Compostable Tie

a compostable tie and tie technology, applied in the field of tie, can solve the problems of inability to quickly break down or compost, the tie is often broken to the ground, and the nylon does not quickly degrade or compost, so as to improve the rate of material degradation, improve the flexibility of the tie, and improve the compostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

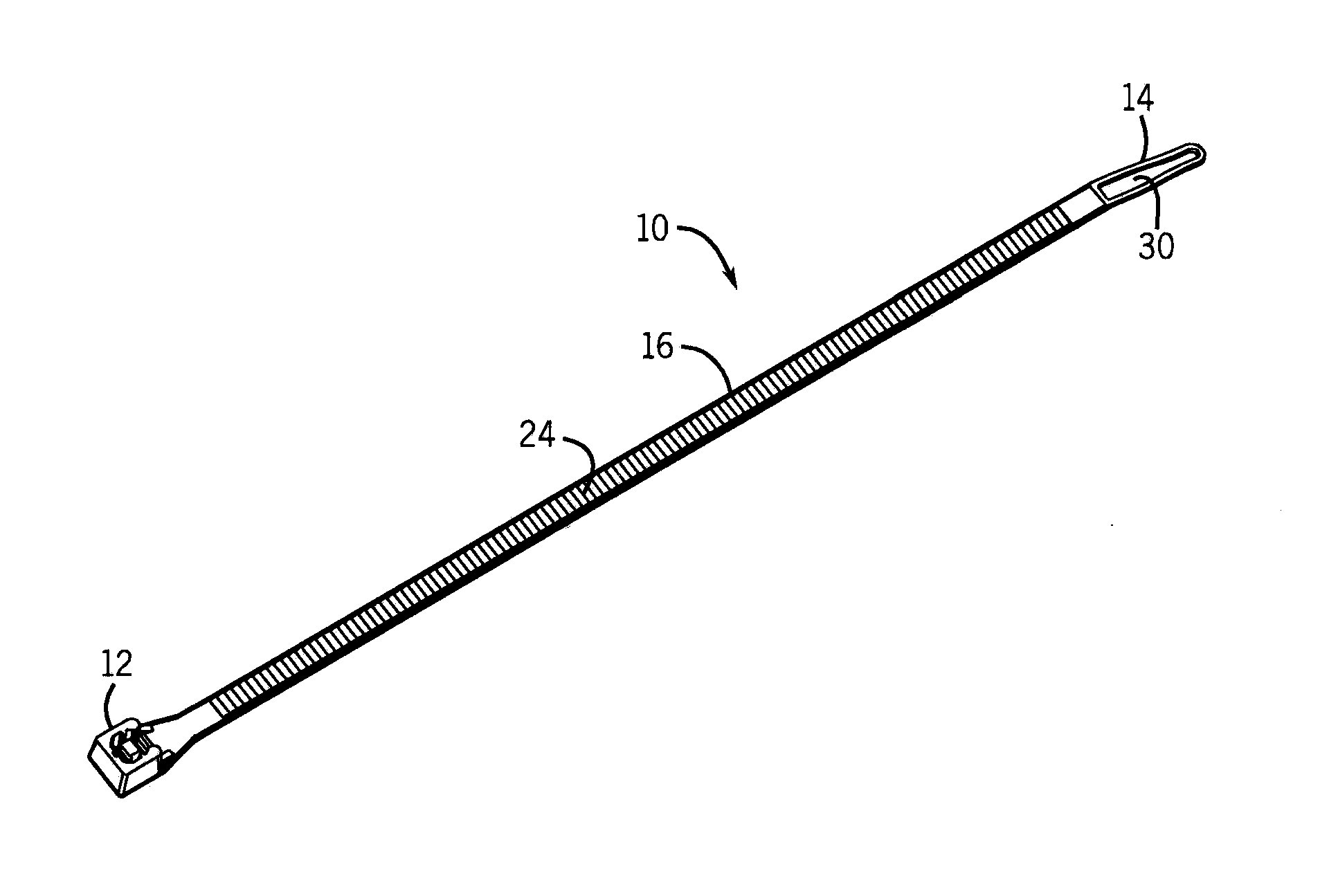

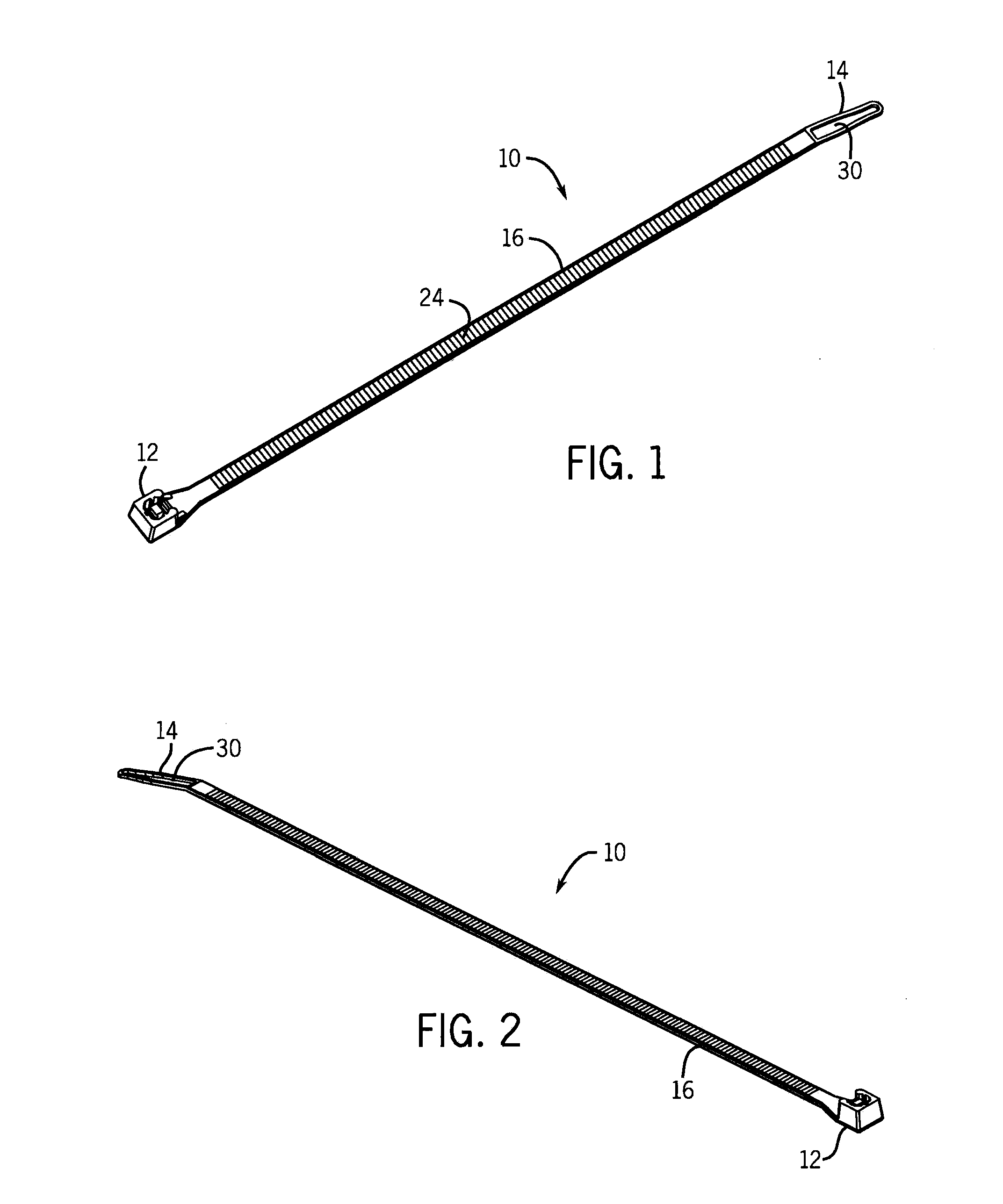

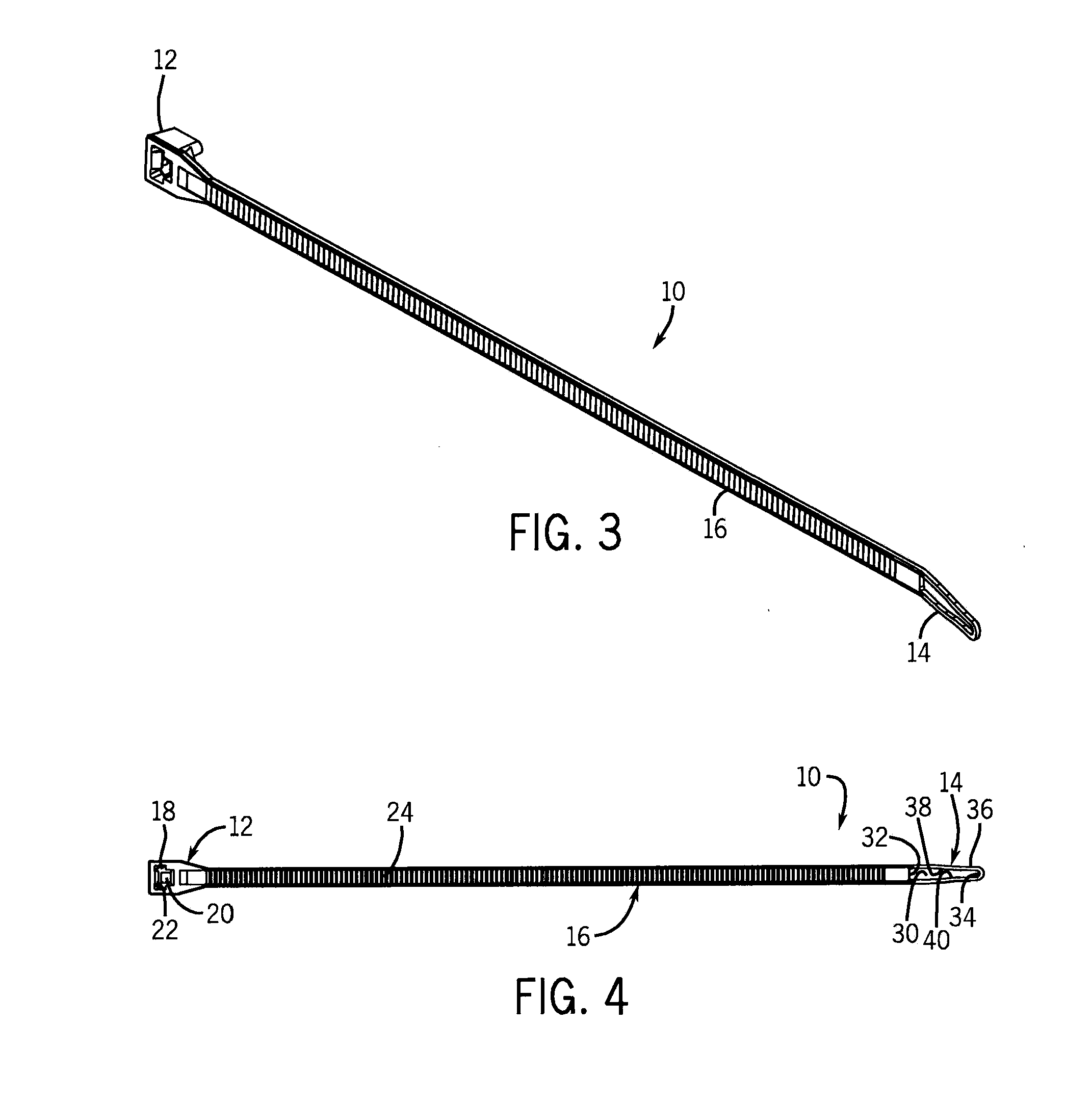

[0024]Referring to FIGS. 1-6, a tie 10 of the invention is generally a solid elongated strip of plastic with a head 12 at one end, a tail 14 at the other end, and a solid body 16 in between the head 12 and tail 14. The head end 12 includes a hole or eye 18 and a pawl 20 is molded as part of the tie 10 in the hole 18. In addition, engagement teeth 22 can be provided on the opposite side of the hole 18 from the pawl 20. The pawl 20 is like a small leaf spring that engages ratchet teeth 24 of the body 16, which may be on one or both sides of the body (see e.g., U.S. Pat. No. 5,664,294, commonly owned herewith, which is hereby incorporated by reference for its disclosure of tie structures that may be used with the present invention). The teeth 24 are ramped on their leading side and squared off on their trailing side so that once they pass by the resilient pawl 20, the pawl 20 engages the squared-off side and prevents the body 16 from being pulled out of the head 12. Both the front and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com