Hydrogen sulfide scavenger for use in hydrocarbons

a technology of hydrocarbons and scavengers, applied in the field of additives, can solve the problems of toxic and corrosive effects of hydrogen sulfid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

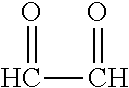

Method used

Image

Examples

example 1

[0026]Condensate, a liquid under ambient conditions which is a mixture of low molecular weight alkanes, is sparged with nitrogen having a hydrogen sulfide concentration of 1% for 1 hour.

[0027]The concentration of the hydrogen sulfide in the condensate prior to treatment (blank) is determined to be 19.9 ppm. The condensate is then tested by introducing a hydrogen sulfide scavenger prepared by reacting glyoxal and DETA at a molar ratio of 1:1 (which is an equivalent ratio of 1:2). The treated condensate and a blank were shaken using an orbital shaker at 400 rpm at ambient conditions for 4 hours. The blank was retested and had a hydrogens sulfide concentration of 10.5 ppm. The treated sample showed no measurable hydrogen sulfide (<0.5 ppm).

example 2

[0028]Example 1 was repeated substantially identically except that the initial concentration of hydrogen sulfide was 30.8 ppm and the hydrogen sulfide scavenger was introduced at a concentration of 300 ppm. After treatment, the blank has a hydrogen sulfide concentration of 13.1 ppm. The treated sample showed no measurable hydrogen sulfide (<0.5 ppm).

example 3

[0029]The hydrogen scavenger of Example 1 is used to immerse carbon steel corrosion coupons. The immersed coupons were held at about 40° C. for 14 days. The corrosion rate was determined to be about 19.19 mpy.

Discussion of Examples

[0030]The examples show that the claimed hydrogen sulfide scavengers are effective at reducing the concentration of hydrogen sulfide in hydrocarbons. They also show that the claimed hydrogen sulfide scavengers have a very low corrosion rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

| water soluble | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com