Synthetic Dry Adhesives

a technology of synthetic adhesives and adhesives, applied in the direction of film/foil adhesives, coatings, transportation and packaging, etc., can solve the problems of high cost, high cost, and limited use of such adhesives in climbing applications, and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

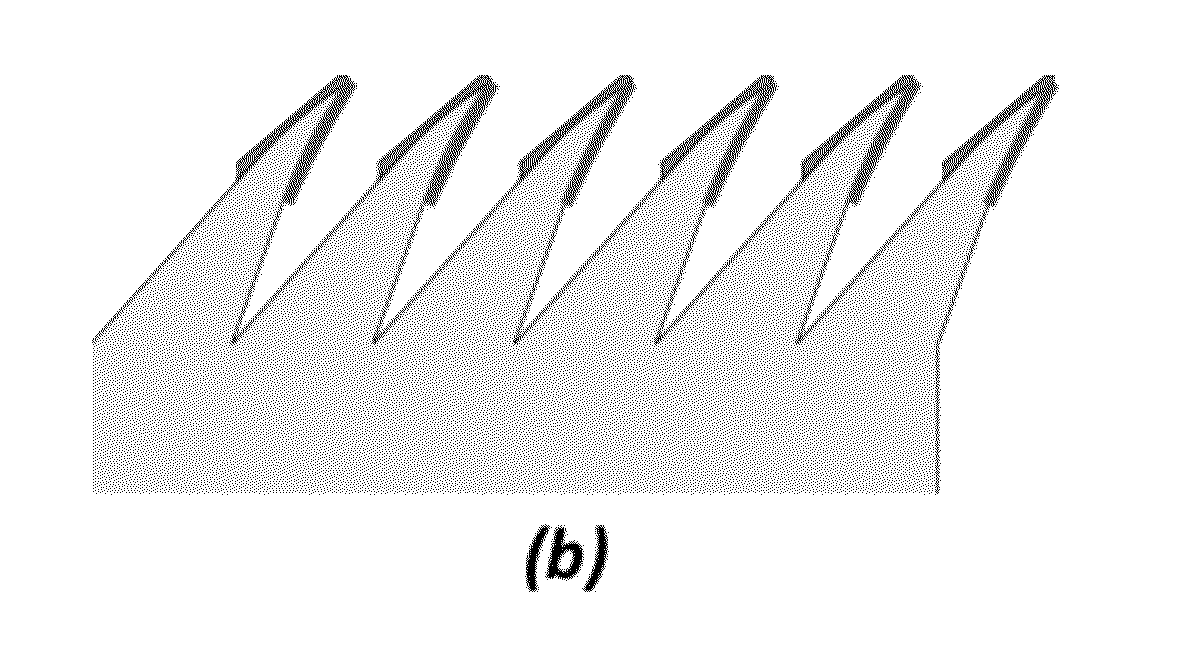

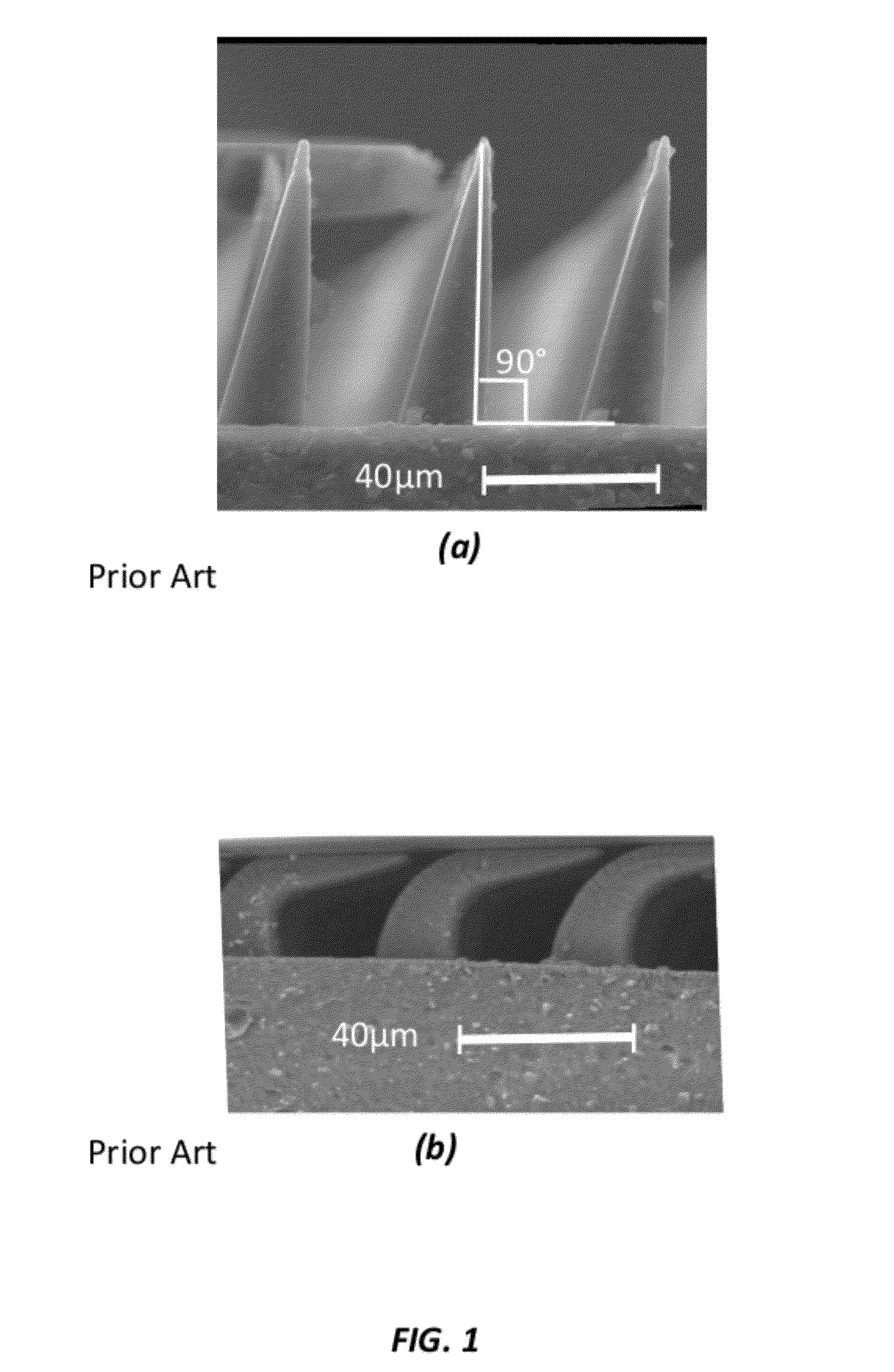

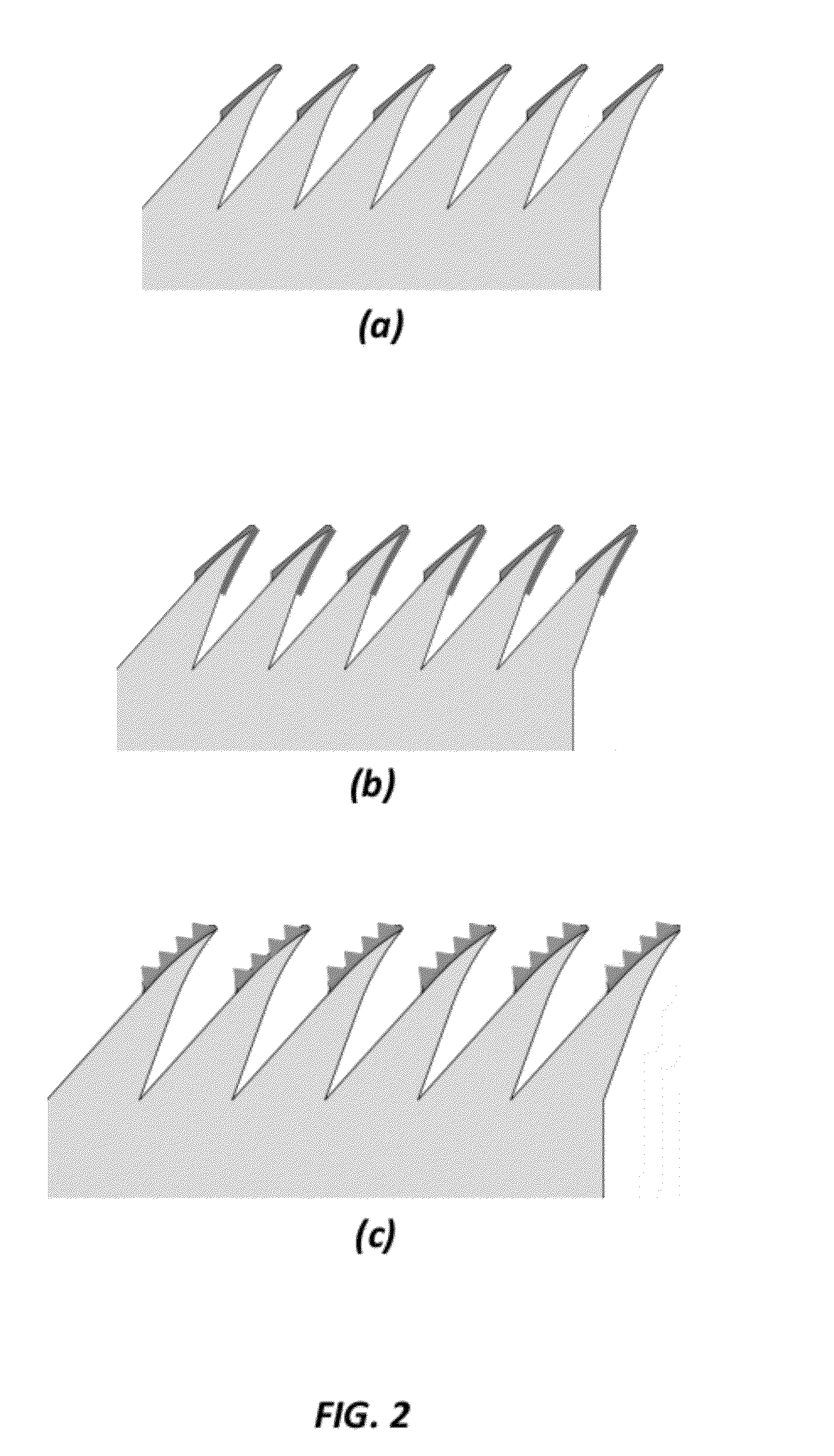

[0038]Directional dry adhesives are inspired by animals such as geckos and are a particularly useful technology for climbing applications. Previously, they have generally been manufactured using photolithographic processes. The current invention provides a micro-machining process that makes cuts in a soft material using a sharp, lubricated tool to create closely spaced negative cavities of a desired shape. The machined material becomes a mold into which an elastomer is cast to create the directional adhesive. The trajectory of the tool is varied to avoid plastic flow of the mold material that may adversely affect adjacent cavities. The relationship between tool trajectory and resulting cavity shape is established through modeling and process characterization experiments.

[0039]The micro-machining process of the current invention is much less expensive than previous photolithographic processes used to create similar features and allows greater flexibility with respect to the micro-sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com