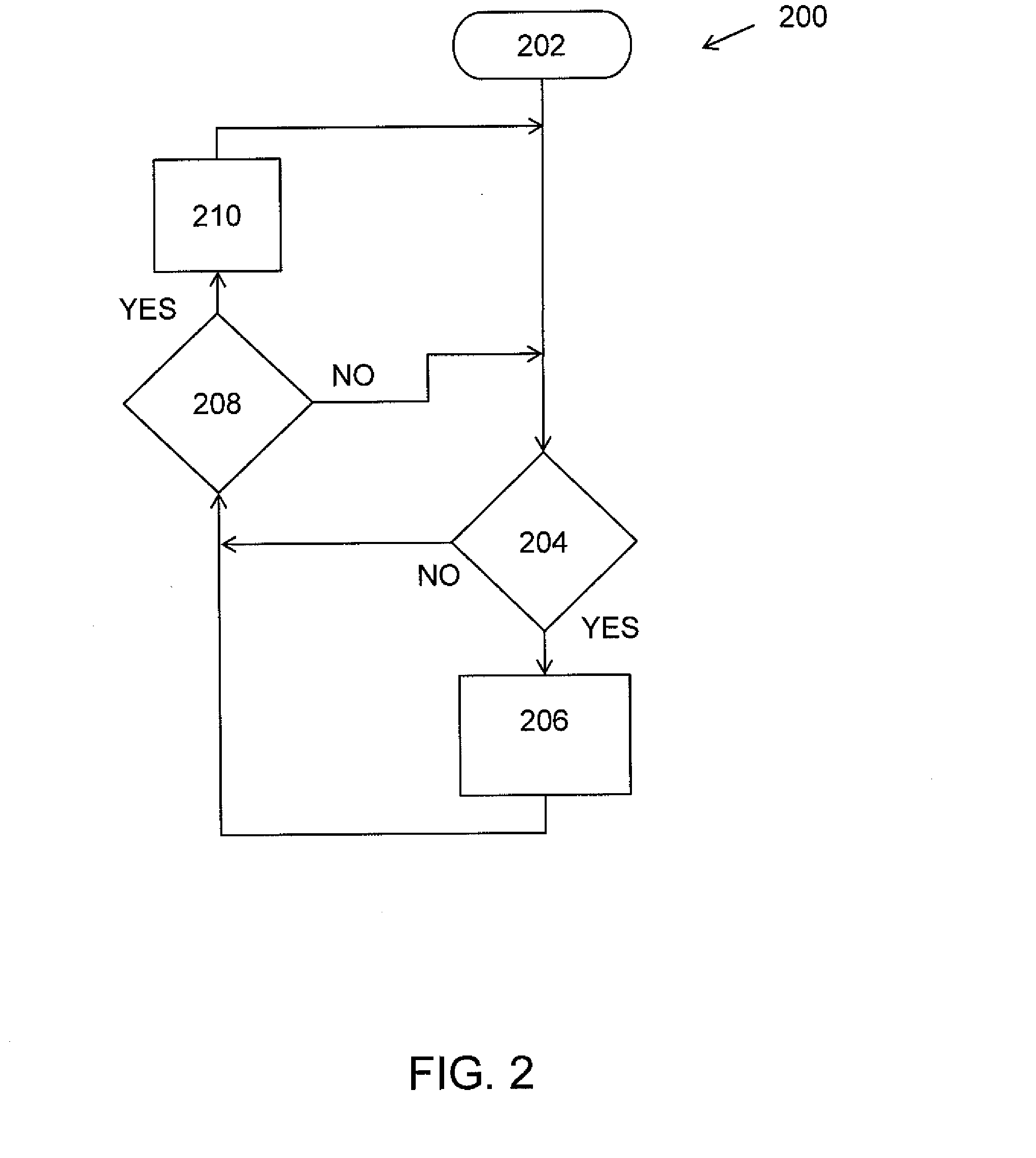

A method and system for controlling regenerative braking of a hybrid electric vehicle. The regenerative braking system has a driver-operable brake pedal, a hydraulically actuated friction brake for at least one front wheel, an anti-lock braking system hydraulically connected to said hydraulically actuated friction brake, and an electrically actuated friction brake for at least one rear wheel. The regenerative braking system further comprises an electric machine connected to said at least one rear wheel and capable of performing regenerative braking of said at least one rear wheel, and an electronic control unit that controls the stability of said hybrid electric vehicle, wherein said regenerative braking system is configured to provide increased braking torque of said front hydraulically actuated friction brake by means of said anti-lock braking system for compensating a decreased or limited rear wheel braking torque initiated by said electronic control unit.

Owner:VOLVO CAR CORP

Haptic solenoid system

ActiveUS20100013614A1Low costEasy to operateWindingsFrequency-division multiplex detailsSolenoid valveEngineering

Owner:JOHNSON ELECTRIC SA

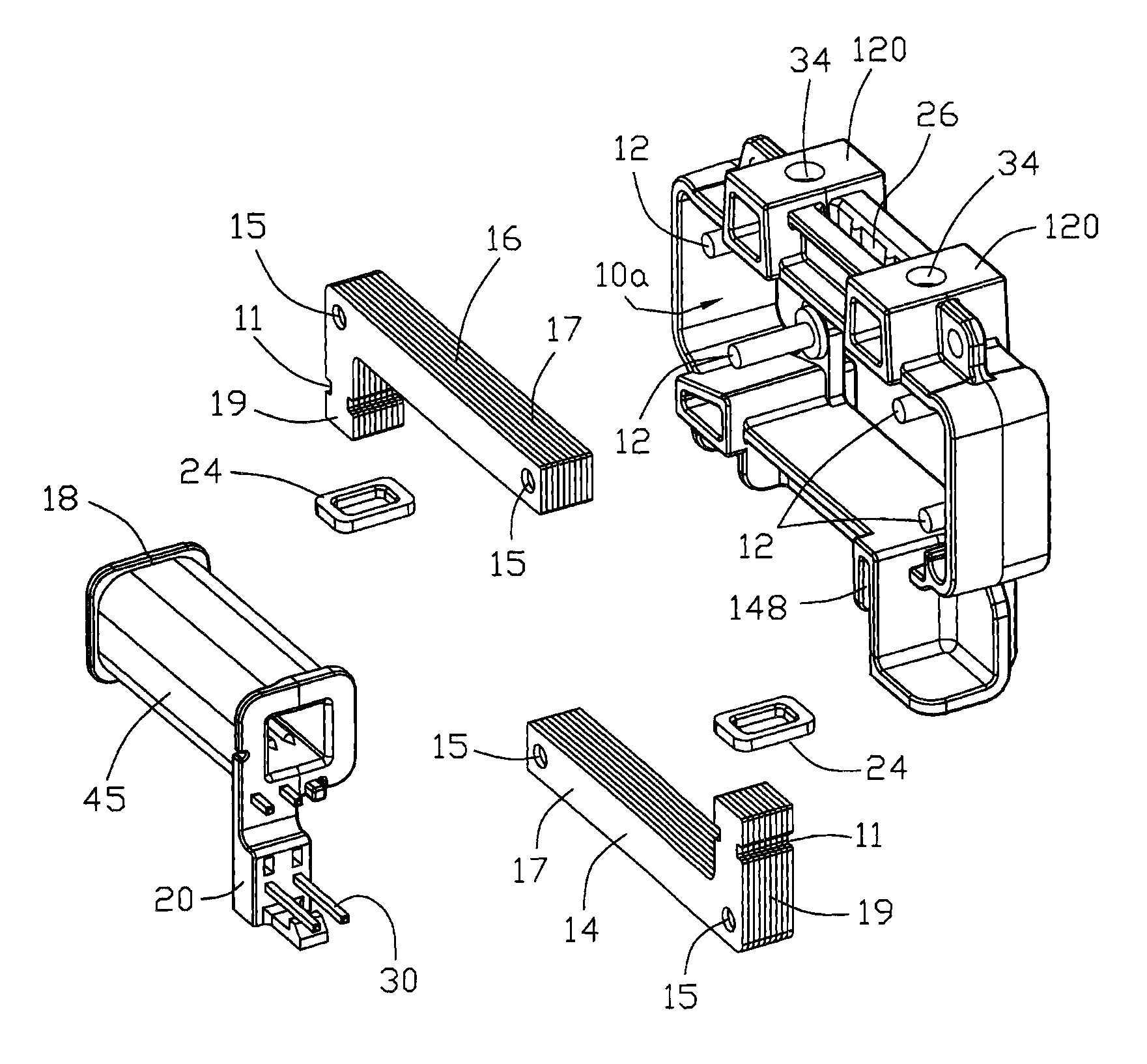

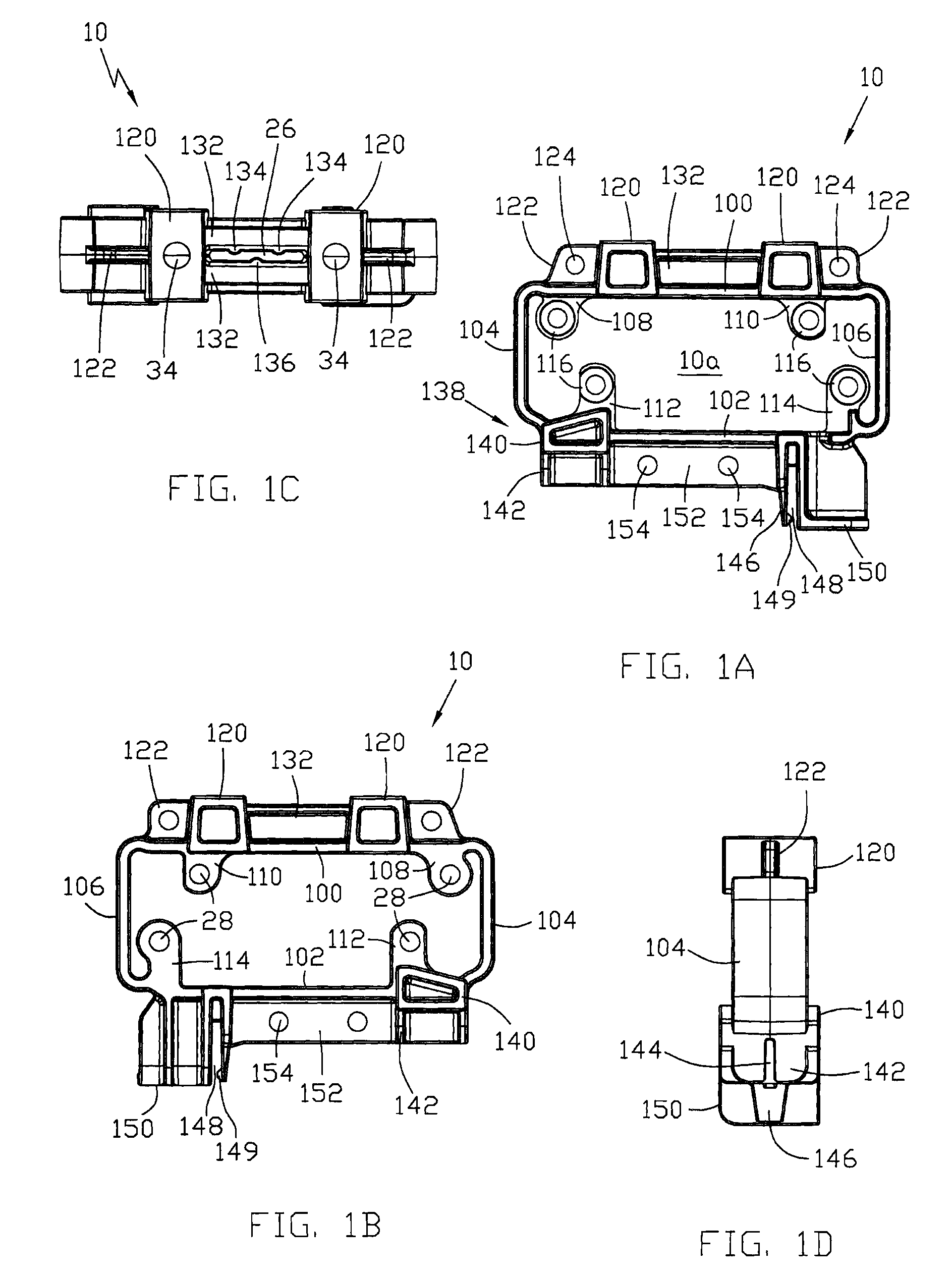

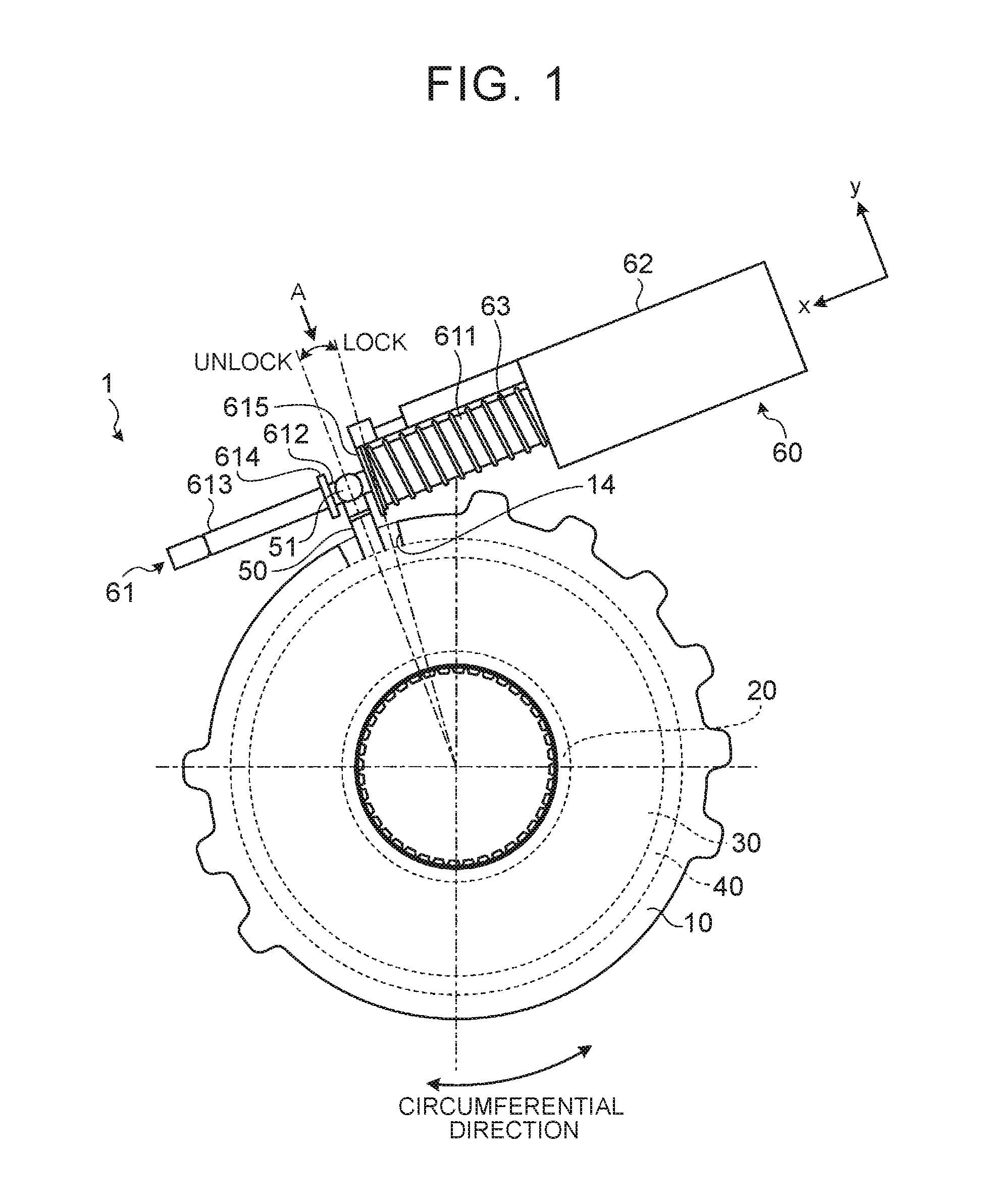

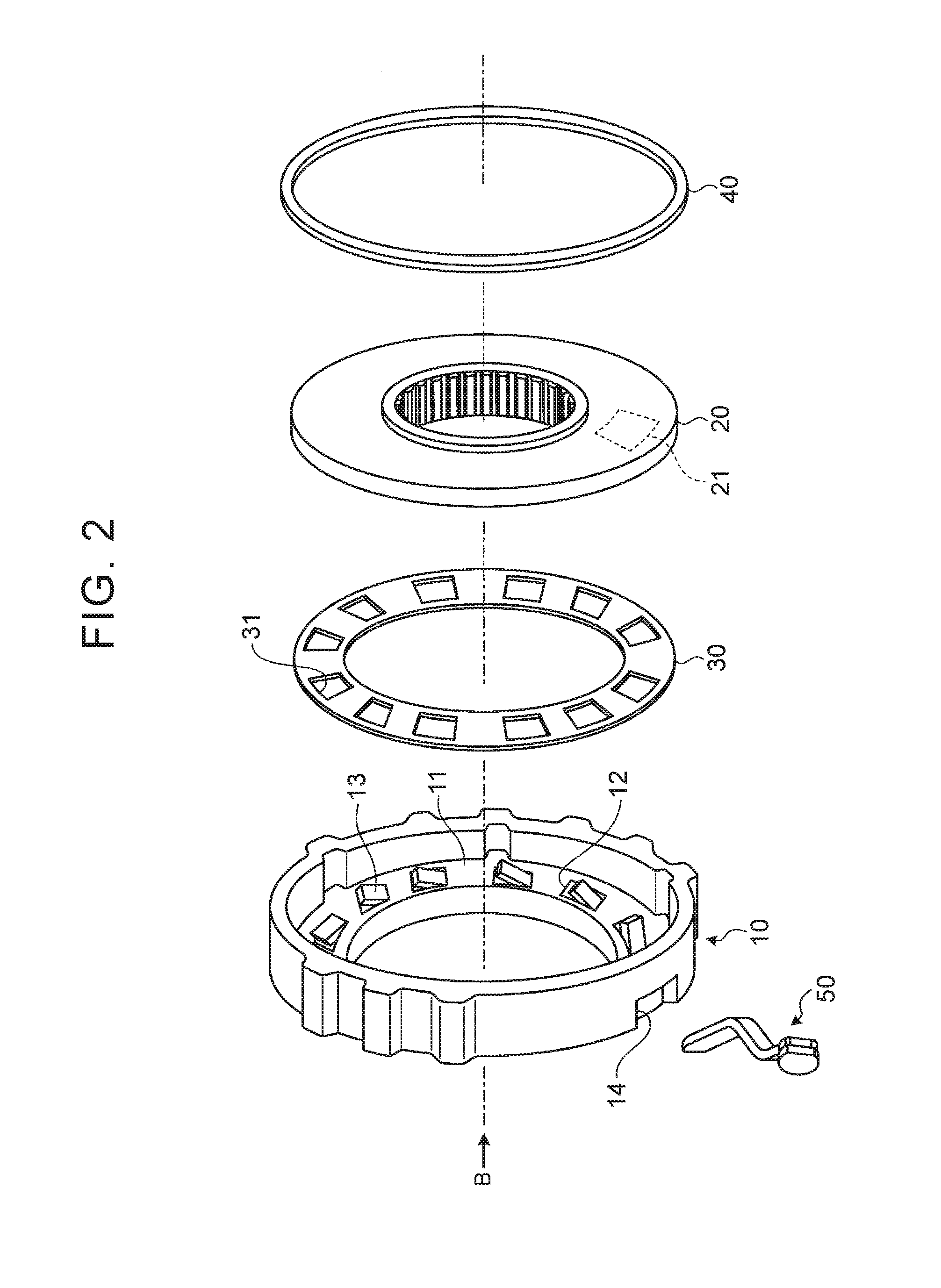

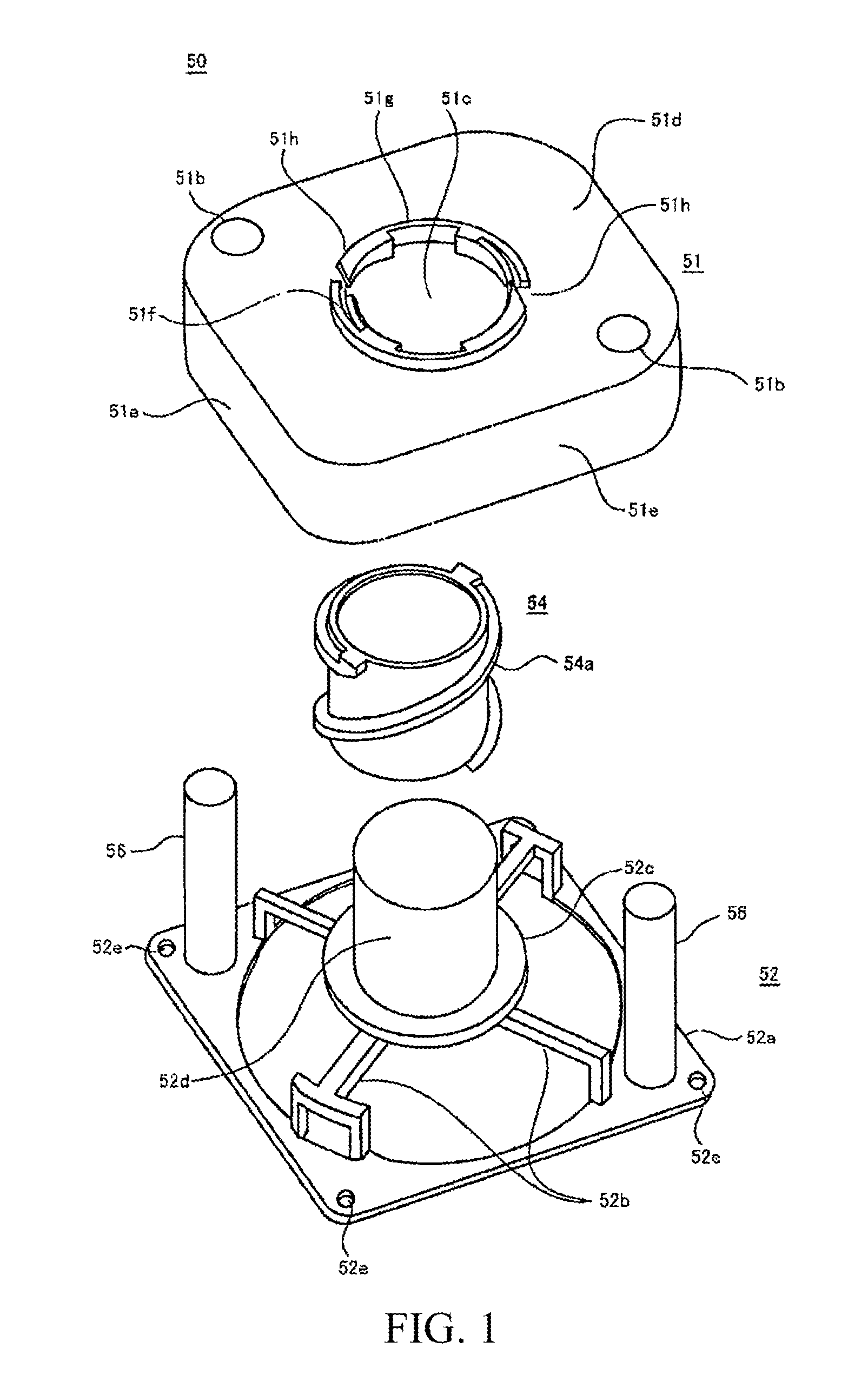

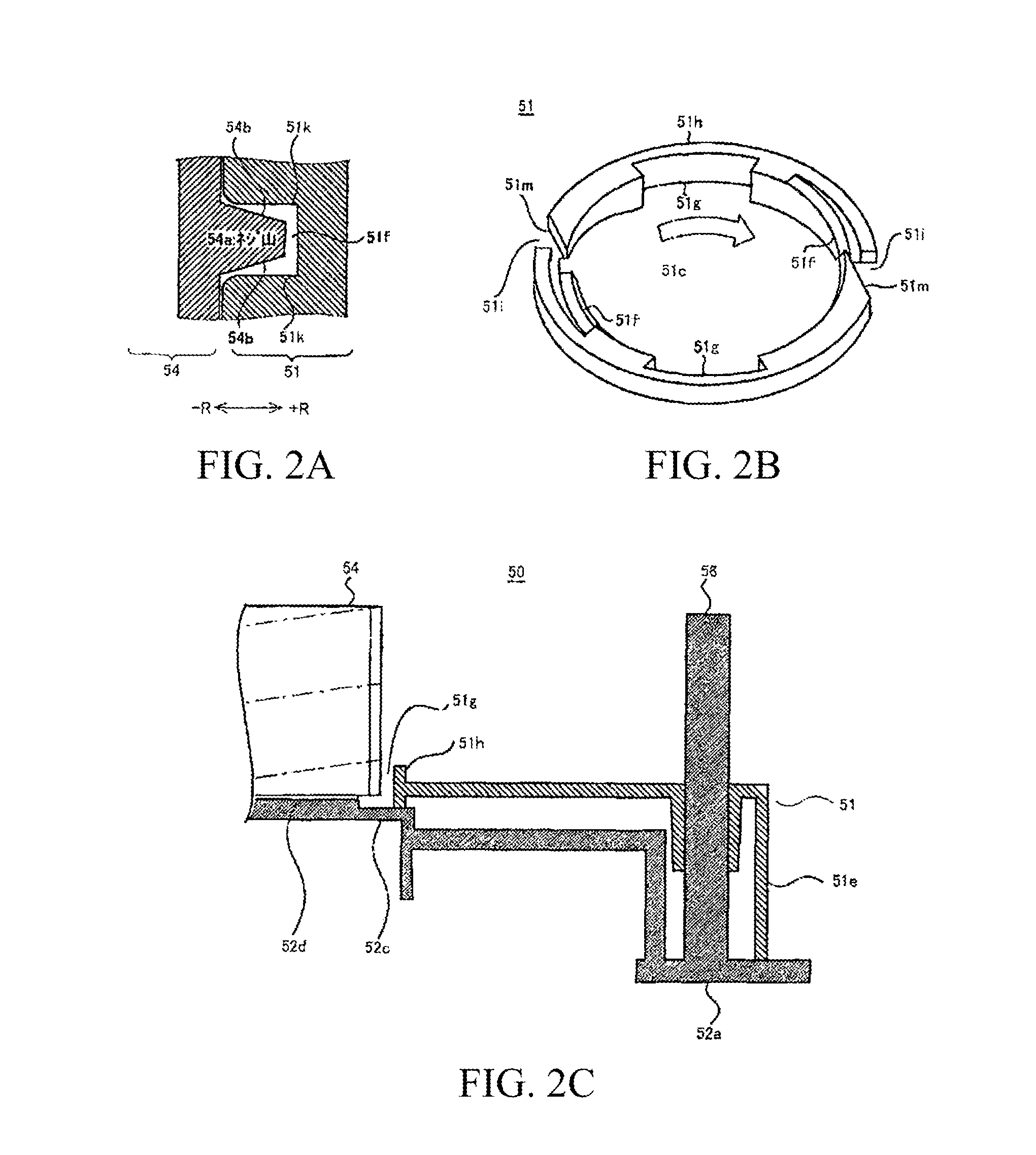

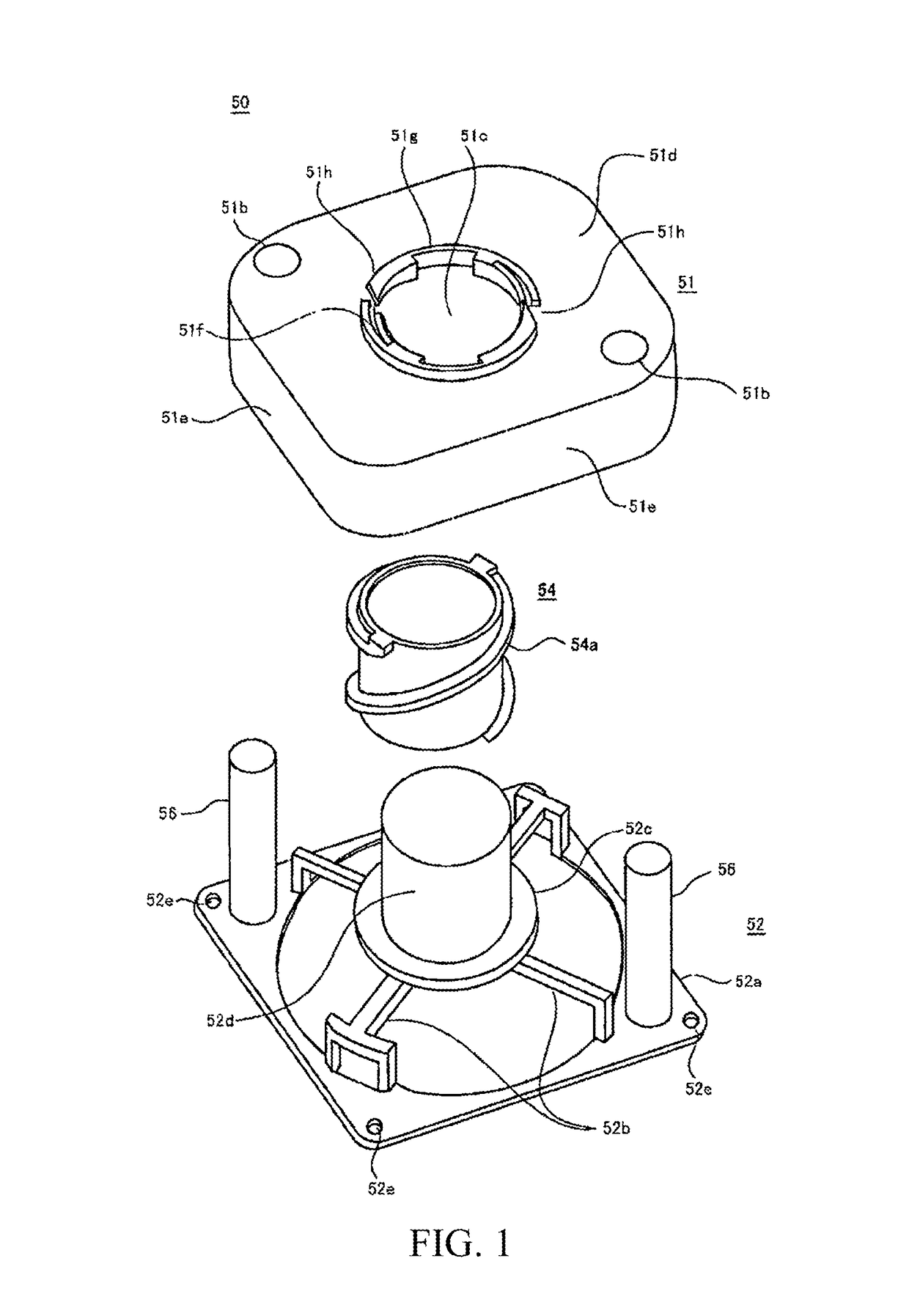

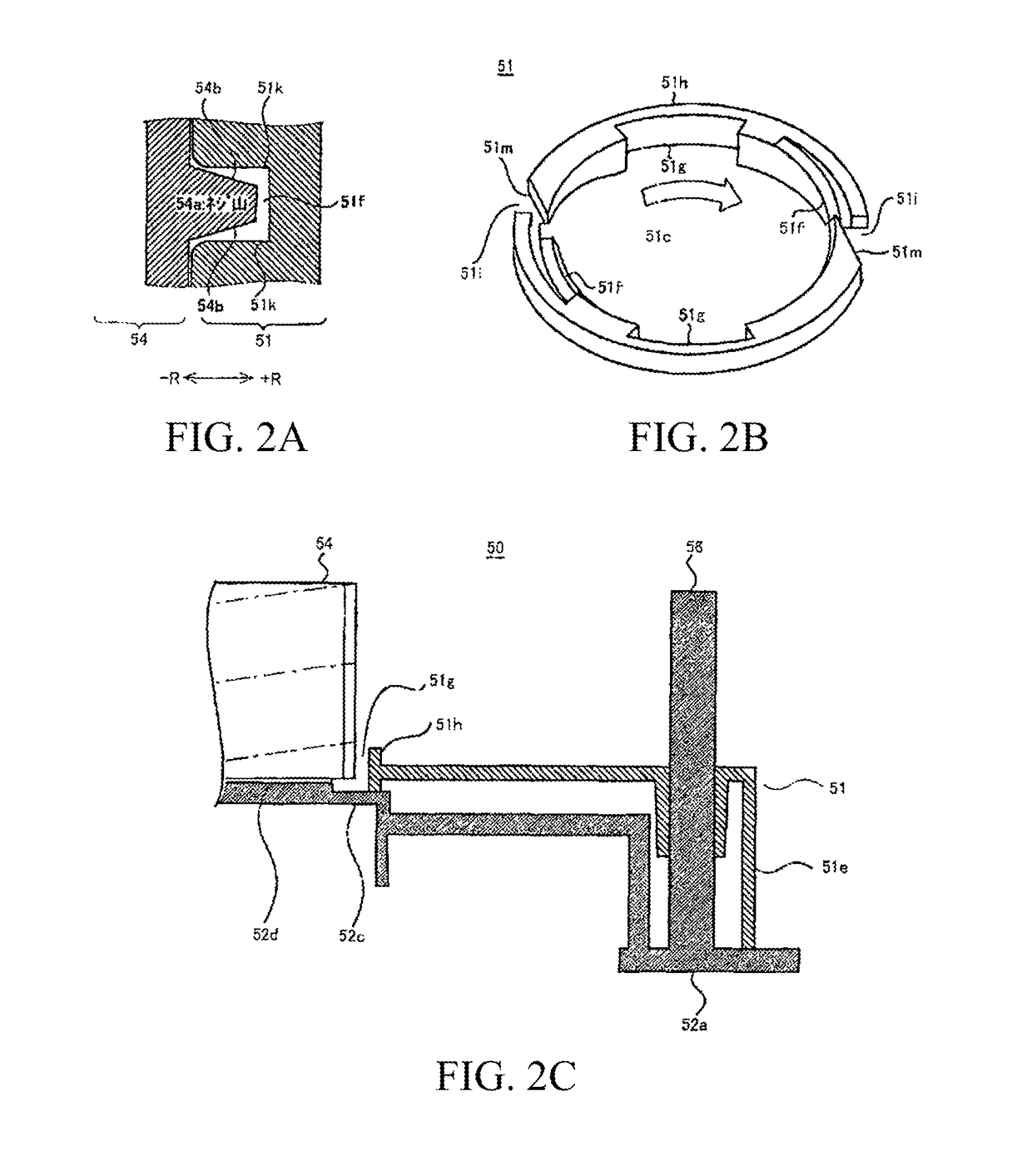

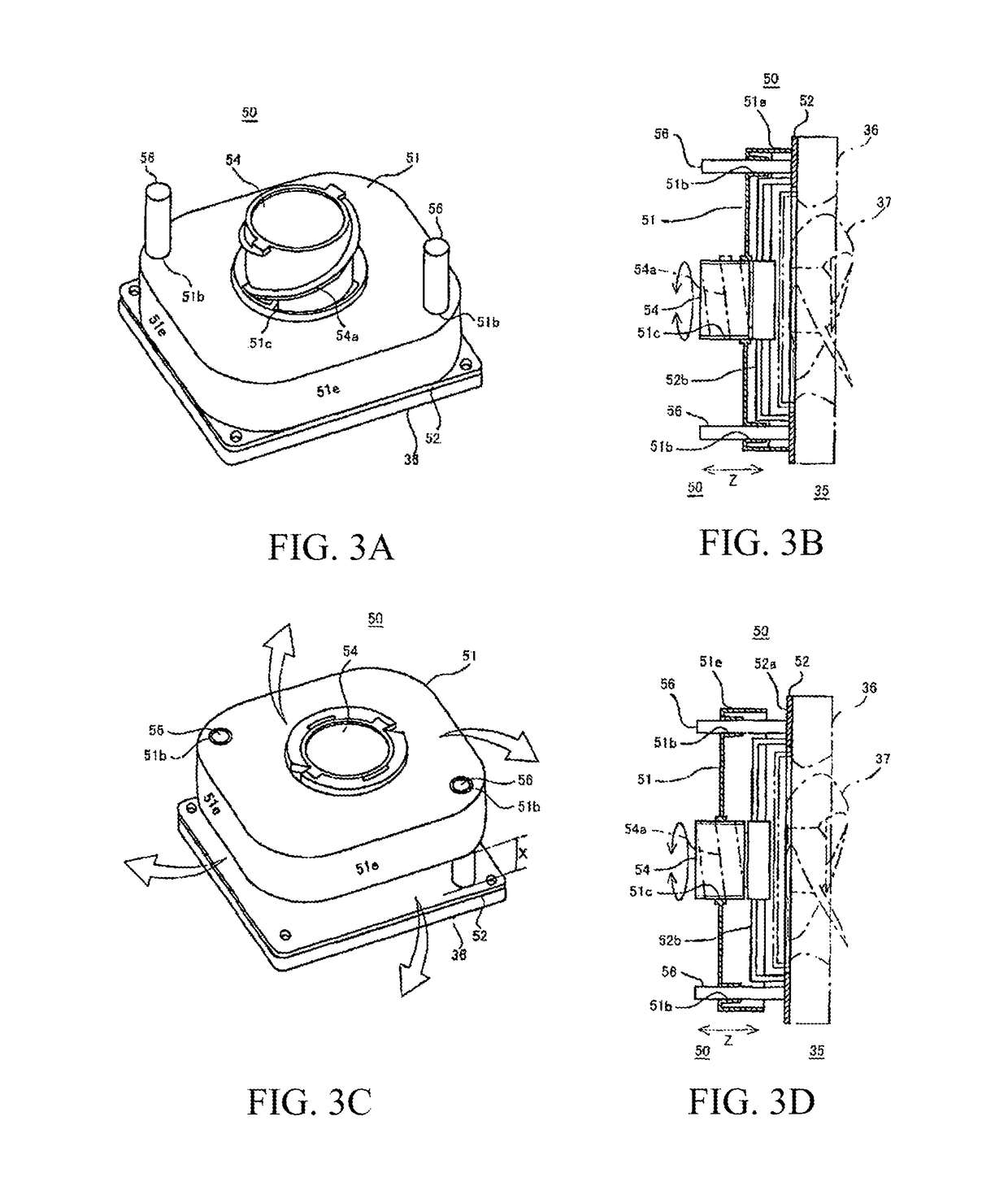

Selectable one-way clutch

InactiveUS20170037914A1Increase contact areaSmooth movementMechanical actuated clutchesFreewheel clutchesActuatorClutch

A selectable one-way clutch includes: a pocket plate; a notch plate; an annular selector plate; an arm; and an actuator. An operating shaft is configured to move the arm along a circumferential direction of the selector plate so as to move the arm to an engagement position and to a non-engagement position. The operating shaft includes a slope portion inclined relative to a direction of a tangential line to the outer circumference of the selector plate. The slope portion is configured to move the selector plate to a position farther apart from the notch plate in a case where the arm is located at the non-engagement position than a position from the notch plate in a case where the arm is located at the engagement position.

Owner:TOYOTA JIDOSHA KK

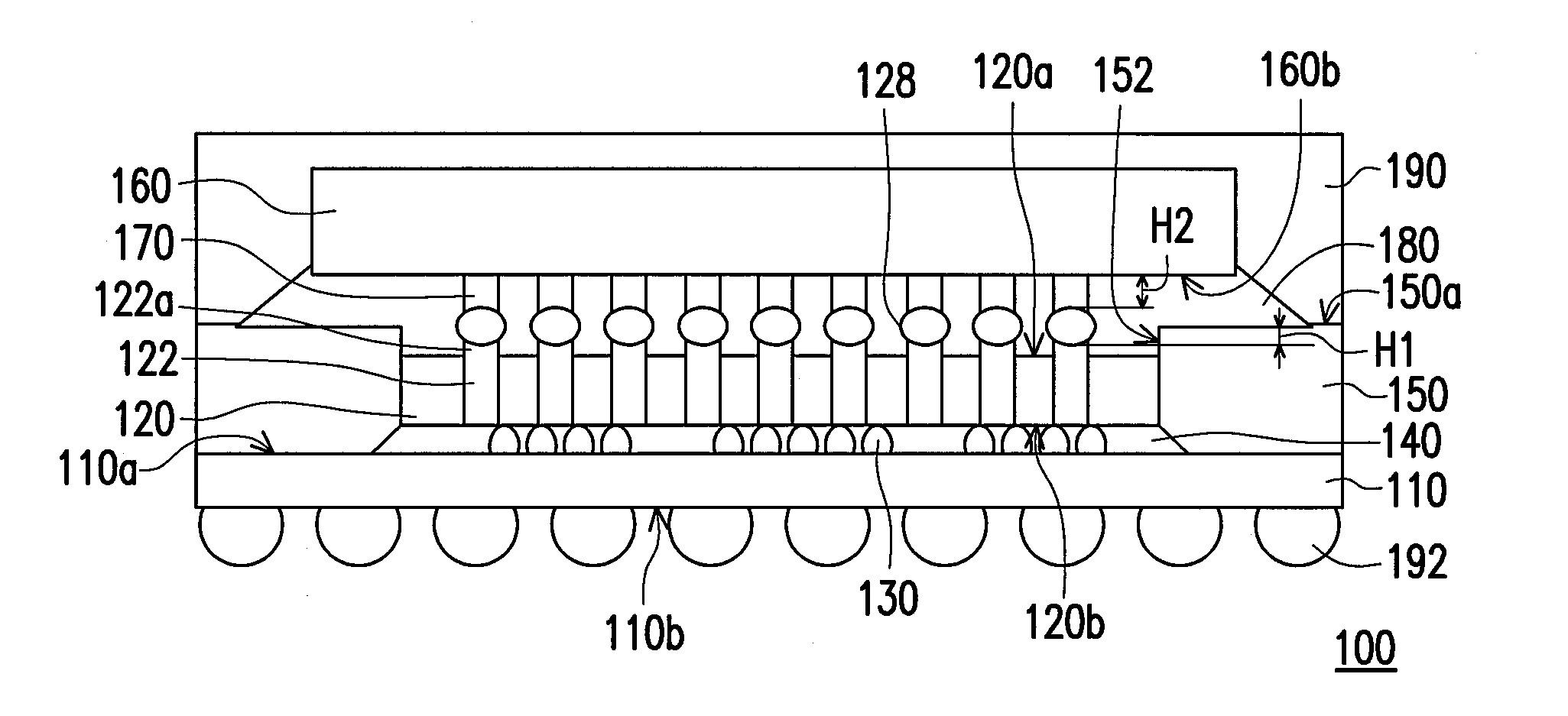

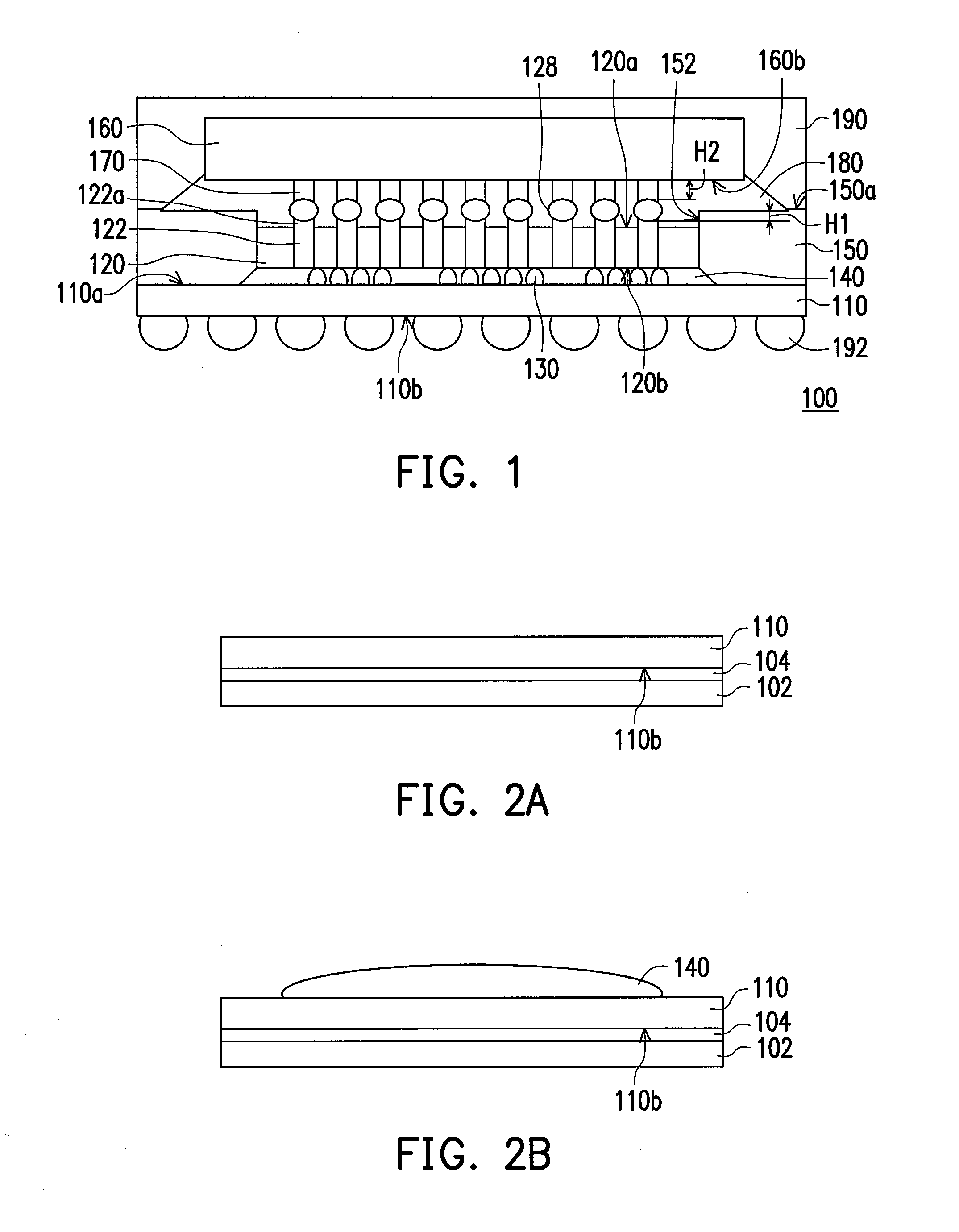

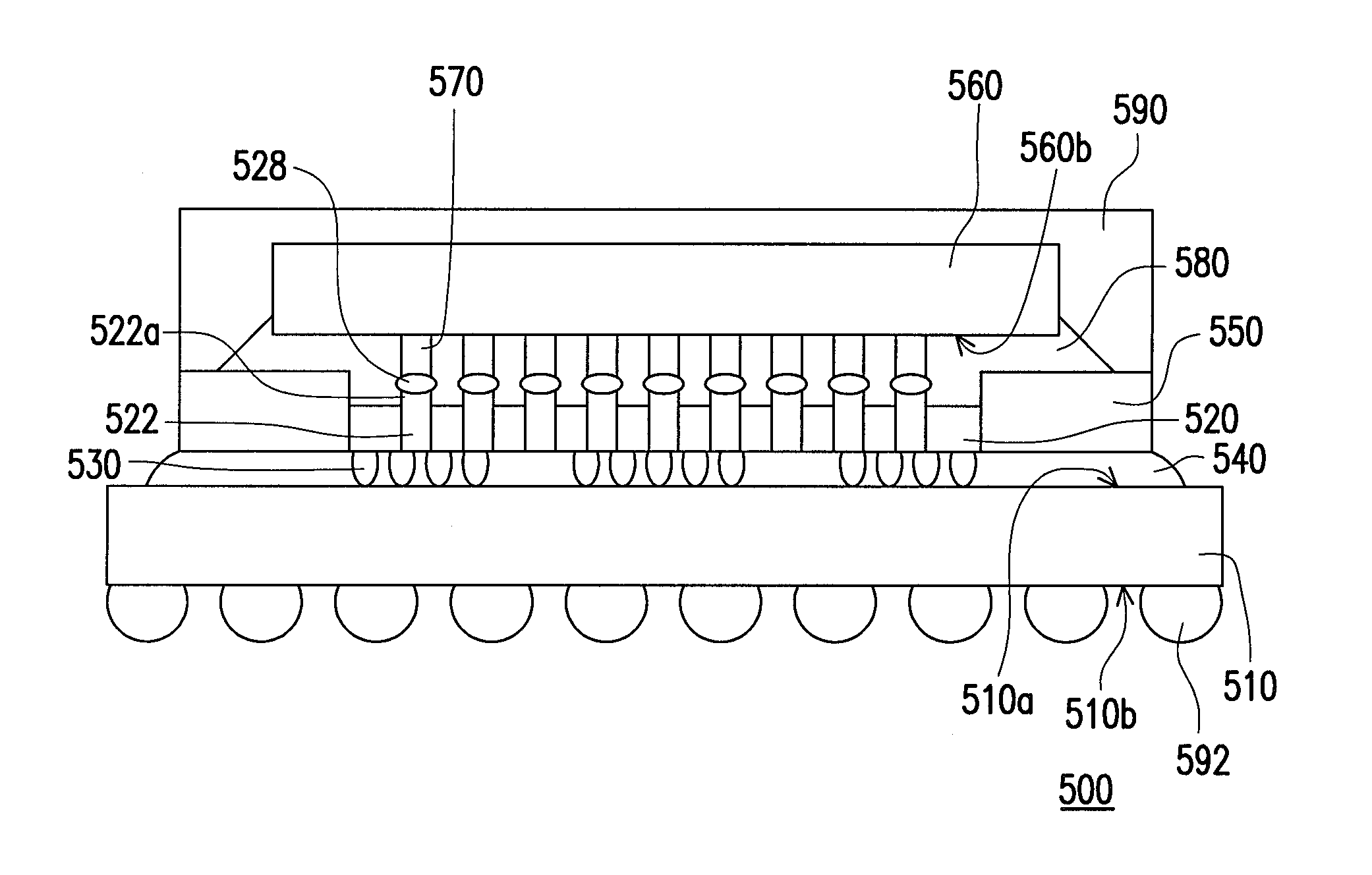

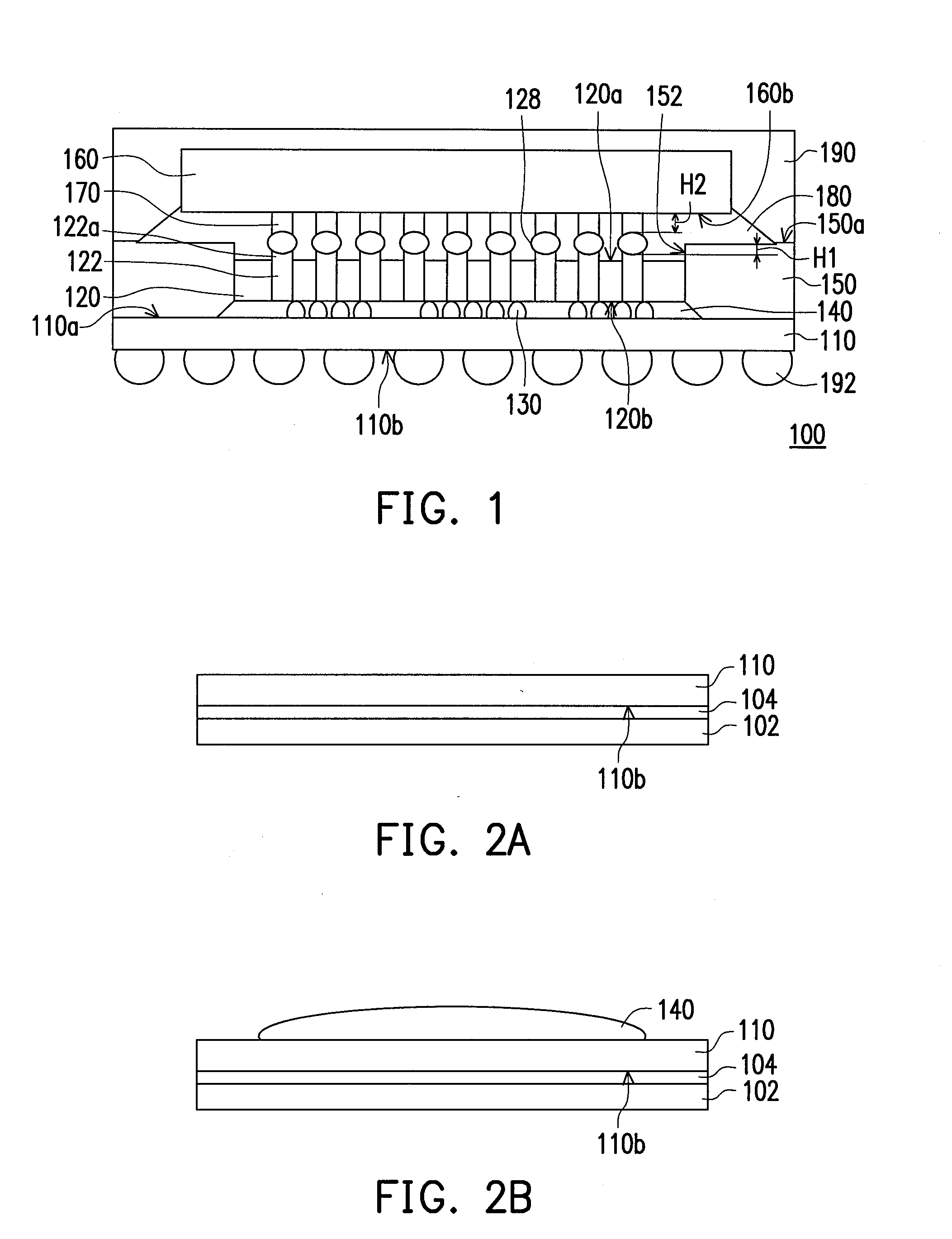

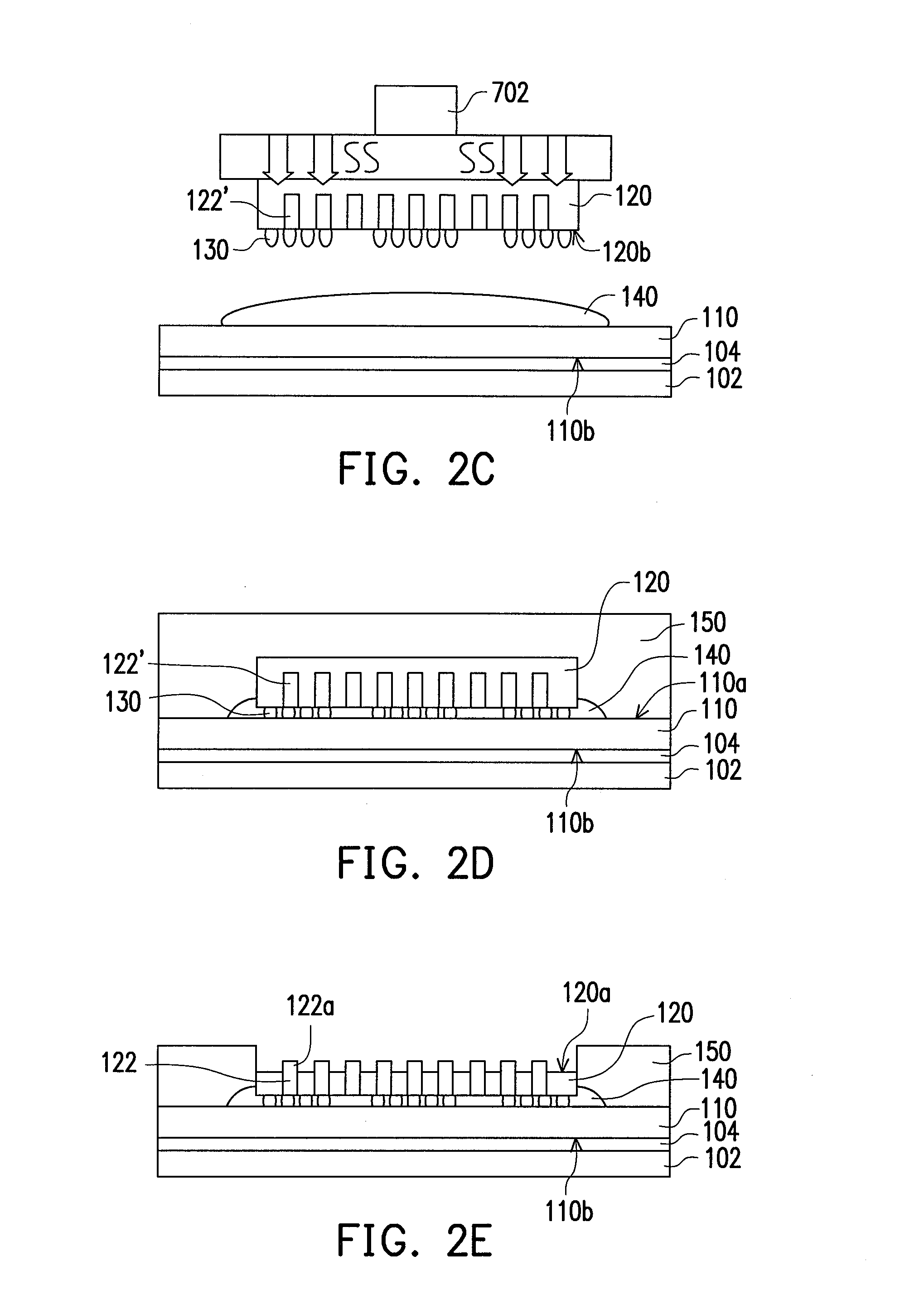

Packaging structure and package process

ActiveUS20110285014A1Improve processing yieldGreat gapSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeight difference

A package structure and a package process are proposed in using pillar bumps to connect an upper second chip and through silicon vias of a lower first chip, wherein a gap between the first chip and the second chip can be controlled by adjusting a height of the pillar bumps. In other words, the pillar bumps compensate the height difference between the first chip and a molding compound surrounding the first chip so as to ensure the bondibility between the pillar bumps and the corresponding through silicon vias and improve the process yield. Furthermore, the pillar bumps maintain the gap between the second chip and the molding compound for allowing an underfill being properly filled into the space between the first chip and the second chip.

Owner:ADVANCED SEMICON ENG INC

Packaging structure

InactiveUS20120205800A1Improve processing yieldGreat gapSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeight difference

A package structure and a package process are proposed in using pillar bumps to connect an upper second chip and through silicon vias of a lower first chip, wherein a gap between the first chip and the second chip can be controlled by adjusting a height of the pillar bumps. In other words, the pillar bumps compensate the height difference between the first chip and a molding compound surrounding the first chip so as to ensure the bondibility between the pillar bumps and the corresponding through silicon vias and improve the process yield. Furthermore, the pillar bumps maintain the gap between the second chip and the molding compound for allowing an underfill being properly filled into the space between the first chip and the second chip.

Owner:ADVANCED SEMICON ENG INC

Shielding device and refrigerator comprising same

ActiveUS20160153693A1Avoid flowMechanism is preventedLighting and heating apparatusCooling fluid circulationDrive shaftEngineering

The disclosure relates to a shielding device for closing a path through which air circulates in a refrigerator and a refrigerator having shielding device. The shielding device includes a forced draft fan cover having a threaded hole formed with a threaded slot; and a drive shaft formed with a thread being screwed with the threaded slot and extended to pass through the threaded hole, where an air duct that allows the air flows from the inside of the forced draft fan cover to the outside is provided between the drive shaft and the forced draft fan cover.

Owner:HAIER ASIA INT CO LTD +1

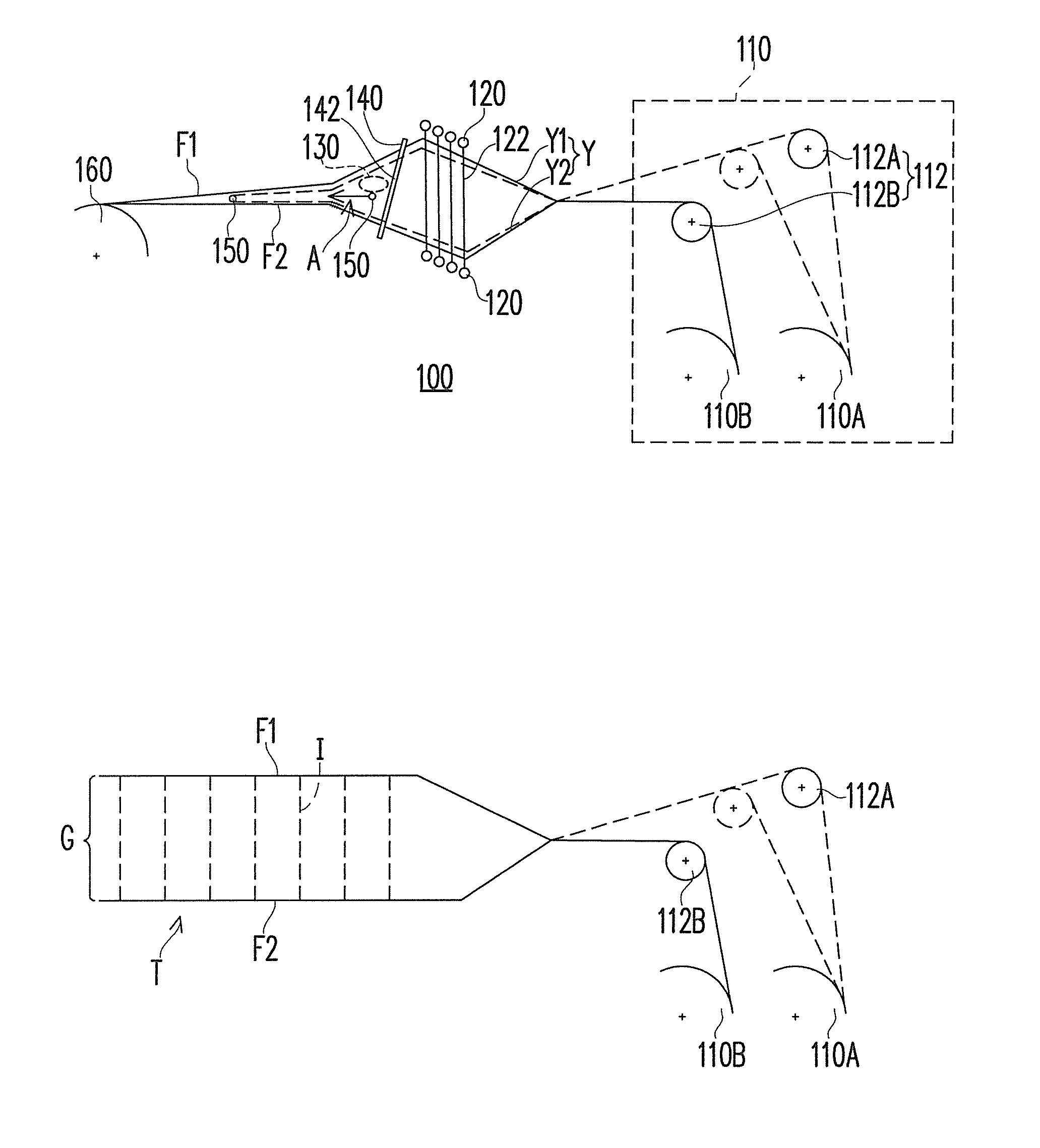

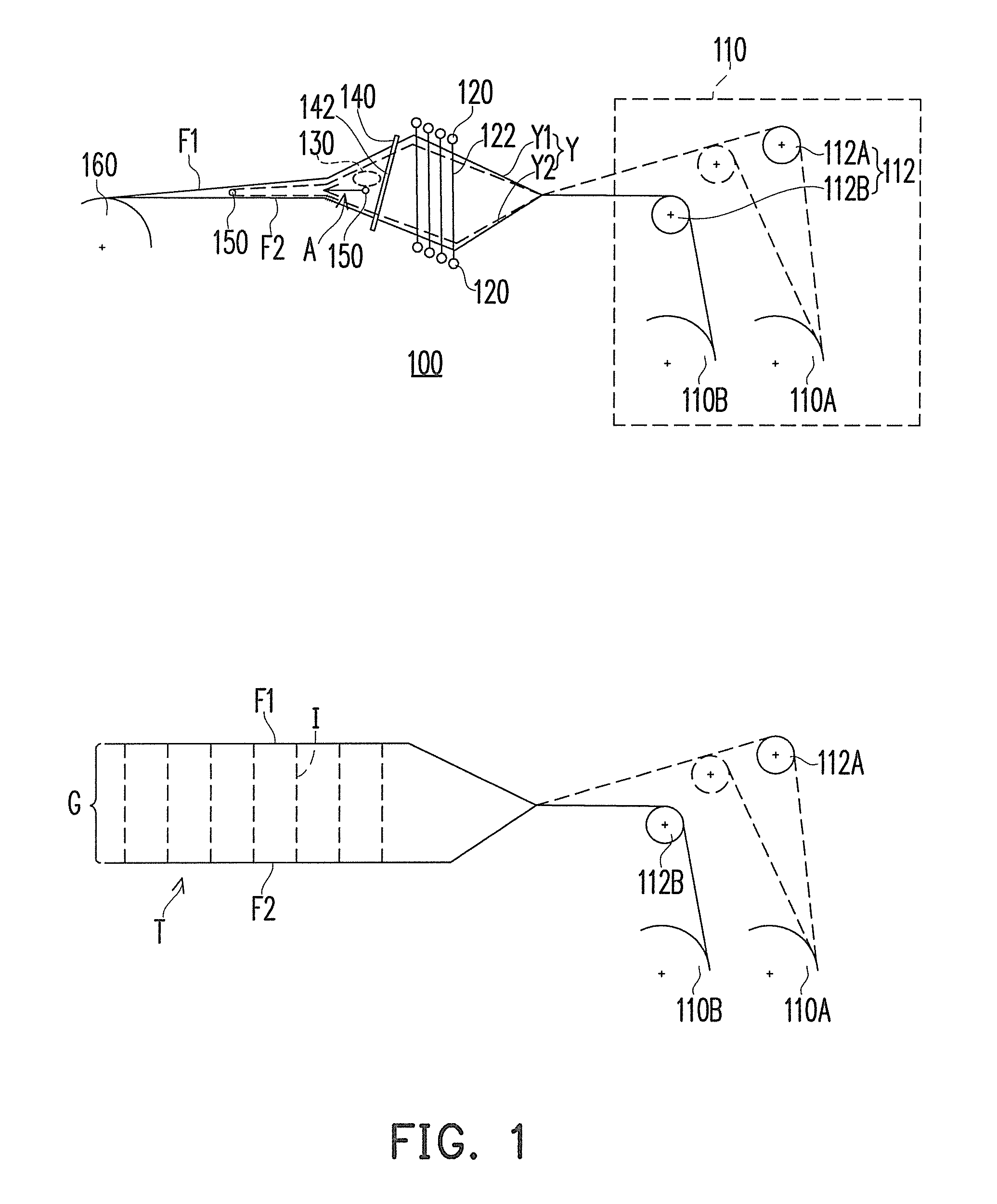

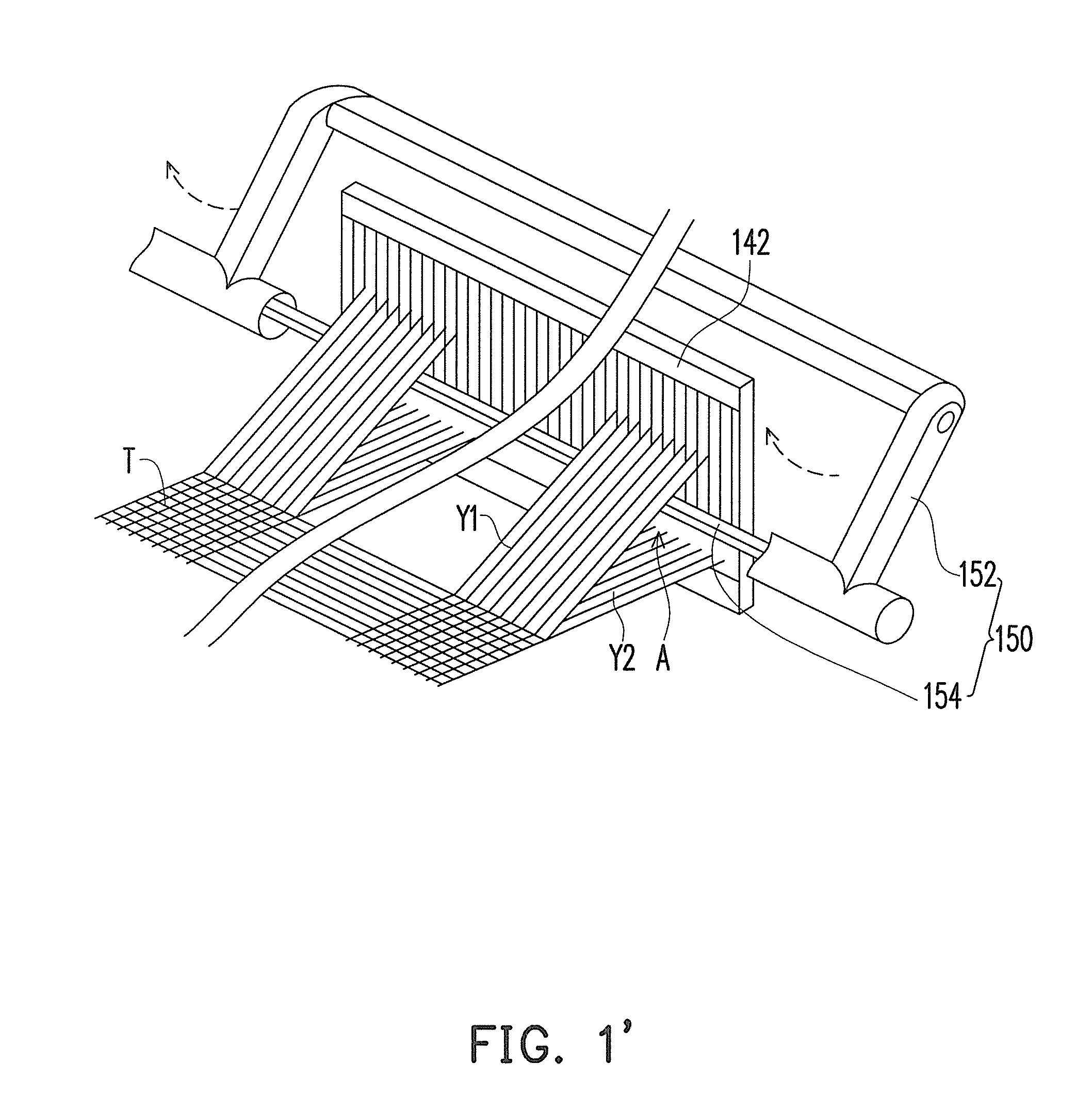

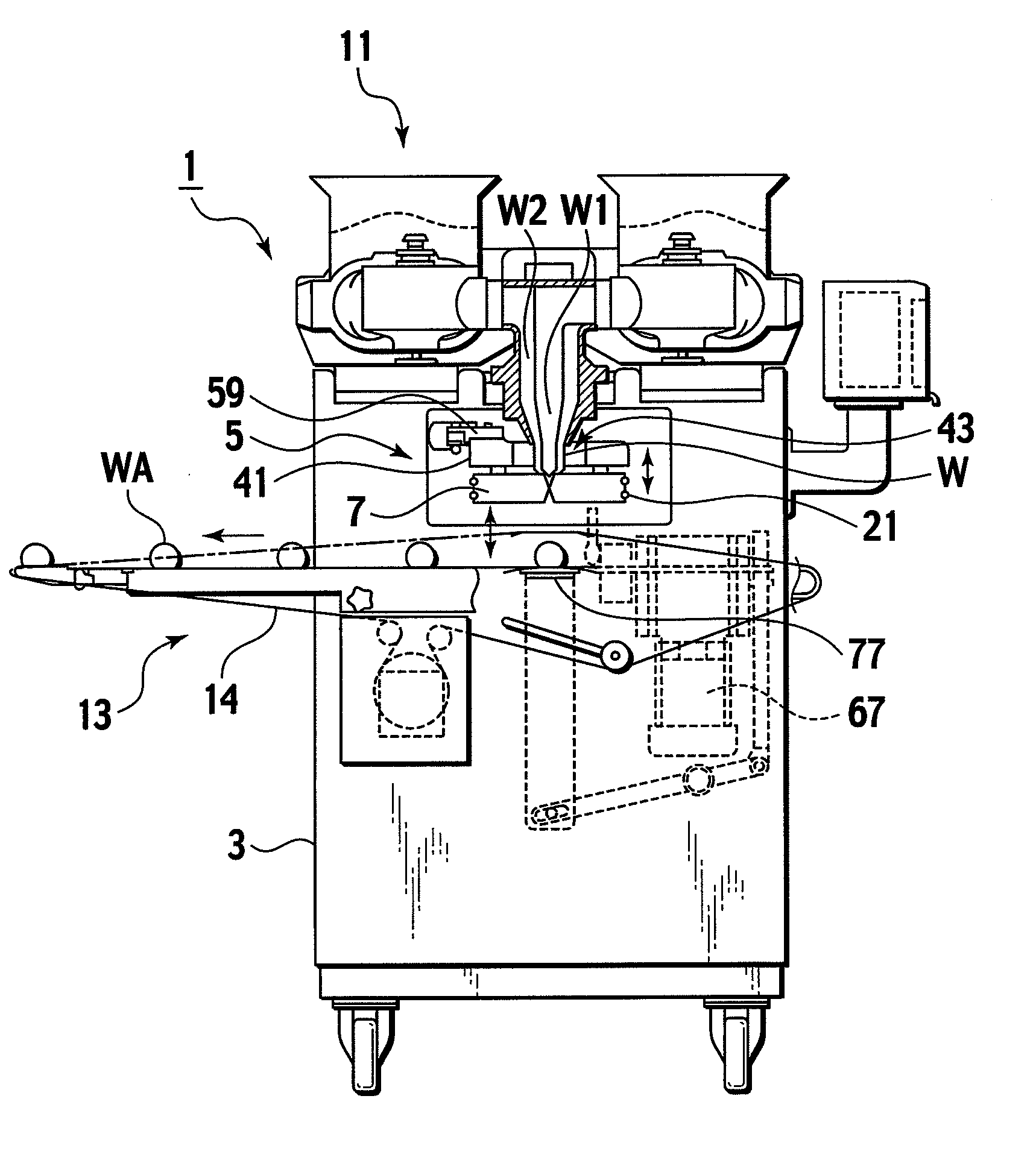

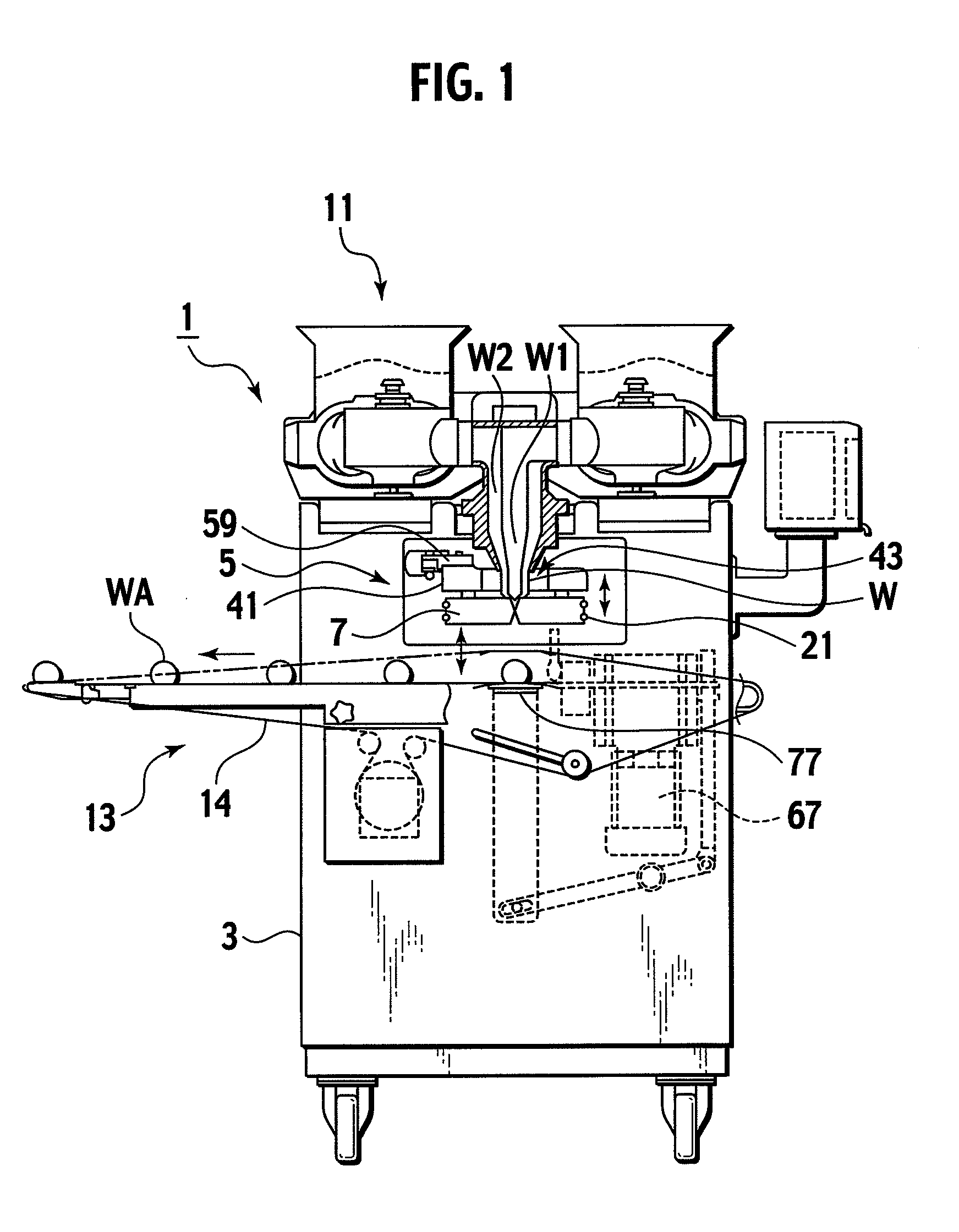

Weaving machines and three-dimensional woven fabrics

ActiveUS8015999B2Increasing costGreat gapOrnamental textile articlesPile-fabric loomsYarnEngineering

A weaving machine for weaving a three-dimensional distance woven fabric including two outer fabrics and inter-yarns connected with the outer fabrics is provided. The weaving machine includes a warp let-off mechanism, heald frames, a picking mechanism, a beating-up mechanism, a yarn raising mechanism, and a take-up mechanism. The warp let-off mechanism includes at least two warp beams for providing and transferring warps. A plurality of vertically arranged heald wires are supported by each of the heald frames, wherein each of the heald wires has a heald eye for the warps passing through. The warps are driven and divided into two warp layers by the heald frames such that a shed is formed between the two warp layers. The picking mechanism transfers wefts to pass through the shed. The yarn raising mechanism is suitable for passing through the shed and raising parts of the warps functioning as the inter-yarns.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

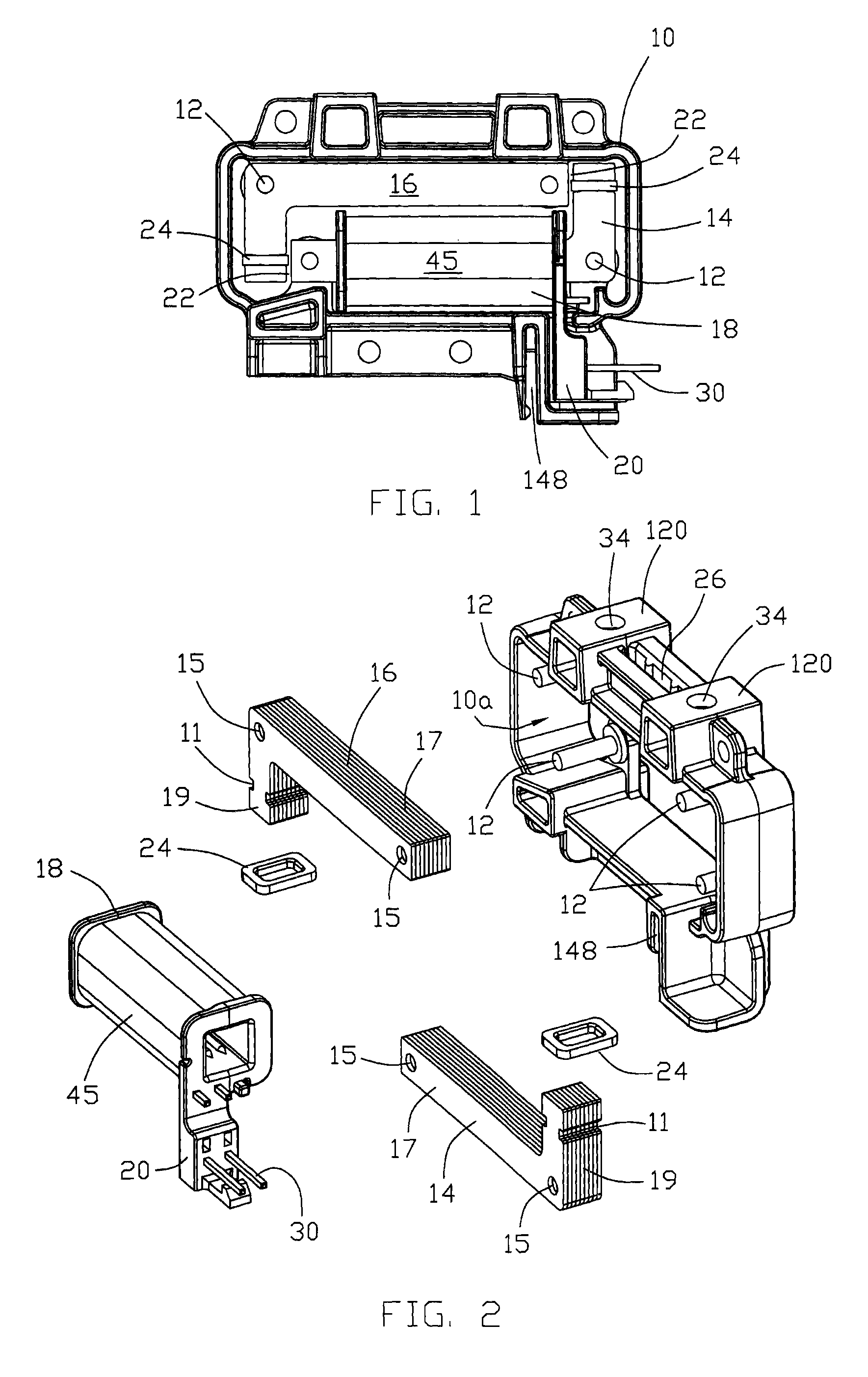

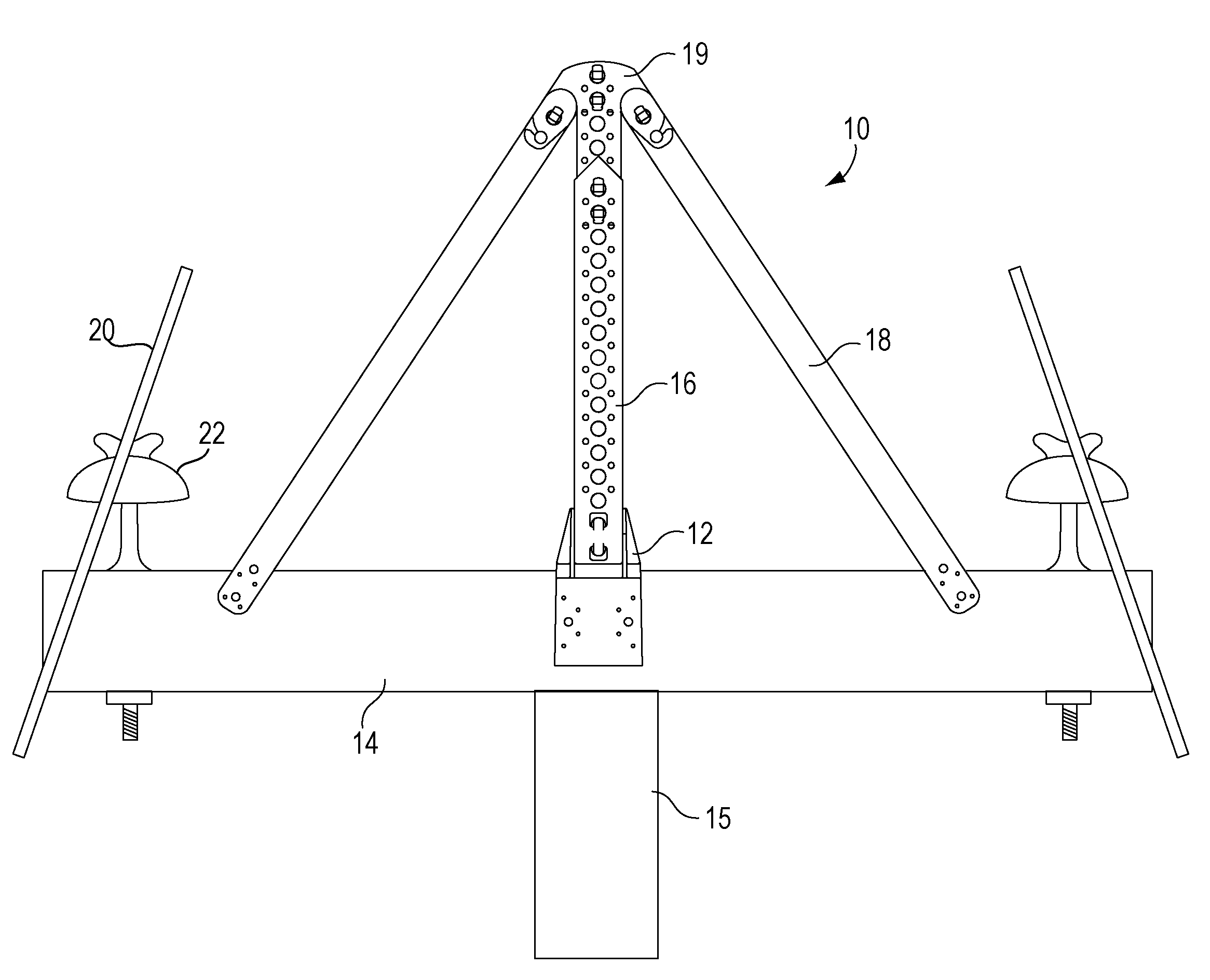

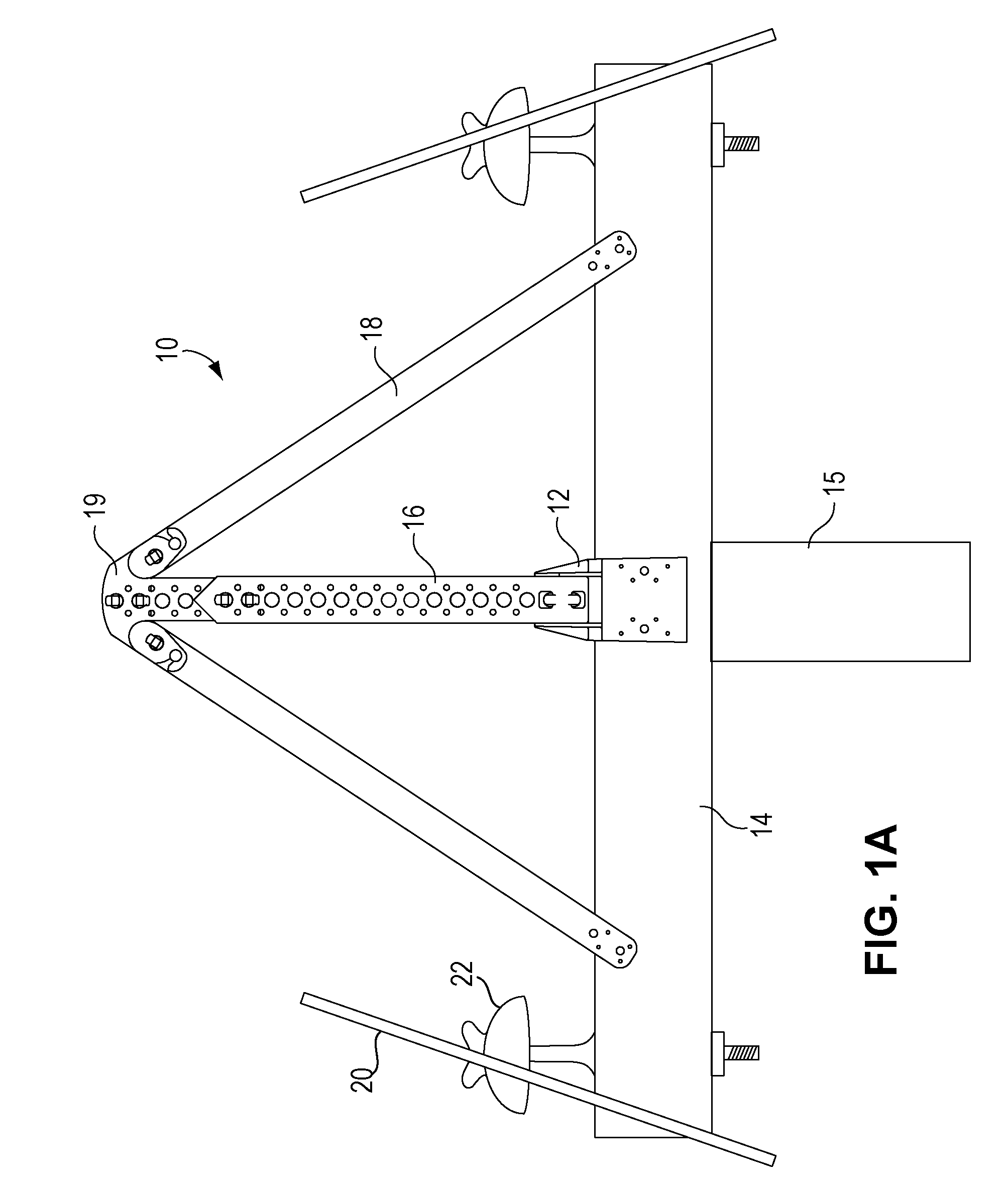

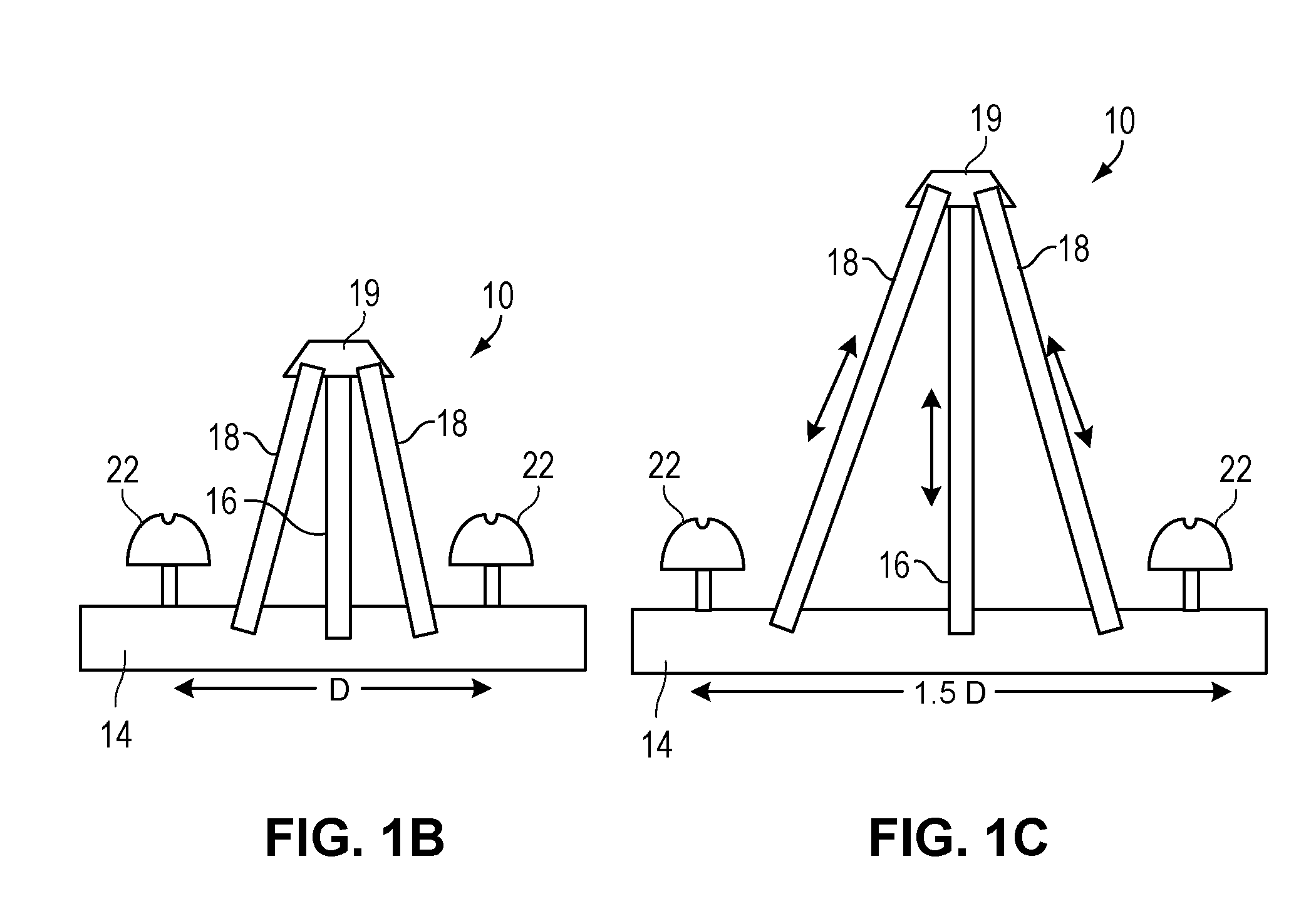

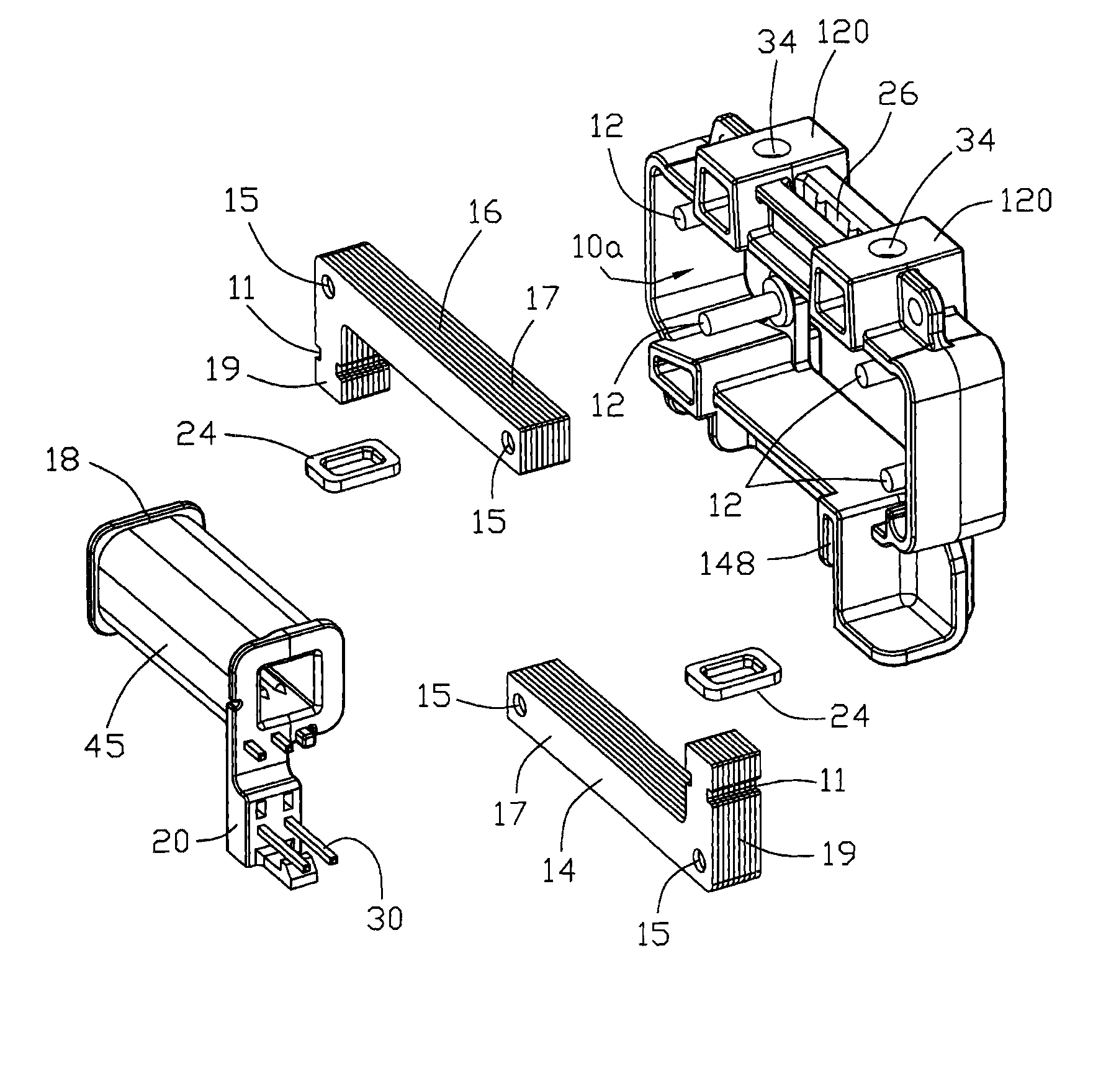

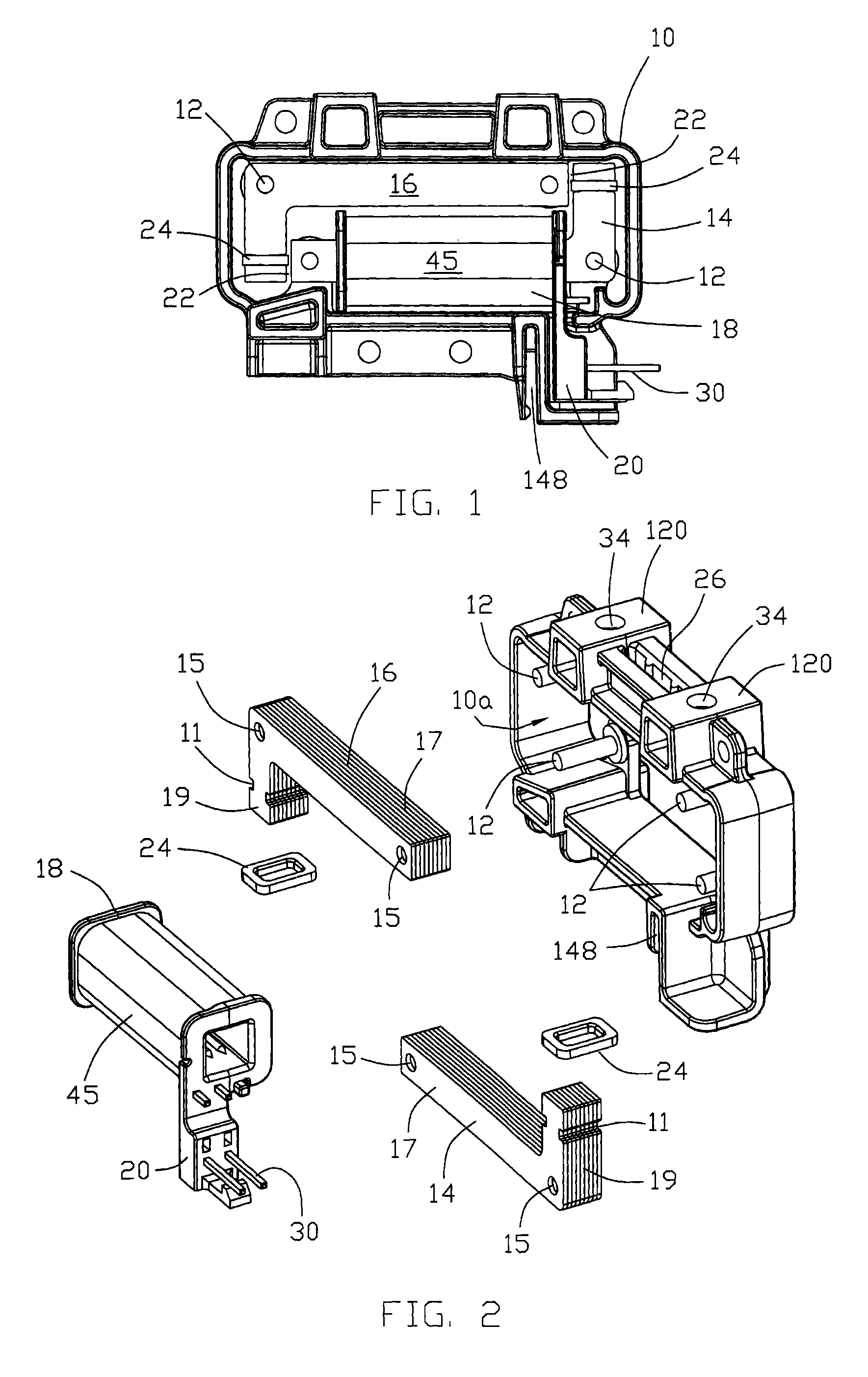

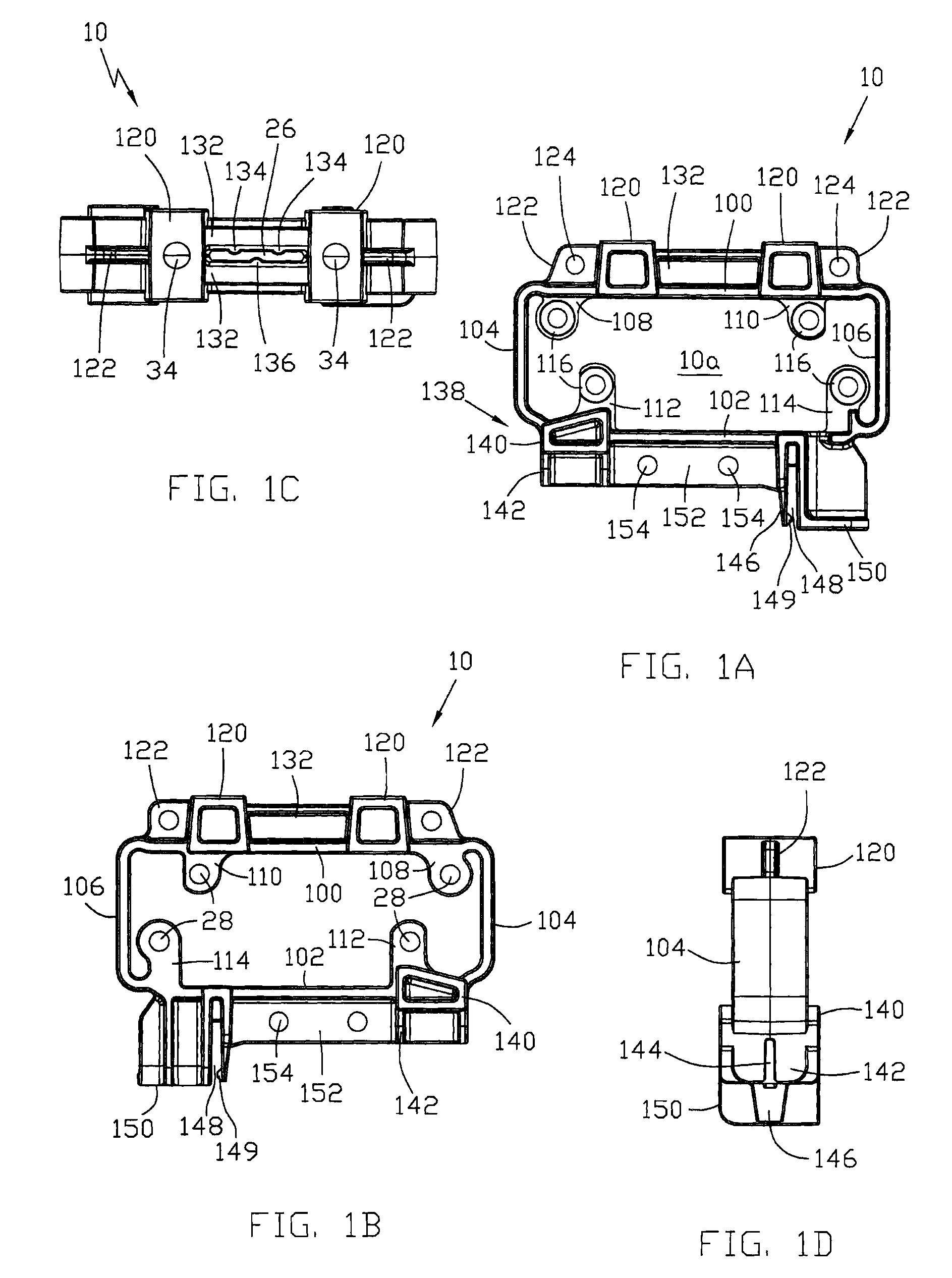

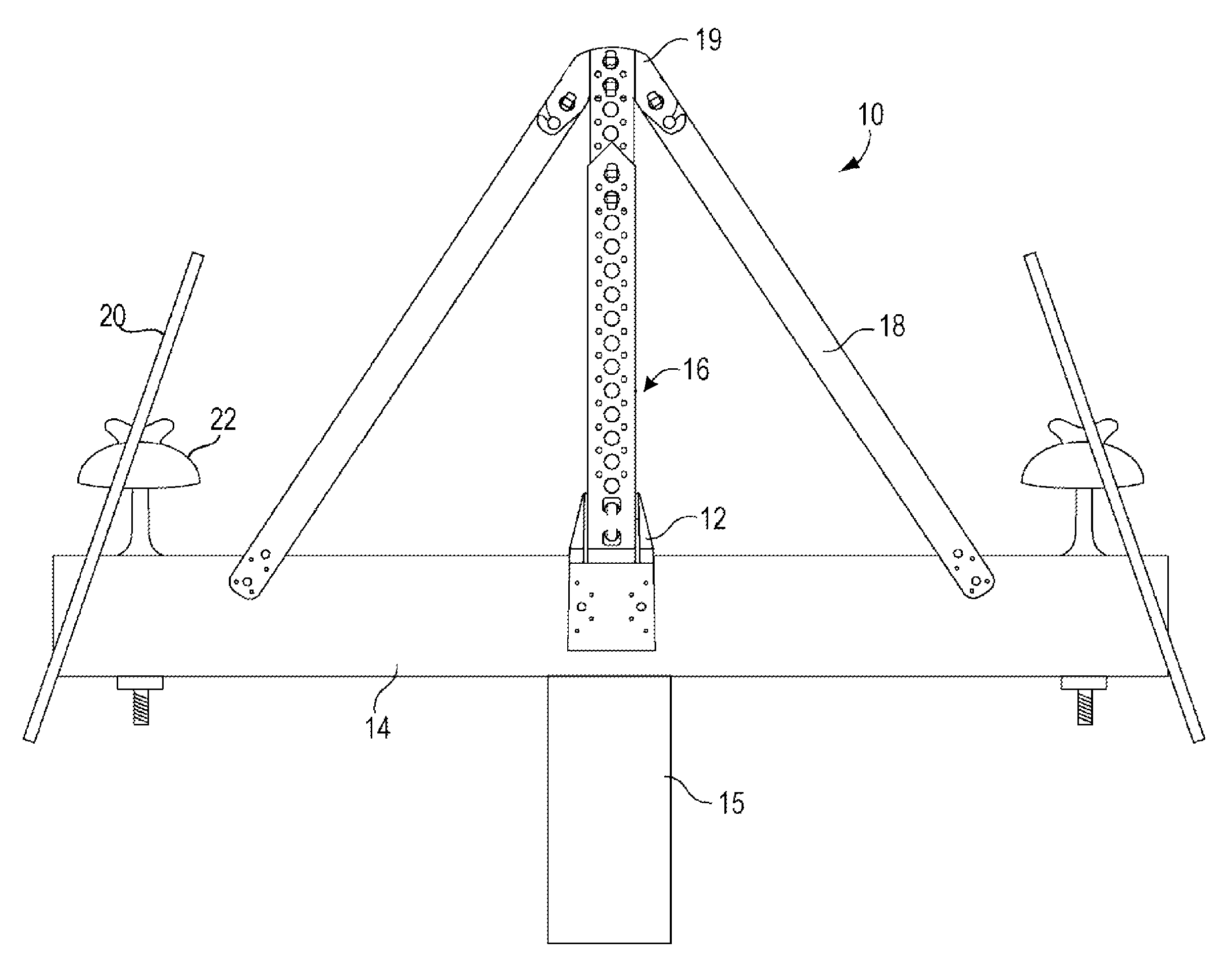

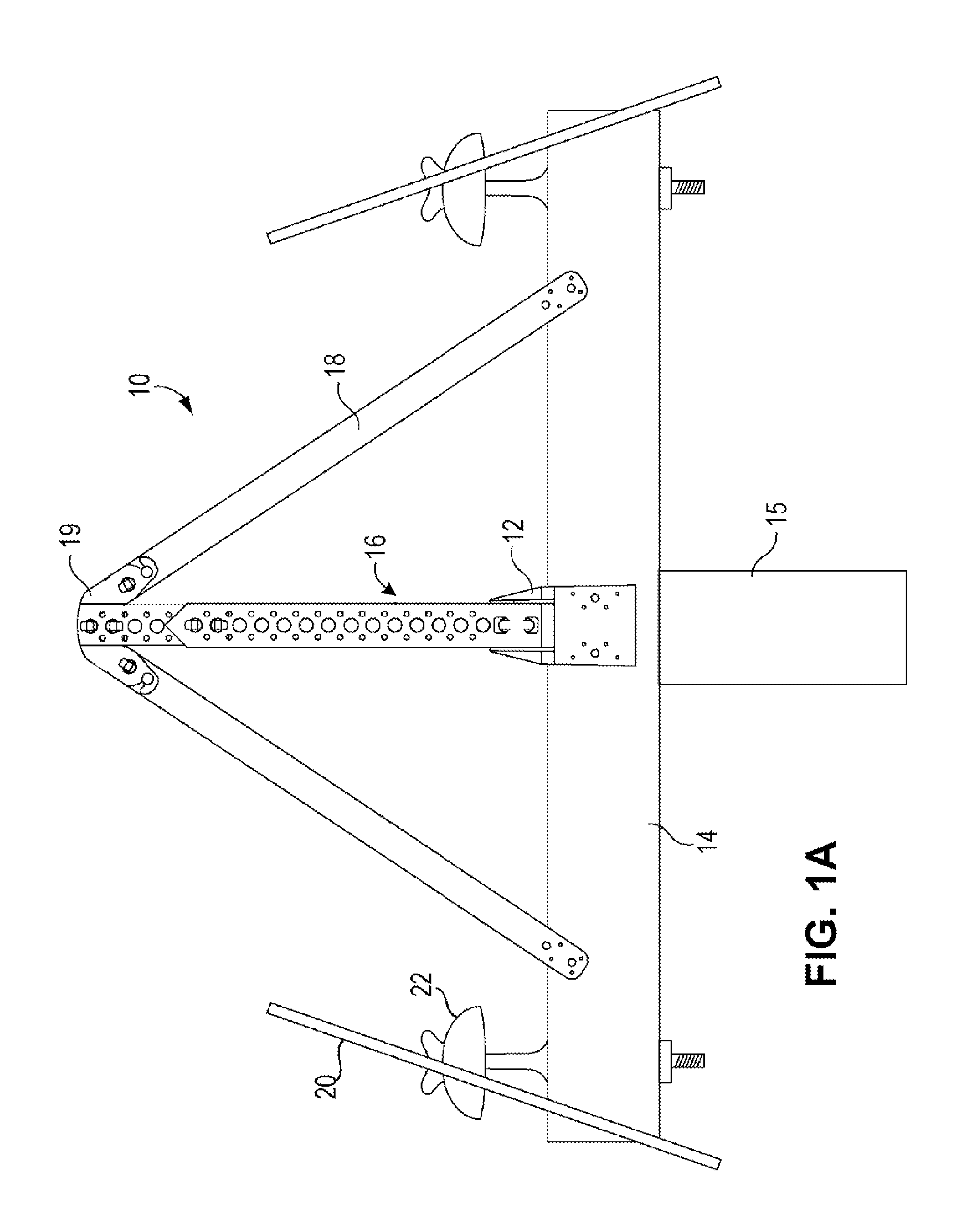

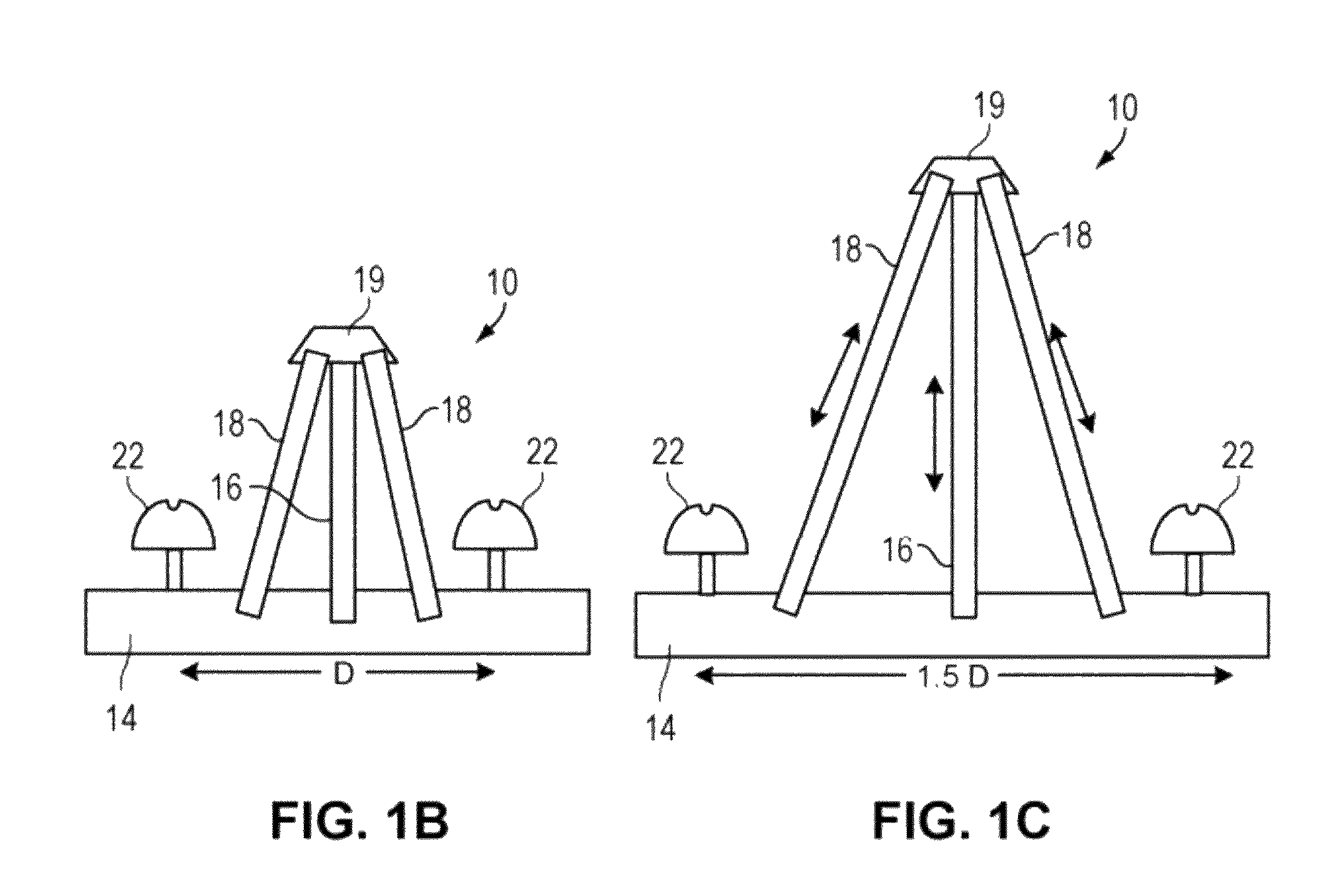

Wildlife Deterrent for High Voltage Supporting Members

A wildlife deterrent for a utility support structure member between two conductors includes a bracket for attachment to the supporting member, a center support piece with a variable height arm connector, and two adjustable arms pivotally attached to the arm connector. No tools are required for the adjustments or attachments. Since the effective lengths of the support and arms are adjustable, either by elongation or using different length parts, the same angle of the arms can be achieved no matter what the separation between the conductors, and the gap between the arms and the conductor can be optimal for both deterrence and flashover prevention. The different pieces forming the deterrent can be selected by the lineman to quickly build an optimal deterrent in the field.

Owner:ECO ELECTRICAL SYST

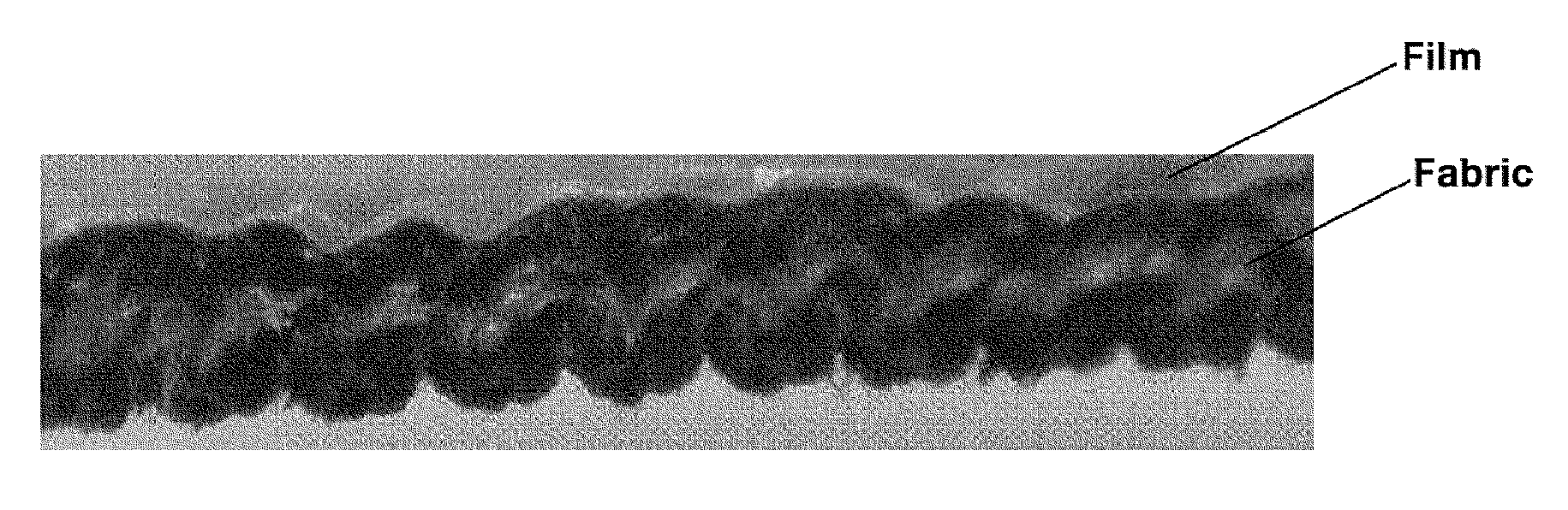

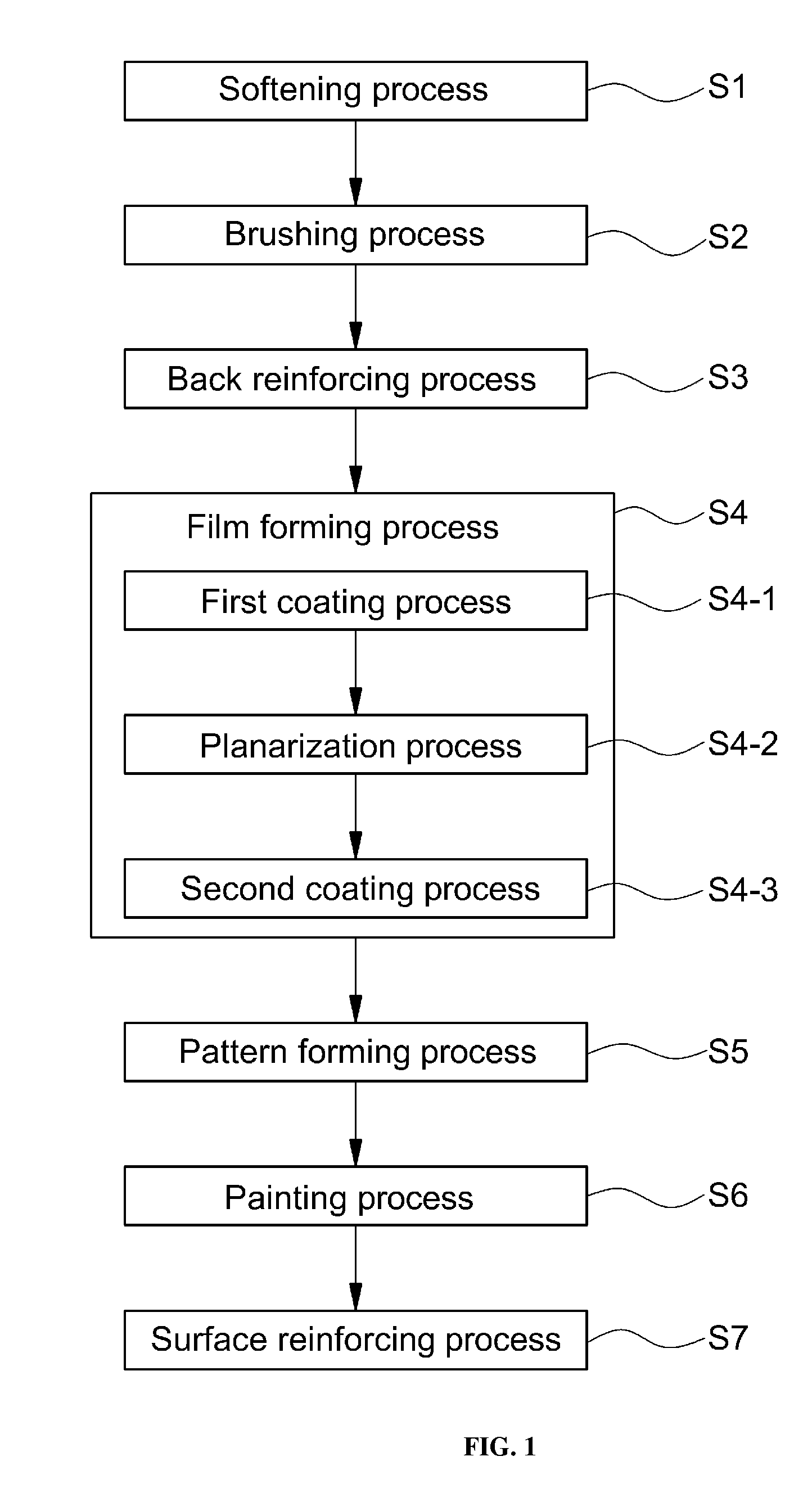

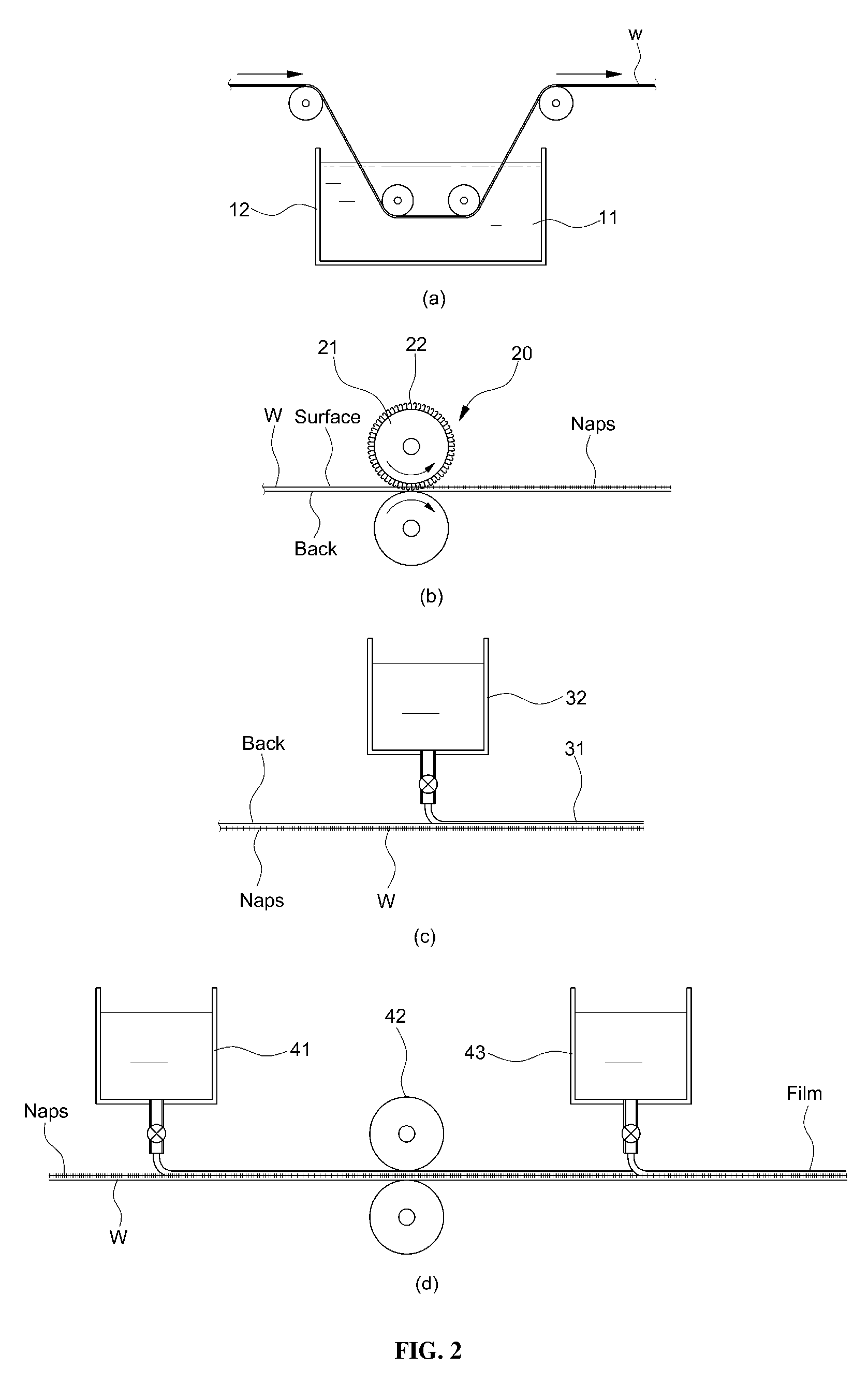

Method for producing synthetic leather having air permeability

ActiveUS20120308726A1Good chemical resistanceImprove hydrolysis resistancePattern makingFibre treatmentEngineeringWater soluble

Disclosed is a synthetic leather produced by directly coating a water-soluble synthetic resin solution on the surface of a fabric to form a film thereon such that fine gaps formed on the fabric are partially left open to have a certain degree of air permeability. In particular, a brushing process is used for brushing the surface of a fabric using a brushing machine to raise a nap. Next, a hydrolysis-resistant and flame-retardant resin solution is coated on the back of the fabric, which is opposite to the surface on which the nap is raised, to reinforce the back of the fabric. A film forming process then applies a water-soluble polyurethane resin solution to the nap raised on the surface of the fabric to form a film on the surface of the fabric thereby producing a synthetic leather product that has air permeability properties that are superior to genuine leather.

Owner:HYUNDAI MOTOR CO LTD +2

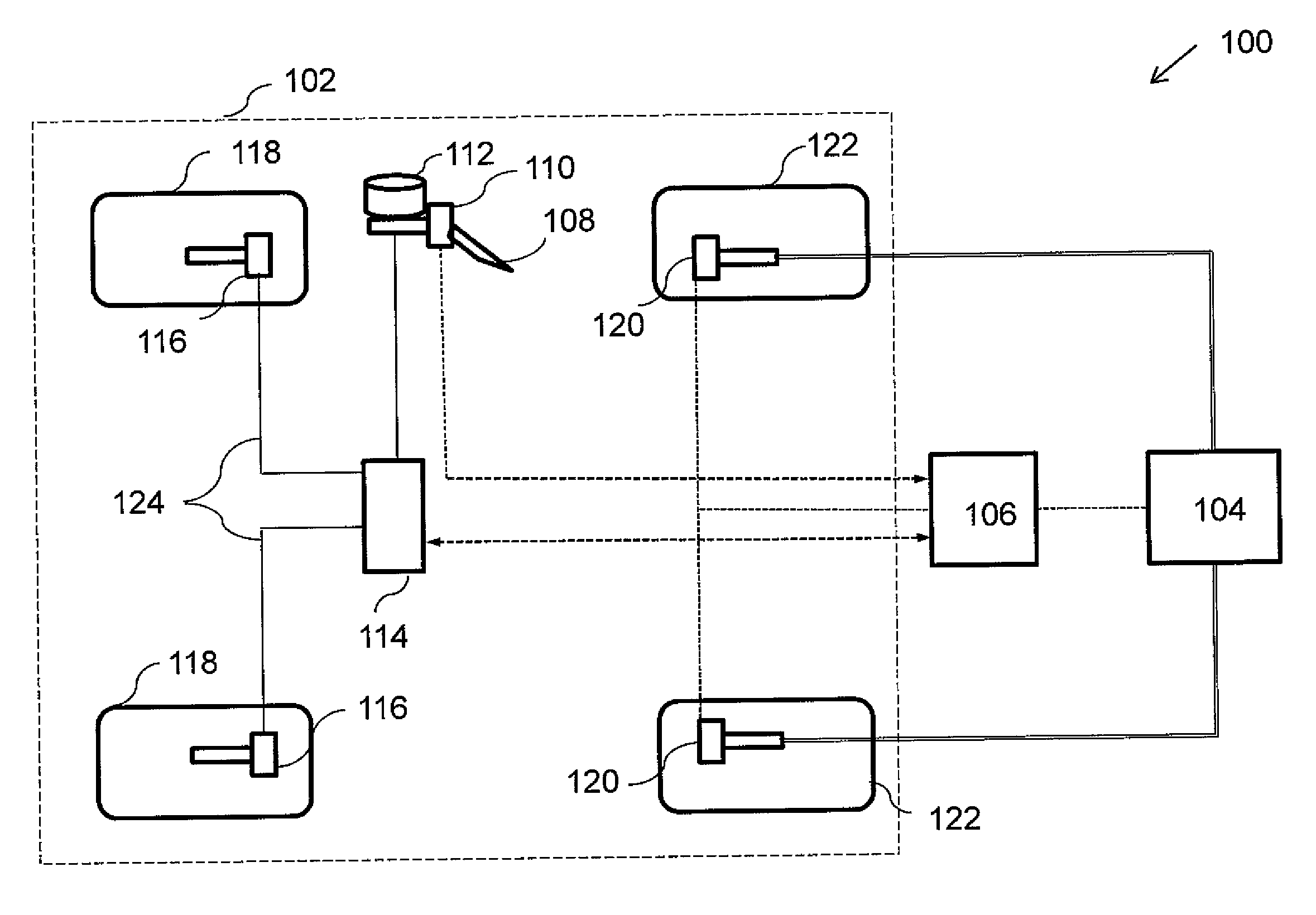

Regenerative braking system for a hybrid electric vehicle and a corresponding method

ActiveUS9266511B2Increased braking torqueDecreased or limited rear wheel braking torqueHybrid vehiclesSpeed controllerElectricityBrake torque

A method and system for controlling regenerative braking of a hybrid electric vehicle. The regenerative braking system includes a driver-operable brake pedal, a hydraulically actuated friction brake for at least one front wheel, an anti-lock braking system hydraulically connected to the hydraulically actuated friction brake, and an electrically actuated friction brake for at least one rear wheel. The regenerative braking system further includes an electric machine connected to the at least one rear wheel and capable of performing regenerative braking of the at least one rear wheel, and an electronic control unit that controls the stability of the hybrid electric vehicle. The regenerative braking system is configured to provide increased braking torque of the front hydraulically actuated friction brake by means of the anti-lock braking system for compensating a decreased or limited rear wheel braking torque initiated by the electronic control unit.

Owner:VOLVO CAR CORP

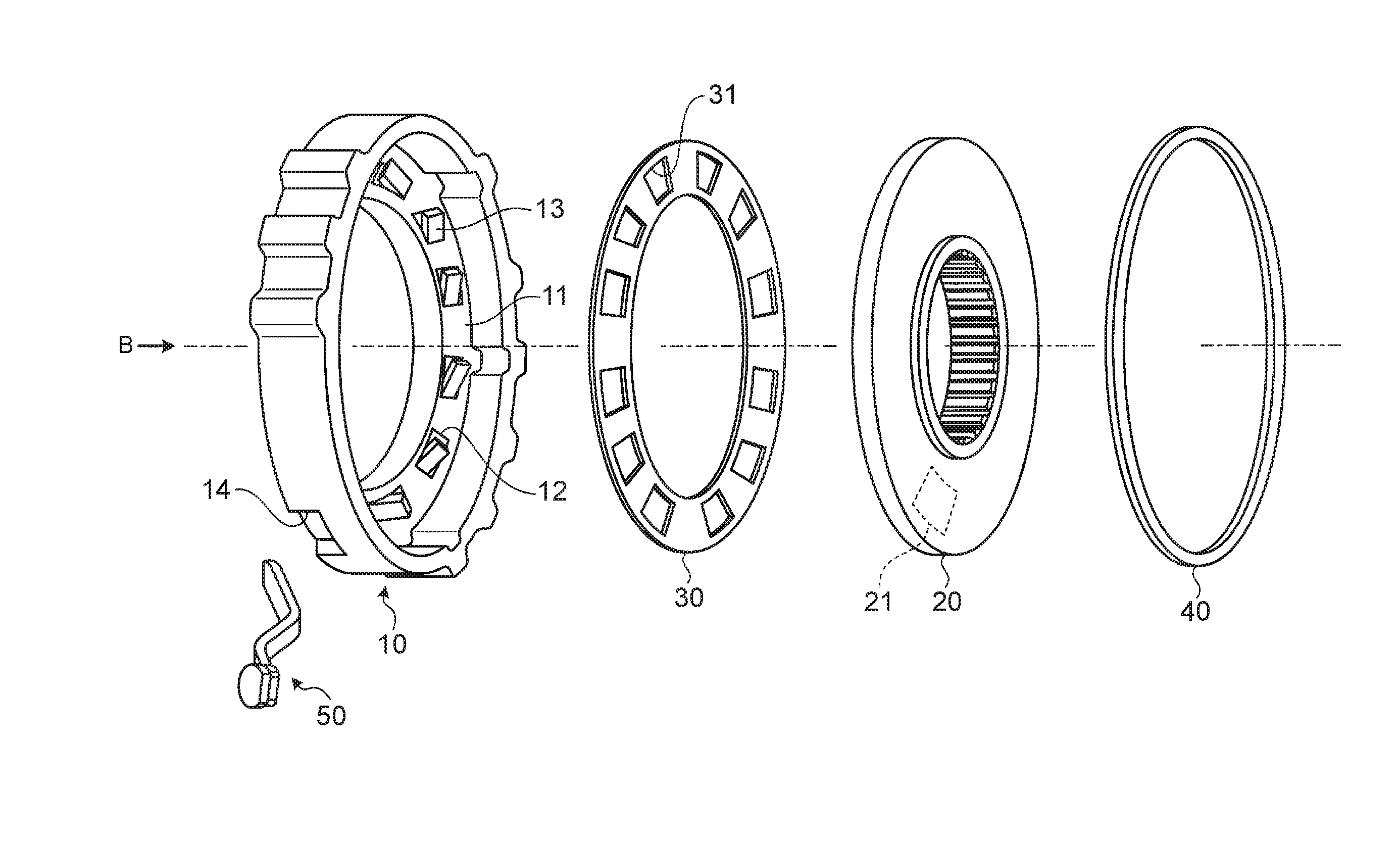

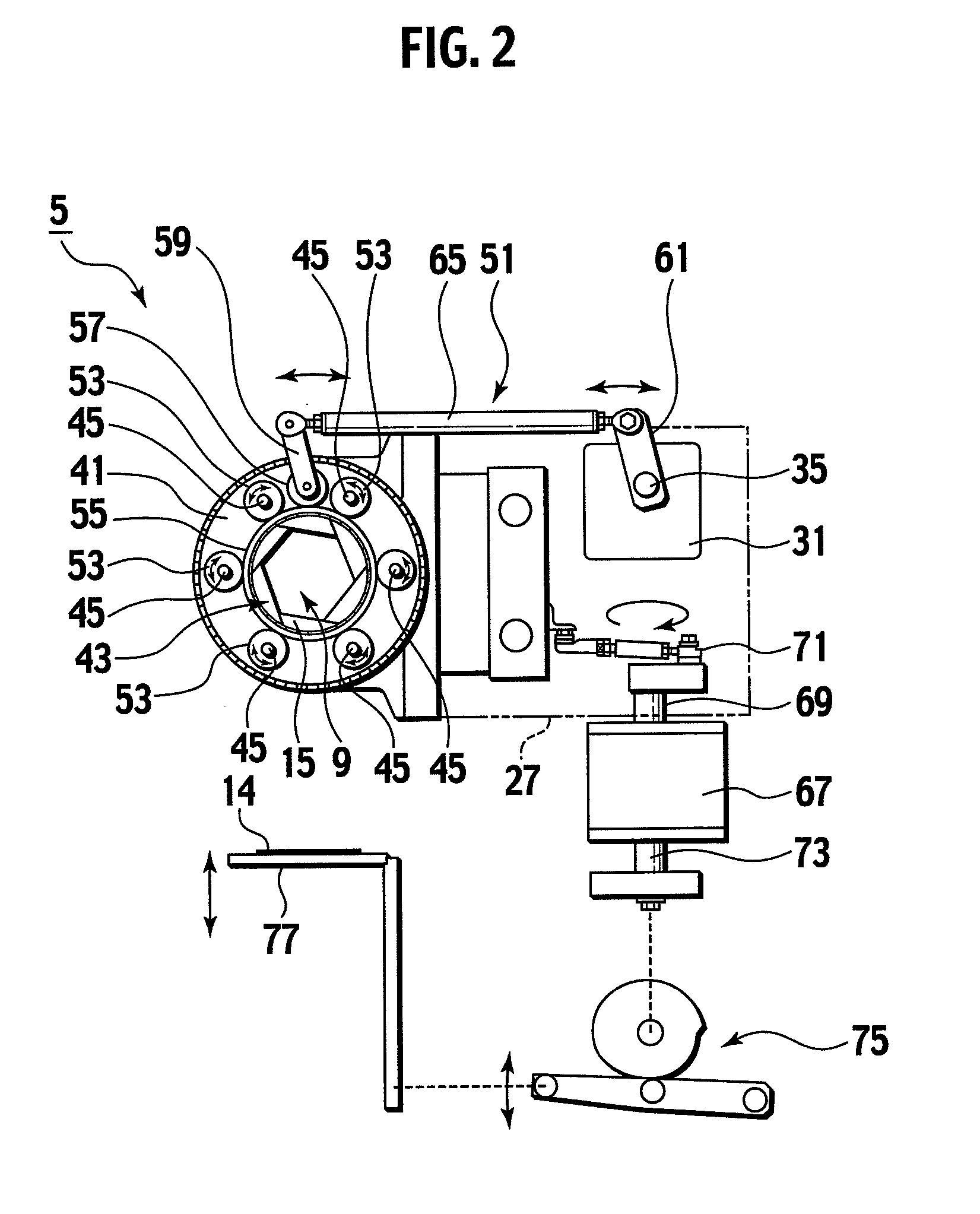

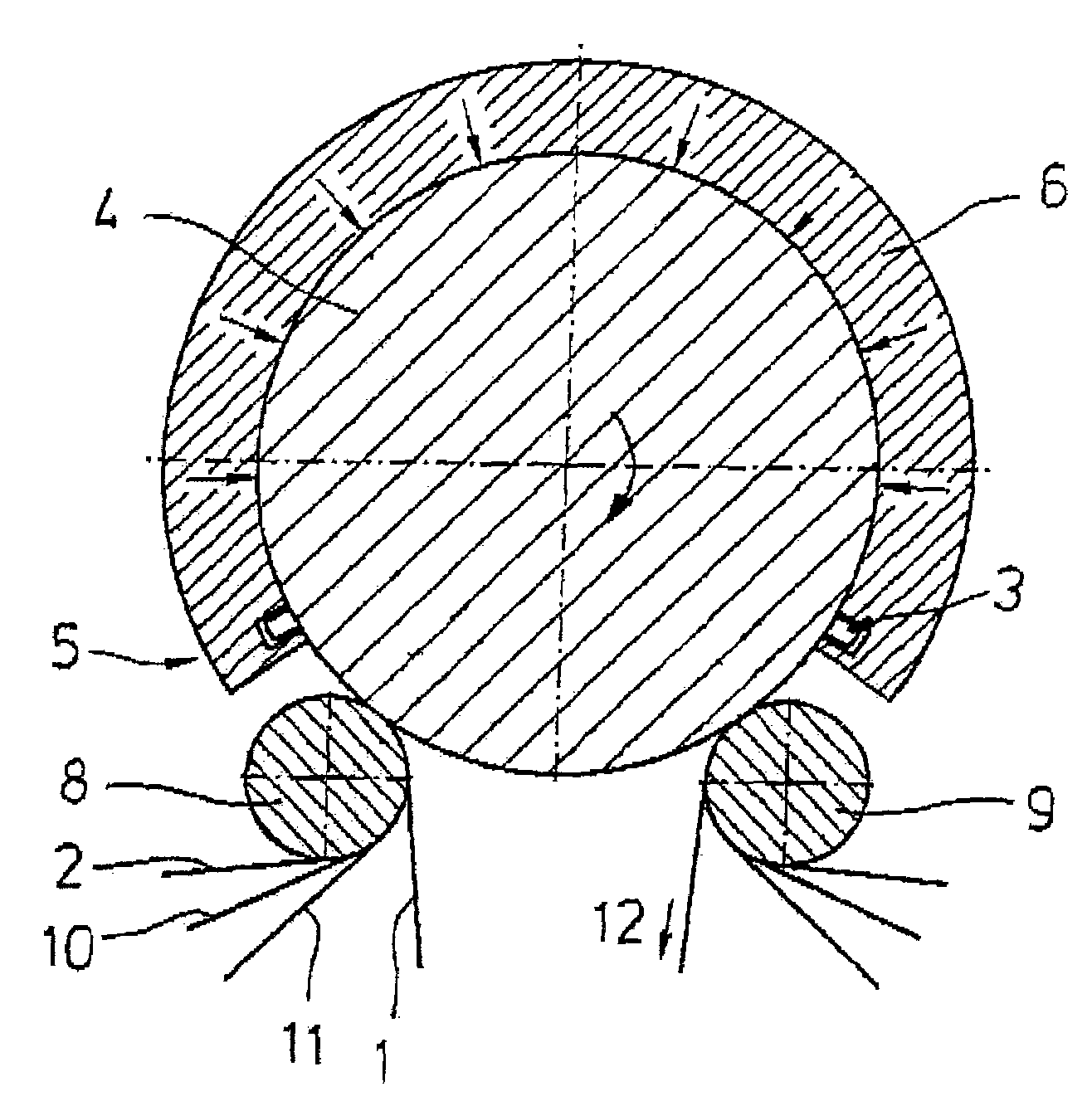

Shape-forming shutter apparatus and shutter piece thereof

Disclosed is an shape-forming shutter apparatus including a plurality of shutter pieces, each having an shaping surface and a sliding surface, which are arranged in a circle with the shaping surface of each shutter piece being slidably in sliding contact with the sliding surface of the neighboring separate shutter piece, and the shape-forming shutter apparatus being capable of dilating and contracting an opening part surrounded by the shaping surfaces respectively of the plurality of shutter pieces. The shape-forming shutter apparatus includes pressure contact biasing means for always keeping the shaping surface of each shutter piece and the sliding surface of the neighboring shutter piece slidably in pressure contact with each other. The pressure contact biasing means is a ring-shaped elastic member for biasing the shutter pieces equally in such a direction to close the opening part. The elastic member is stretchingly wound around the shutter pieces in an end of each shutter piece, which end is separate away from the other end thereof where the shaping surface of the shutter piece and the sliding surface of the neighboring shutter piece intersect each other.

Owner:RHEON AUTOMATIC MASCH CO LTD

Haptic solenoid system

ActiveUS8072317B2Low costEasy to operateWindingsFrequency-division multiplex detailsSolenoid valveEngineering

Owner:JOHNSON ELECTRIC SA

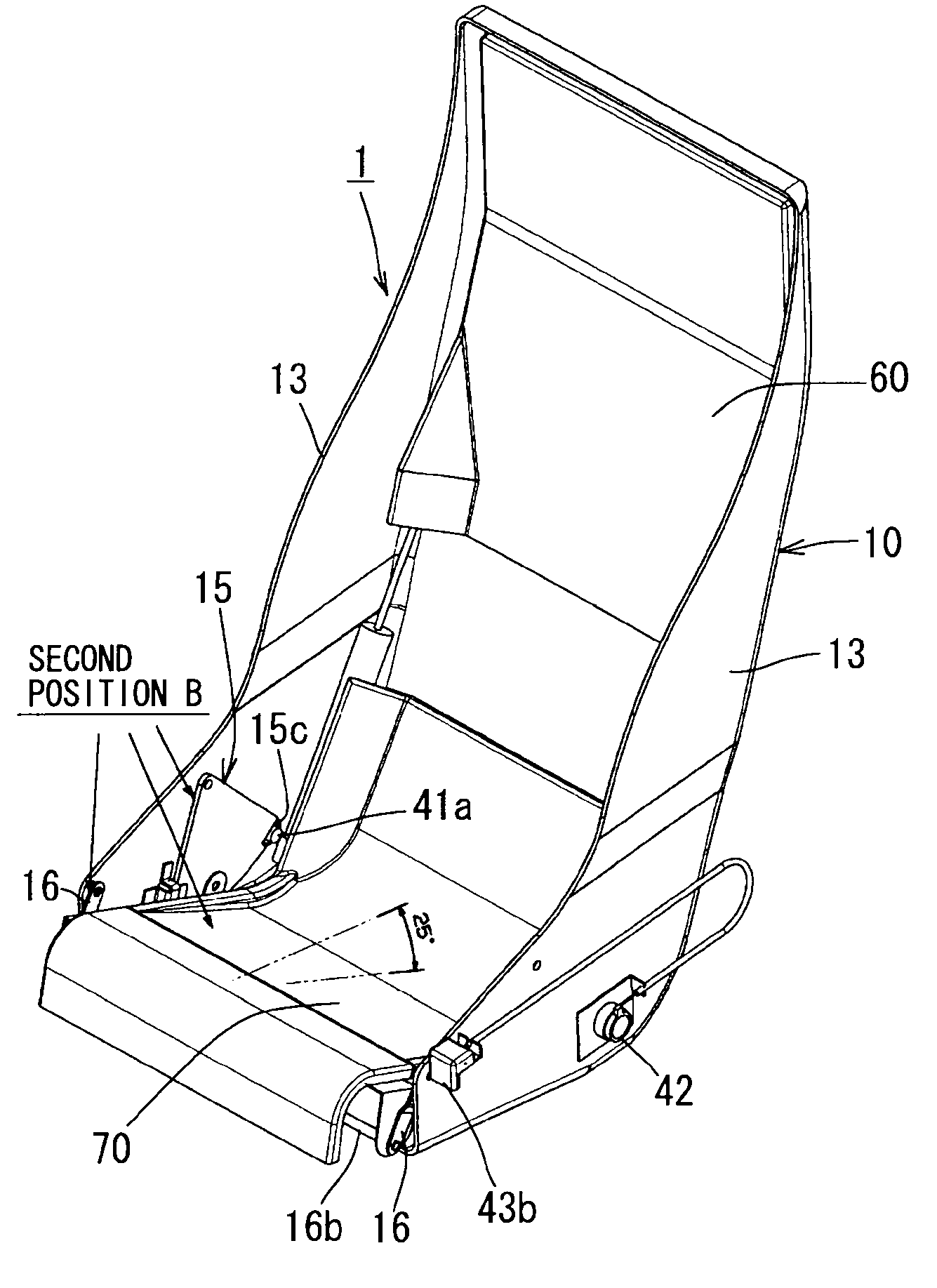

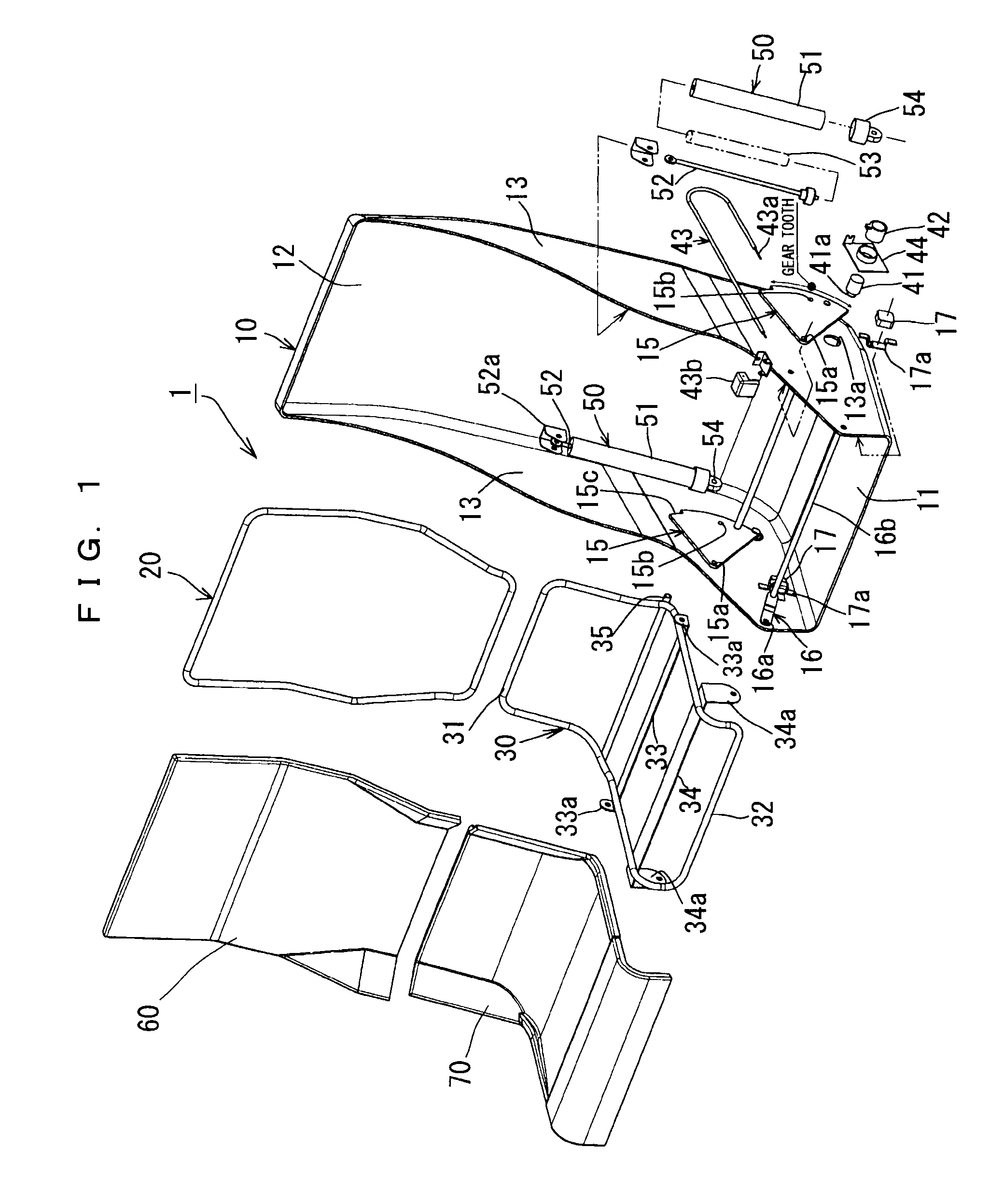

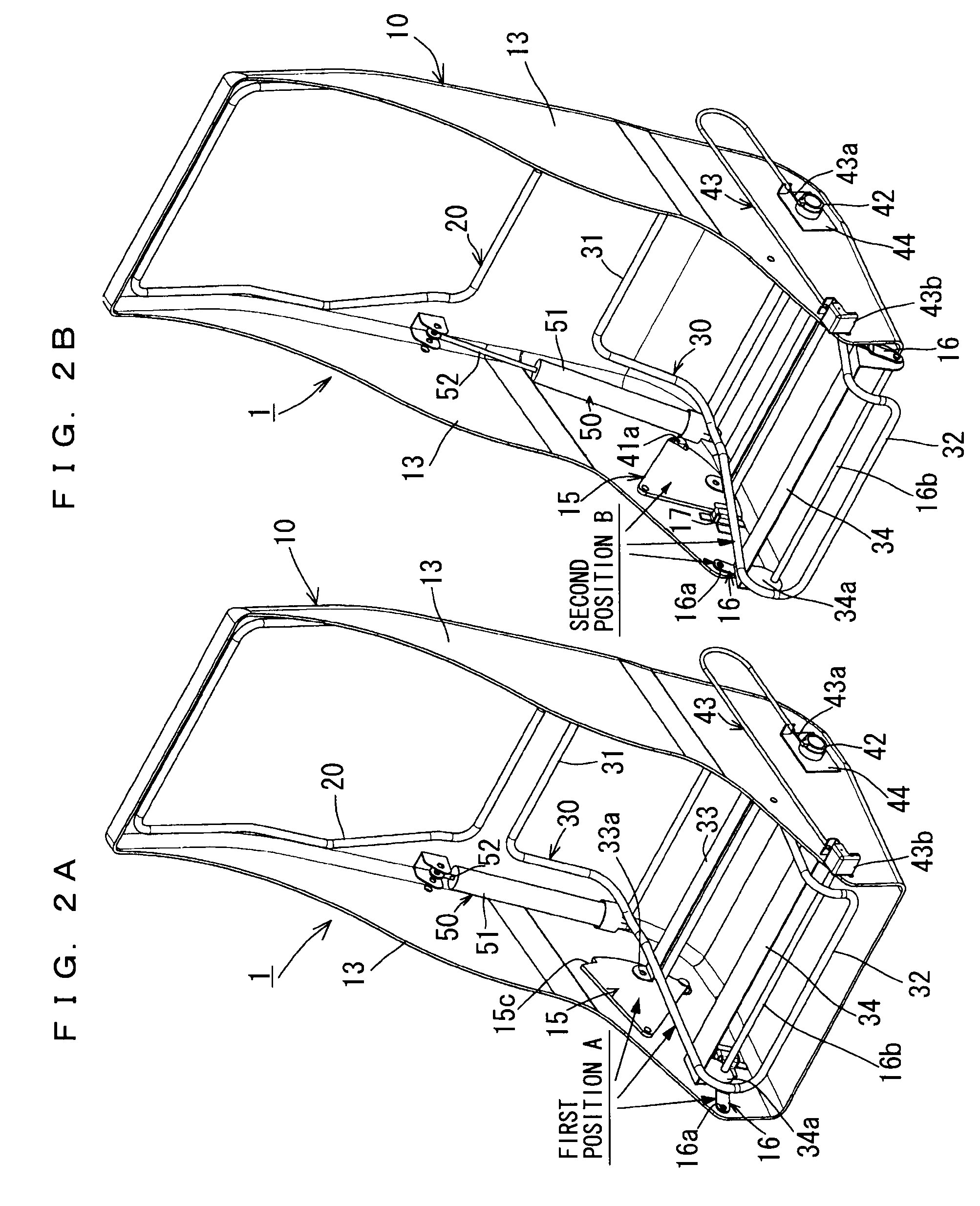

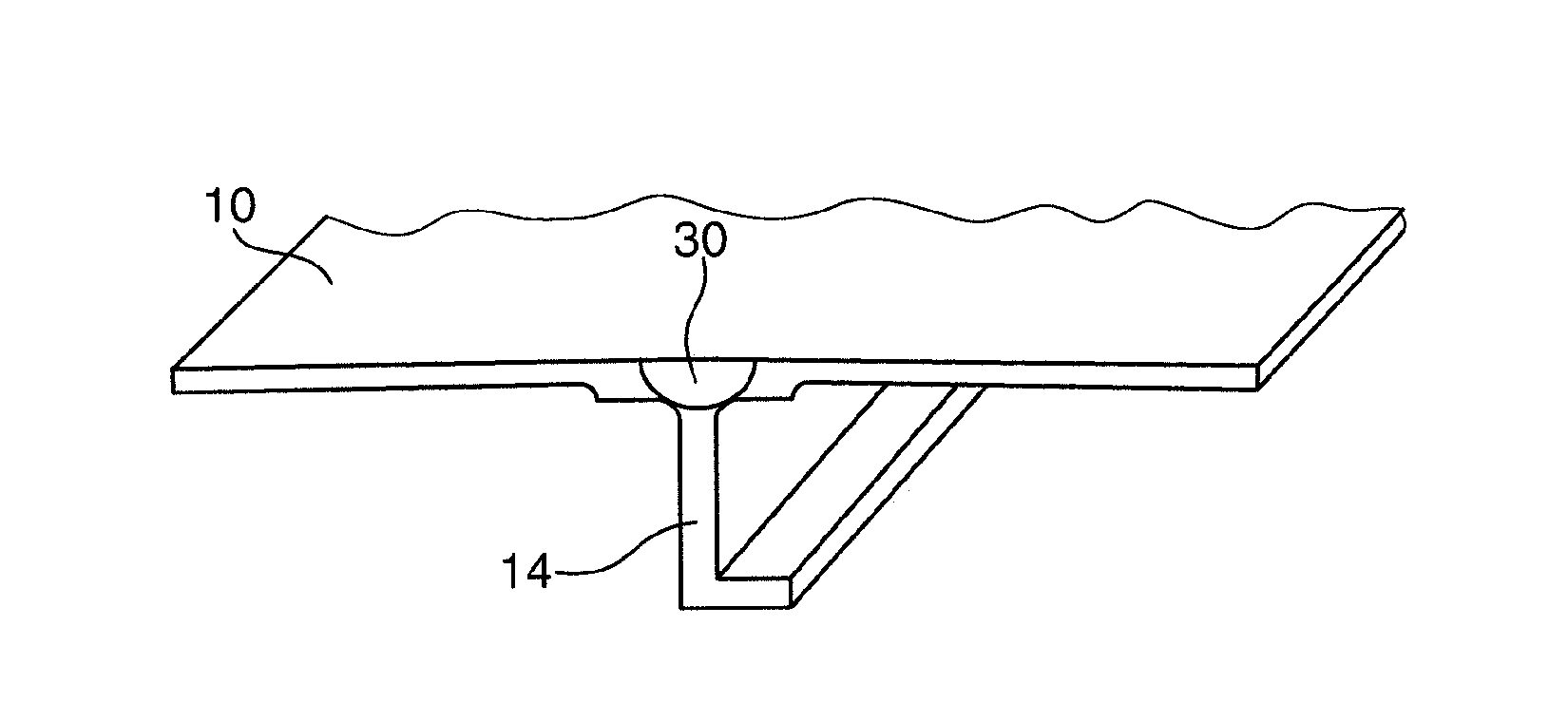

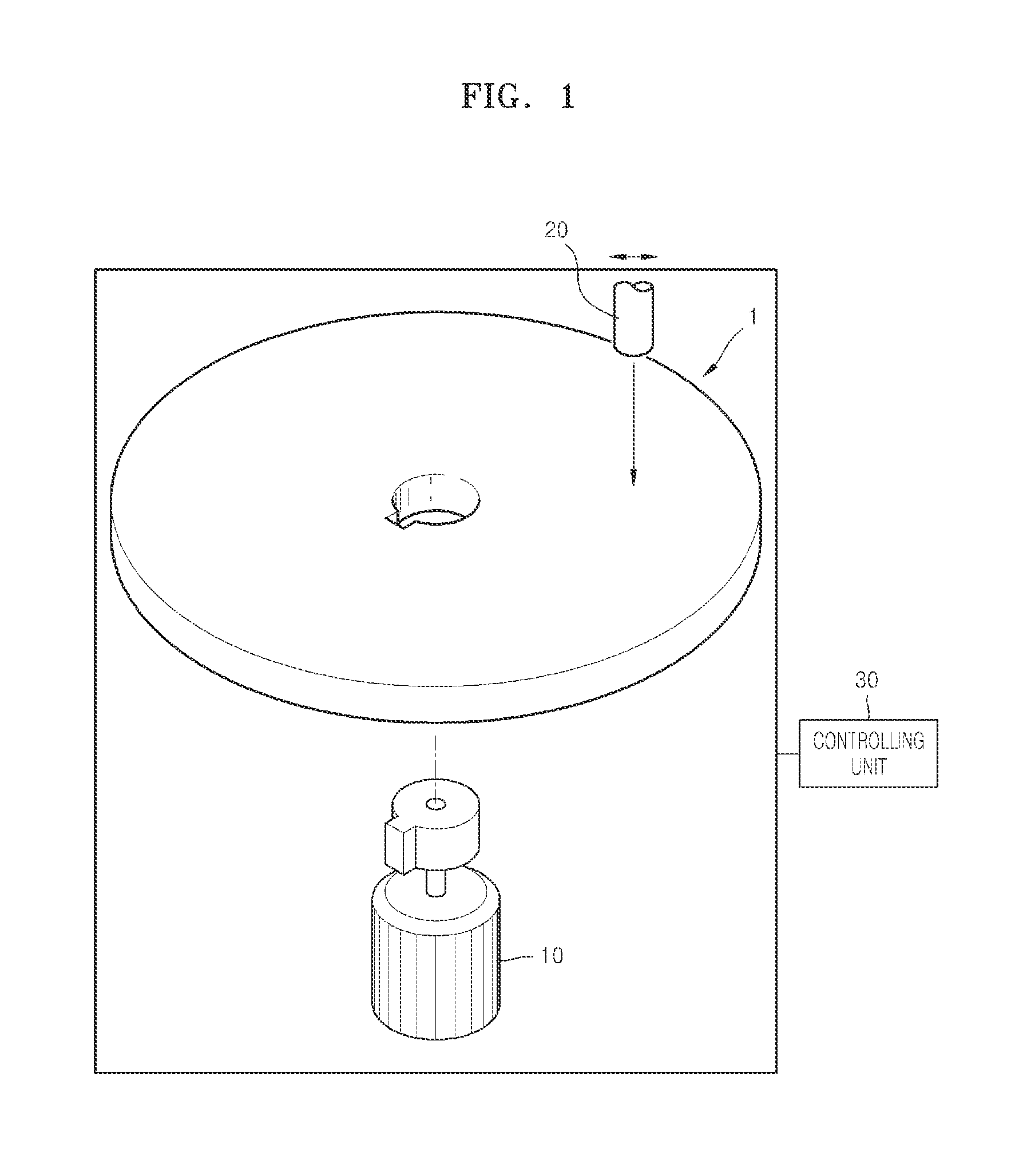

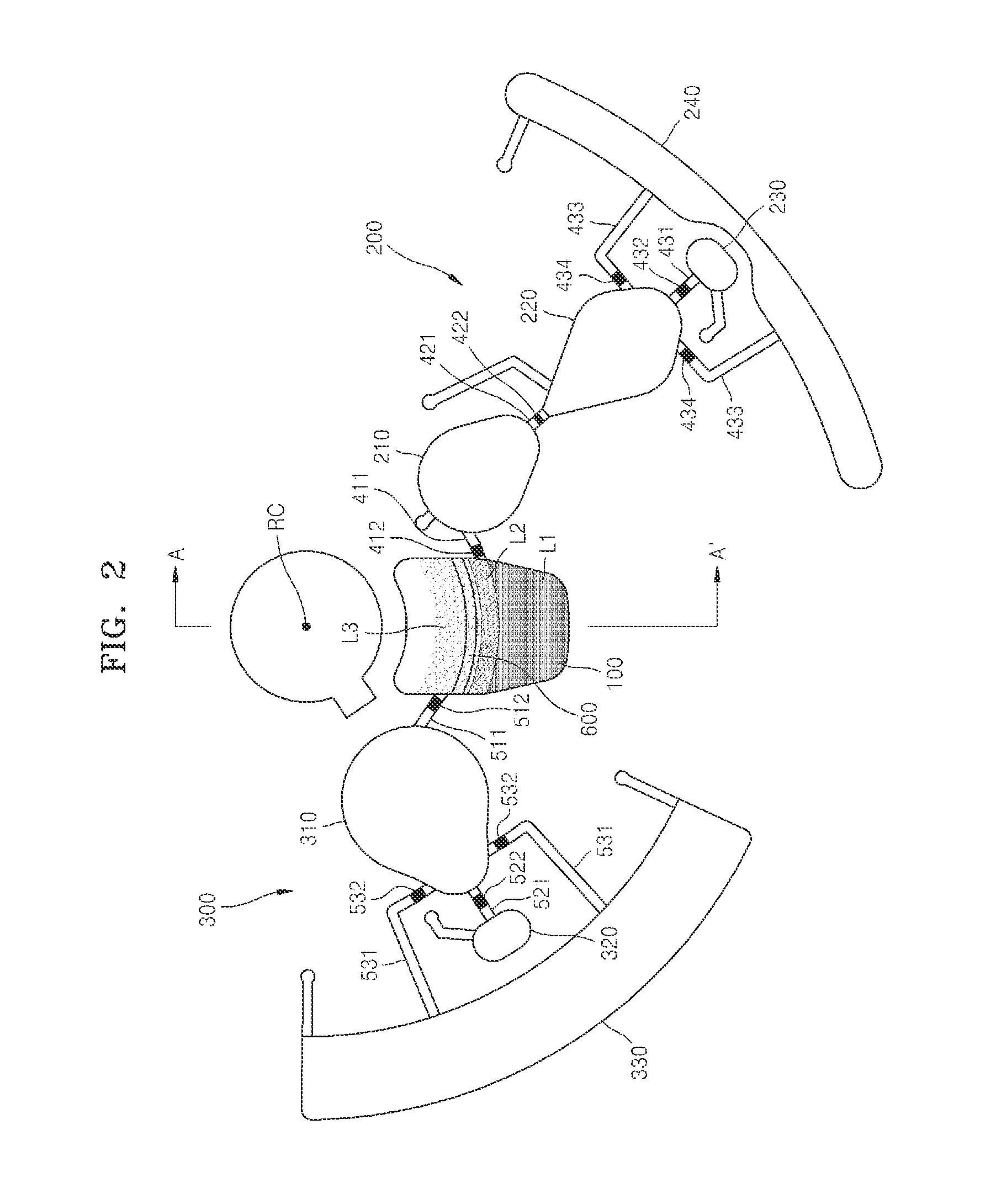

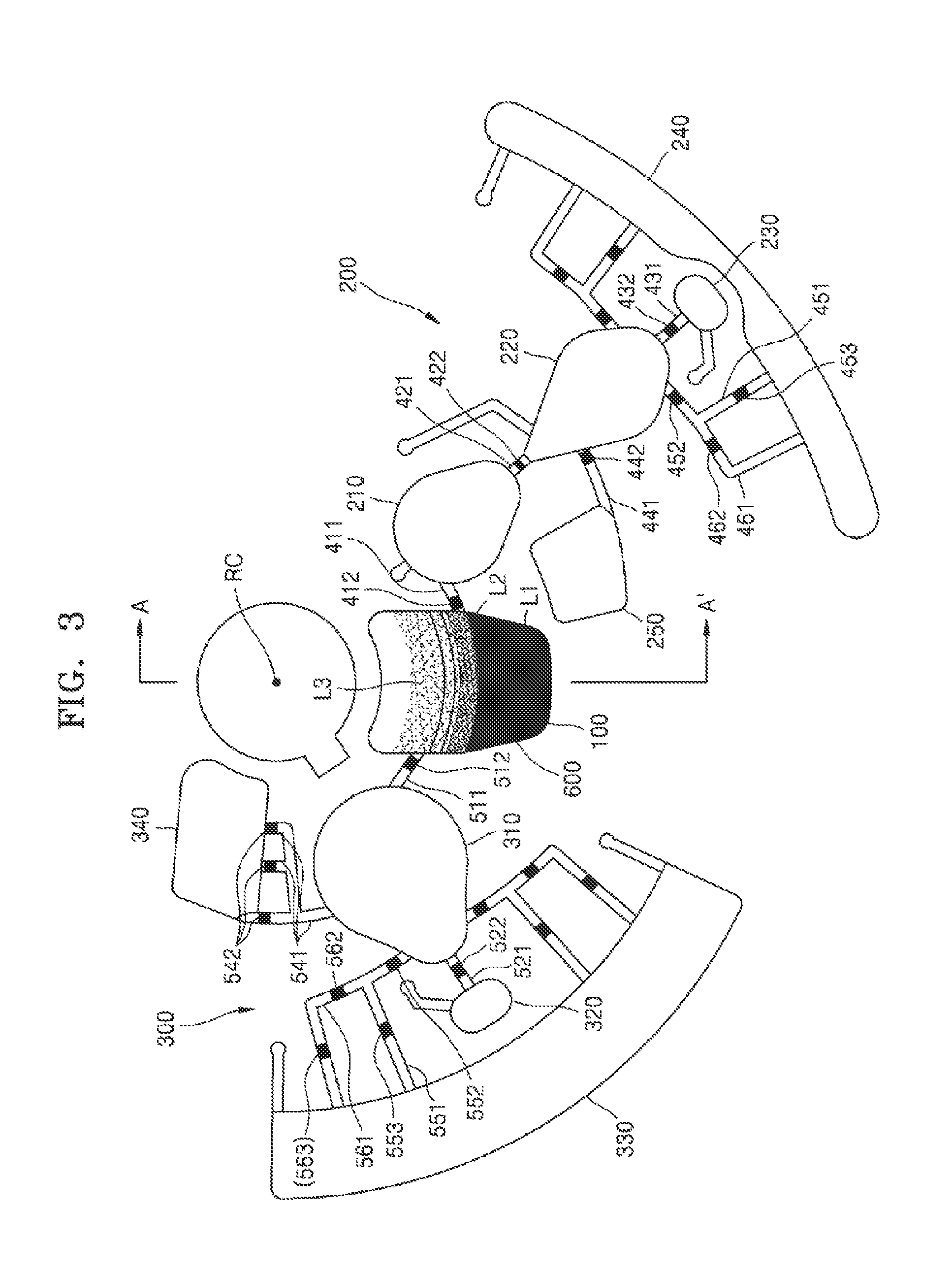

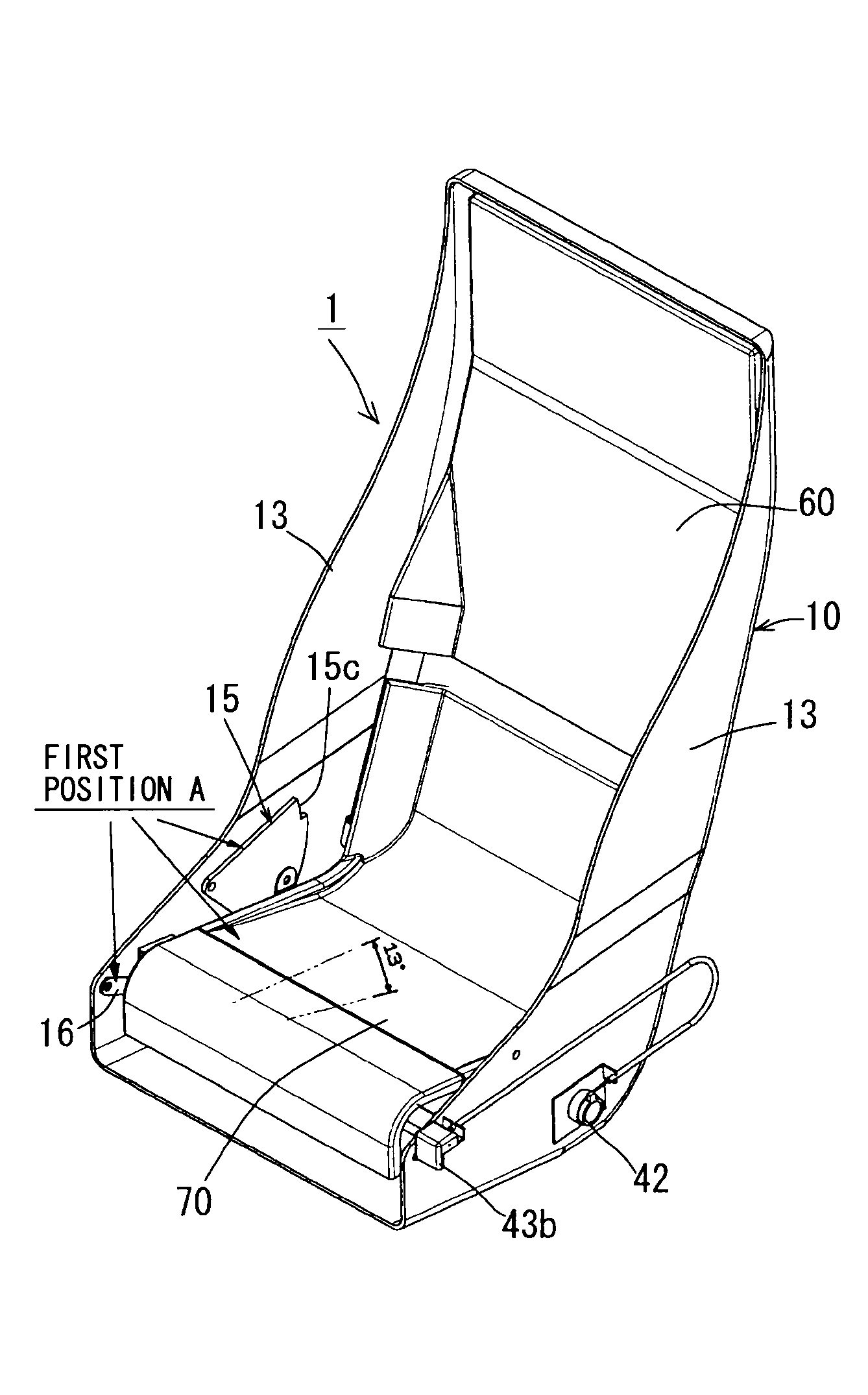

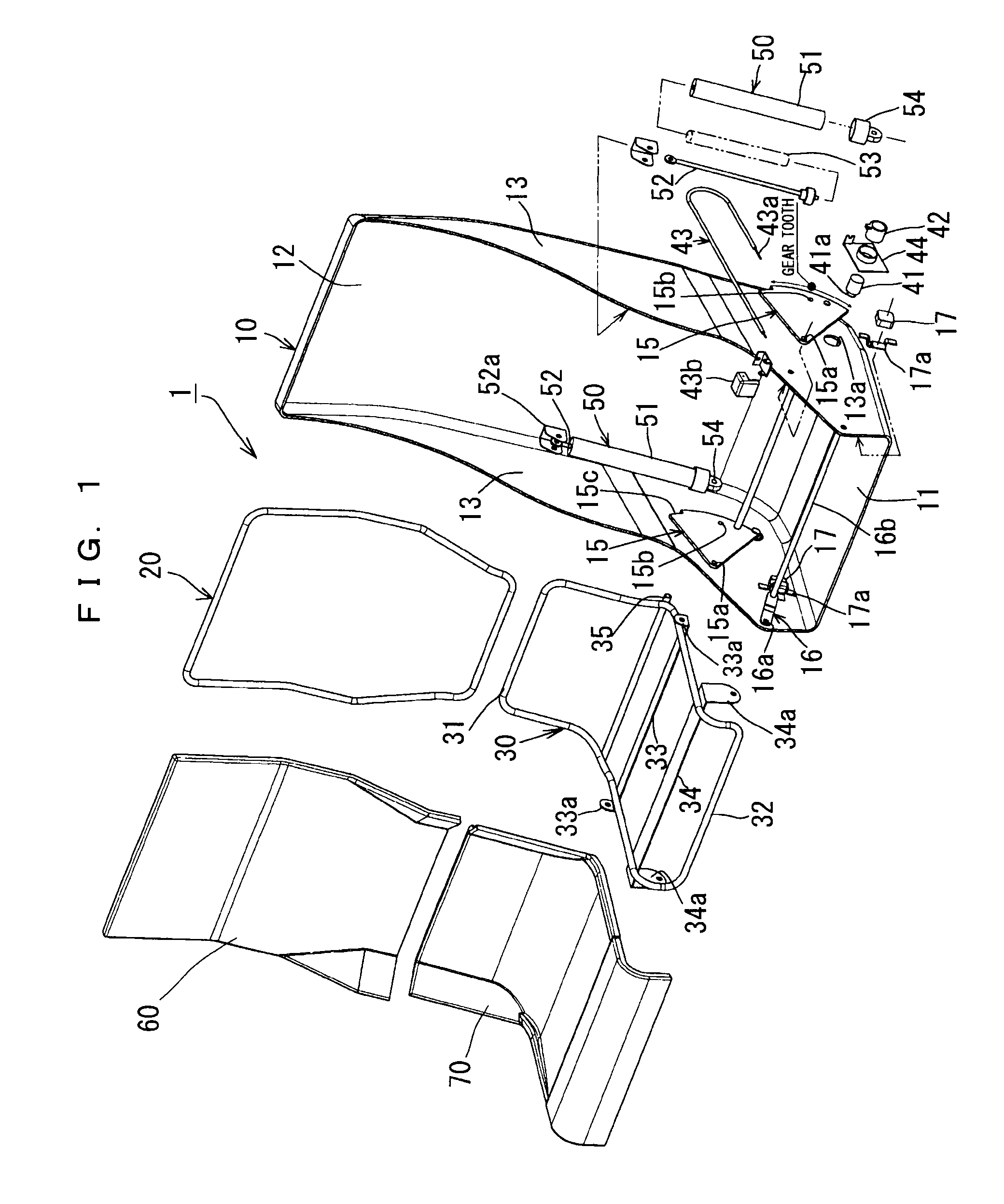

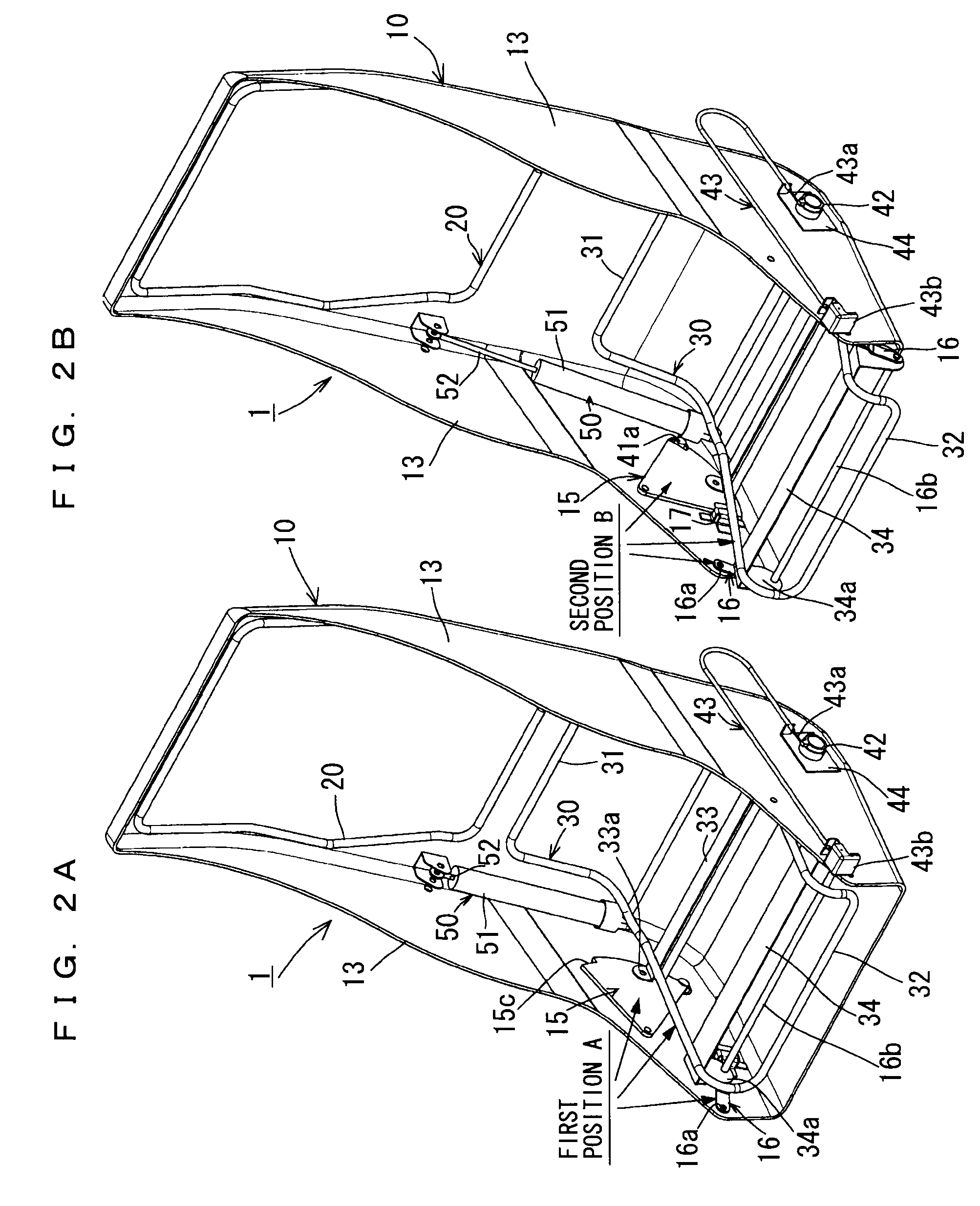

Seat structure

A seat structure capable of dealing with both a normal posture and a resting posture and providing sufficient relaxation in the resting posture while ensuring excellent comfortableness of an occupant.According to the present invention, a back frame 20 itself is fixed to a frame support 10 but a cushion frame 30 shifts from a first position A to a second position B according to an occupant's movement and an inclination angle of a pelvis support 31 increases accordingly. The occupant's pelvis portion and a portion lower than the pelvis portion is moved forward but a part of his or her back above his or her breast is not varied. With this structure, the same effect of the resting posture, that is, the posture in which the back frame is reclined in a conventional seat structure, can be obtained. Since the back is not tilted backward, a leg room (footrest) space in a rear seat is not limited.

Owner:DELTA TOOLING CO LTD

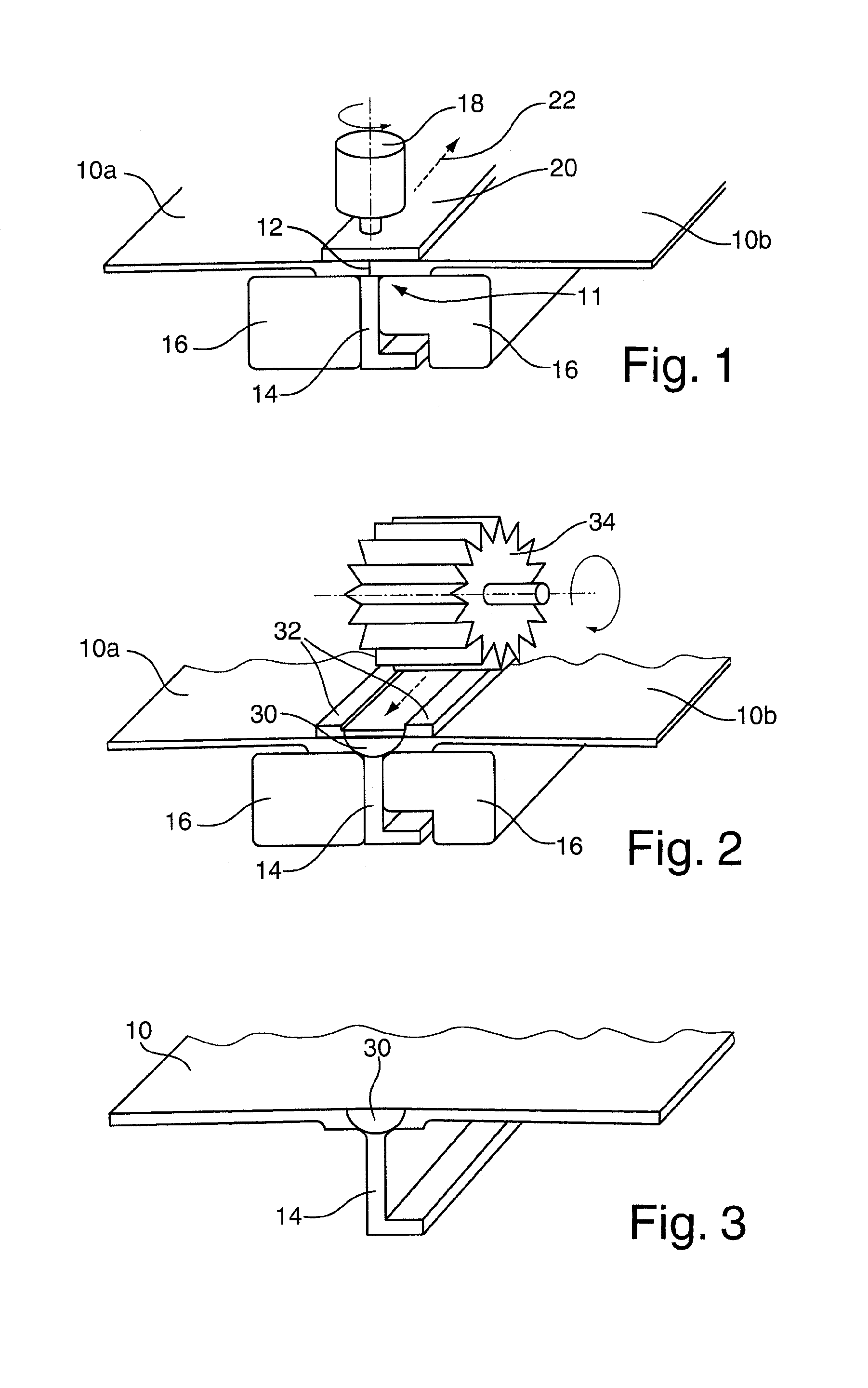

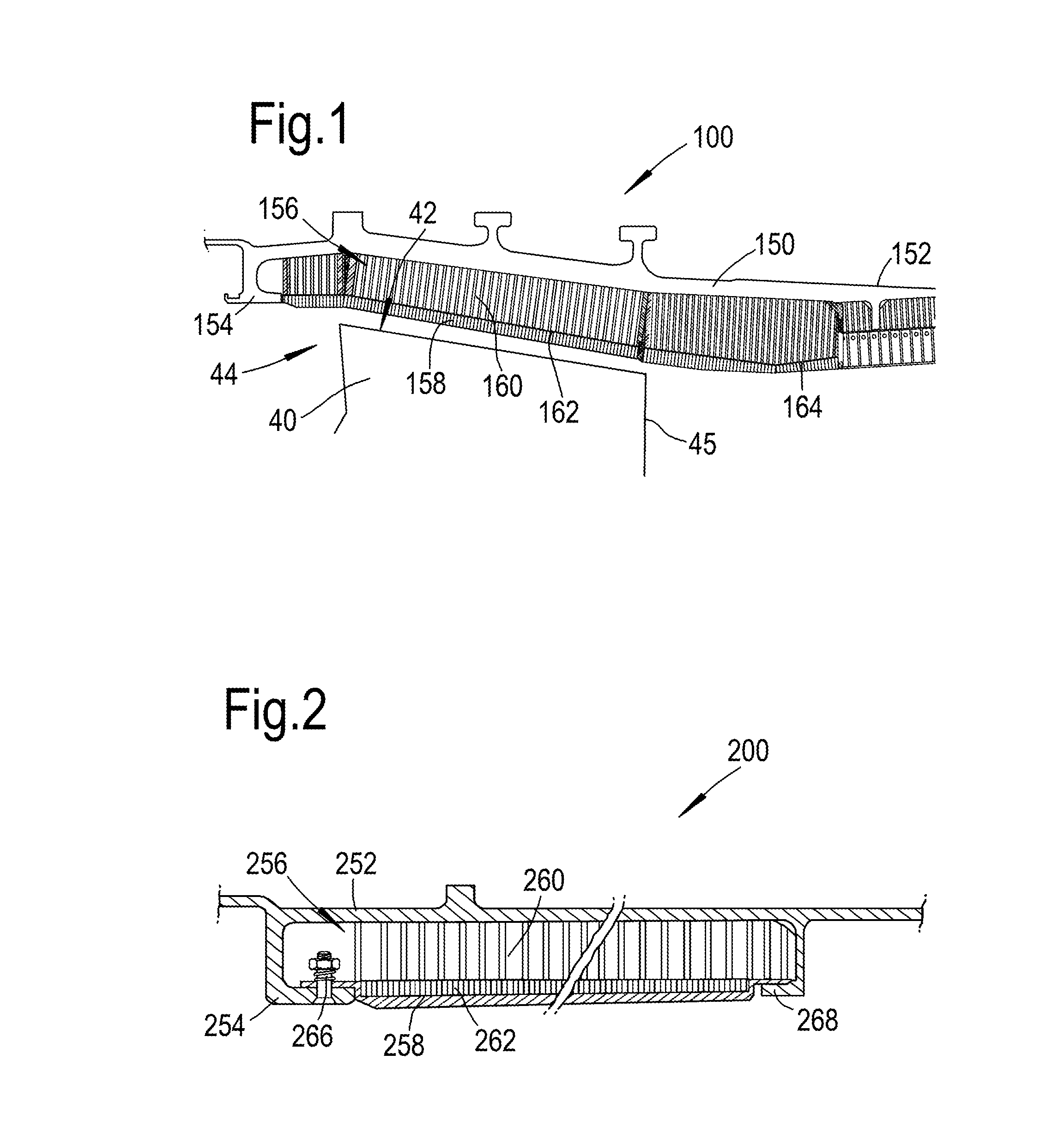

Process for connecting two aircraft fuselage segments by means of friction twist welding

InactiveUS20130206819A1Large gap widthLess materialWelding/soldering/cutting articlesMetal working apparatusFriction weldingFuselage

A process for connecting two aircraft fuselage segments and a reinforcing profile arranged in the joint region of the two aircraft fuselage segments by friction twist welding using a rotating tool, wherein a cover plate is brought onto the aircraft fuselage segments to be connected above the joint regions and after the friction twist welding the remainder of the cover plate is milled off. This makes it possible to overcome significantly greater gap tolerances in the edges to be connected so that the dimension tolerance requirements for the aircraft fuselage segments can be reduced. Furthermore, a smooth surface can be achieved in the welding region.

Owner:AIRBUS OPERATIONS GMBH

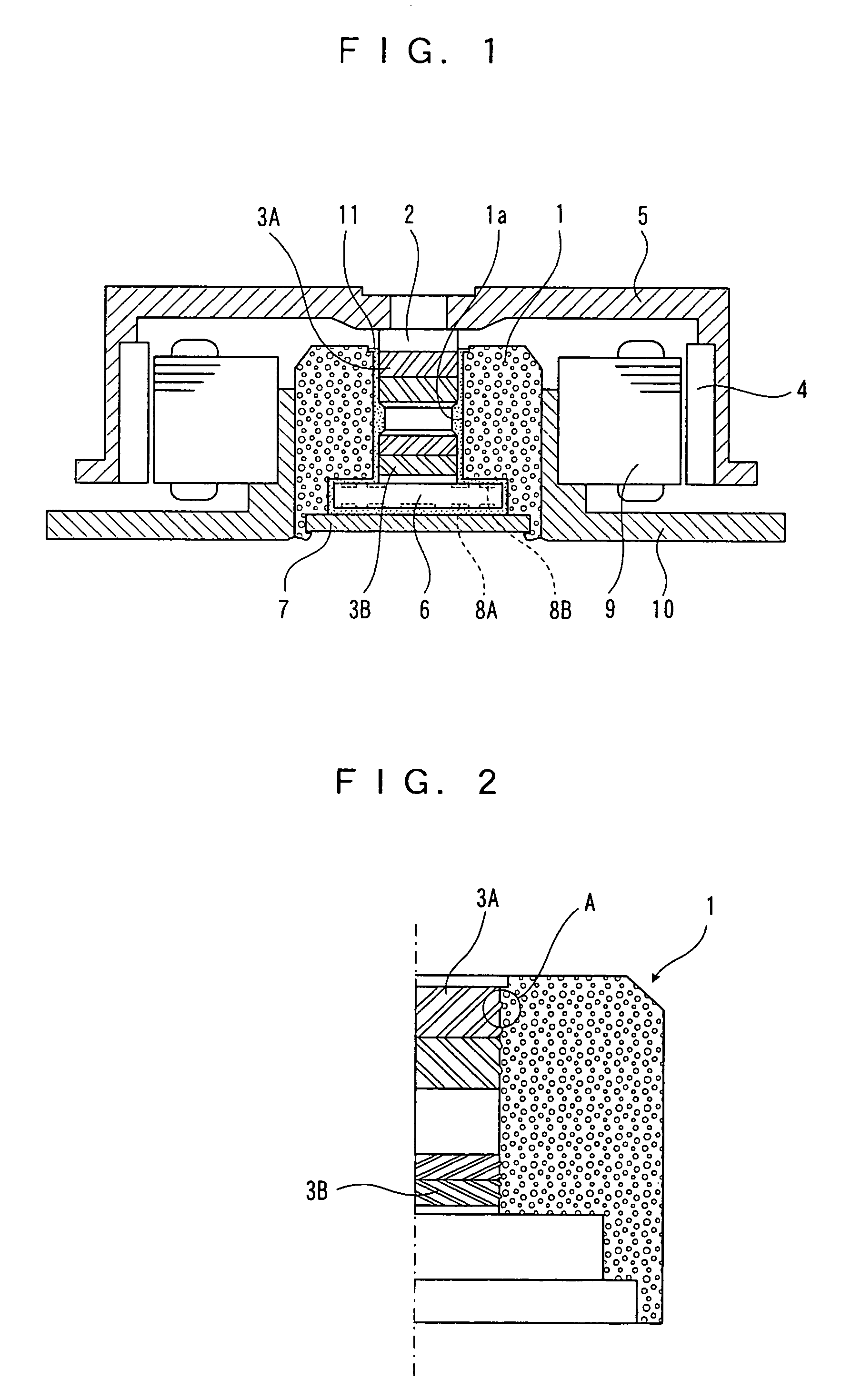

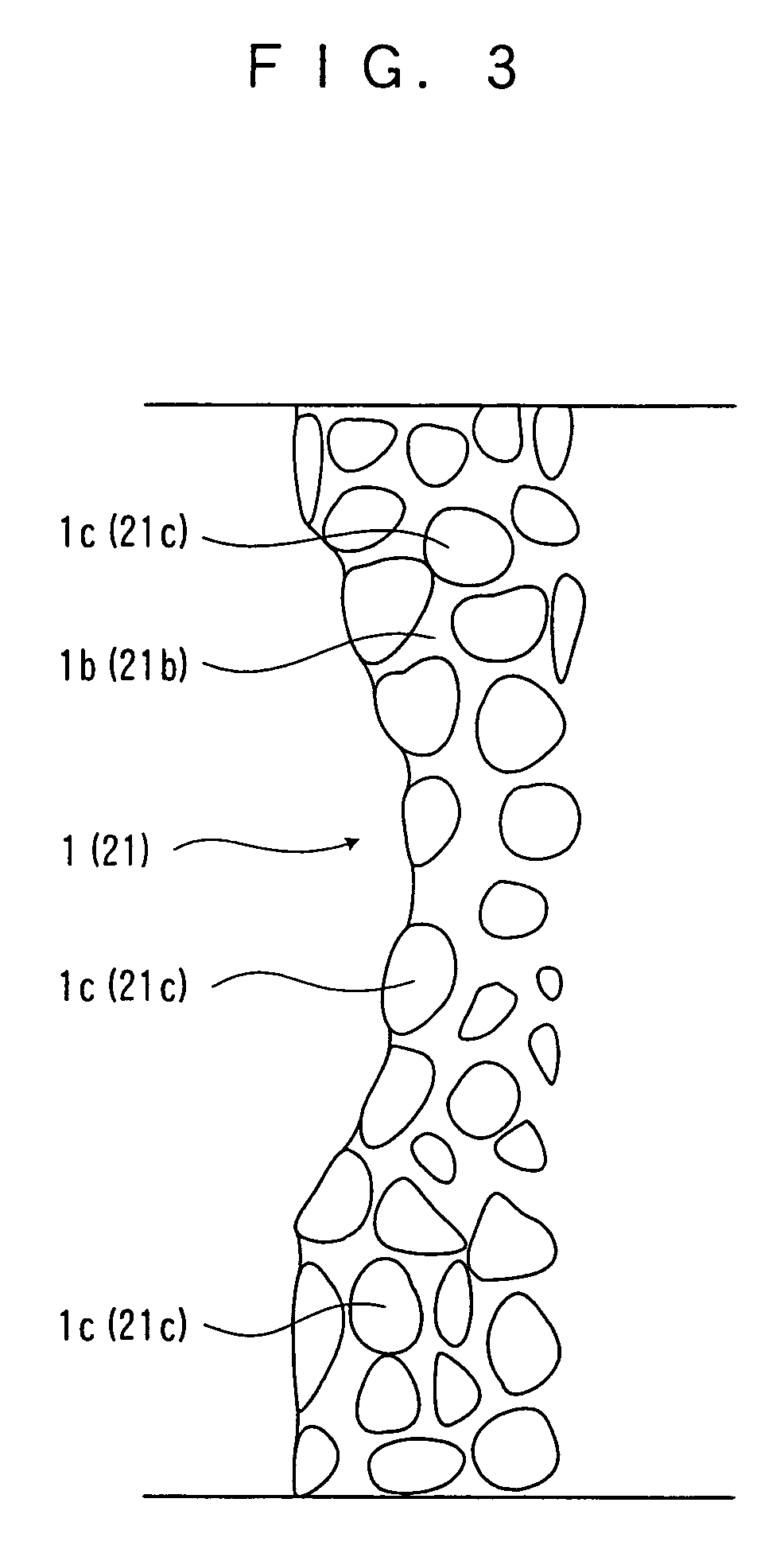

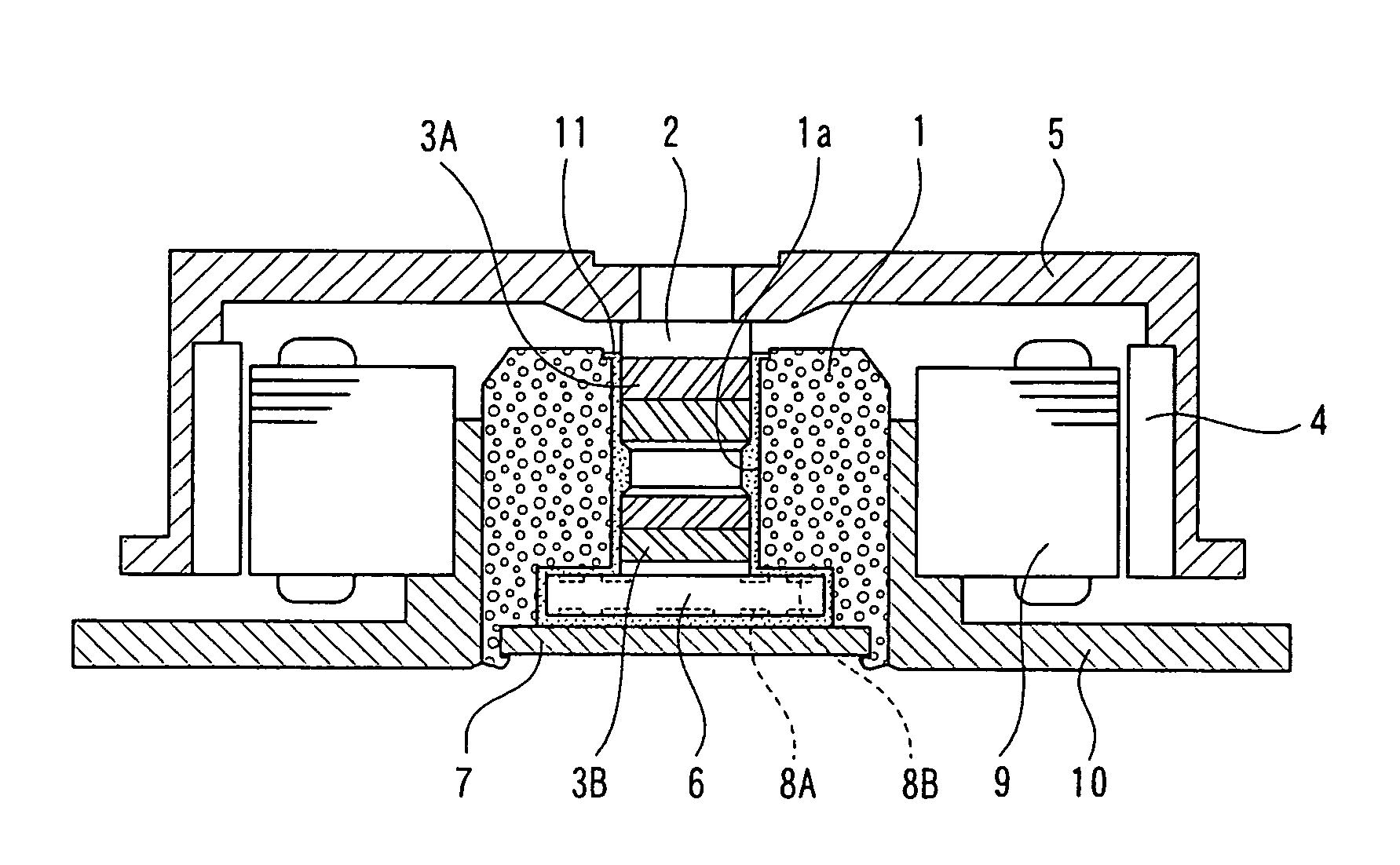

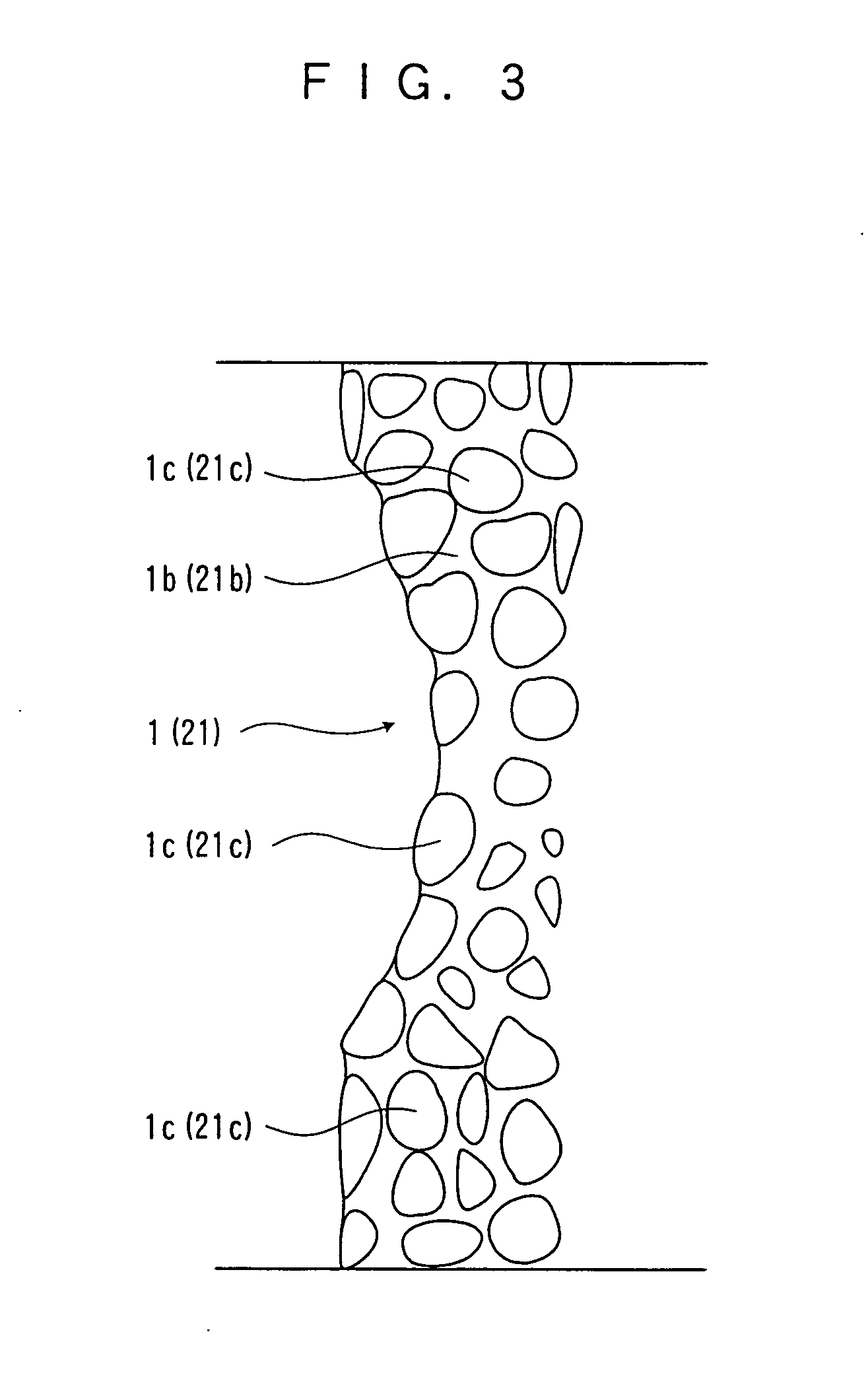

Hydrodynamic bearing device

InactiveUS7186028B2Reduce rigidityImprove performanceShaftsRecord information storageWorking fluidThrust bearing

A hydrodynamic bearing device capable of inhibiting leakage of a working fluid to an outside of a bearing and preventing reduction in radial bearing rigidity, and capable of keeping a gap between a thrust bearing and a radial bearing favorable and rotating stably. The hydrodynamic bearing device includes a shaft relatively rotatably inserted into a bearing hole of a sleeve, a radial bearing surface having dynamic pressure generating grooves formed on at least one of an outer peripheral surface of the shaft and an inner peripheral surface of the sleeve, and a gap filled with a working fluid between the shaft and the sleeve. The shaft is made of high manganese chrome steel or stainless steel, and the sleeve is entirely made of sintered metal of metal particles including at least 60% by weight of iron or copper. Resin, metal or water glass is impregnated in pores on a surface of the sintered metal and cured. Thereby, leakage of the working fluid to the outside of the bearing from the sleeve can be inhibited, and reduction in the pressure inside the bearing can be prevented.

Owner:NIDEC CORP

Shielding device and refrigerator comprising same

ActiveUS10228180B2Avoid flowMechanism is preventedLighting and heating apparatusCooling fluid circulationDrive shaftEngineering

The disclosure relates to a shielding device for closing a path through which air circulates in a refrigerator and a refrigerator having shielding device. The shielding device includes a forced draft fan cover having a threaded hole formed with a threaded slot; and a drive shaft formed with a thread being screwed with the threaded slot and extended to pass through the threaded hole, where an air duct that allows the air flows from the inside of the forced draft fan cover to the outside is provided between the drive shaft and the forced draft fan cover.

Owner:HAIER ASIA INT CO LTD +1

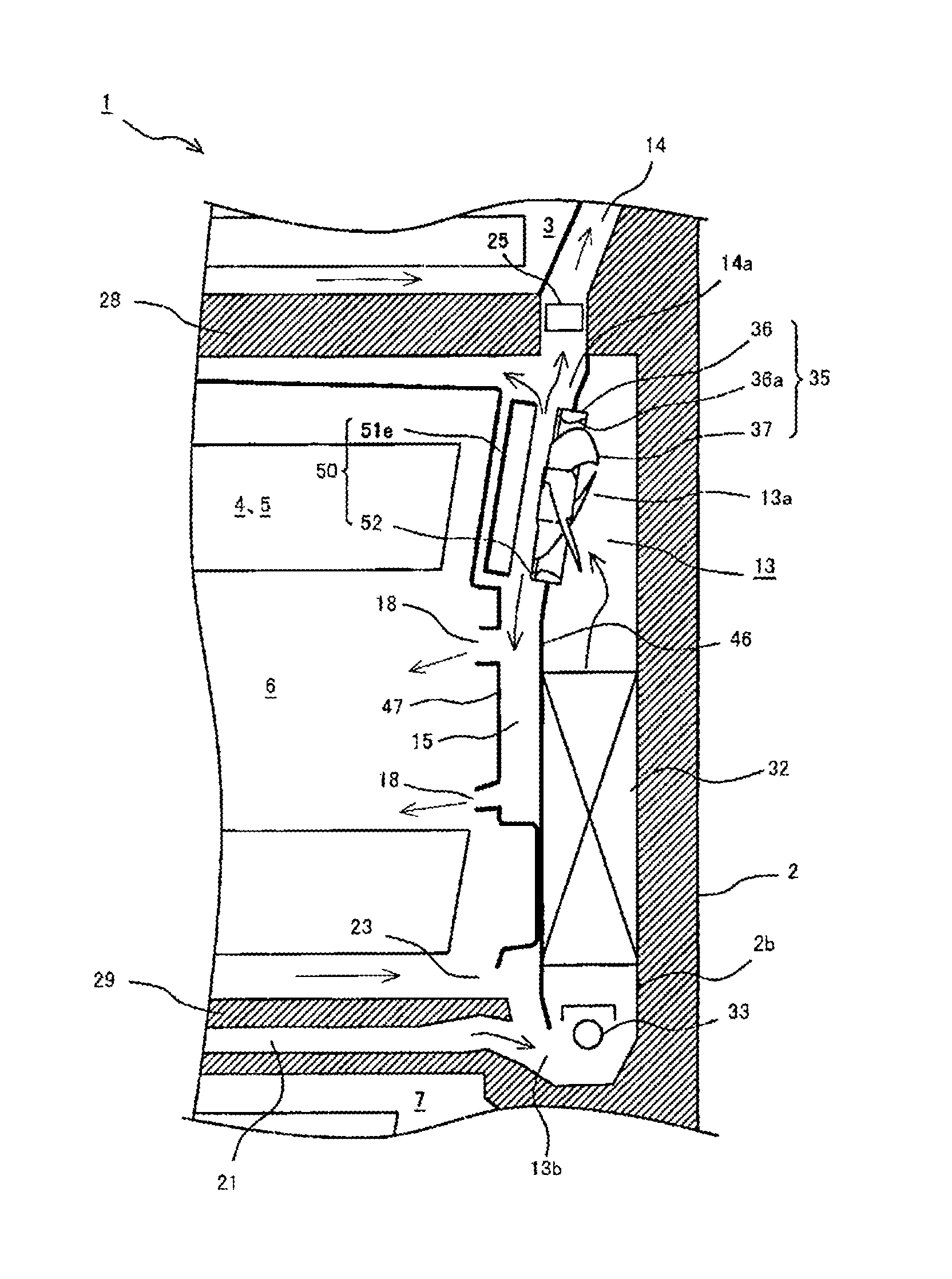

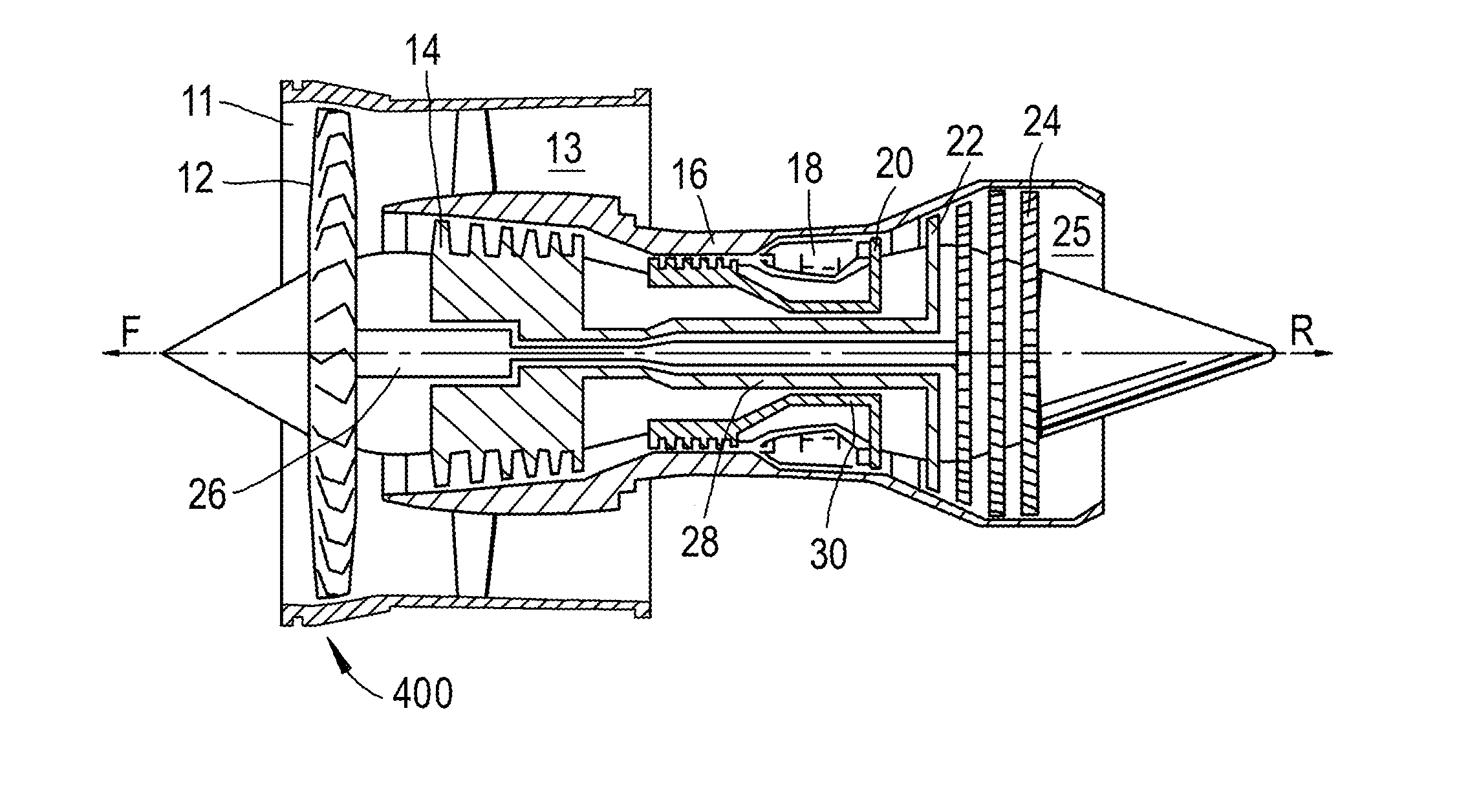

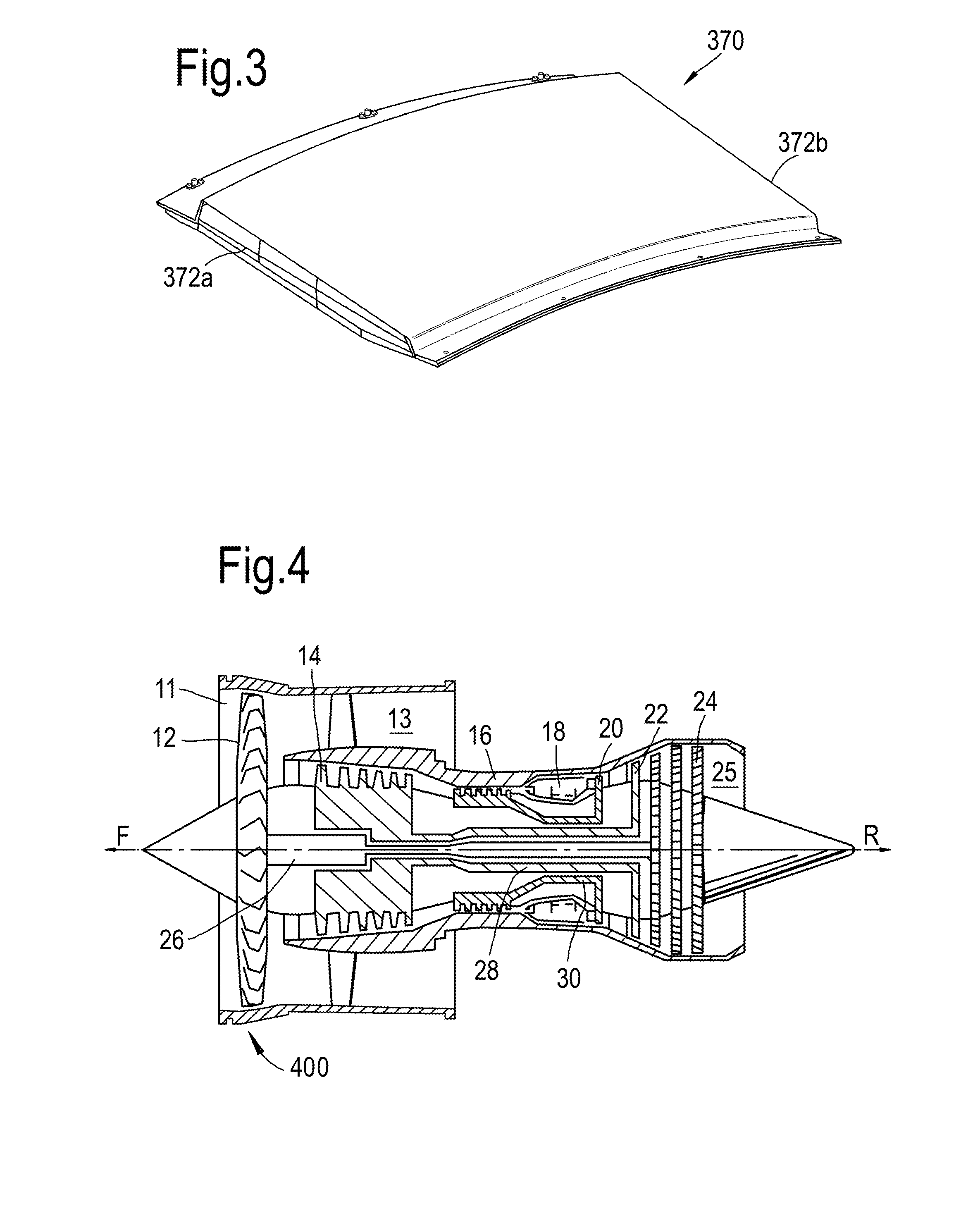

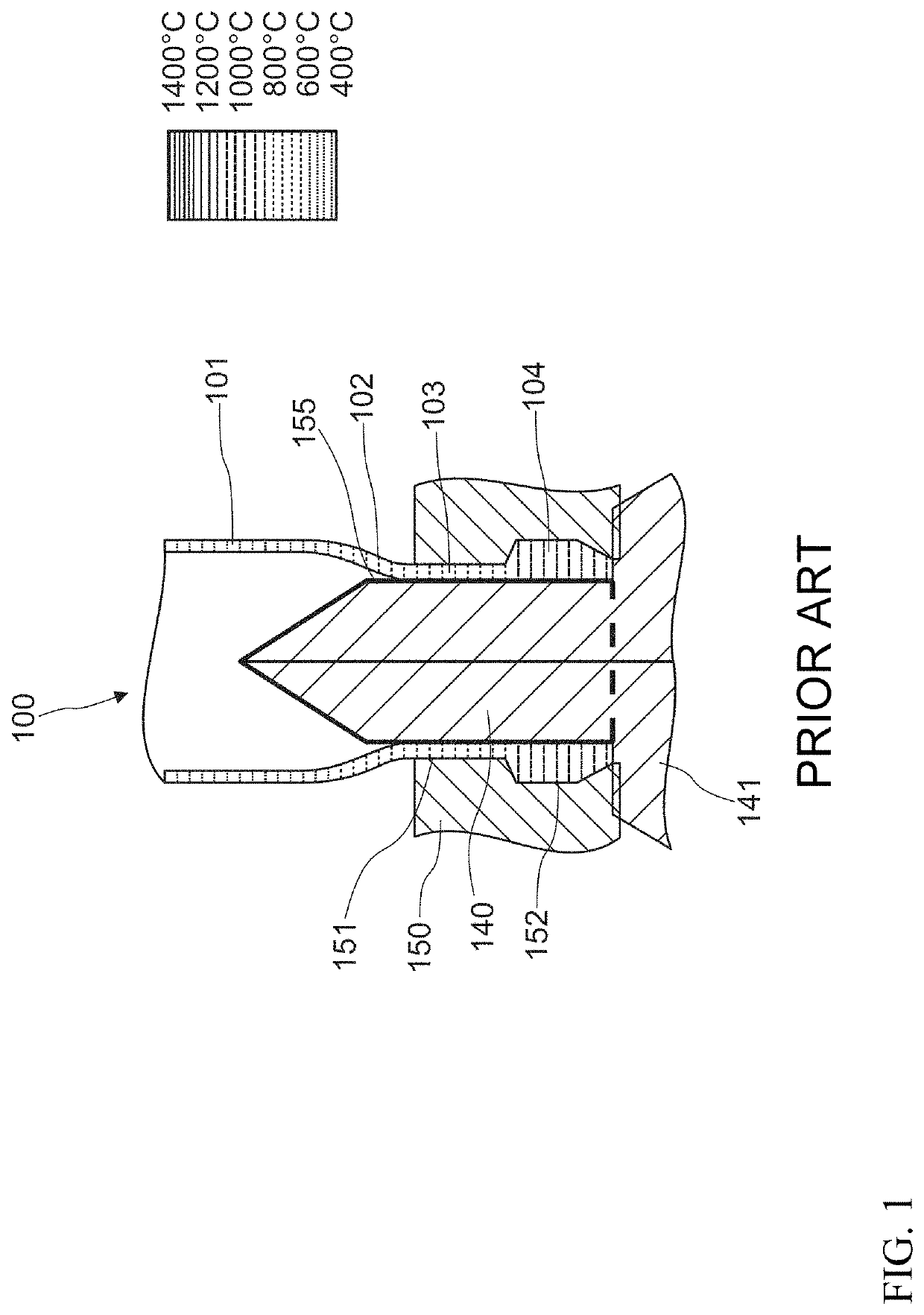

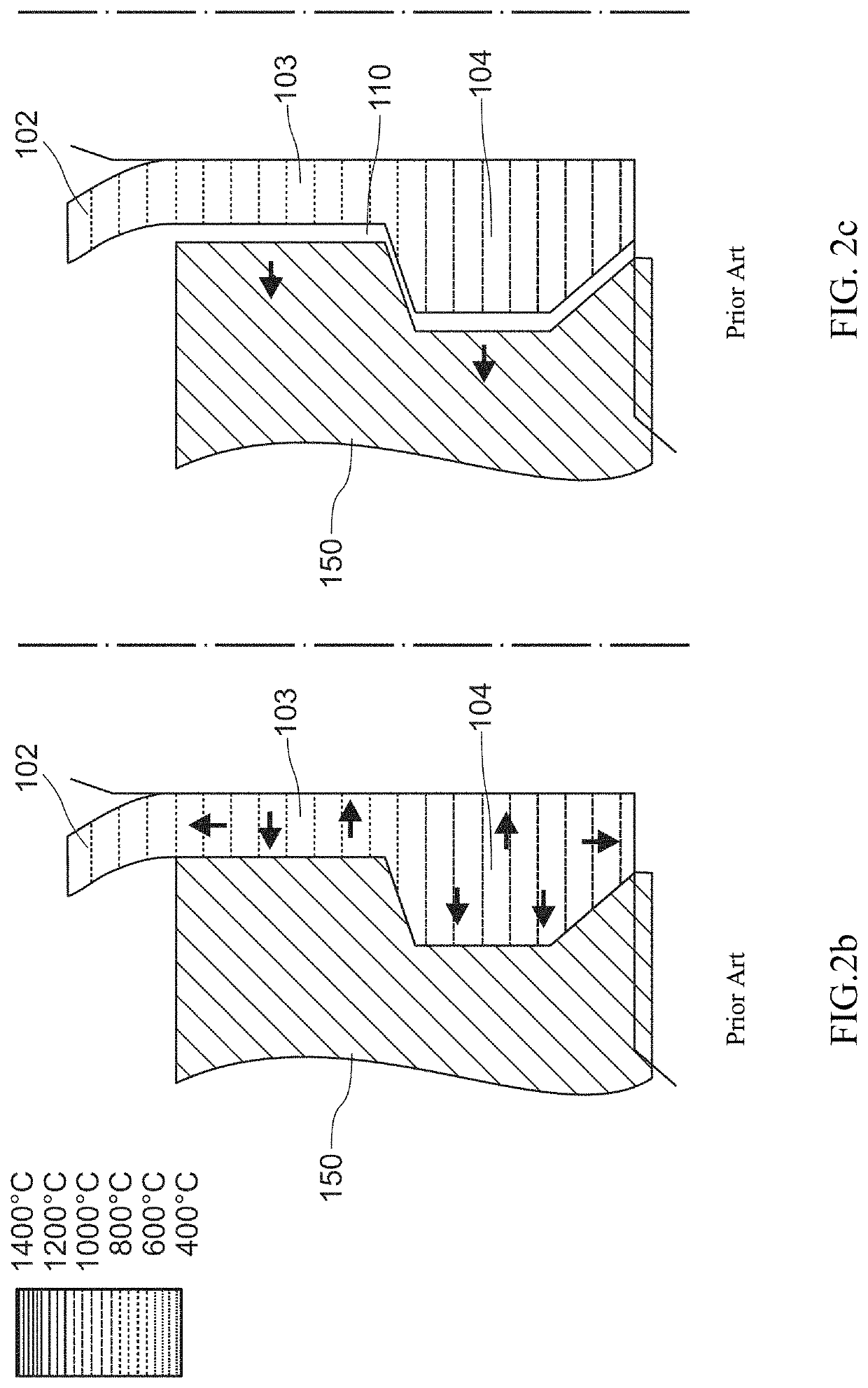

Gas turbine engine

InactiveUS20150233262A1Reduced manufacturing tolerance requirementsGreat gapEngine manufactureEngine fuctionsGas turbinesEngineering

A fan containment system for fitment around an array of radially extending fan blades mounted on a hub in an axial gas turbine engine, including: a fan case having an annular casing element for encircling an array of fan blades and an annular fan track liner lining a radially inner side of the casing element, including a first fan track liner panel positioned circumferentially adjacent a second fan track liner panel. An engagement arrangement engages the first fan track liner panel to the second, extending along at least a portion of adjacent sides of the liner panels, and is configured and the liner panels are shaped such that axial movement of the first fan track liner panel by a distance less than the length of the engagement arrangement, being measured in a direction parallel to the adjacent sides of the liner panels, disengages the first liner panel from the second.

Owner:ROLLS ROYCE PLC

Hydrodynamic bearing device

InactiveUS20050201645A1Favorable performanceReduce pressure insideRecord information storageBearing componentsBearing surfaceWorking fluid

A hydrodynamic bearing device capable of inhibiting leakage of a working fluid to an outside of a bearing and preventing reduction in radial bearing rigidity, and capable of keeping a gap between a thrust bearing and a radial bearing favorable and rotating stably. The hydrodynamic bearing device includes a shaft relatively rotatably inserted into a bearing hole of a sleeve, a radial bearing surface having dynamic pressure generating grooves formed on at least one of an outer peripheral surface of the shaft and an inner peripheral surface of the sleeve, and a gap filled with a working fluid between the shaft and the sleeve. The shaft is made of high manganese chrome steel or stainless steel, and the sleeve is entirely made of sintered metal of metal particles including at least 60% by weight of iron or copper. Resin, metal or water glass is impregnated in pores on a surface of the sintered metal and cured. Thereby, leakage of the working fluid to the outside of the bearing from the sleeve can be inhibited, and reduction in the pressure inside the bearing can be prevented.

Owner:NIDEC CORP

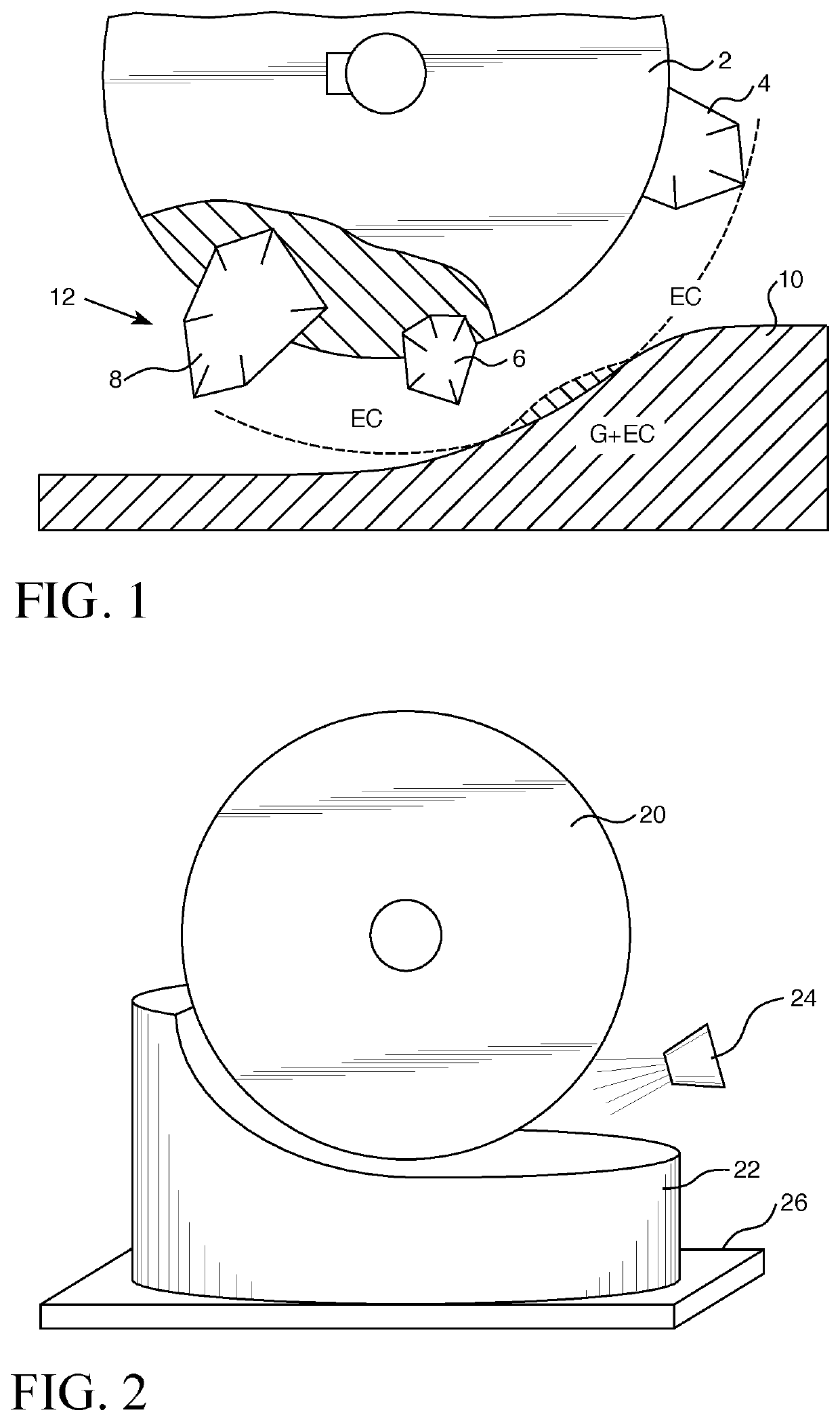

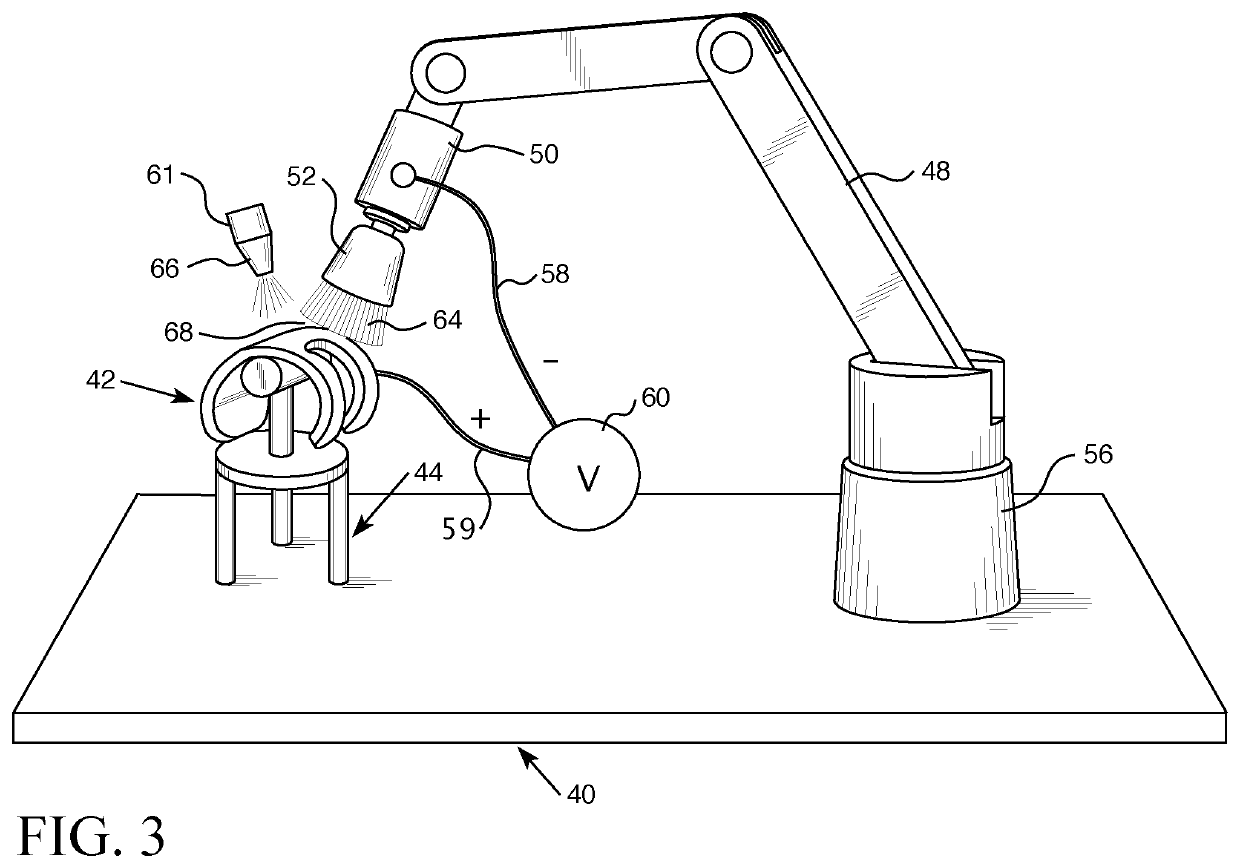

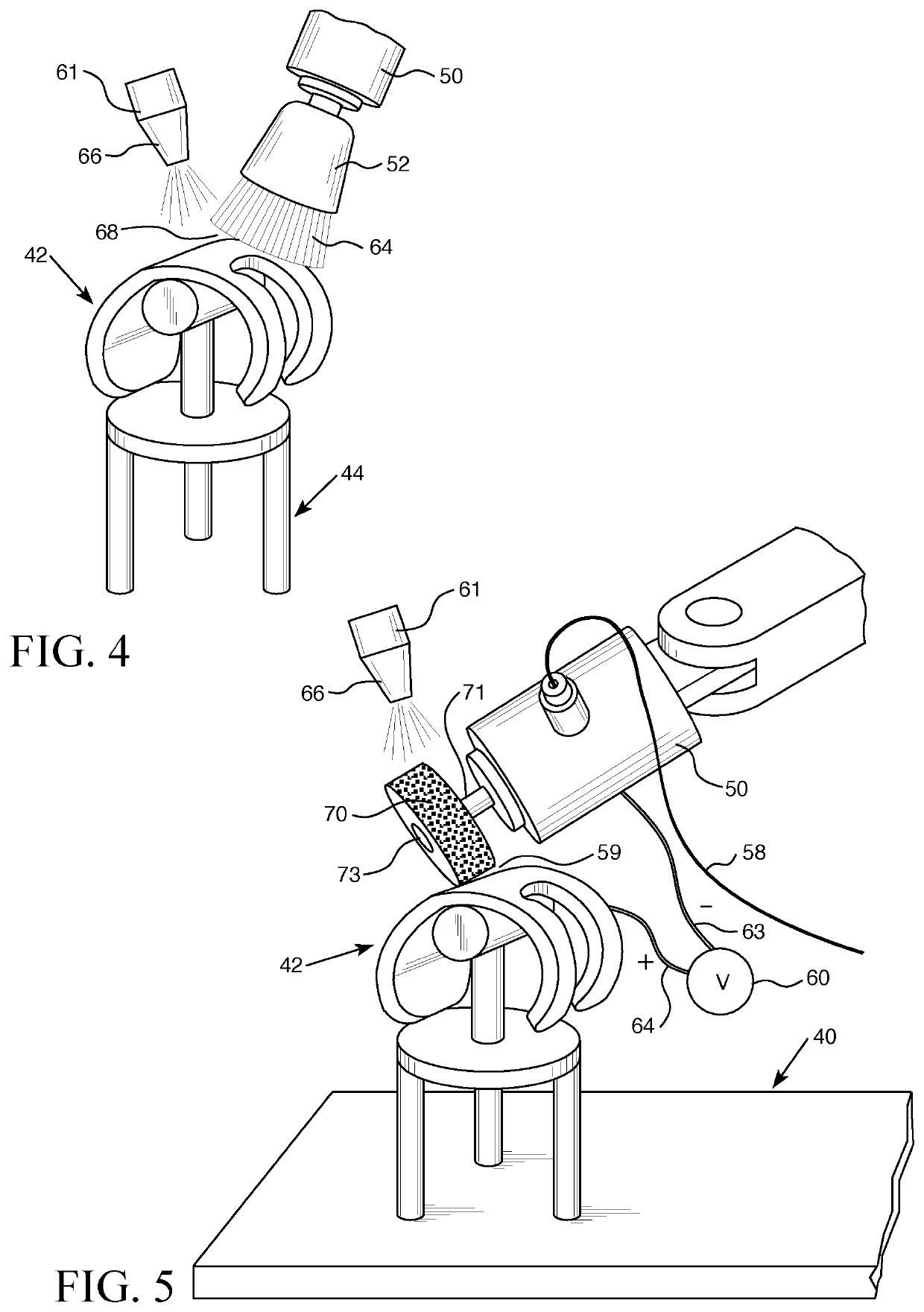

Method and apparatus for finishing complex and curved surfaces using a conformal approach for additively manufactured products and other parts, and the resultant products

InactiveUS20200070249A1Create efficientlyGood precisionAdditive manufacturing apparatusIncreasing energy efficiencySurface finishGrinding wheel

A method and apparatus for conformal surface finishing and / or forming of additive manufactured products and an improved system for a combined electrolytic removal of material followed by precise mechanical cleaning and removal of excess material to create improved precision in a single stage without requiring the use of a grinding wheel. An automated computerized embodiment is disclosed.

Owner:OBERG INDS

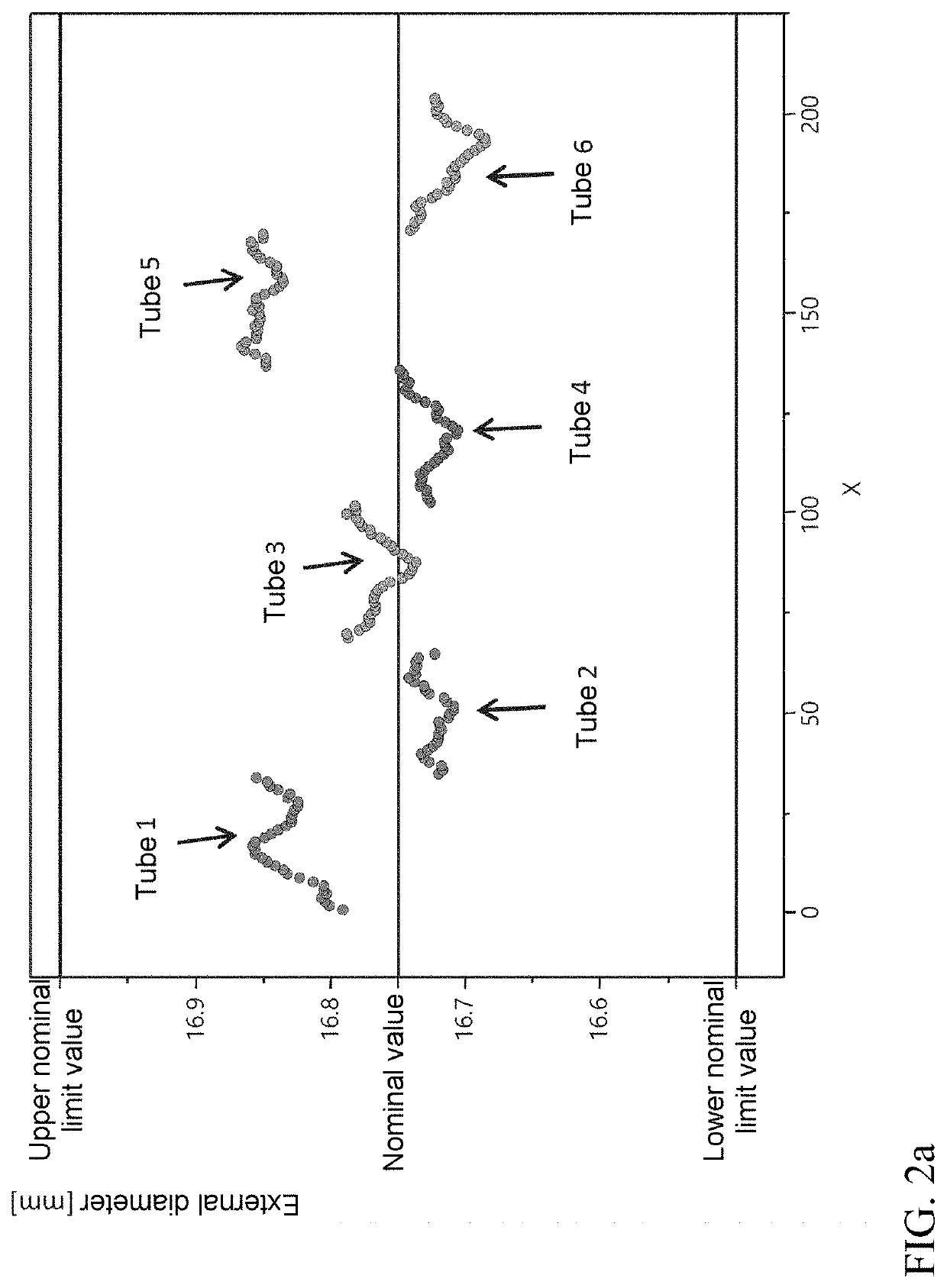

Method and device for hot-shaping glass containers

PendingUS20200354255A1Reliably and efficiently producedIncrease cycle rateGlass reforming apparatusBULK ACTIVE INGREDIENTActive ingredient

A method for molding end portions on glass containers that store pharmaceutical active ingredients is provided. The glass containers are produced from a glass tube by hot-forming, an end portion having a neck opening using a centrally disposed opening forming tool interacting with a shaping tool at one end of the glass containers. In the method, dimensional data is provided for the respective glass tube and the position of the shaping tool is adjusted in a motorized manner in the axial direction (z) of the glass containers so as to correspond to the provided dimensional data for the respective glass tube.

Owner:SCHOTT PHARMA SCHWEIZ AG

Sealing arrangement

InactiveUS7510086B2Great gapLower drive power/torqueEngine sealsPiston ringsContact pressurePaperboard

This invention relates to an arrangement for sealing off a fluid-filled, stationary pressurized compartment from an endlessly circulating, impermeable belt of a machine for producing and / or refining a paper, paperboard, tissue or other fibrous web with the help of at least one seal of the pressurized compartment, whose contact pressure toward the belt is variable, wherein the belt is pressed by the pressurized compartment against a co-driven support element and the fibrous web runs alone or jointly with one or more function belts between the belt and the support element. The sealing is improved in this case, while producing as little leakage and wear as possible, in that the contact pressure of the seal is controlled as a factor of the drive power and / or the drive torque channeled into the belt and / or as a factor of the leakage of fluid through the gap between the seal and the belt and / or as a factor of the pressure of the fluid in the pressurized compartment.

Owner:VOITH PATENT GMBH

Weld-solder filler

InactiveUS20060018784A1Improve corrosion resistanceReduce energy inputWelding/cutting media/materialsSoldering mediaManganeseCopper

Conventional weld fillers contain copper, aluminum and manganese. These weld fillers are as a rule not suited for the welding of thin or rust-free sheet metals. The inventive weld filler contains 0.5 to 6.0 percent by weight Al, 0.5 to 8.0 percent by weight Mn, the usual impurities are less than or equal to 1.0 percent by weight and as the remainder Cu. This weld filler is better suited for the welding of thin or rust-free sheet metals than the up to now known weld fillers.

Owner:BERKENHOFF GMBH

Wildlife deterrent for high voltage supporting members

A wildlife deterrent for a utility support structure member between two conductors includes a bracket for attachment to the supporting member, a center support piece with a variable height arm connector, and two adjustable arms pivotally attached to the arm connector. No tools are required for the adjustments or attachments. Since the effective lengths of the support and arms are adjustable, either by elongation or using different length parts, the same angle of the arms can be achieved no matter what the separation between the conductors, and the gap between the arms and the conductor can be optimal for both deterrence and flashover prevention. The different pieces forming the deterrent can be selected by the lineman to quickly build an optimal deterrent in the field.

Owner:ECO ELECTRICAL SYST

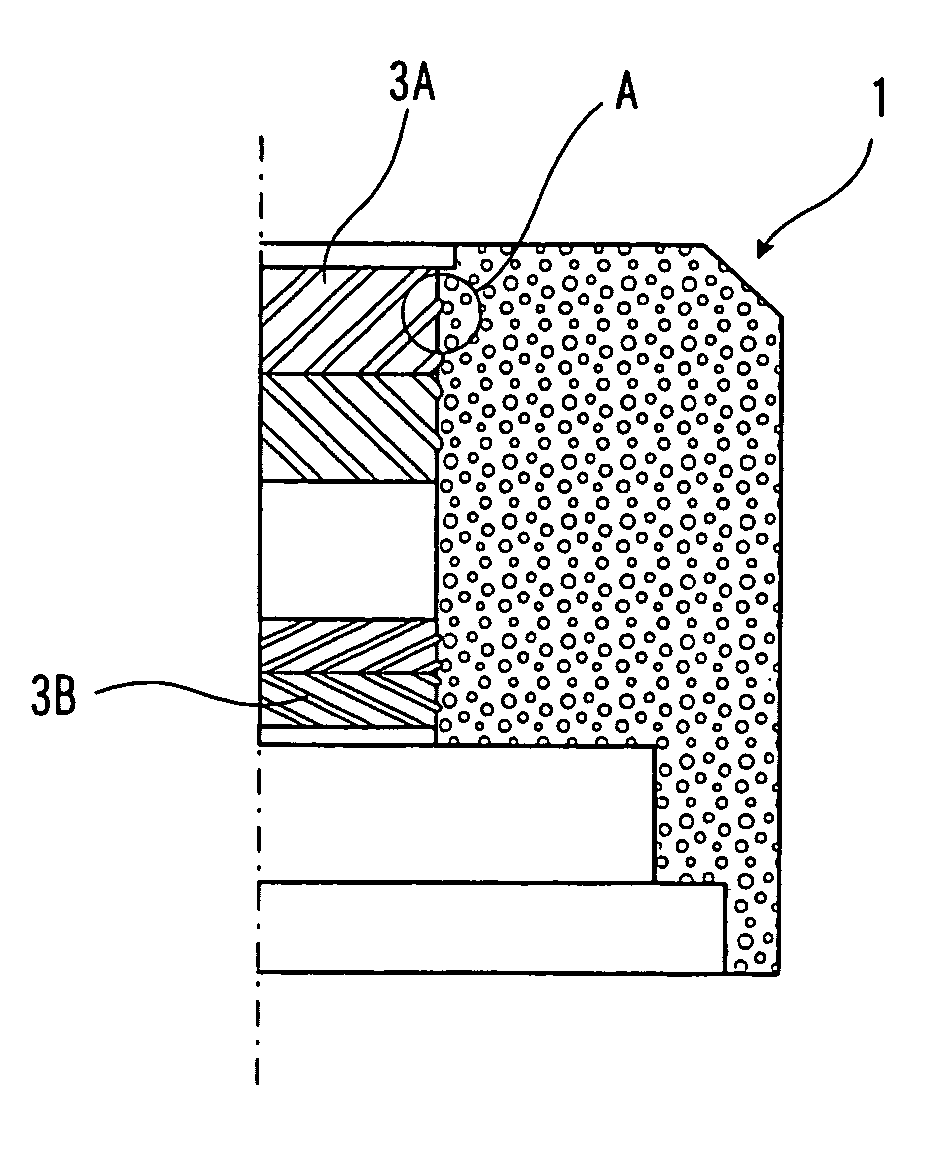

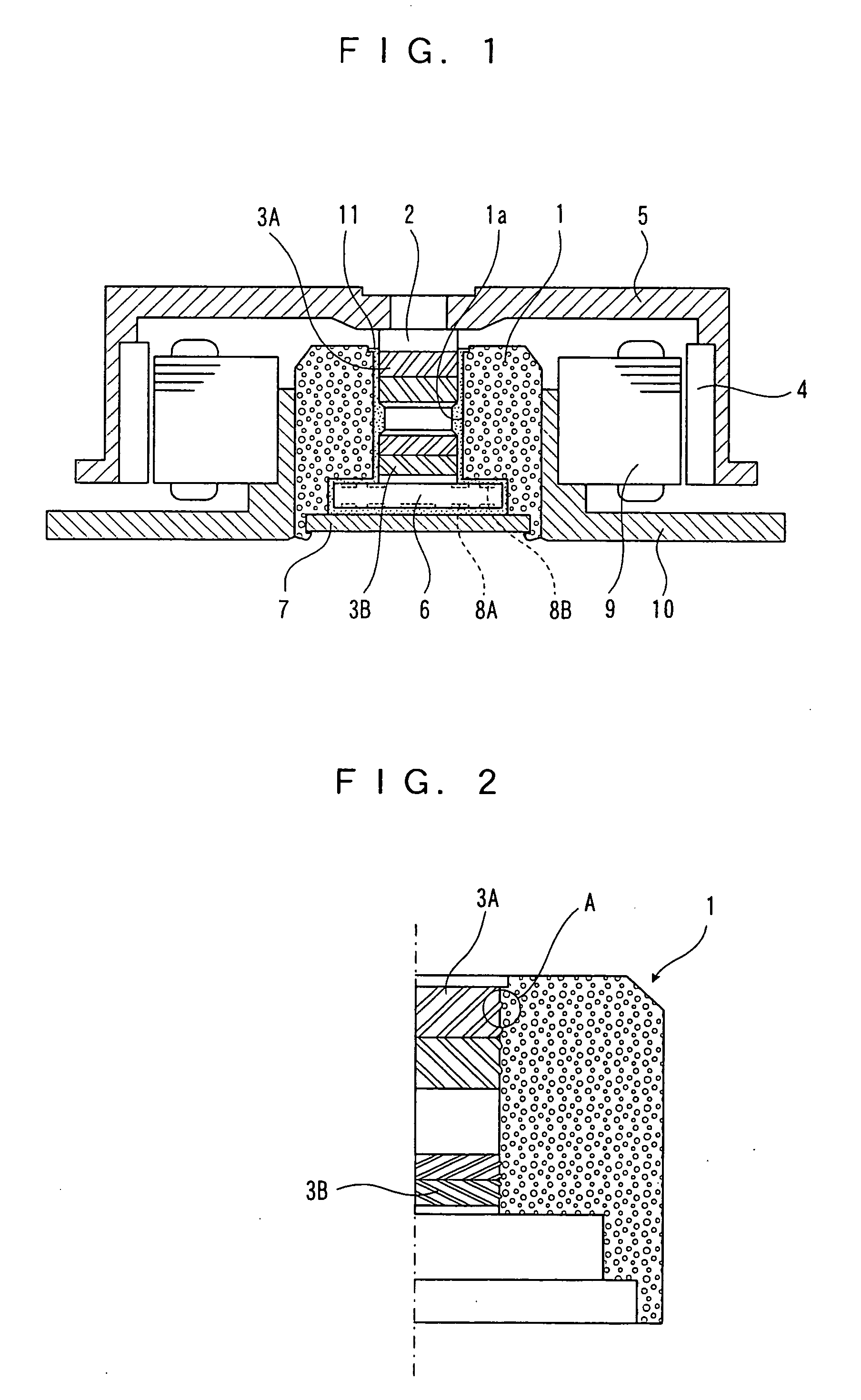

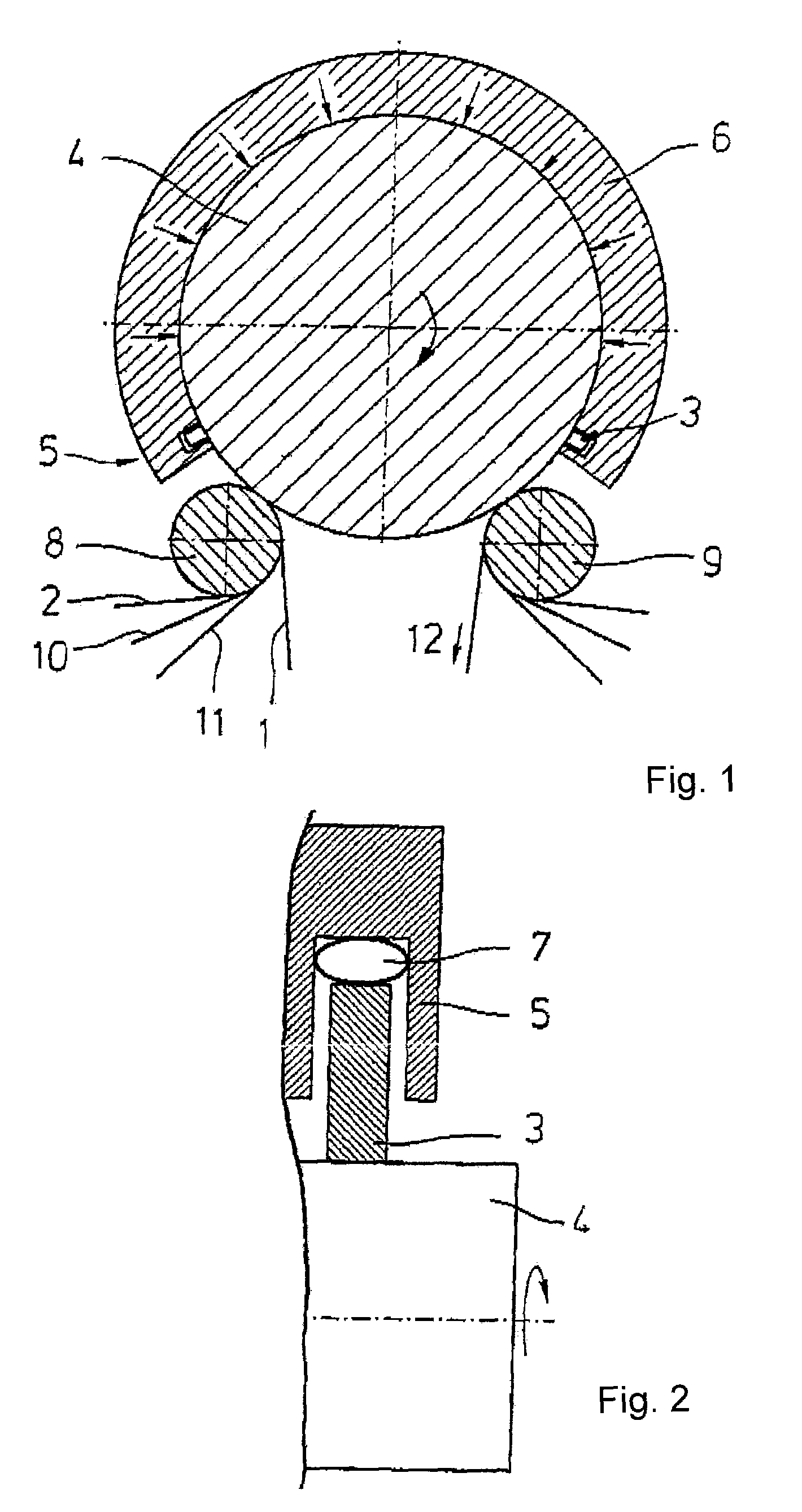

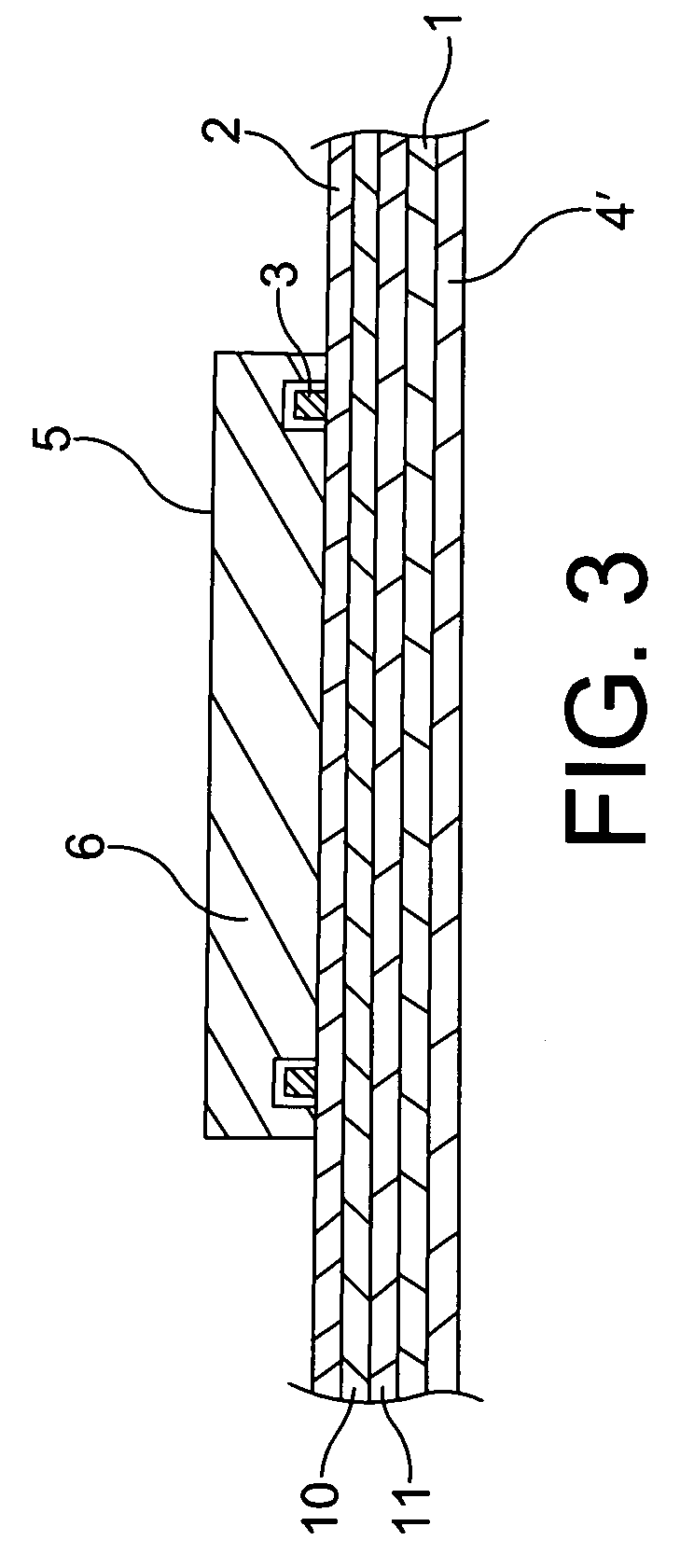

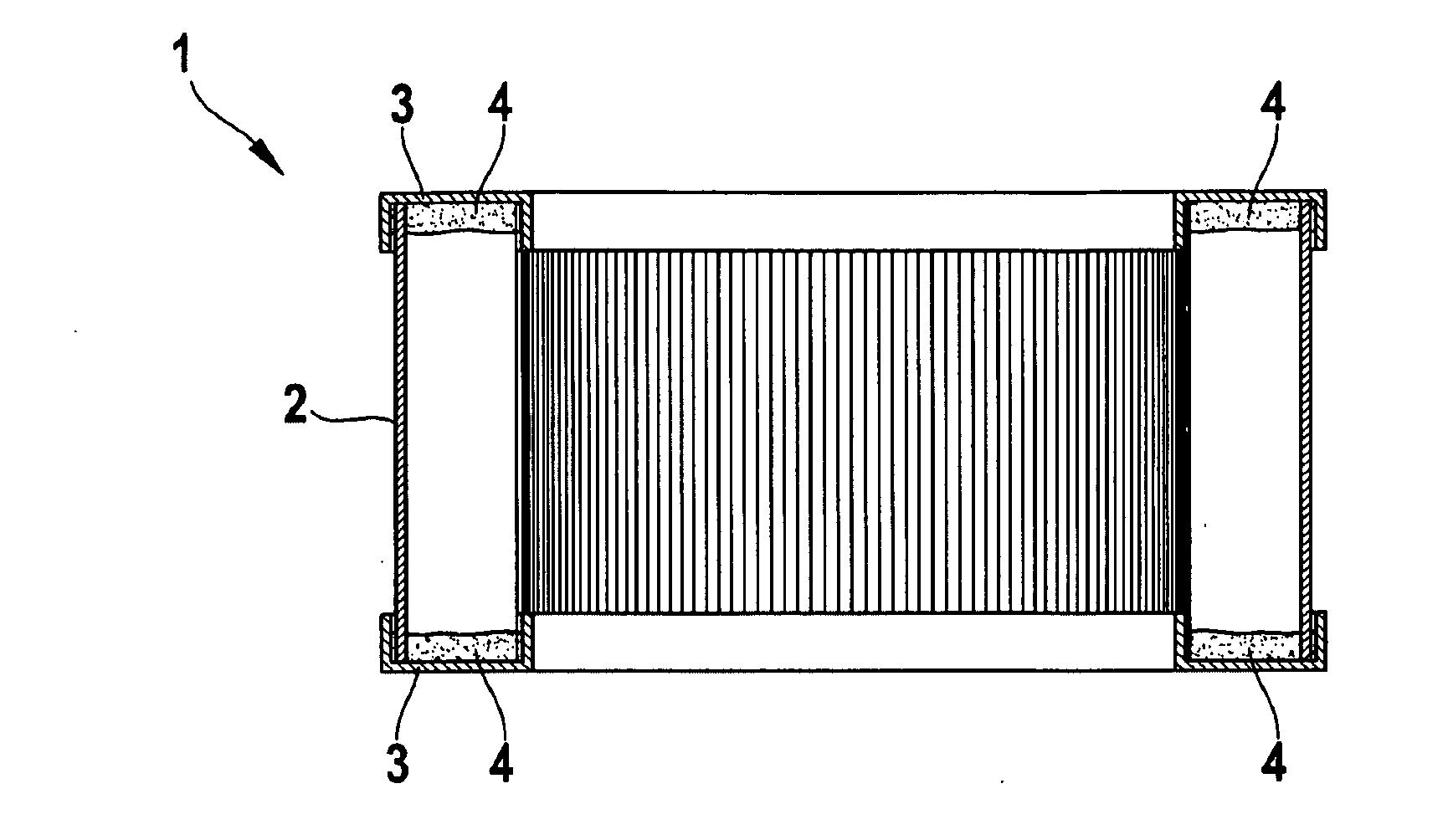

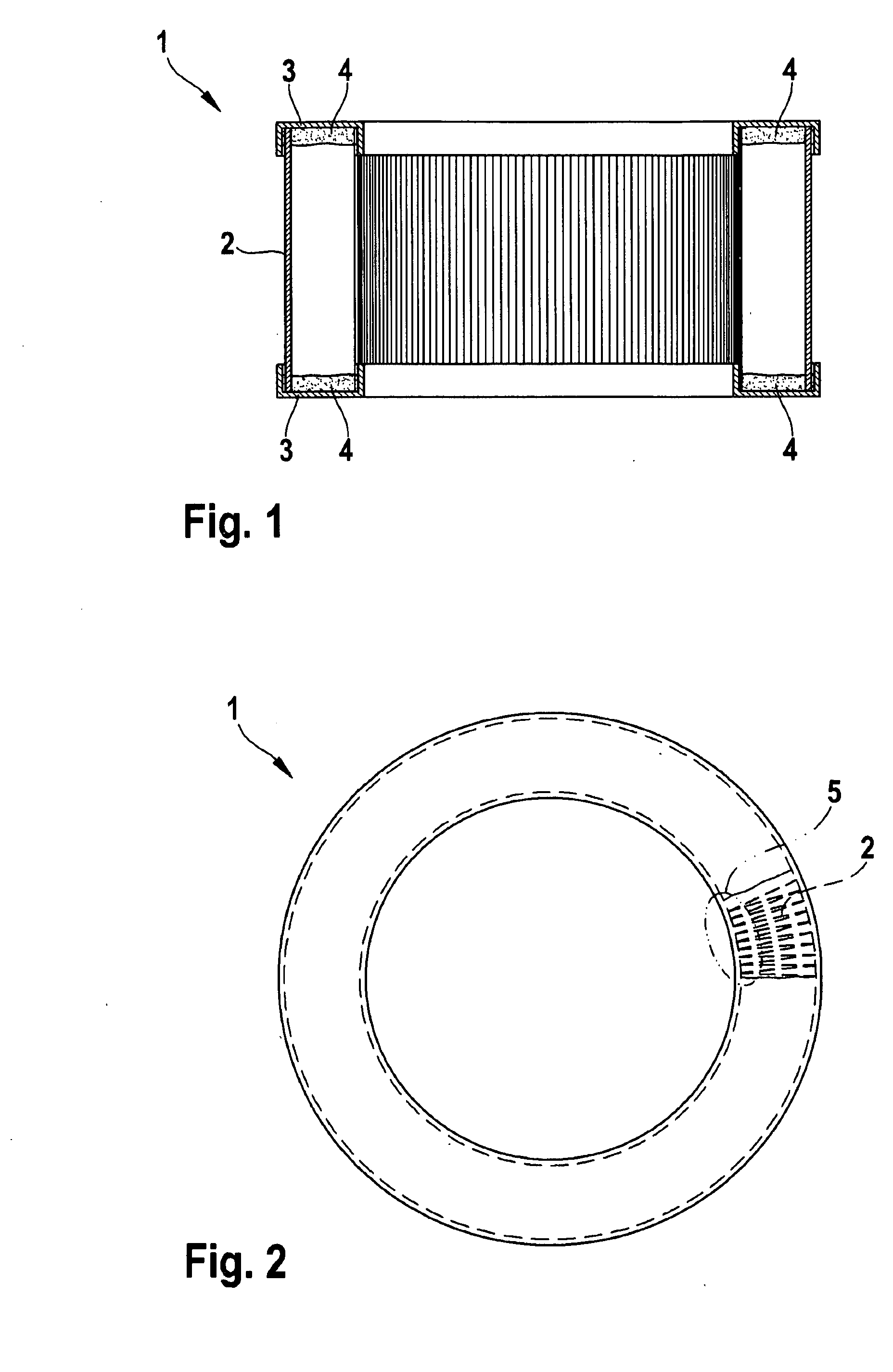

Filter Element with Glued-On Terminal Disk

InactiveUS20100051537A1Great gapGreat volumeDispersed particle filtrationMembrane filtersFace contourIntermediate space

A filter element (1) with a hollow-cylindrical star-shaped folded filter medium (2) and glued-on terminal disks (3) on at least one of the end faces of the filter medium (2) is proposed in which the respective end face contour of the filter medium (2), the intermediate space between the filter medium (2) and the respective terminal disks (3), and / or the respective contour of the terminal disk (3) is designed, for example, by slants (8, 9) or spacers (10), such that at the inner diameter of the hollow-cylindrical star-shaped folded filter medium (2) an enlarged gap for an adhesive connection (4) between the filter medium (2) and the respective terminal disks (3) is provided so that the folds at the inner diameter are thus safely adhesively connected.

Owner:MANN HUMMEL GMBH

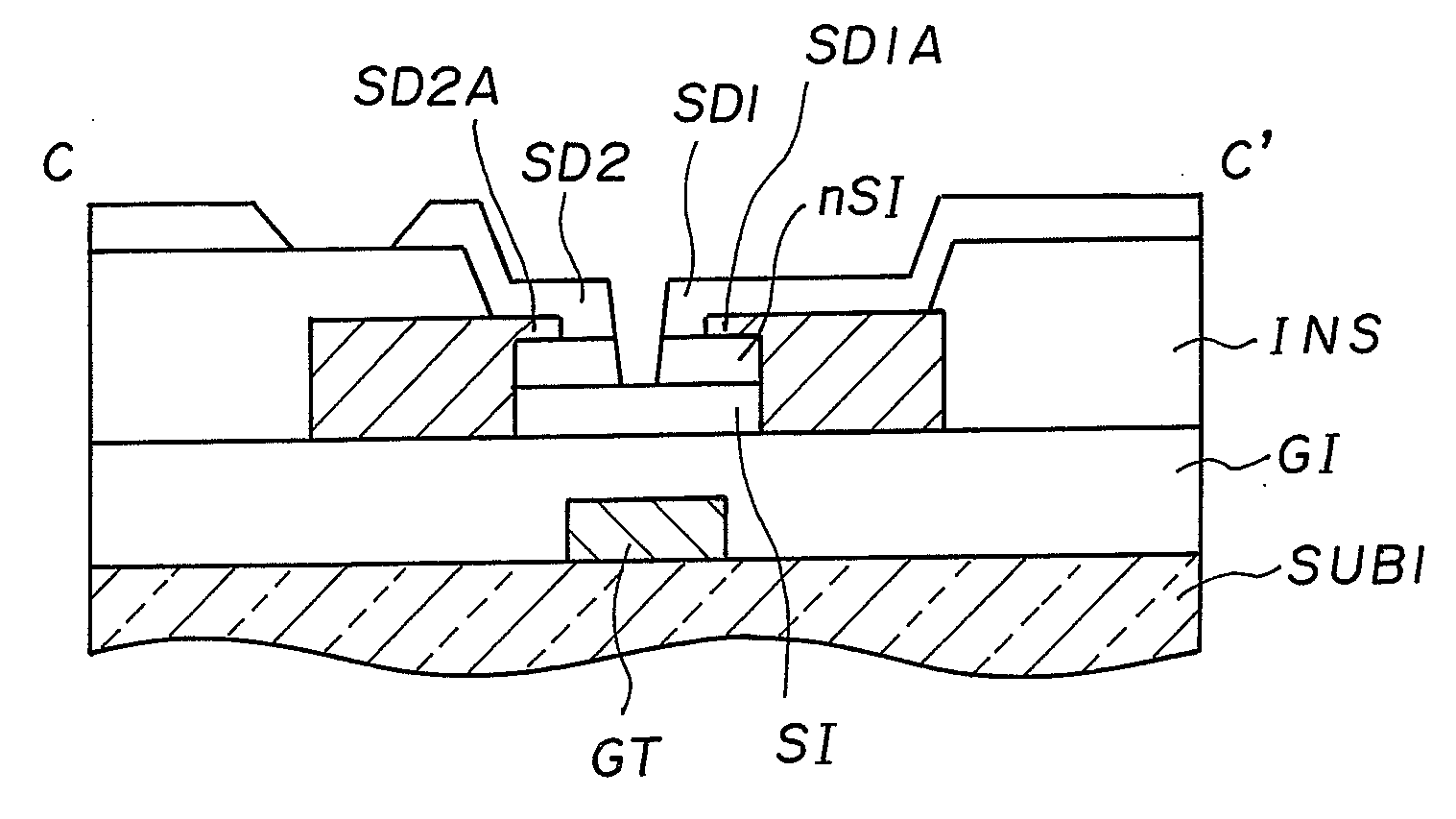

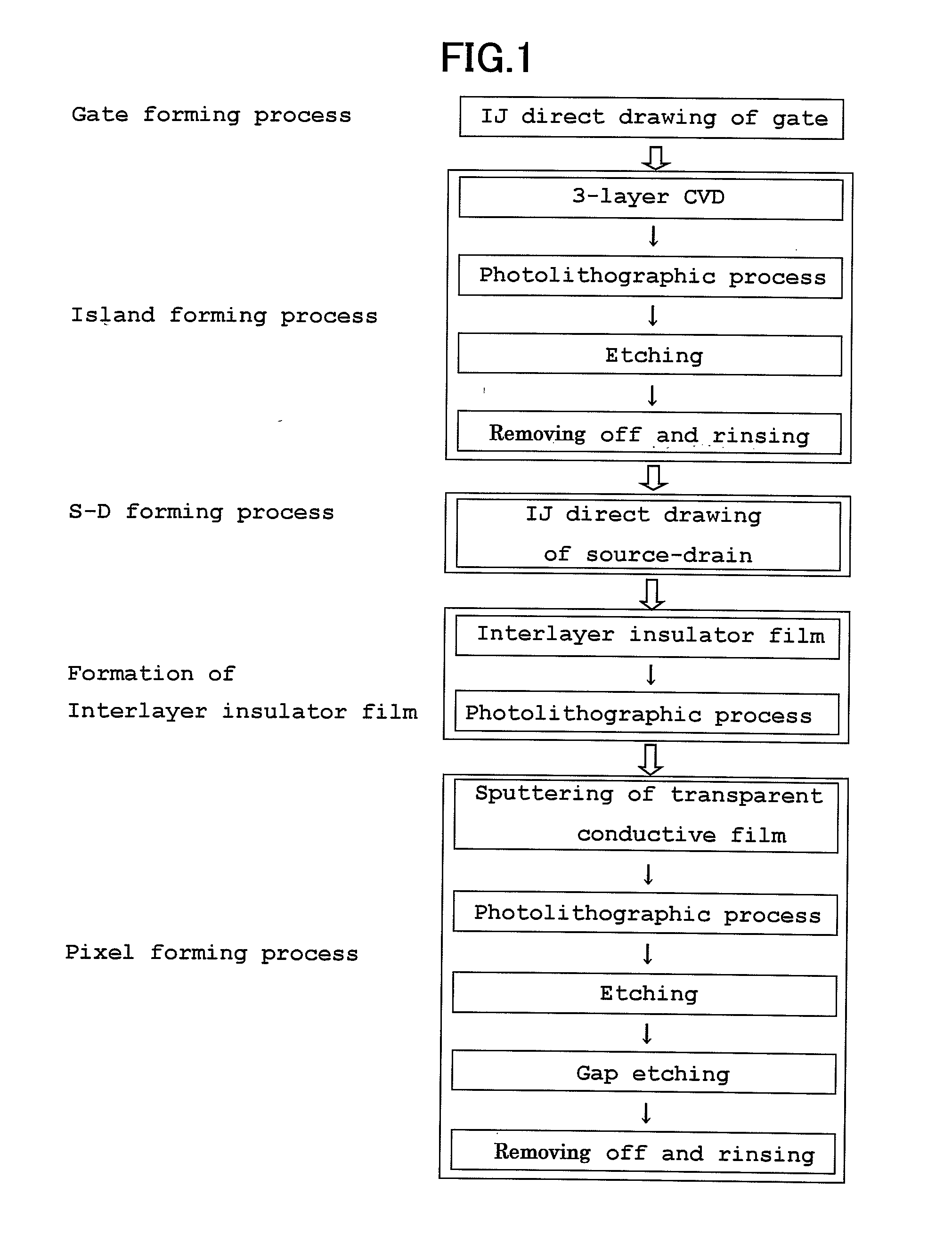

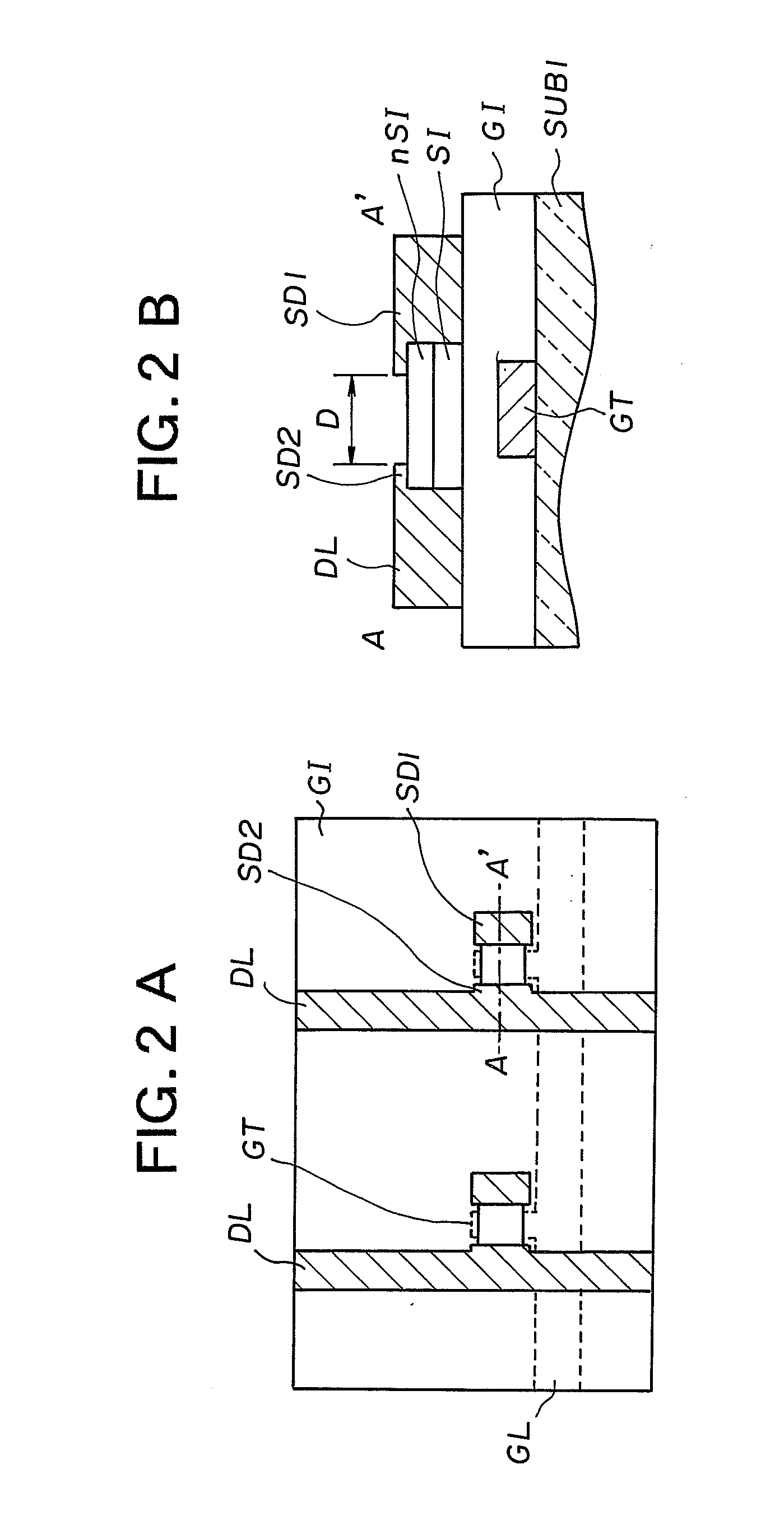

Liquid crystal display panel and method for manufacturing the same

InactiveUS20080055508A1Reduce in quantityGreat gapSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The present invention provides a new technique, in which direct drawing of ink jet is used and a gap between a source electrode and a drain electrode is narrowed down to 4 μm or less without increasing the number of processes. According to this technique, a conductive layer SD1A and a conductive layer SD2A arranged at opposed positions with a first gap are prepared by direct drawing of ink jet on upper layer of a silicon semiconductor layer SI by forming a source electrode SD1 and a drain electrode SD2 on a thin-film transistor, and by a laminating layer of the transparent conductive films SD1 and SD2 with a second gap, which is narrower than the first gap between the opposed ends of the conductive layers, to cover the upper layer of said first layer and the opposed ends of the conductive layers arranged at opposed positions.

Owner:FUTURE VISION

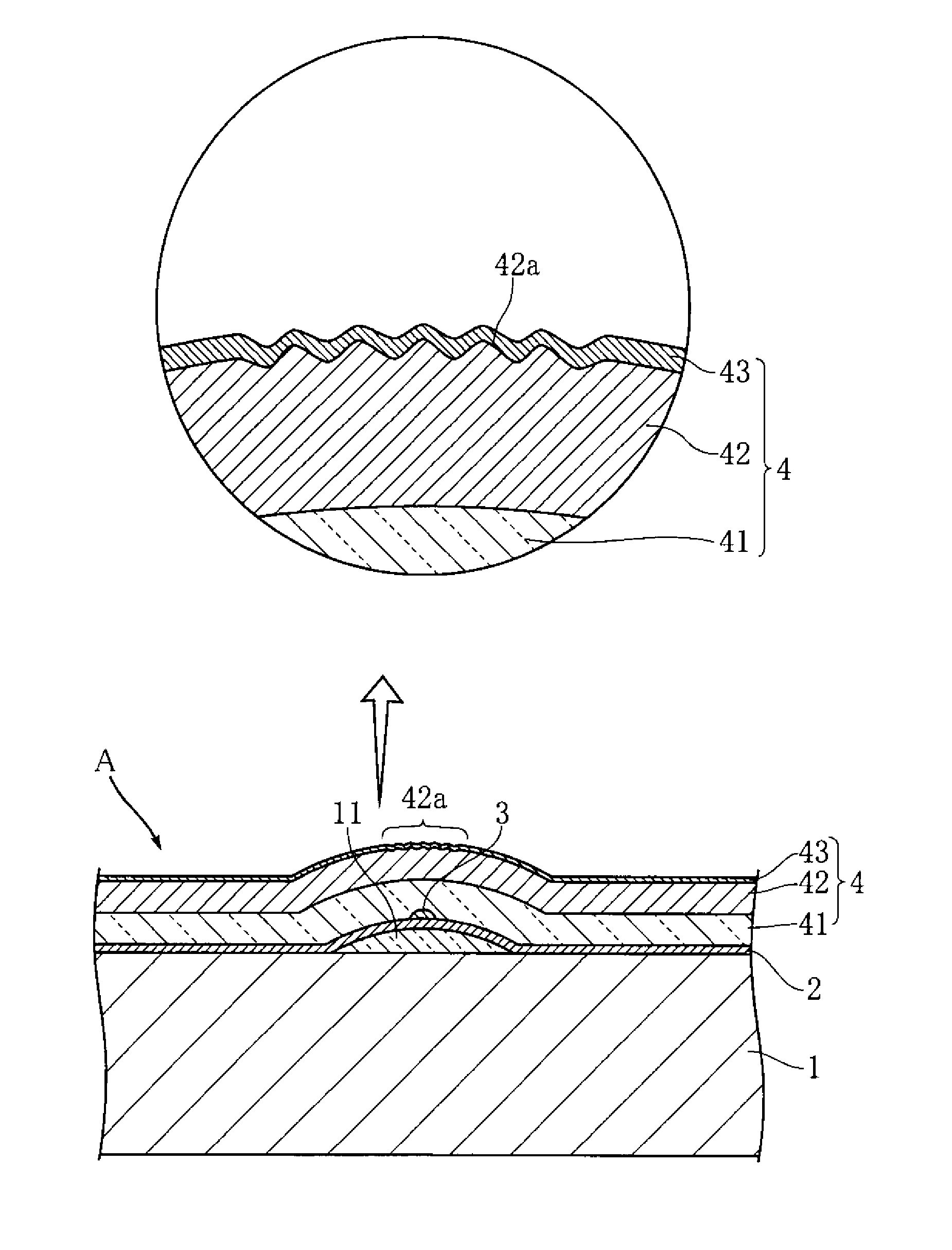

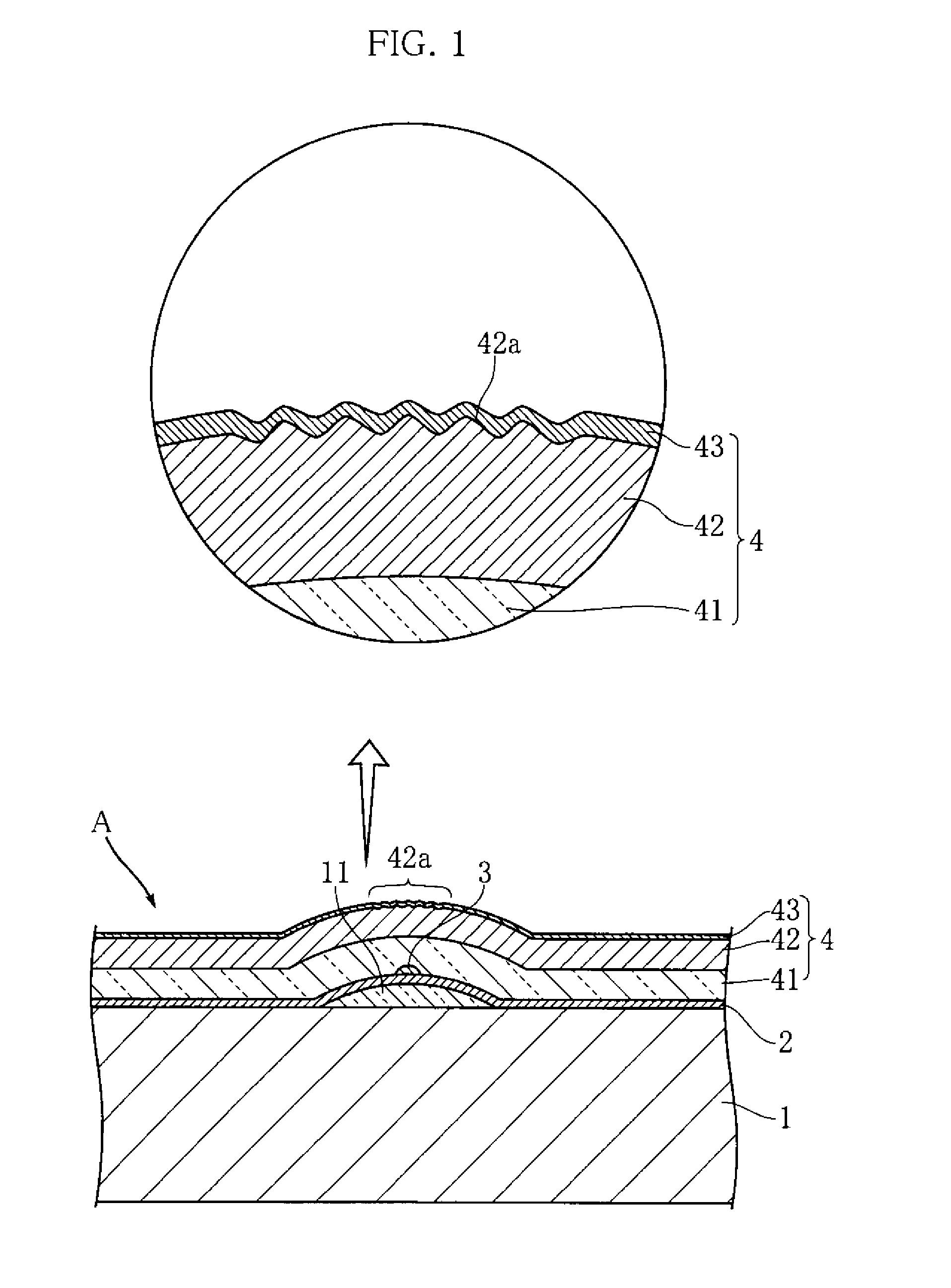

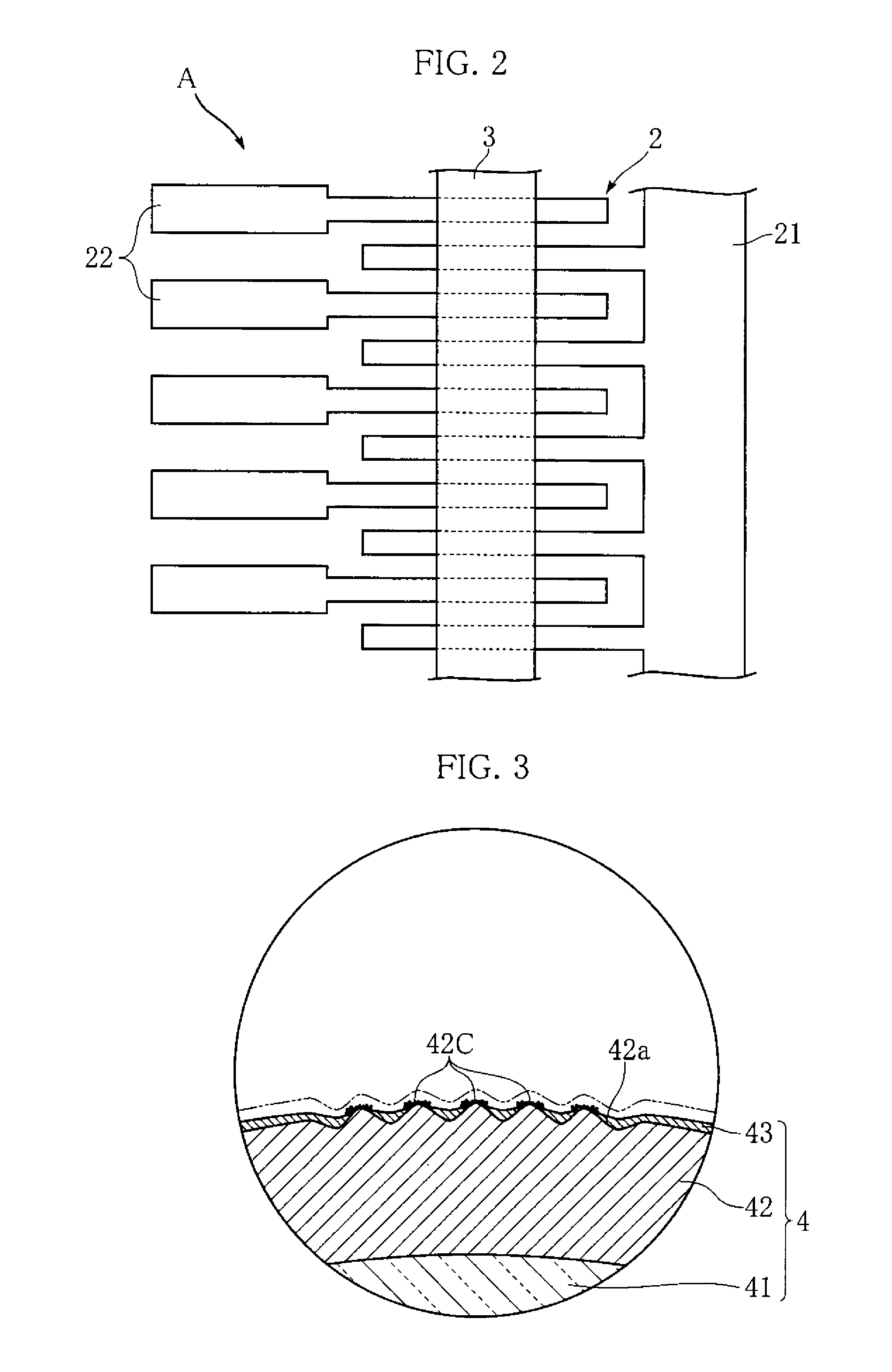

Thermal print head

A thermal print head A includes a substrate 1, a heat generating resistor 3 supported by the substrate 1, and a protective layer 4 which covers the heat generating resistor 3. The protective layer 4 includes a first inner layer 41 which is in contact with the heat generating resistor 3, a second inner layer 42 formed on the first inner layer 41, and an outer layer 43. Part of the second inner layer 42 is formed as a rough surface 42a which has a surface roughness of Ra 0.1 through 0.3. The rough surface 42a is disposed at a position corresponding to the heat generating resistor 3. The outer layer 43 is made of a metal nitride or a chemical compound containing a metal nitride, and has a thickness of 0.1 through 0.5 μm.

Owner:ROHM CO LTD

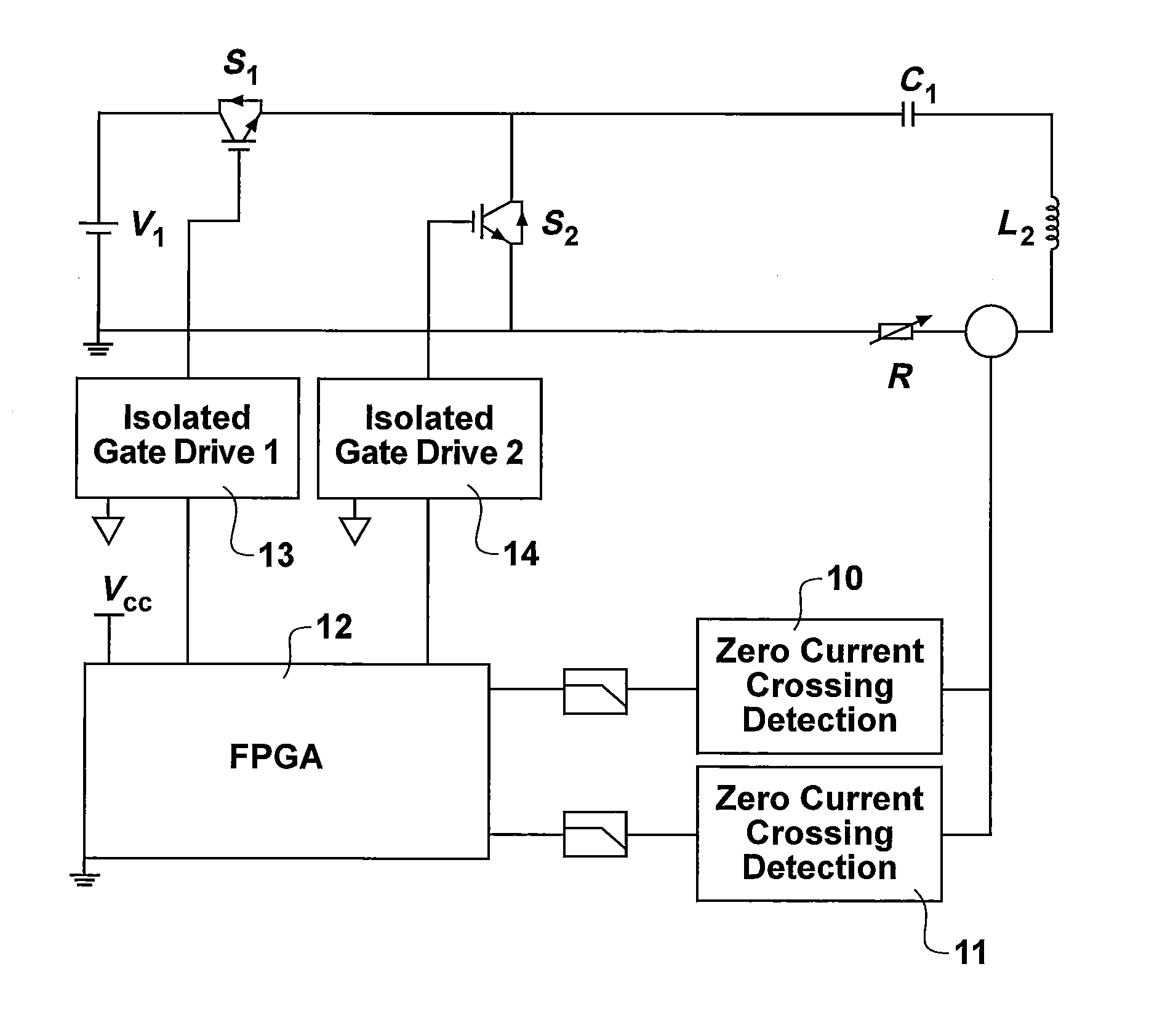

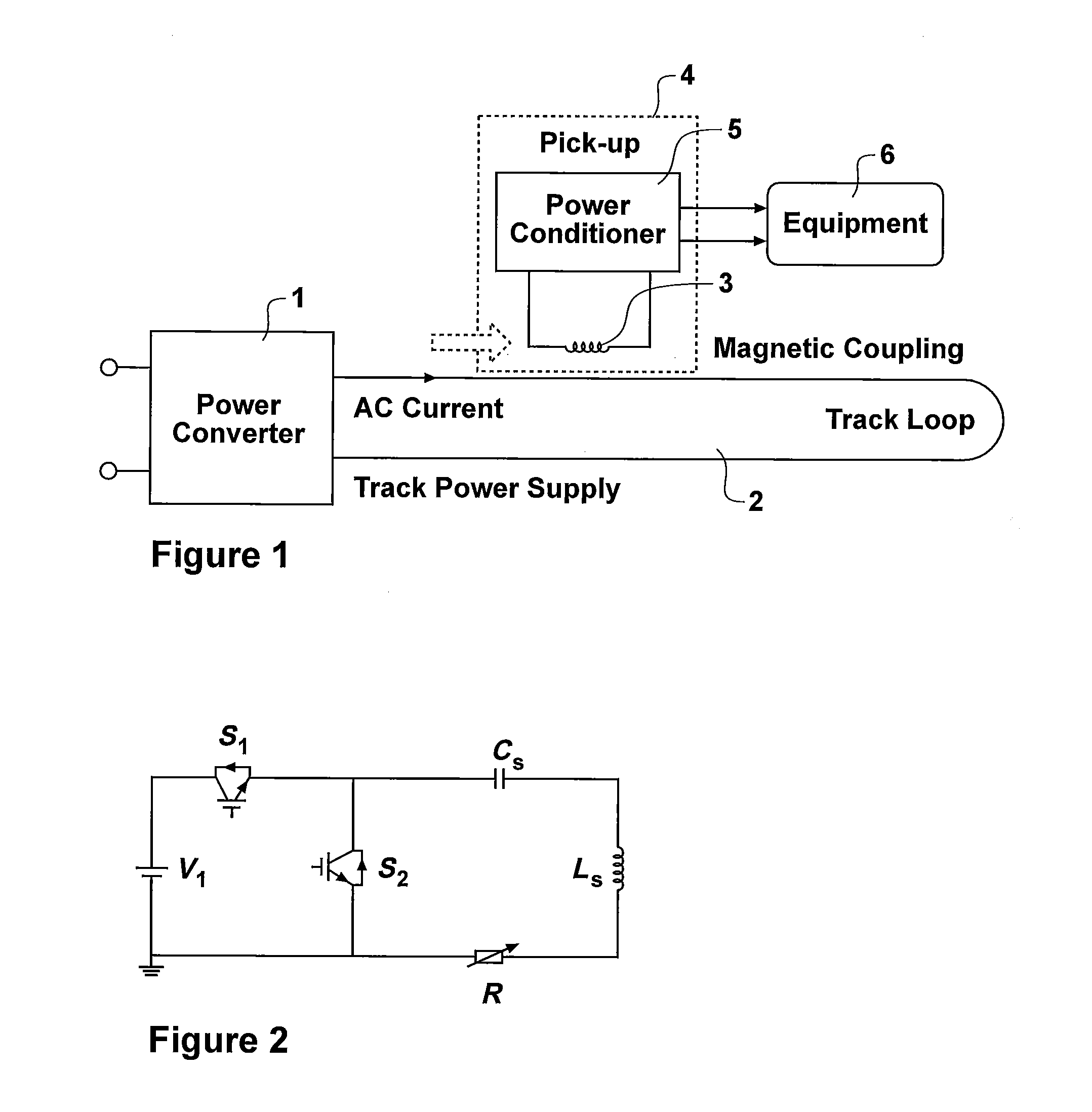

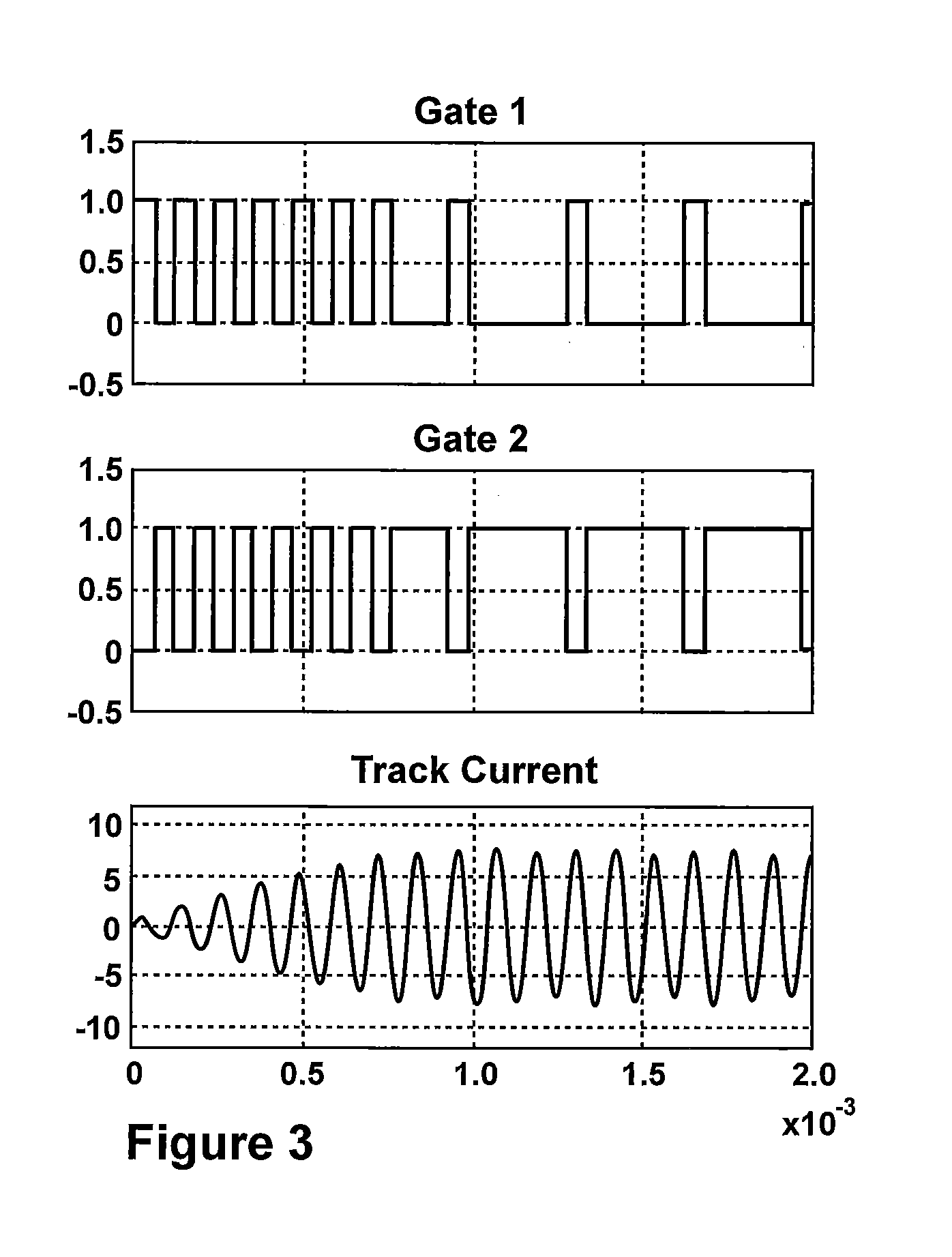

Inductive power transfer control using energy injection

ActiveUS20150244177A1Improve disadvantagesEasy to adaptBatteries circuit arrangementsElectromagnetic wave systemEngineeringParameter dependent

The invention relates to inductive power transfer (IPT) systems, and has particular relevance to control of IPT systems, and to operation of IPT system primary power supplier. There is provided a method for controlling an IPT system primary power supply having a switched resonant circuit; the method comprising: determining the value of a parameter of the system; determining an energy injection switching pattern having a duration dependent on the parameter value; controlling the resonant circuit according to the determined energy injection switching pattern.

Owner:AUCKLAND UNISERVICES LTD

Microfluidic apparatus and method of enriching target material in biological sample by using the same

ActiveUS20140154664A1Great gapBioreactor/fermenter combinationsBiological substance pretreatmentsChemical physicsMicrofluidics

A micro fluidic apparatus includes a sample chamber that divides a sample into a first fluid layer and a second fluid layer due to a centrifugal force; a first enriching unit a that receives the first fluid layer from the sample chamber, forms a first complex of a first fine particle and the first target material, and separates the first complex from the first fluid layer using a density difference; and a second enriching unit that receives the second fluid layer from the sample chamber, forms a second complex of a second fine particle and the second target material, and separates the second complex from the second fluid layer using a density difference.

Owner:SAMSUNG ELECTRONICS CO LTD

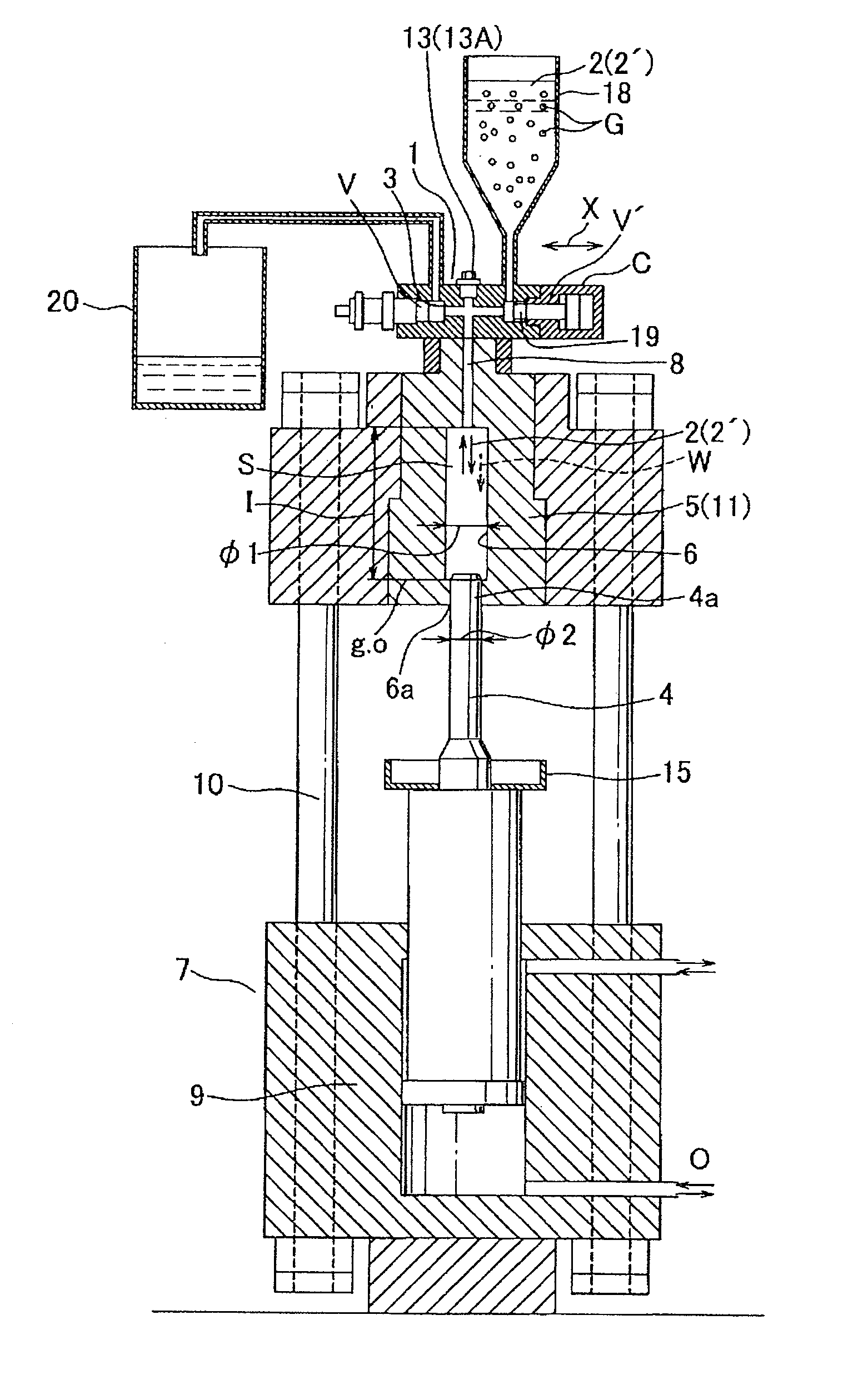

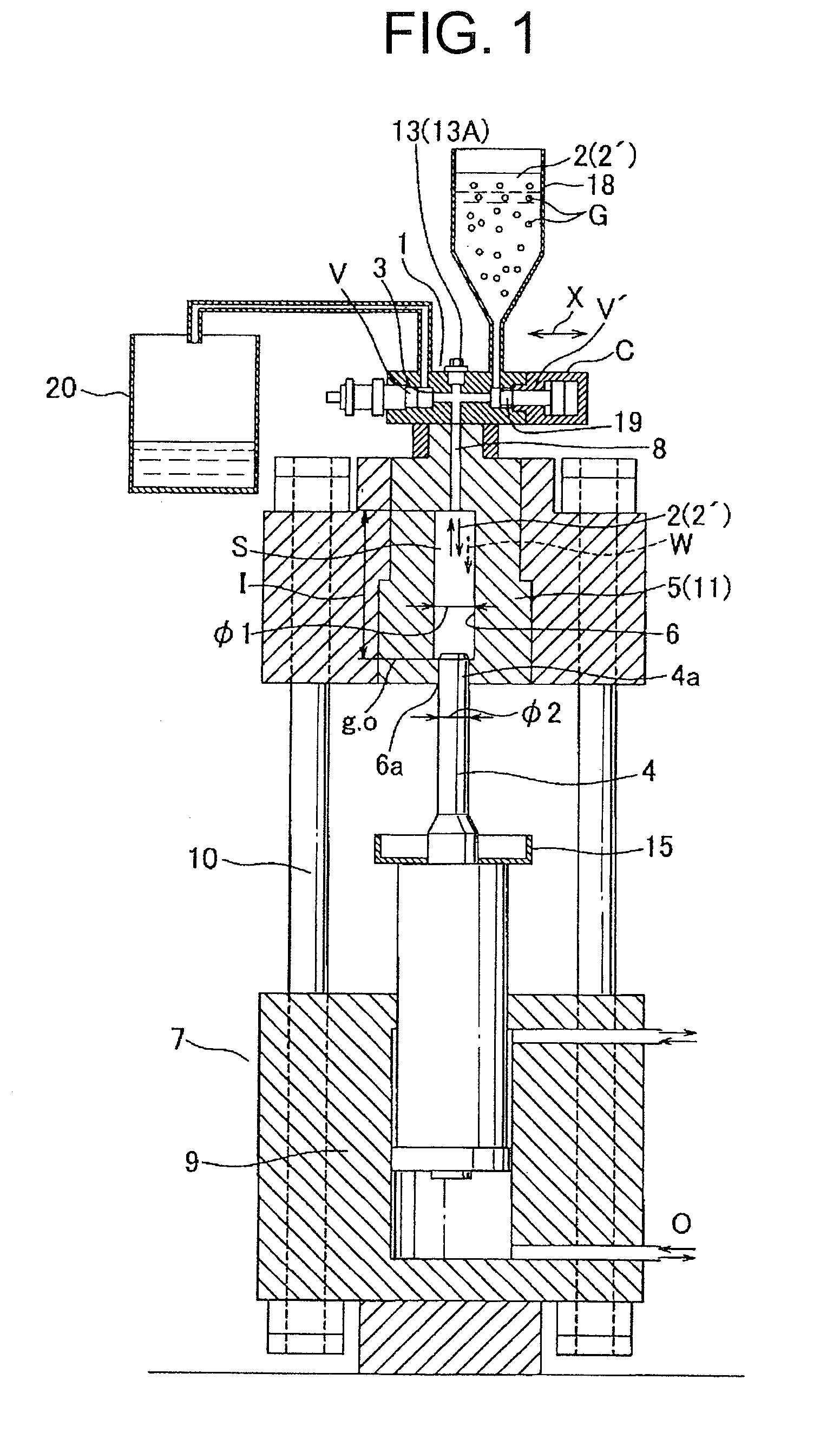

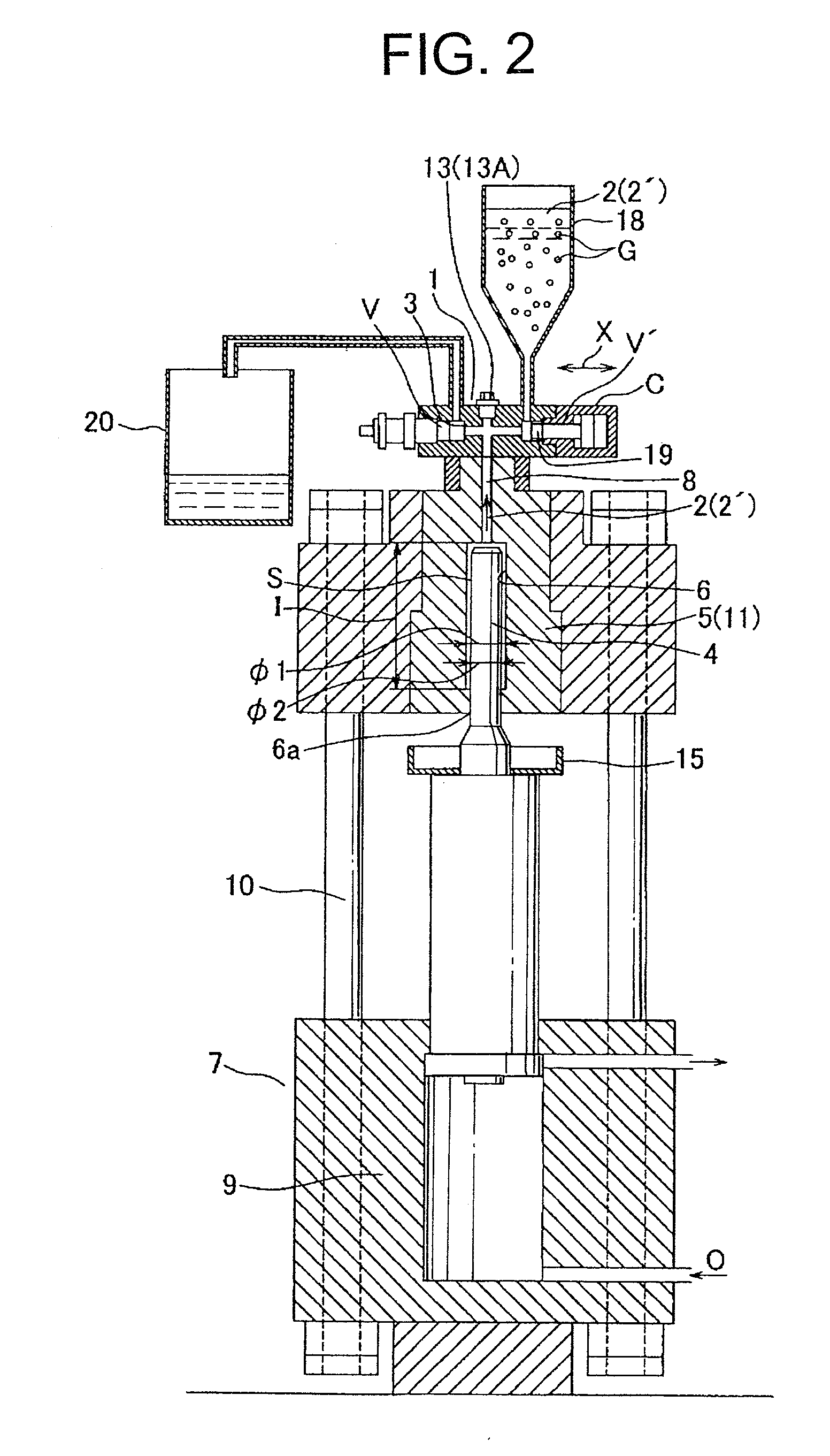

High-pressure homogenizing apparatus

InactiveUS20100208545A1Improve maintainabilityImprove manageabilityFlow mixersTransportation and packagingHigh pressureMaterials processing

A high-pressure homogenizing apparatus, in which a material receiving recess can be easily cleaned without disassembling / assembling a pressurizing mechanism, is provided. The apparatus includes a high-pressure homogenizing mechanism (1) in which a suspension (2) or semisolid (2′) containing a raw material (G) is passed through the orifice (3) to be subdivided; and a material receiving passage (8) communicated with the high-pressure homogenizing mechanism (1). One of the inserting member (5) and the material processing piston (4) is moved relatively to each, thereby the suspension or semisolid including the raw material is transferred into the material receiving passage (8) so as to be subdivided and processed. When the material processing piston is moved back over open end (6a) of the material processing recess, the cleaning liquid (W) is introduced through the material receiving passage into the material processing recess and the inside of the material processing recess is cleaned.

Owner:ANDO SHIGEO +2

Seat structure

Owner:DELTA TOOLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com