Building system and method

a building system and building technology, applied in special buildings, building repairs, parkings, etc., can solve the problems affecting the construction efficiency of buildings, and requiring a large amount of time and effort, so as to achieve minimal time and labor, and rapid deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

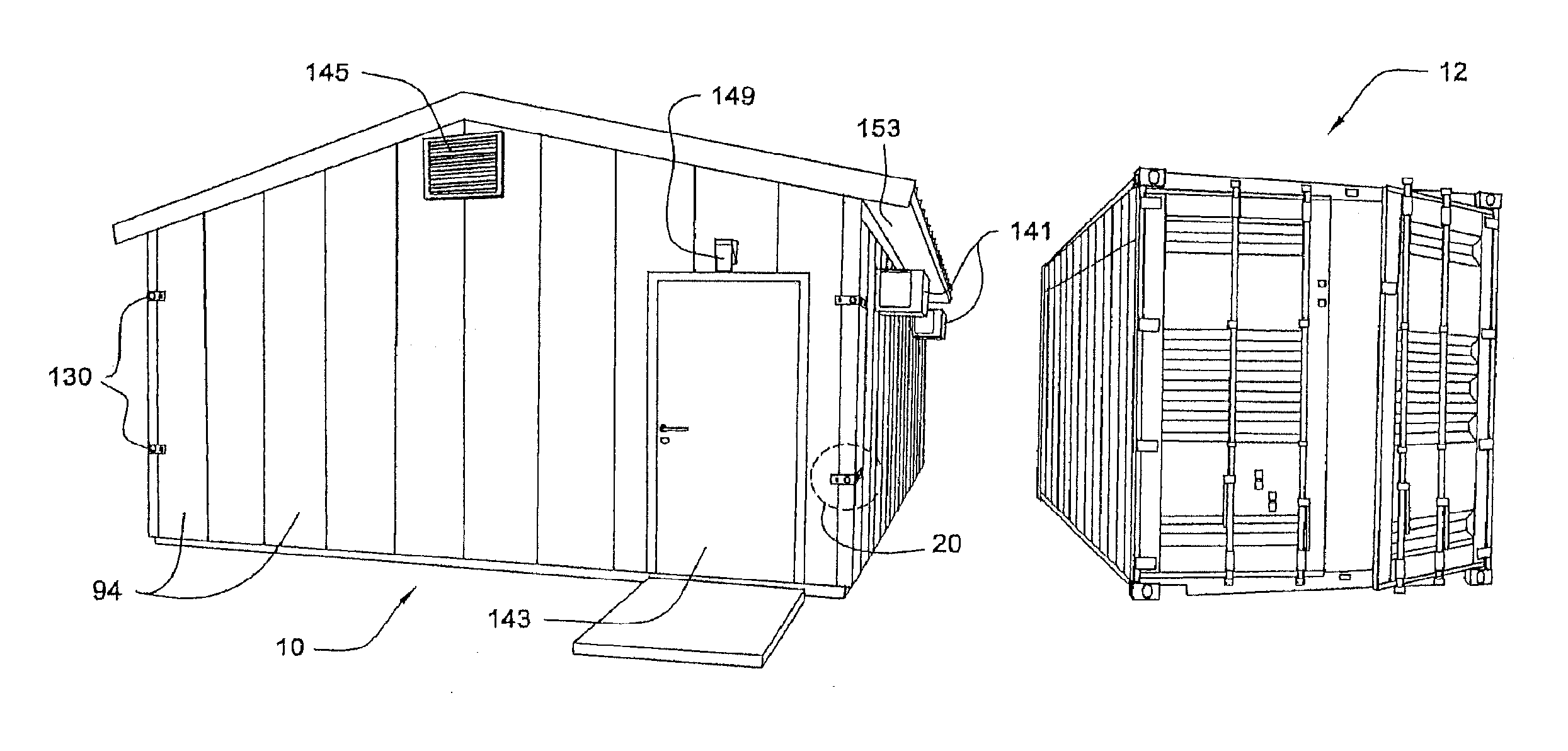

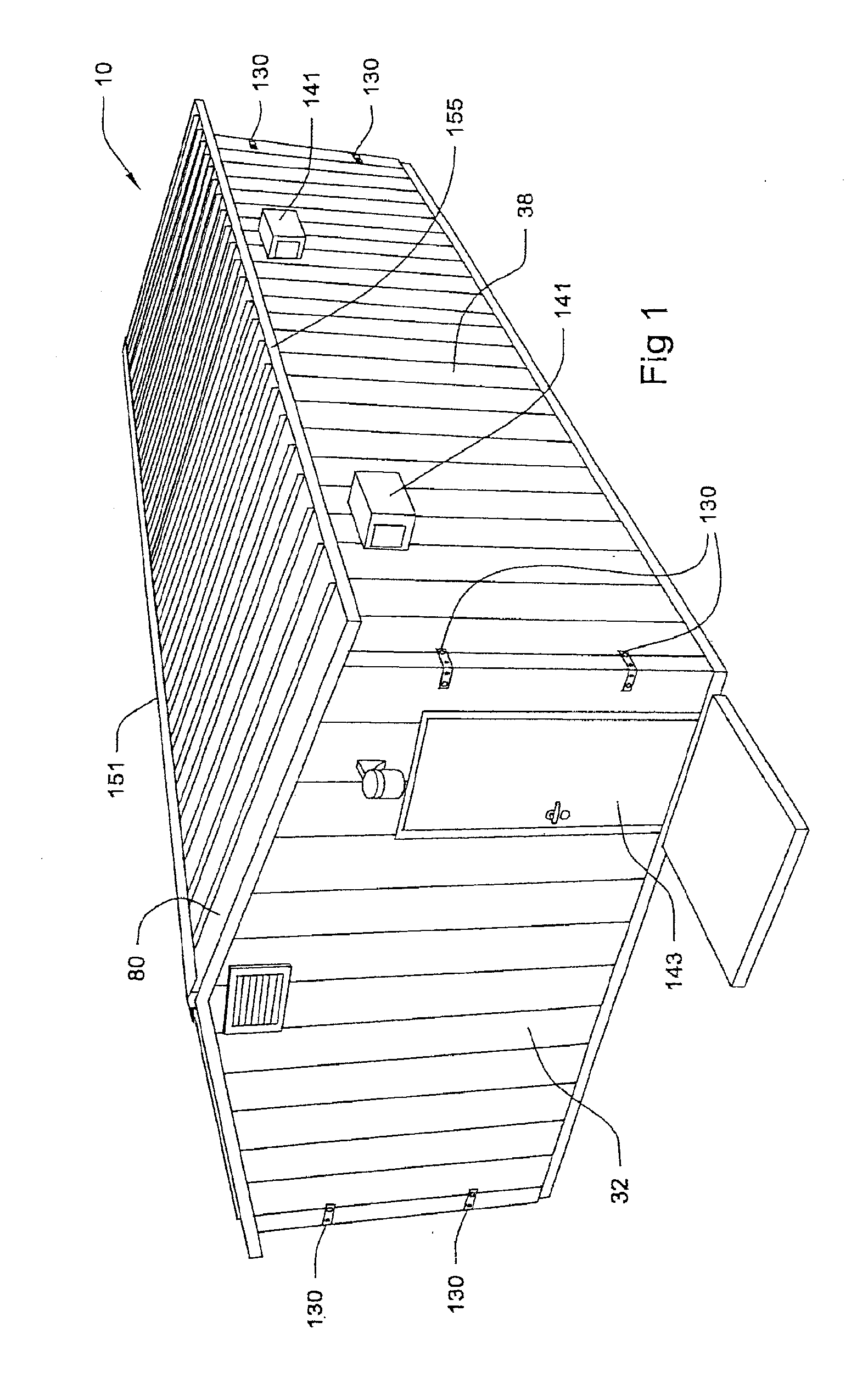

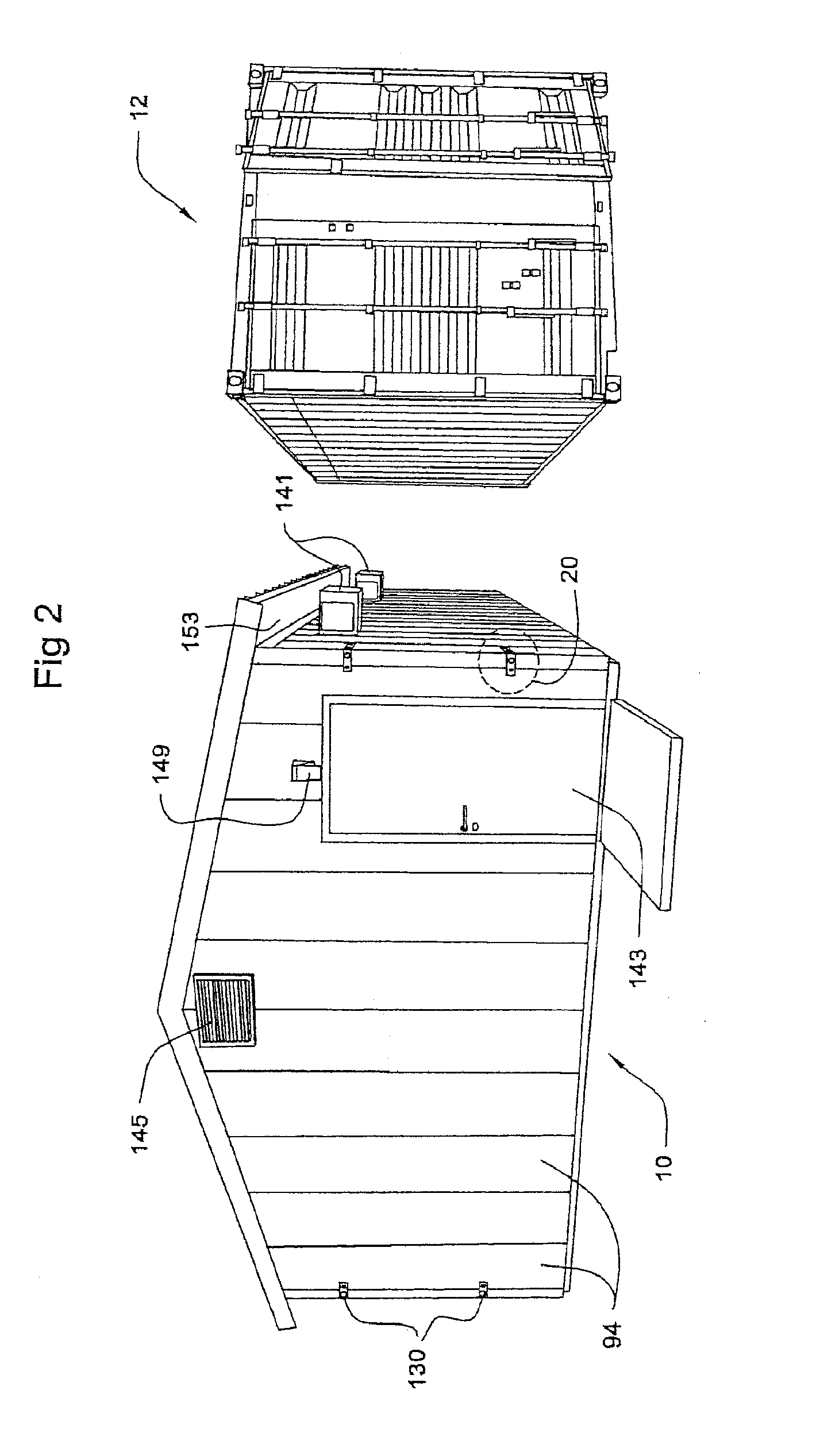

[0050]FIG. 1 generally depicts the finished building 10 of the present invention in its preferred embodiment. FIG. 2 depicts building 10 adjacent to shipping container 12 of the preferred embodiment of the present invention. Container 12 is large enough to accommodate, and is used to transport, all of the building components, supplies and tools needed to construct the finished building 10 at the desired building site.

[0051]Container 12 is preferably a 20-foot long metal container which complies with the specifications and standards set by the International Organization for Standardization, commonly referred to as a 20-foot ISO shipping container. Container 12 can be shipped by any number of transportation means, including truck, train, boat, and air transport.

[0052]FIGS. 3 and 4 generally depict the building components, supplies and tools loaded and nested inside container 12 in the preferred embodiment of the invention. Container doors 14 are closed during transport of the loaded c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com