Heat sink having juxtaposed heat pipes and method for manufacturing the same

a heat sink and heat pipe technology, applied in the field of heat sinks, can solve the problems of limited heat conductivity efficiency of the whole structure, damage or burnout of electronic heat-generating sources, and other heat pipes that cannot help inactive heat pipes to conduct heat, etc., and achieve the effect of increasing the thermal contact area and increasing the heat-dissipation efficiency of the heat sinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

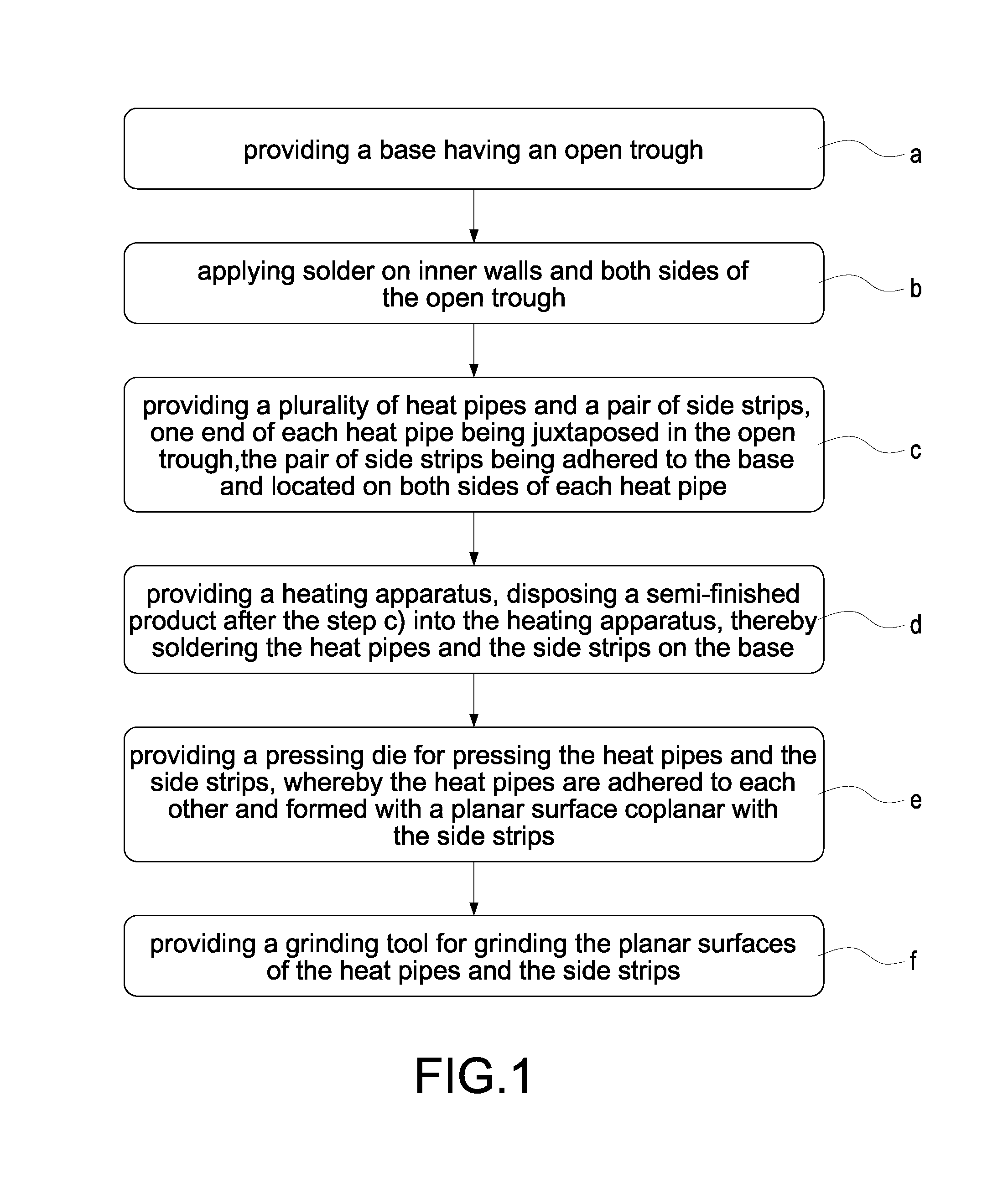

[0025]The detailed description and technical contents of the present invention will become apparent with the following detailed description accompanied with related drawings. It is noteworthy to point out that the drawings is provided for the illustration purpose only, but not intended for limiting the scope of the present invention.

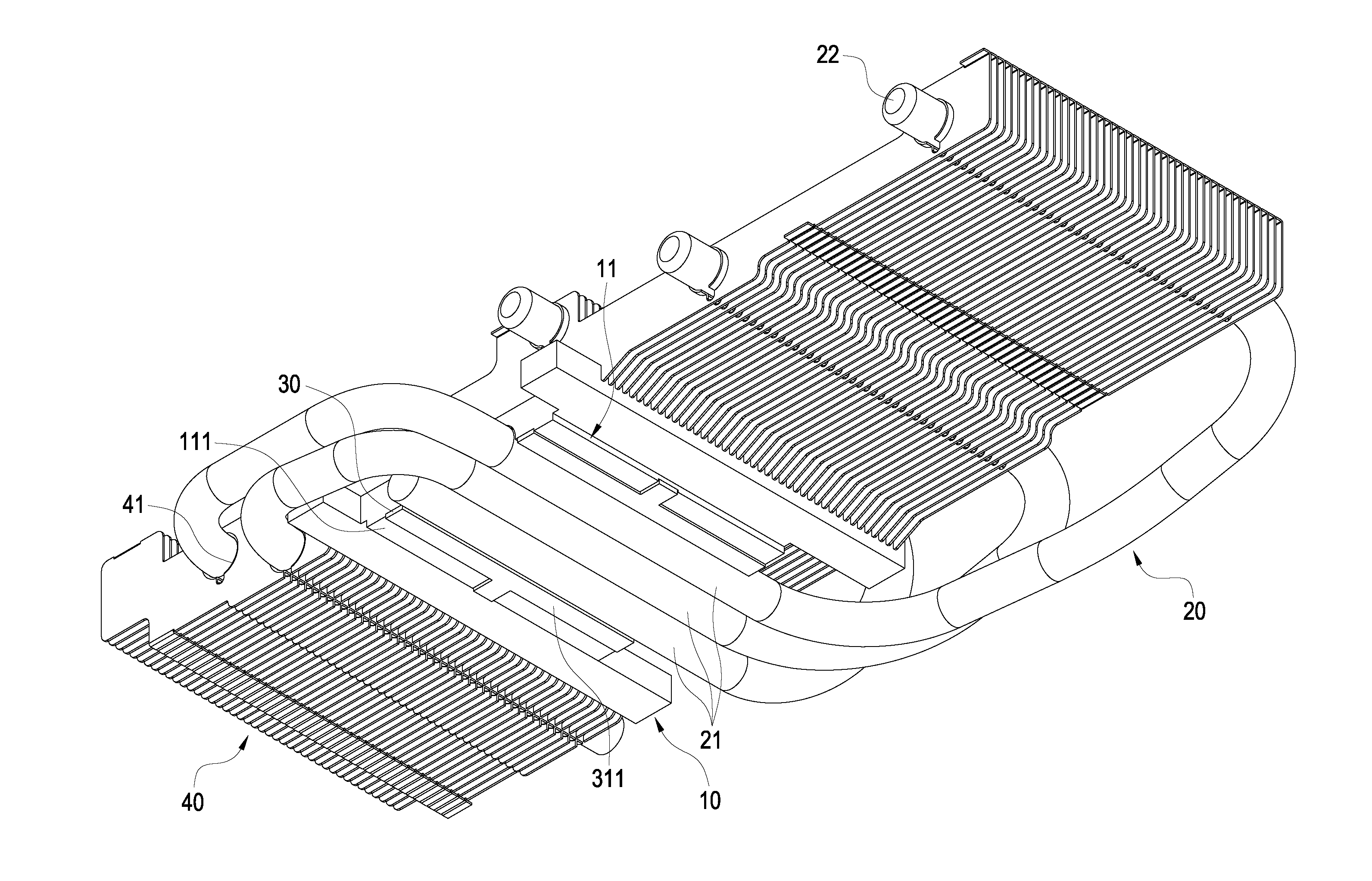

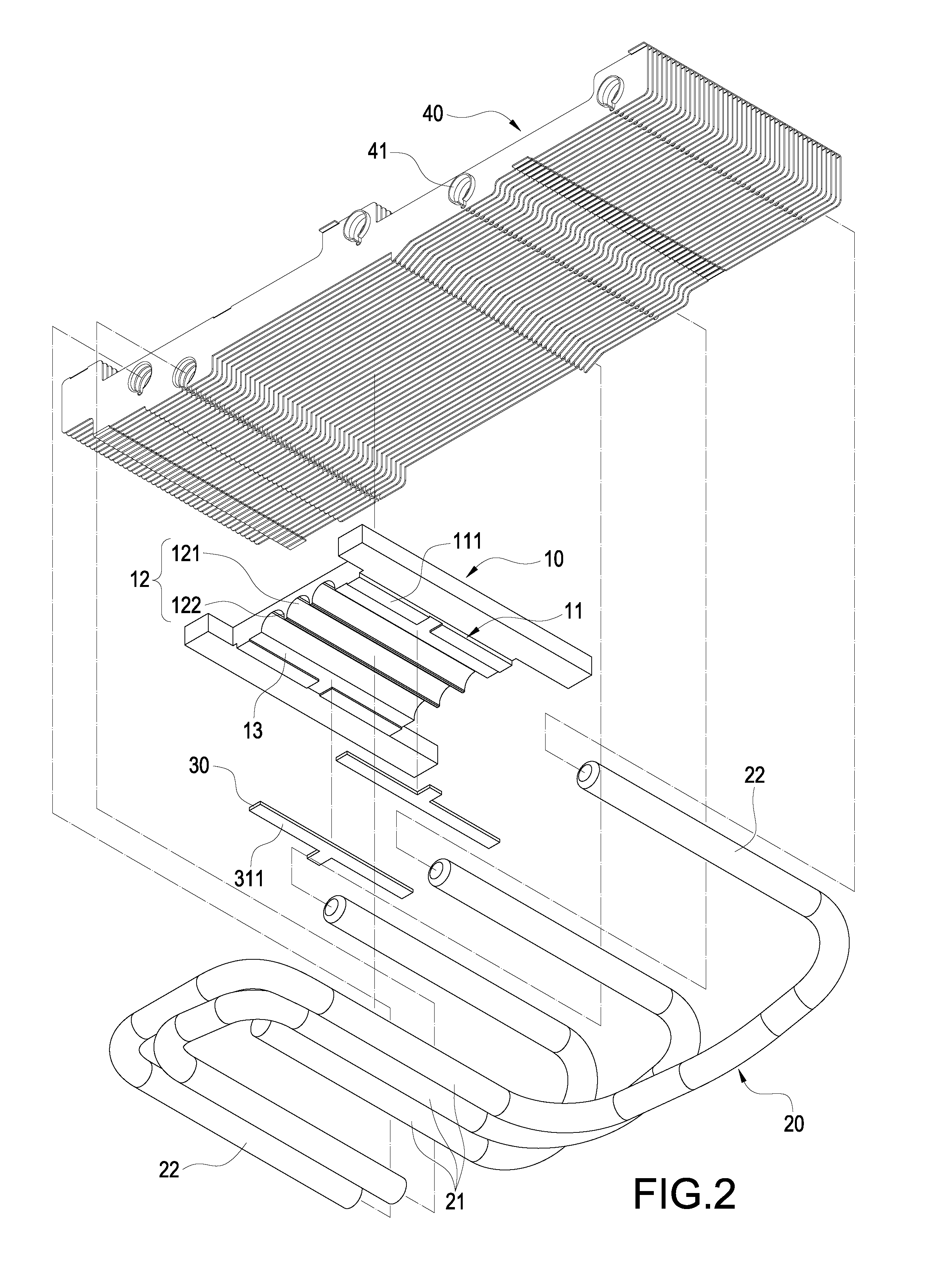

[0026]Please refer to FIGS. 2 and 4. The present invention provides a heat sink having juxtaposed heat pipes, which includes a base 10, a plurality of heat pipes 20, and a pair of side strips 30.

[0027]The base 10 is made of metallic materials such as aluminum or alloys thereof. In the present embodiment, the base 10 is formed into an H-shaped plate. The shape of the base 10 is not limited thereto, and may be formed into other shapes. The middle portion of the base 10 is provided with a protruding stage 11. The protruding stage 11 has a surface 111. The surface 111 is provided with an open trough 12. The interior of the open trough 12 is formed with three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| heat-conducting coefficient | aaaaa | aaaaa |

| heat-conducting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com