Bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

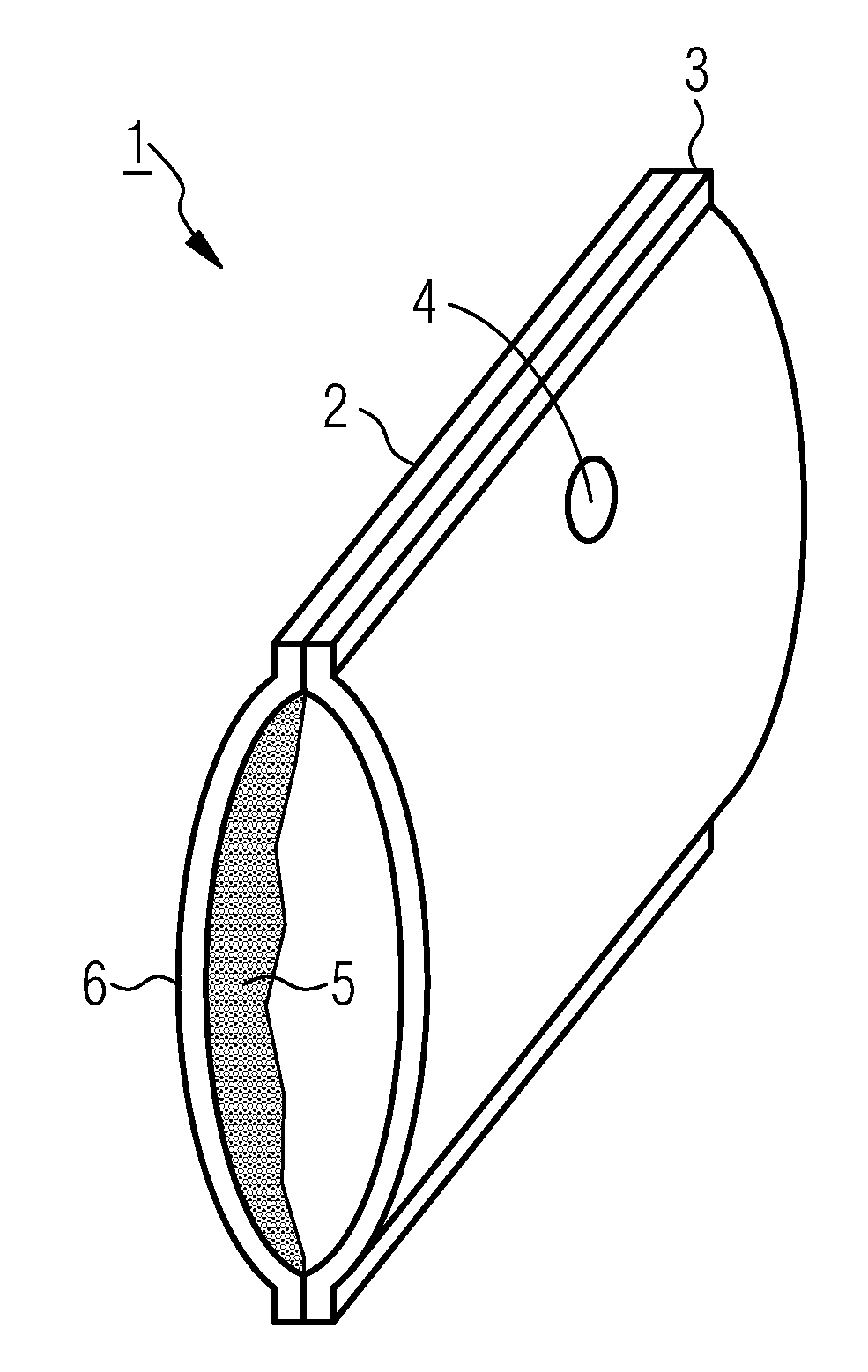

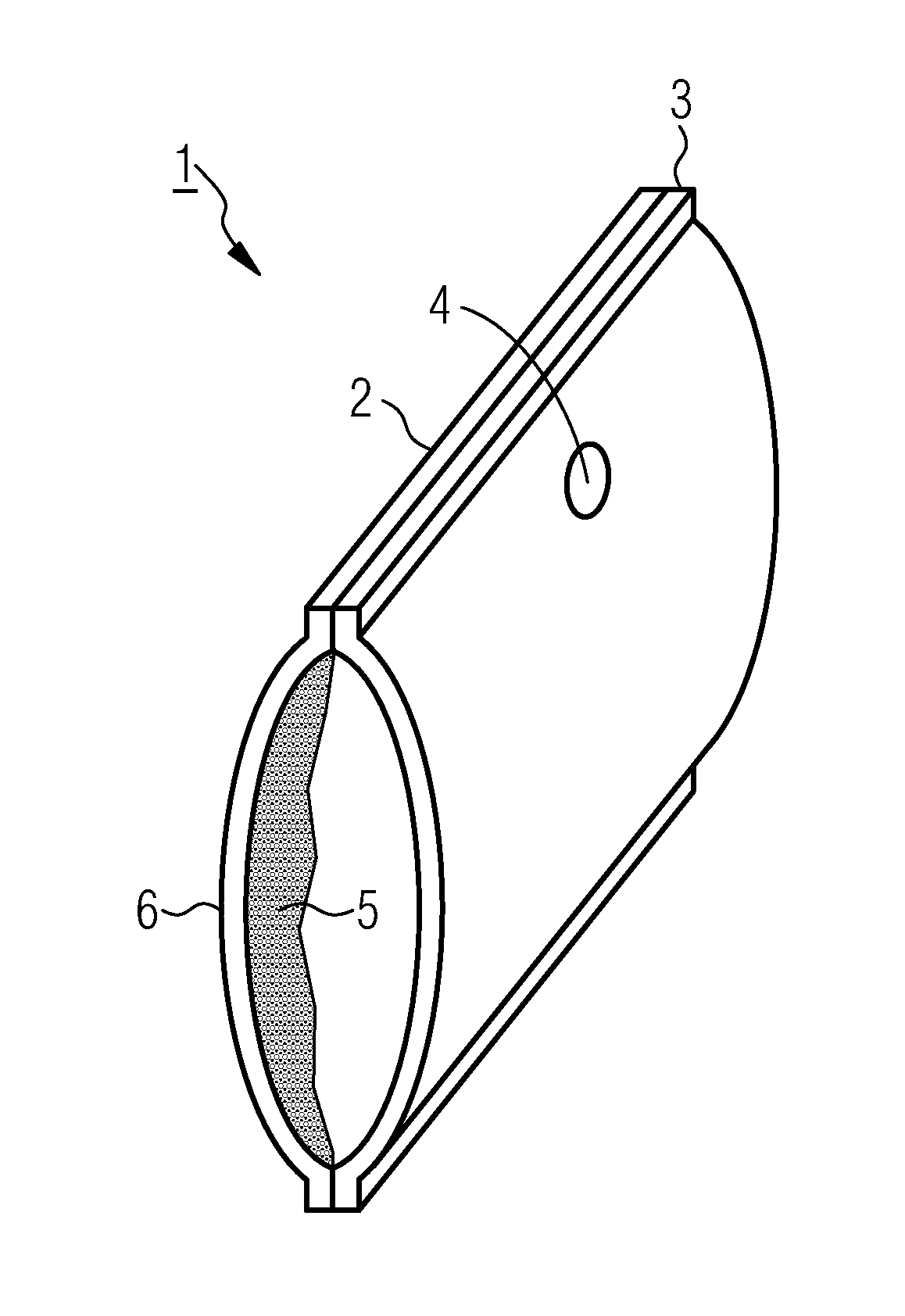

[0023]Referring now to the single FIGURE of the drawing in detail, there is shown a bag 1 in a form of a flat bag as in the invention, composed of a rough film 2 and of an opposite smooth film 3, and welded together at the respective edges. The bag 1 has an aperture 4 for the adhesive fastening of a screw-thread closure which has circular cross section and is not depicted in the drawing.

[0024]The roughened lateral film 2 has been configured as a multilayer film. The film 2 has been coextruded in three layers in a blown-film system and has a rough internal side 5, where the rough internal side 5 faces toward the internal side of the bag. The external side 6 of the film 2 is smooth. The rough internal side 5 and the smooth external side 6 of the film 2 have been manufactured from LLDPE, and for the roughening of the internal side 5 here coarse silica has been admixed only into the layer as a roughening additive alongside lubricants, fine anti-blocking agents, and processing aids. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com