Dual-loop cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

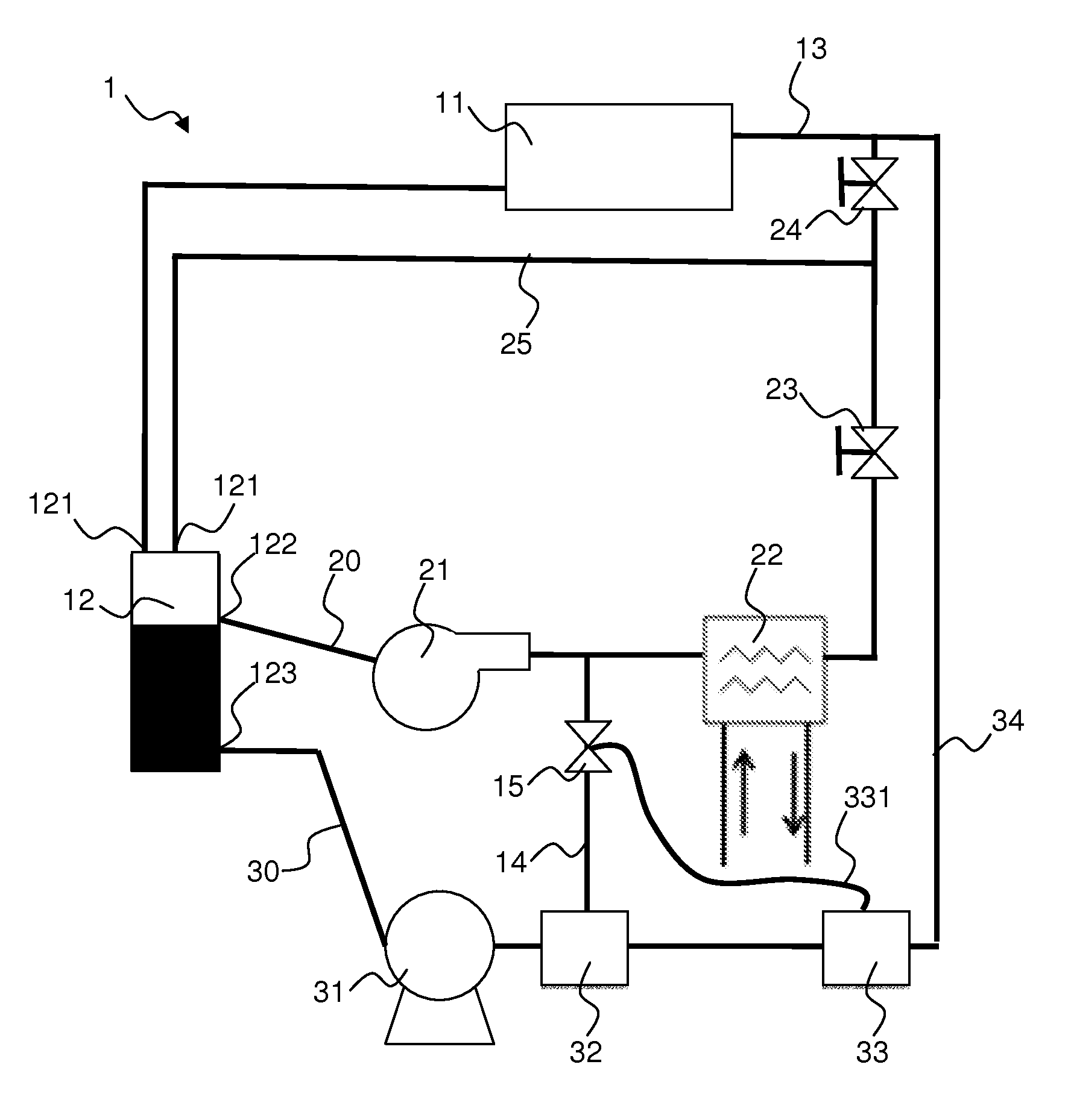

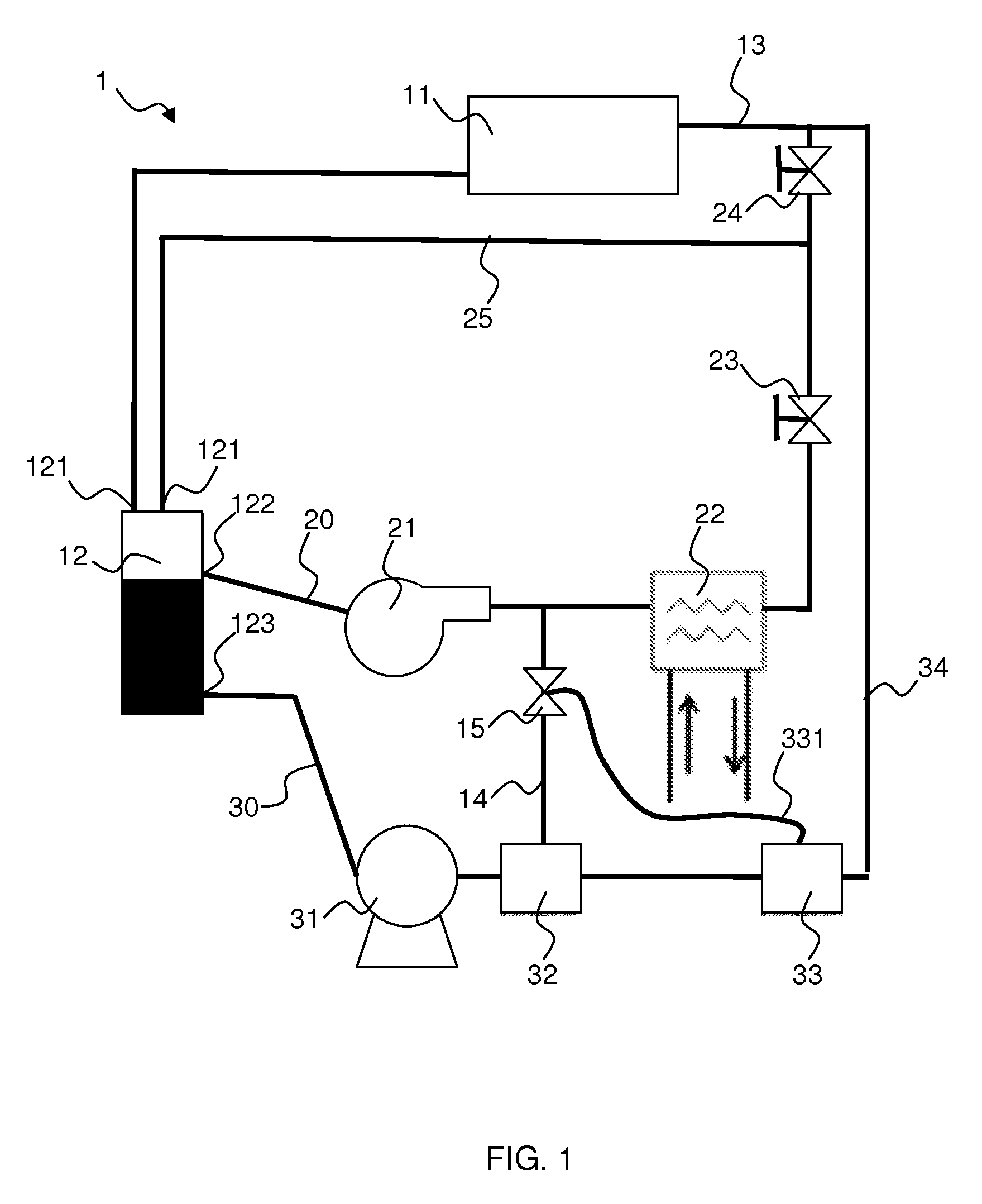

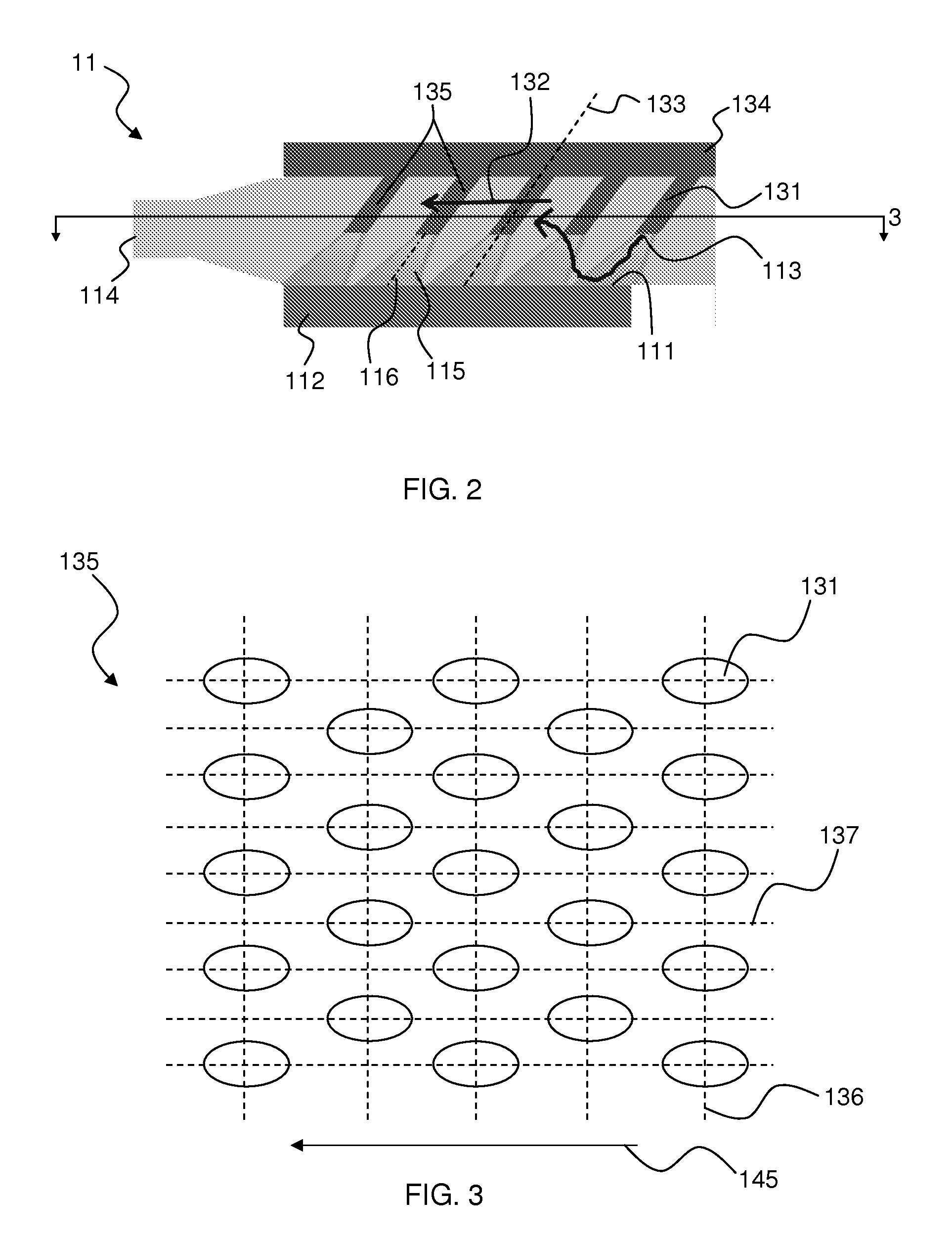

[0032]One aspect of the present invention involves cooling a surface in a chamber with a liquid coolant wherein the coolant at least partially undergoes a phase change to a vapor (i.e., evaporates) upon entering the chamber and prior to contacting the surface. This is achieved by preparing coolant to be introduced in the chamber at or approximately at the coolant's saturation condition.

[0033]The general term “coolant” refers to any fluid capable of undergoing a phase change from liquid to vapor or vice versa at or near the operating temperatures and pressures of an apparatus as described herein. The term refers herein to the fluid in the liquid phase, the vapor phase, and mixtures thereof. A number of coolants may be selected for use within the apparatus described herein depending on cost and level of optimization desired. Non-limiting examples include water, HFE-7000, R-245fa, FC-72, and FC-40. Other coolants are known in the art. Water is readily abundant and inexpensive. However,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com