Oil cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0035]An oil cooler 100 according to the present invention will be explained hereinafter by referring to FIG. 1 to FIG. 7.

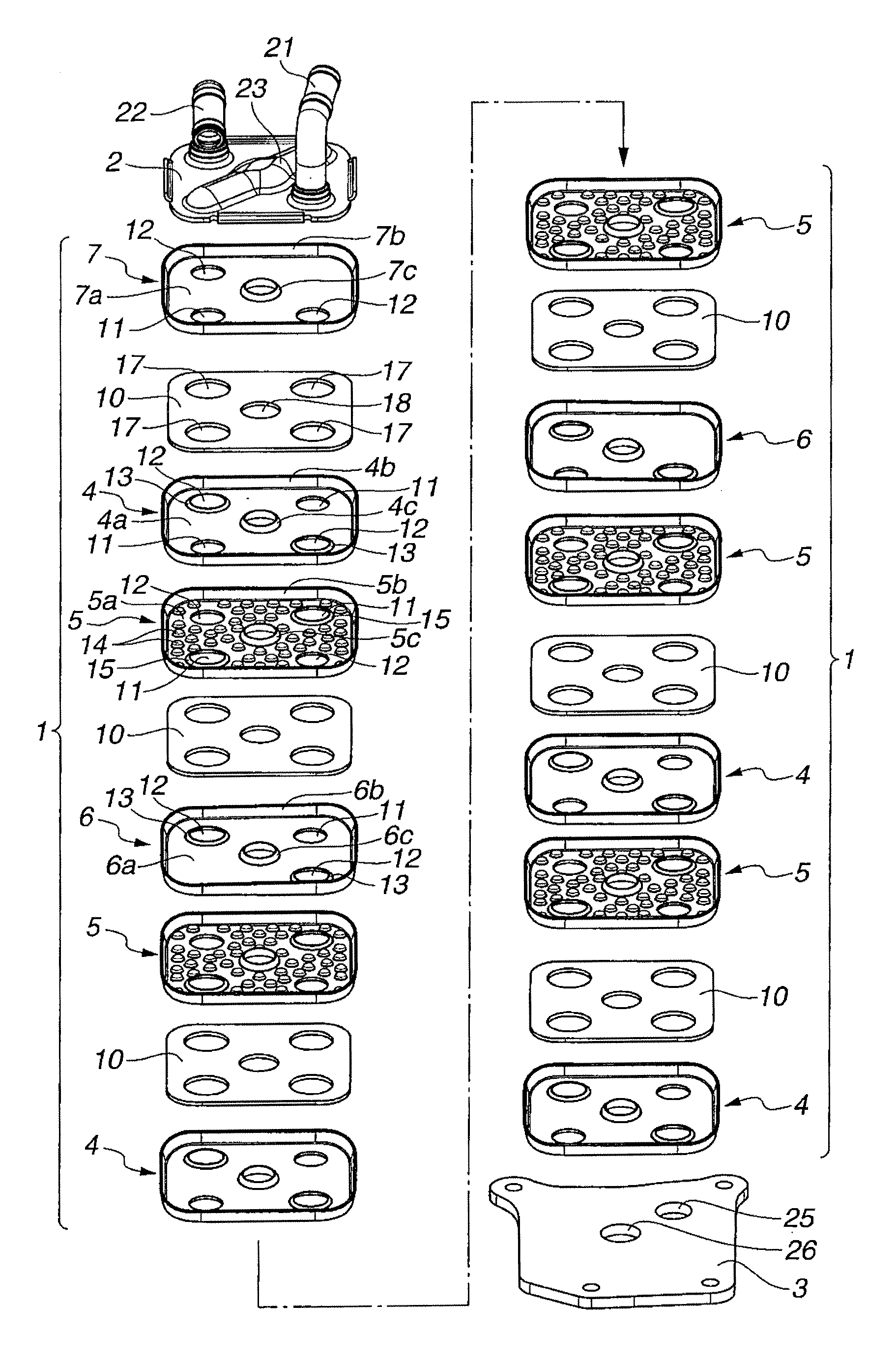

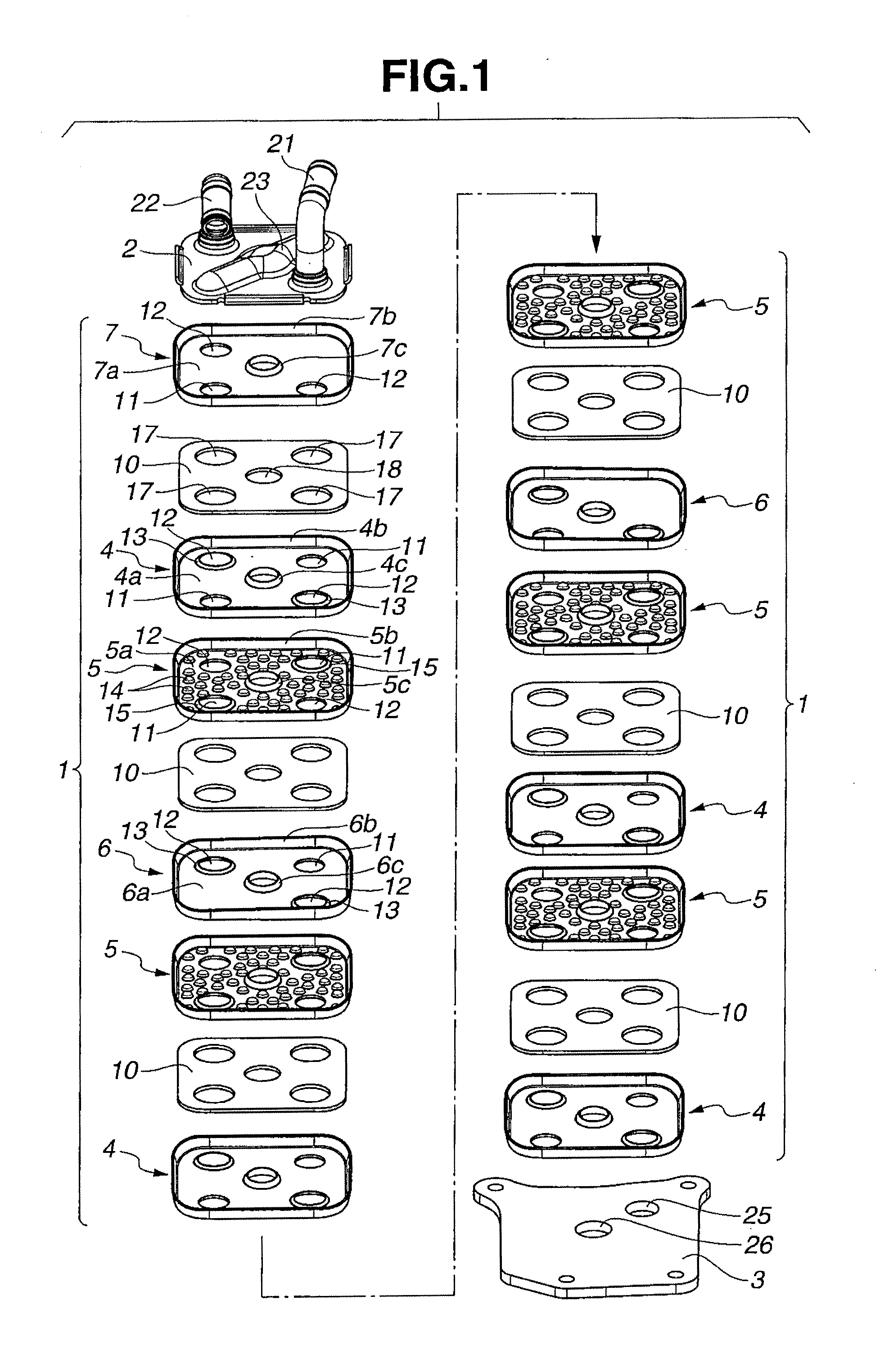

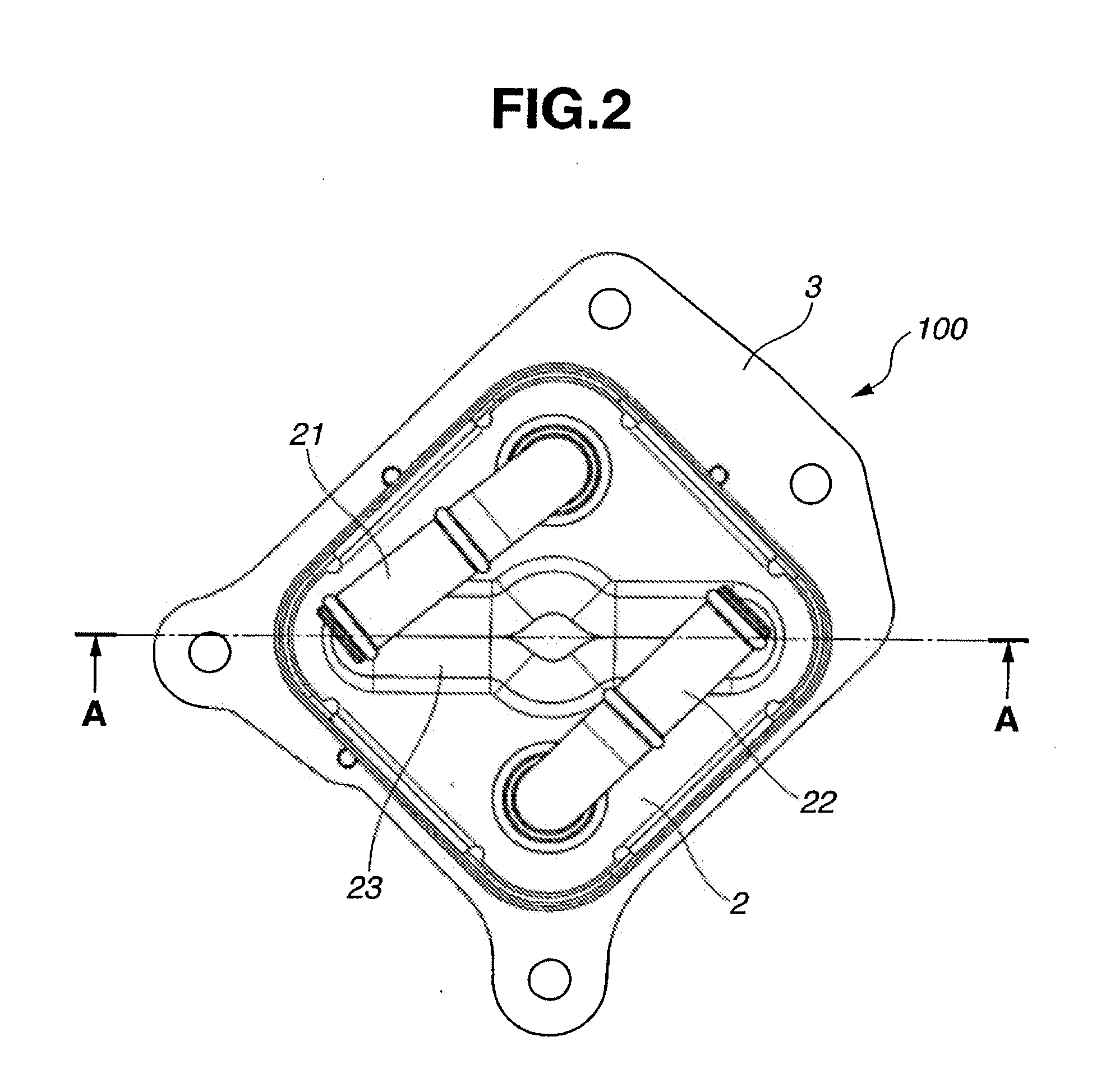

[0036]FIG. 1 is an exploded perspective view of the oil cooler 100. FIG. 2 is a plan view of the oil cooler 100. FIG. 3 is a sectional view of the oil cooler 100, taken along line A-A shown in FIG. 2

[0037]A construction of the oil cooler 100 as a whole is explained. The oil cooler 100 is entirely made of aluminum, for example. As shown in FIG. 1, the oil cooler 100 includes a core module 1 that performs heat exchange between oil and cooling water, a top plate 2 that is mounted to a top surface of the core module 1 and has a relatively large thickness, and a bottom plate 3 mounted to a bottom surface of the core module 1.

[0038]The core module 1 includes four kinds of core plates 4, 5, 6, 7 which basically have substantially the same shape and are stacked on each other in a predetermined order. The core module 1 also includes oil passages 8 and cooling water passag...

second embodiment

[0063]As shown in FIG. 8 and FIG. 9, a height of the circumferential wall 6b of the second core plate 206 in the second embodiment is varied along the circumferential direction of the base wall 6a such that among two pairs of diagonally opposed corner portions 31a, 31b and 31c, 31d, the height at one corner portion 31b of the pair of diagonally opposed corner portions 31a, 31b which is located on the side of the oil communication hole 11 and the height at the pair of diagonally opposed corner portions 31c, 31d respectively located on the side of the cooling water communication holes 12 are largest and equal to each other, and the height at the other corner portion 31a of the pair of diagonally opposed corner portions 31a, 31b is smallest. That is, the circumferential wall 6b of the second core plate 206 is formed such that among the four corner portions 31a, 31b, 31c, 31d, one corner portion 31a (i.e., one of the pair of diagonally opposed corner portions 31a, 31b) which is not loca...

third embodiment

[0067]As shown in FIG. 11 to FIG. 13, a height of the circumferential wall 6b of the second core plate 306 in the third embodiment is varied along the circumferential direction of the base wall 6a as follows. The height at one corner portion 31b of the pair of diagonally opposed corner portions 31a, 31b which is located on the side of the oil communication hole 11 and the height at one corner portion 31d of the pair of diagonally opposed corner portions 31c, 31d which are respectively located on the side of the respective cooling water communication holes 12 are largest and equal to each other. In contrast, the height at the other corner portion 31a of the pair of diagonally opposed corner portions 31a, 31b and the height at the other corner portion 31c of the pair of diagonally opposed corner portions 31c, 31d are smallest and equal to each other. That is, the circumferential wall 6b of the second core plate 306 is formed such that among the two pairs of diagonally opposed corner p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com