Semiconductor device reducing risks of a wire short-circuit and a wire flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

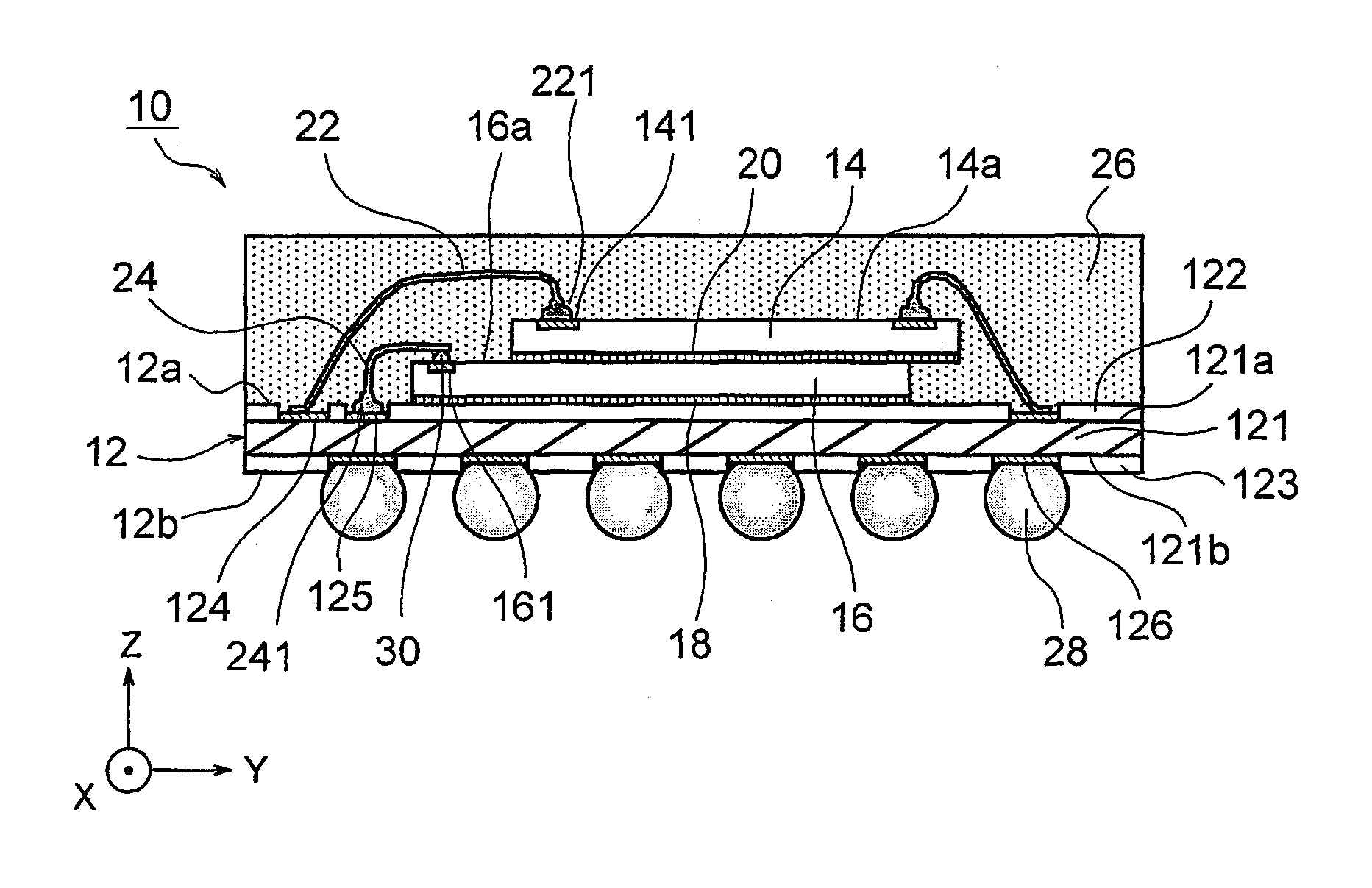

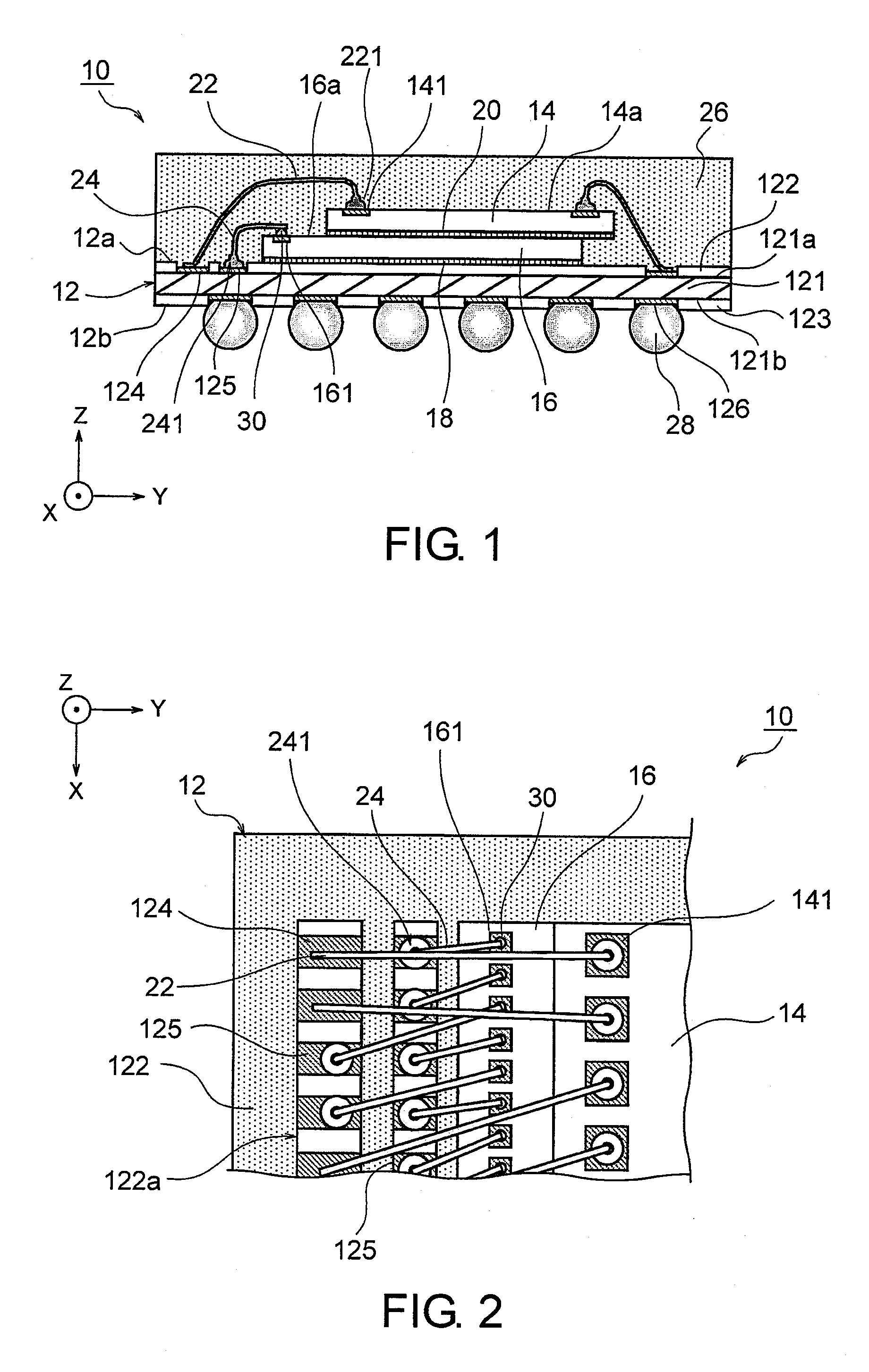

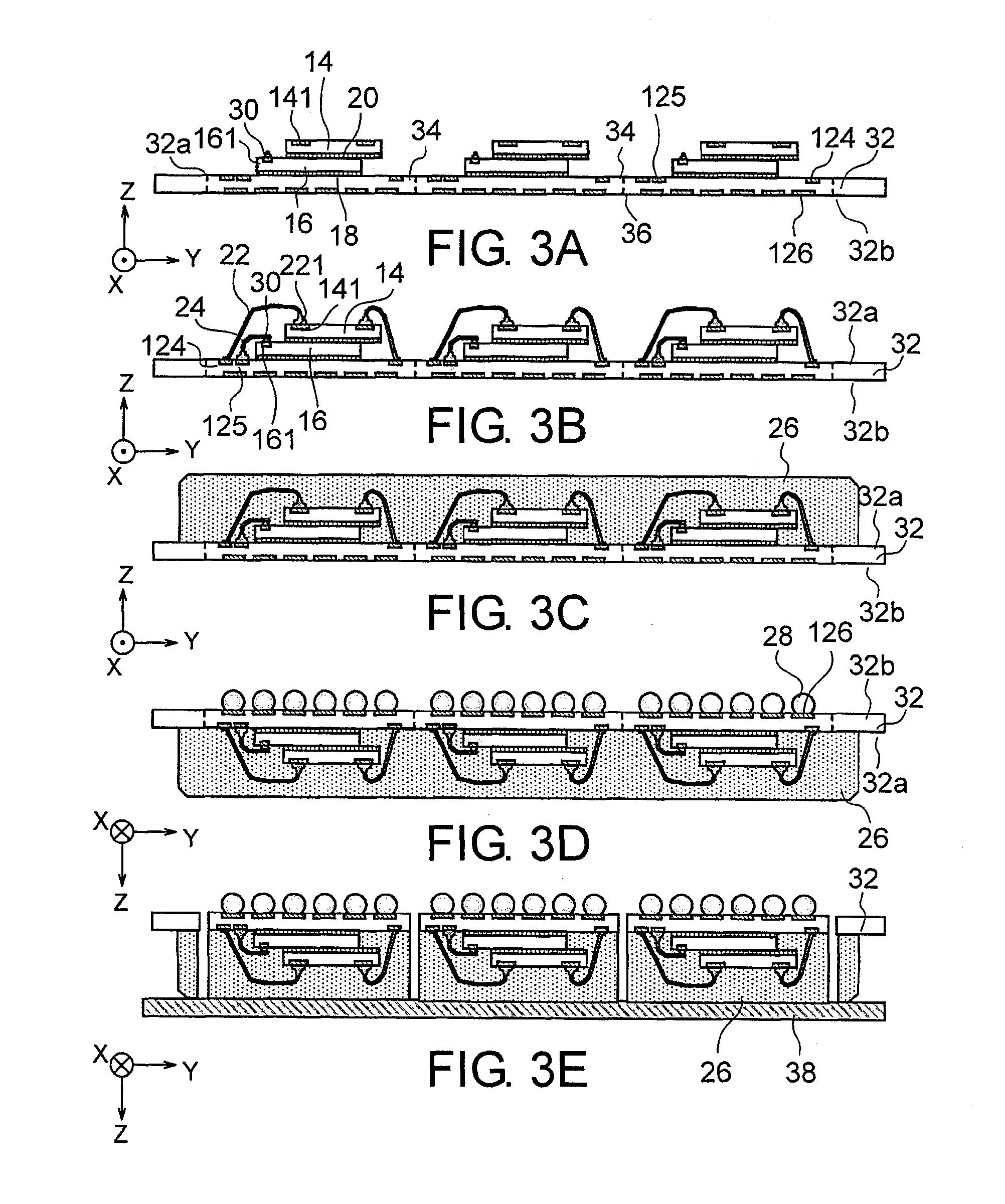

[0034]Referring now to FIGS. 1 and 2, the description will proceed to an MCP type semiconductor device 10 according to a first exemplary embodiment of this invention. FIG. 1 is a cross-sectional view schematically showing the MCP type semiconductor device 10 and FIG. 2 is a plan view showing a main part of a wire connection portion of the MCP type semiconductor device 10. In the plan view of FIG. 2, a sealing resin (denoted by the reference numeral 26 in FIG. 1) is omitted from the illustration.

[0035]Herein, in the manner shown in FIGS. 1 and 2, an orthogonal coordinate system (X, Y, Z) is used. In a state illustrated in FIGS. 1 and 2, in the orthogonal coordinate system (X, Y, Z), an X-axis direction is a fore-and-aft direction (a depth direction), a Y-axis direction is a left-and-right direction (a width direction), and a Z-axis direction is an up-and-down direction (a height direction).

[0036]The illustrated semiconductor device 10 comprises a wiring substrate 12, a first semicond...

first modified example

[0073]Referring to FIG. 4, the description will proceed to an MCP type semiconductor device 10A according to a first modified example of the first exemplary embodiment of this invention. FIG. 4 is a cross-sectional view showing a main portion of the MCP type semiconductor device 10A. In the first modified example, the same elements as in the MCP type semiconductor device 10 illustrated in FIGS. 1 and 2 are denoted by the same reference numerals, and the description will be made as regards only differences for the sake of simplification of the description.

[0074]The illustrated semiconductor device 10A is similar in structure to the semiconductor device 10 according to the first exemplary embodiment except that a spacer 40 comprising a silicon substrate and a third adhesive member 42 are inserted between the first semiconductor chip 14 and the second semiconductor chip 16. In addition, the first semiconductor chip 14 and the second semiconductor chip 16 are stacked to each other witho...

second modified example

[0077]Referring to FIG. 5, the description will proceed to an MCP type semiconductor device 10B according to a second modified example of the first exemplary embodiment of this invention. FIG. 5 is a cross-sectional view showing a main portion of the MCP type semiconductor device 10B. In the second modified example, the same elements as in the MCP type semiconductor device 10 illustrated in FIGS. 1 and 2 are denoted by the same reference numerals, and the description will be made as regards only differences for the sake of simplification of the description.

[0078]The illustrated semiconductor device 10B is similar in structure to the semiconductor device 10 according to the first exemplary embodiment except that an adhesive member 44 enable to embed and bond wires are inserted between the first semiconductor chip 14 and the second semiconductor chip 16. As such an adhesive member 44, for example, a film on wire (FOW) may be used. In addition, the first semiconductor chip 14 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com