Diagonal clamshell protective enclosure

a protective enclosure and diagonal technology, applied in the field of enclosures for outdoor pipeline sampling instruments, can solve the problems of reducing the efficiency of the enclosure, affecting the efficiency of the enclosure, affecting the safety of the enclosure, etc., and reducing the risk of hydrocarbon dew point dropout, maximizing the opening size, and increasing the enclosure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Exemplary, non-limiting, embodiments of the present invention are discussed in detail below. While specific configurations and dimensions are discussed to provide a clear understanding, it should be understood that the disclosed dimensions and configurations are provided for illustration purposes only. A person skilled in the relevant art will recognize that other dimensions and configurations may be used without departing from the spirit and scope of the invention.

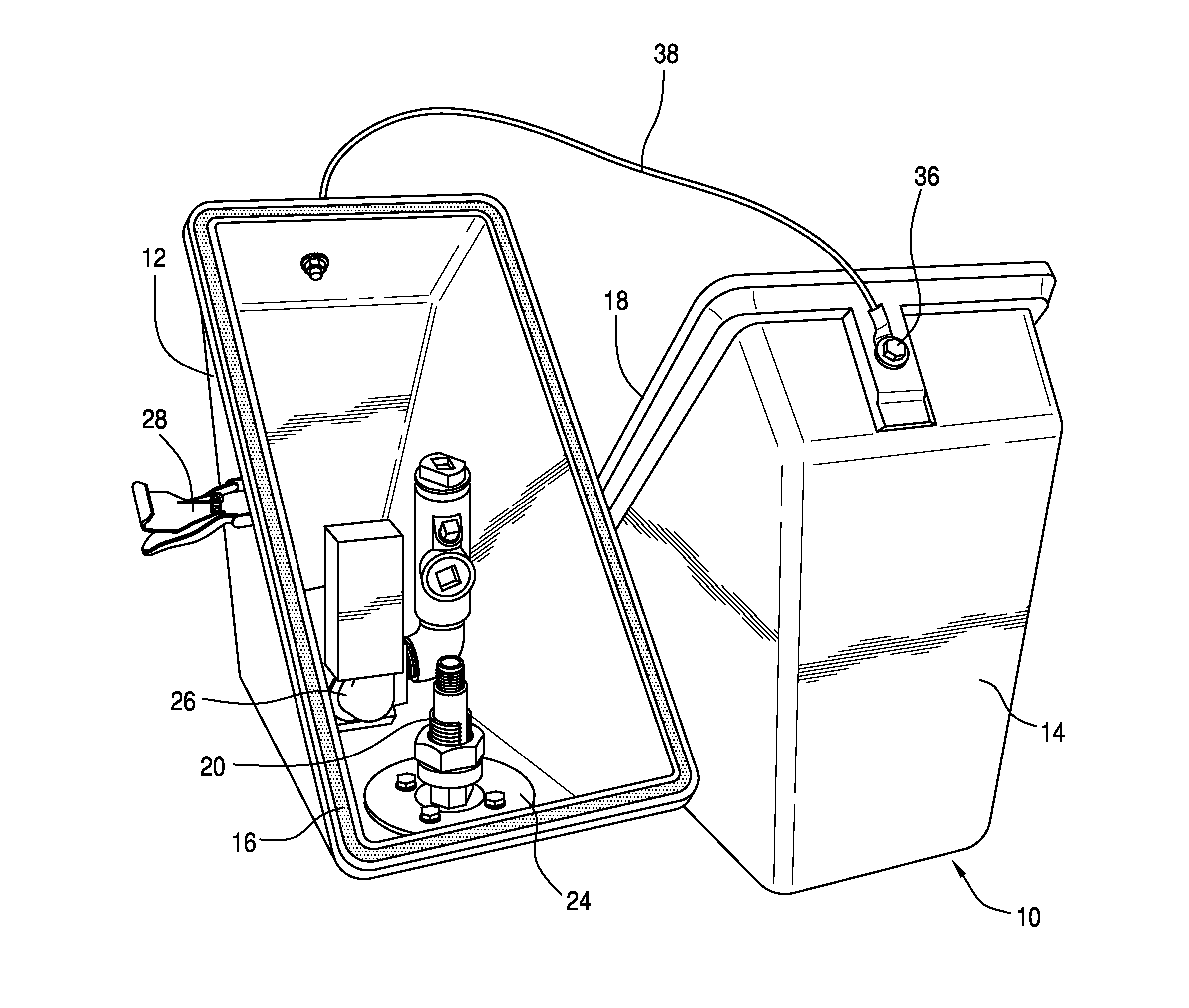

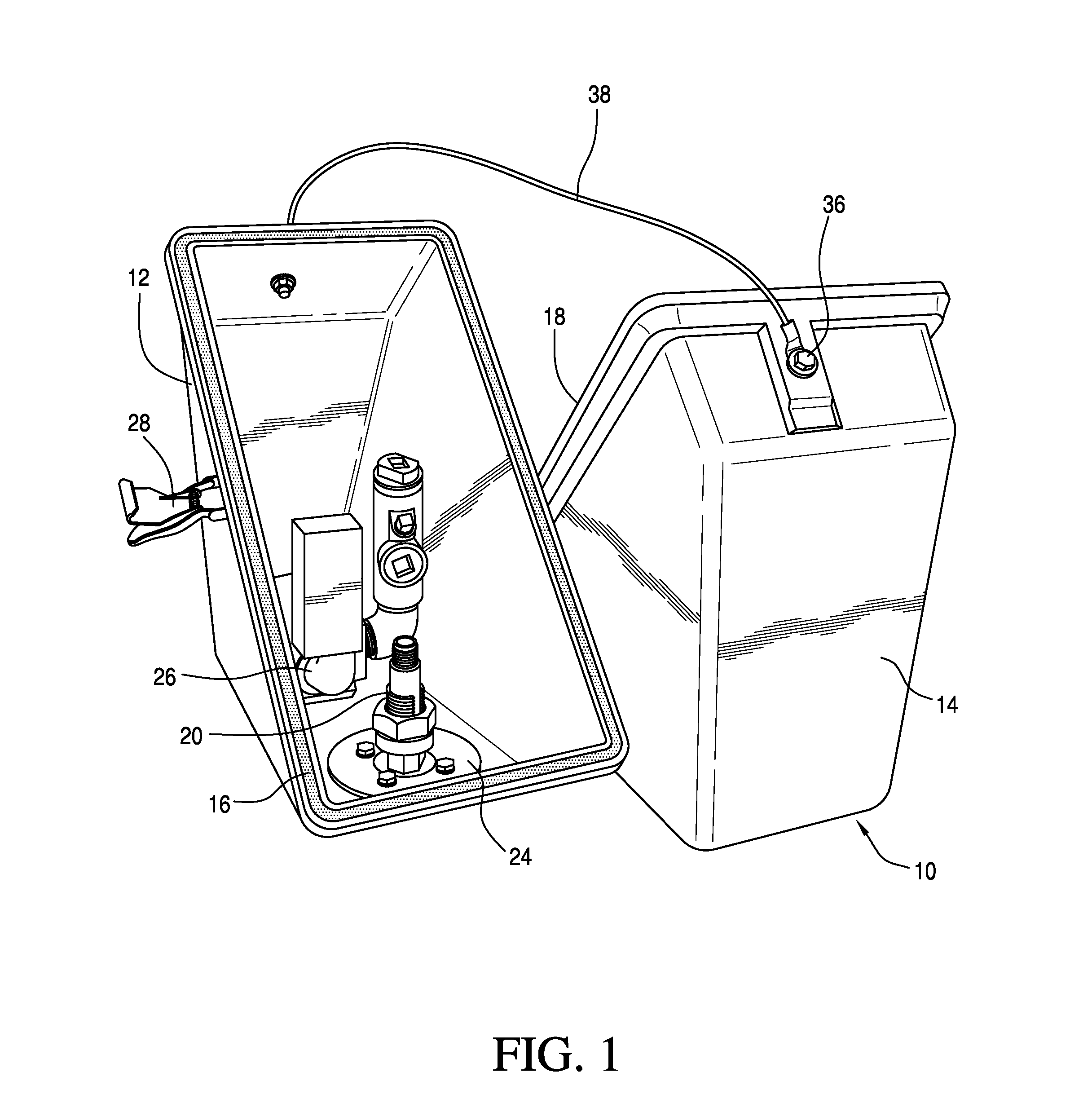

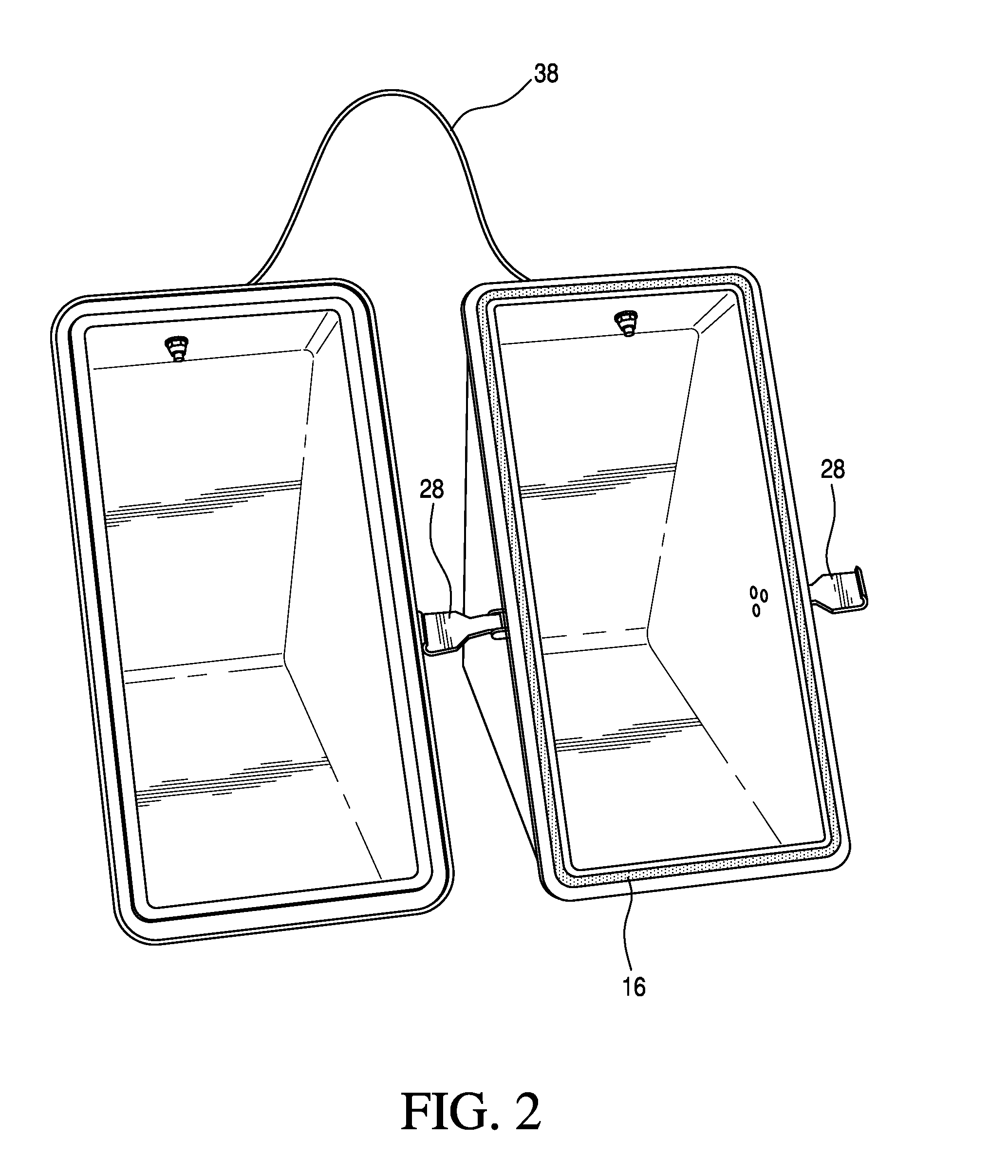

[0030]FIG. 1 illustrates a disassembled housing 10 in accordance with the present invention. The housing 10 is formed by a bottom half 12 and a top half 14. (The use of the word “half” is employed as a convenience herein but is not intended to limit the invention strictly to that size. Rather it is intended to approximate the general relative dimensional characteristics of the respective housing portions.) The bottom half has a long rear wall and a short front wall while the top portion has a short rear wall and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com