Damping device

a technology of adamant device and a sway bar, which is applied in the direction of shock absorbers, mechanical equipment, transportation and packaging, etc., can solve the problems of lowering the dynamic performance of the wheel truck, and achieve the effects of improving the dynamic performance, high diamond resistant rigidity, and good dynamic performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]To further illustrate the invention, experiments detailing a damping device are described below. It should be noted that the following examples are intended to describe and not to limit the invention.

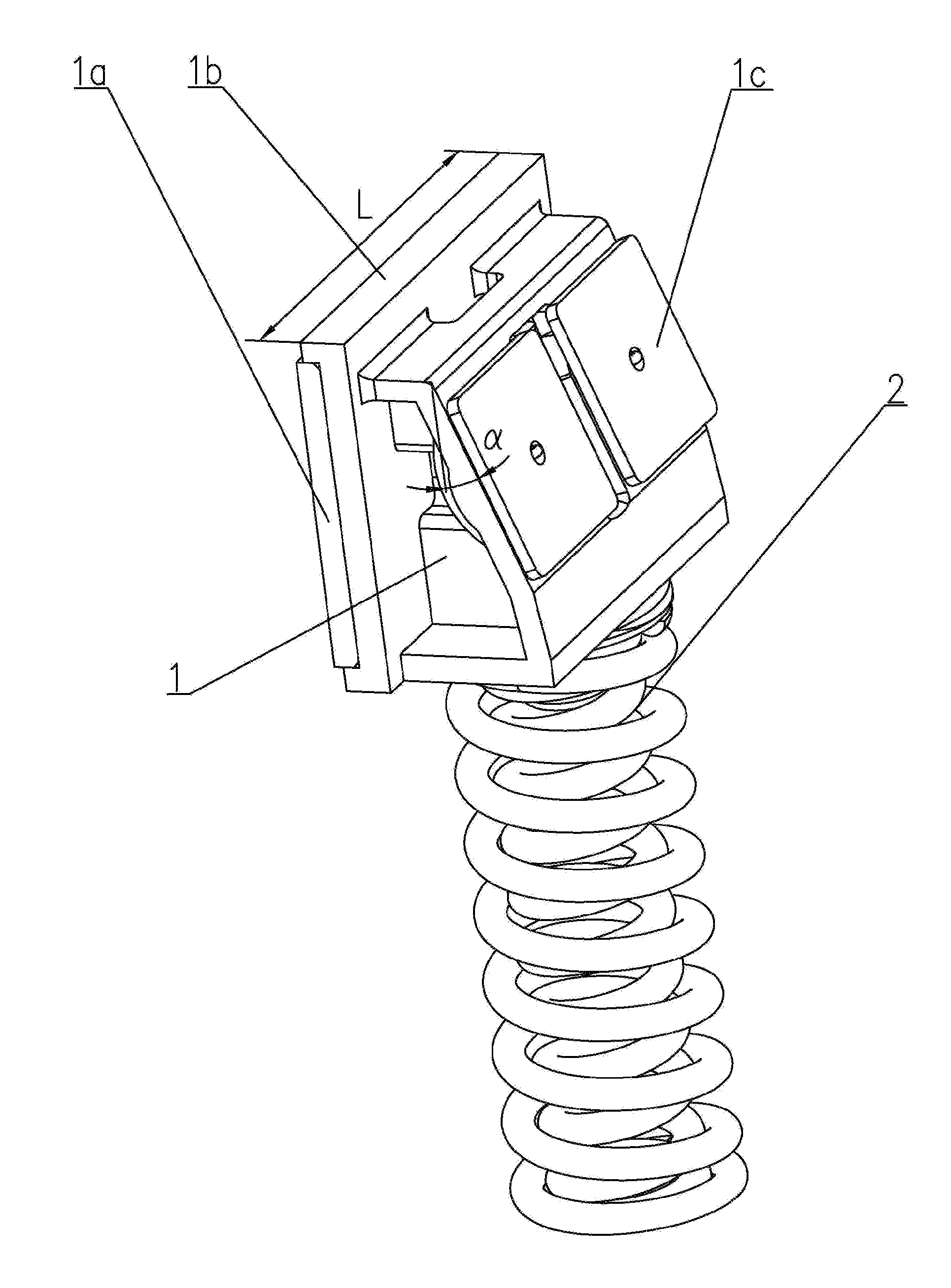

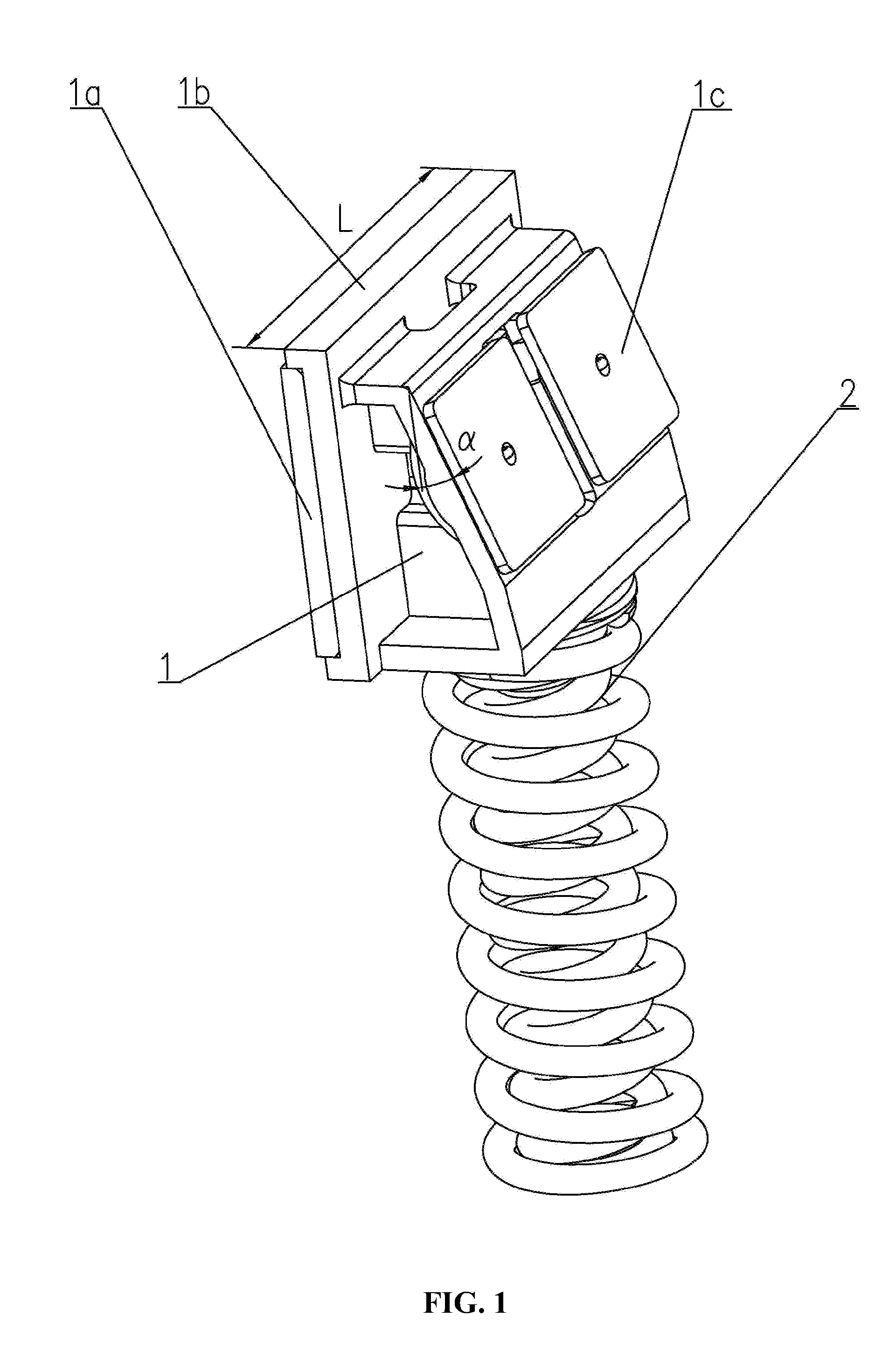

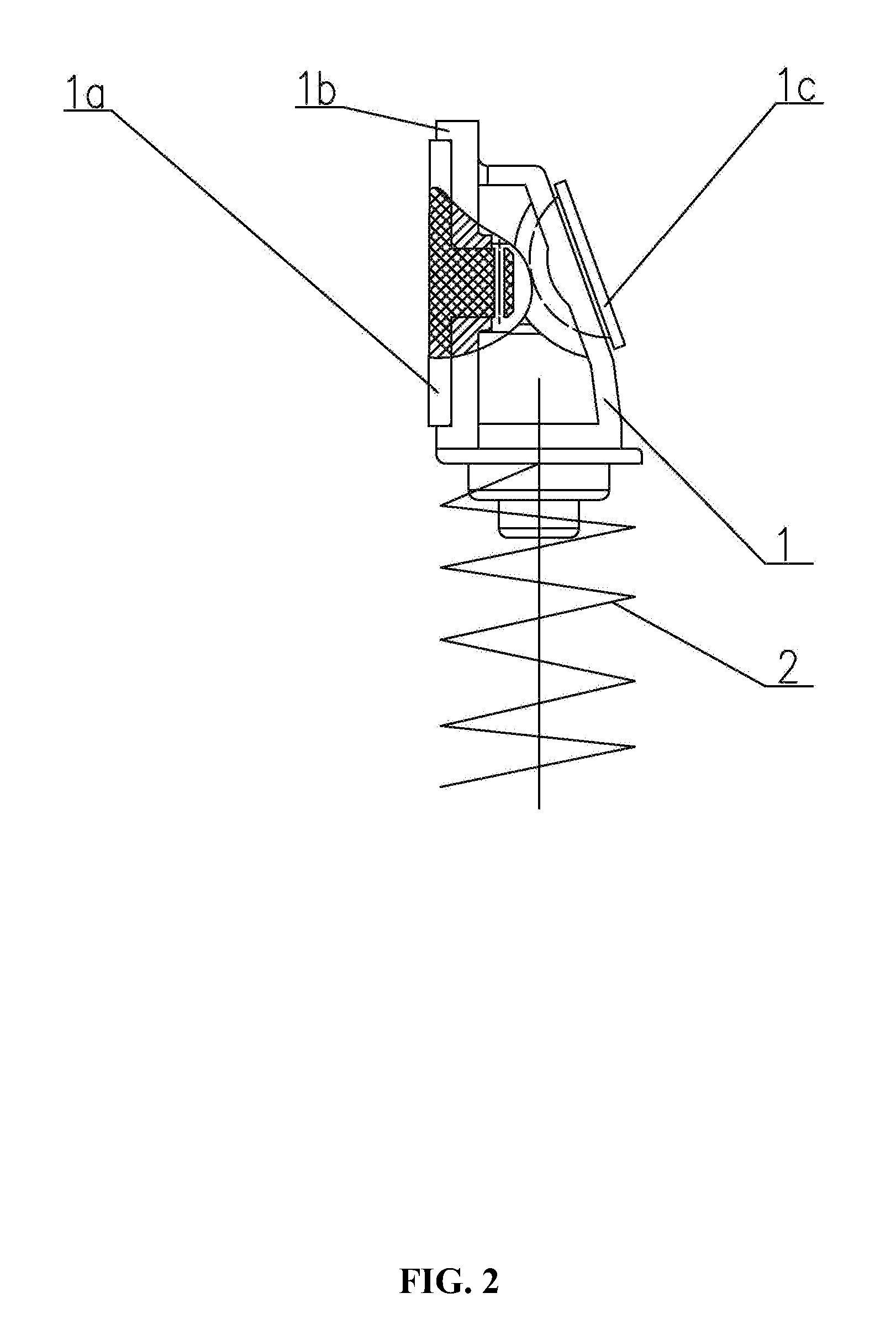

[0024]As shown in FIGS. 1 and 2, a damping device for a wedge of a wheel truck of a railroad freight car comprises a wedge assembly 1 and a damping spring assembly 2 disposed underneath the wedge assembly 1. The wedge assembly 1 comprises a wedge 1b comprising a vertical surface and an inclined surface, a primary friction board 1a is disposed on the vertical surface, and a secondary friction board 1c is disposed on the inclined surface. Structure parameters of the wedge assembly 1 are as follows: L=200-260 mm, α=16-30°, and μ1. Of them, L represents a width of the wedge assembly 1; α represents an included angle between a friction surface of the secondary friction board 1c and a vertical plane; μ represents a friction coefficient of the primary friction board 1a; and μ1 represents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com