Space truss support device in large-scale tower

a technology of support device and space truss, which is applied in the direction of distillation separation, chemistry apparatus and processes, separation processes, etc., can solve the problem that the existing support main beam cannot meet the strict demand, and achieve the effect of small flexibility, good rigidity and large intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

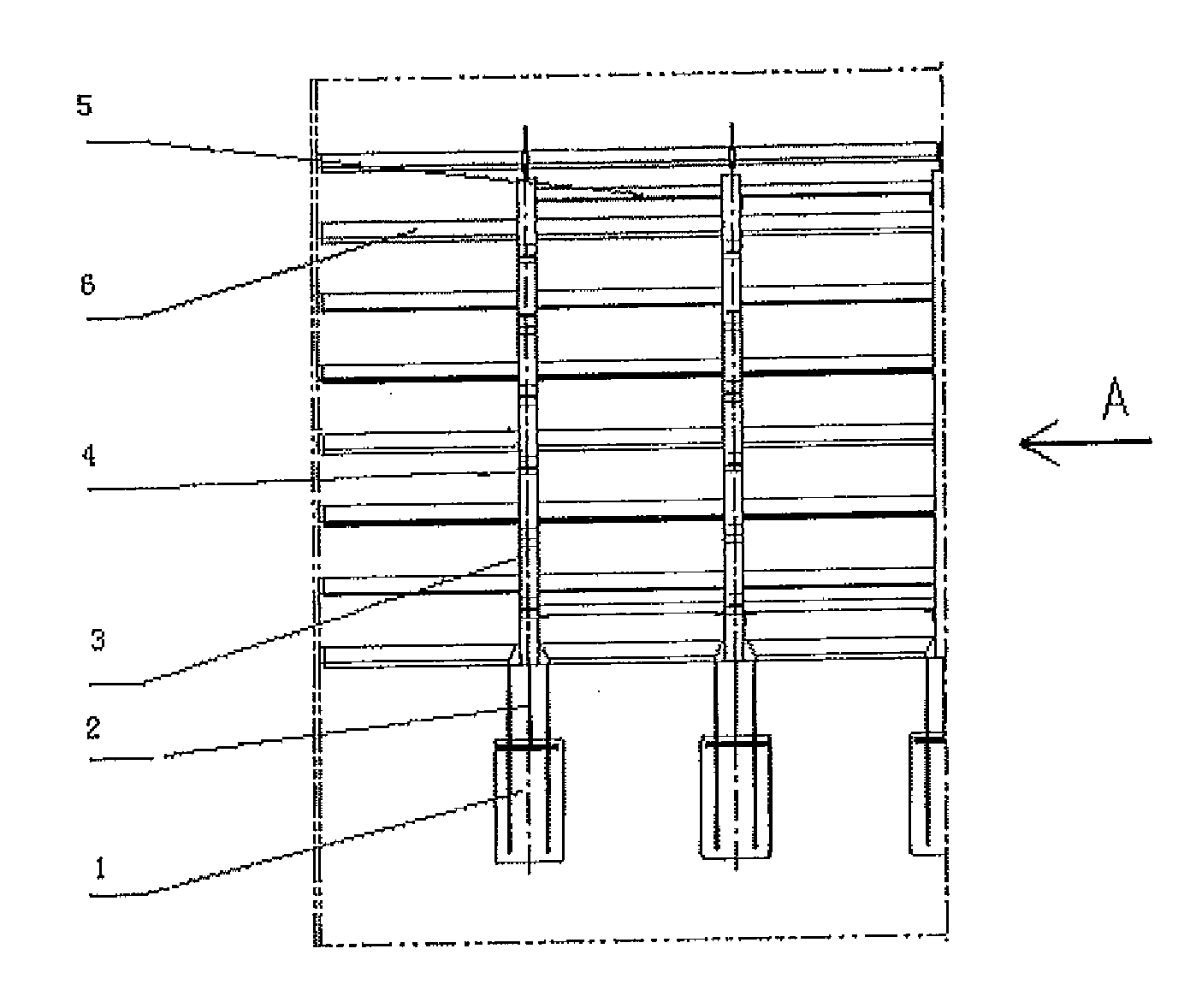

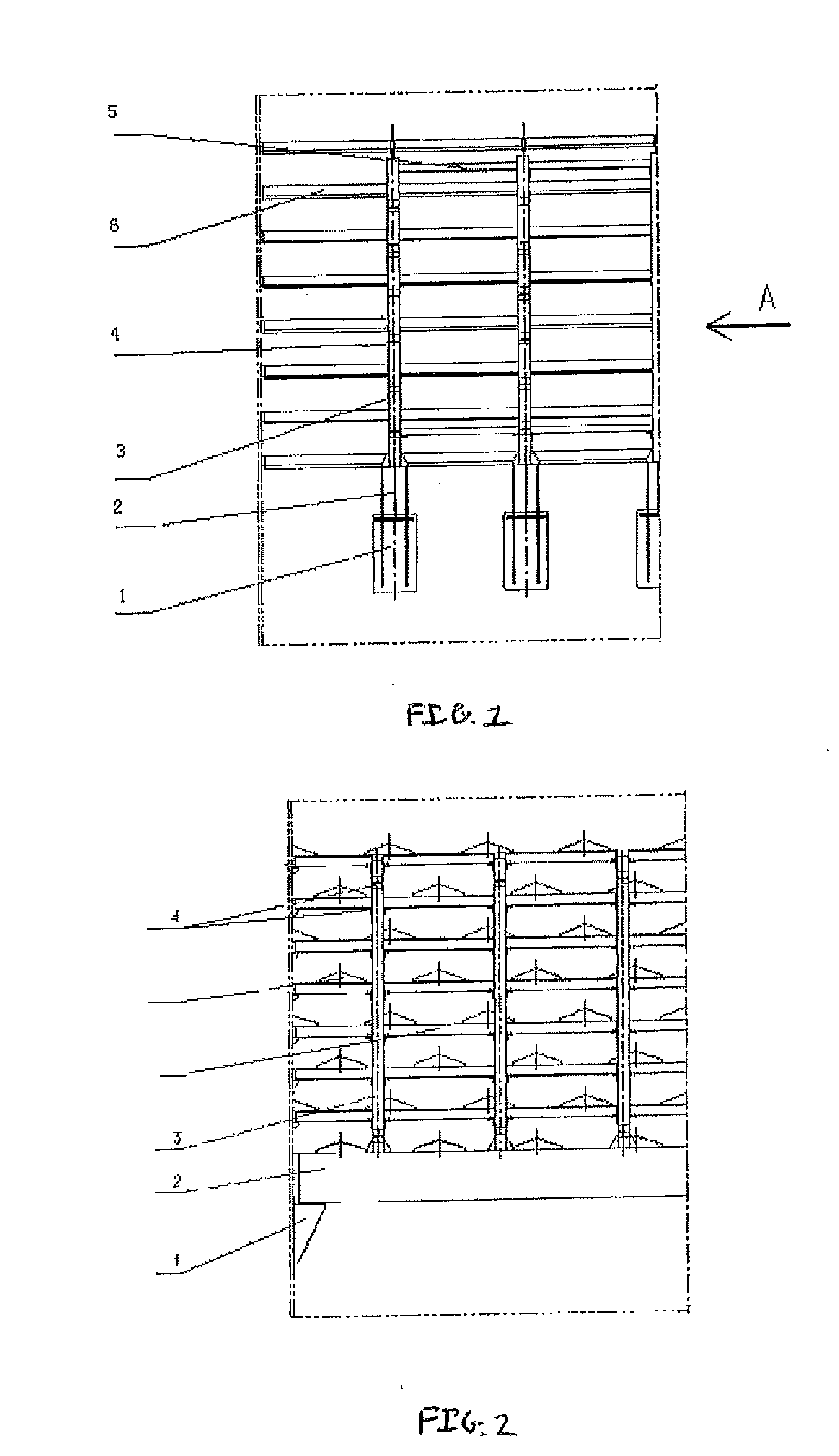

[0030]In the embodiment 1 shown as FIGS. 1 and 2, a fence beam 2, which is a foundation beam, is supported on a pedestal 1 at the bottom of the large-scale tower.

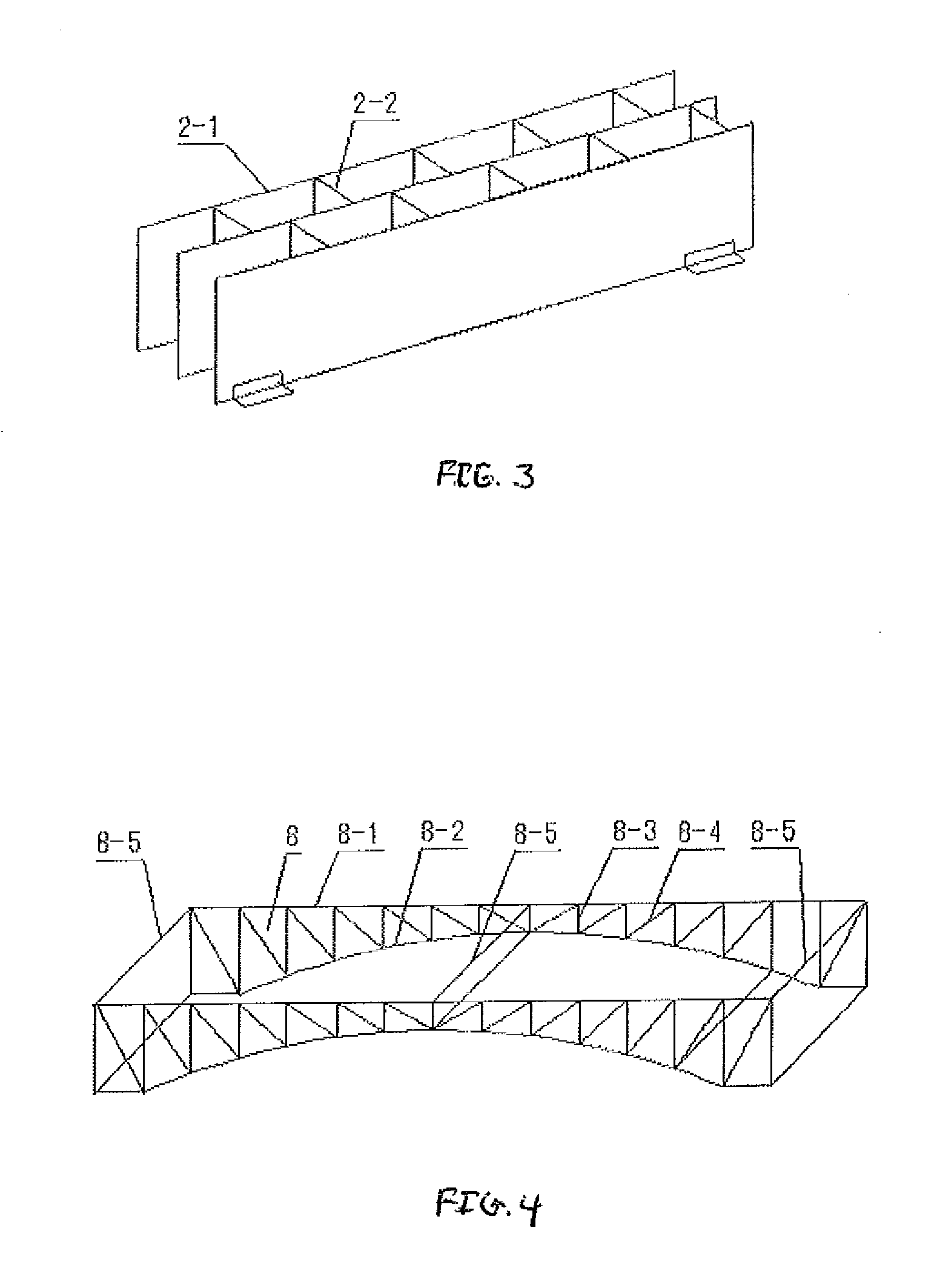

[0031]The fence beam, structurally shown as FIG. 3, is formed by parallel and uniformly spaced vertical plates 2-1 and ribbed slabs 2-2 which are distributed between the vertical plates in a staggered manner and fixedly connected with the vertical plates.

[0032]Shown as FIGS. 1, 2 and 3, pillars 3 formed by square tubes arc distributed at intervals on the surface of the fence beam 2, and both layering and horizontal support of X-direction cross beams 5 and Y-direction cross beams 7 are realized between the pillars and between the pillars on the periphery and a tower body. Two ends of the X-direction cross beams and the Y-direction cross beams in the embodiment 1 are fixedly connected with the corresponding pillars or with the corresponding pillars and support bases 4 arranged on tower body respectively.

[0033]The X-direction ...

embodiment 2

[0037]The embodiment 2, shown as FIGS. 8, 9 and 10, pertains to the examples in which the space truss support device of the invention supports multi-flow tower tray or multi-downcomer tower tray.

[0038]In the embodiment 2, the structures of the foundation beam 1, the X-direction cross beams 5 and the Y-direction cross beams 7 positioned at a central line of a seal pan in the space truss support device are identical, in width, to tower tray exit weirs 15 of the multi-flow tower tray or the multi-downcomer tower tray and arc the same as the embodiment 1, and the difference therebetween only lies in the structural relationship between the pillars and the Y-direction cross beams positioned at the tower tray exit weirs.

[0039]Shown as FIG. 8, the pillar 3 is I steel, and the pillars at the same row arc positioned, at intervals, on the central line of the down comers and the seal pans on the same perpendicular line of the multi-overflow trays or the multi-down comer trays. The support bases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com