Drum lagging material and installation apparatus therefor

a technology of installation apparatus and drum lagging material, which is applied in the direction of mechanical equipment, manufacturing tools, portable power-driven tools, etc., can solve the problems of requiring several days of work and machine downtim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Initially, although embodiments are disclosed in the context of a drive drum in a corrugator machine, ordinarily skilled artisans will appreciate that the disclosed embodiments of the lagging material and installation device have application to other drive roll covers or other industrial machines that include drive drums, such as papermaking machines and nonwovens manufacturing machinery.

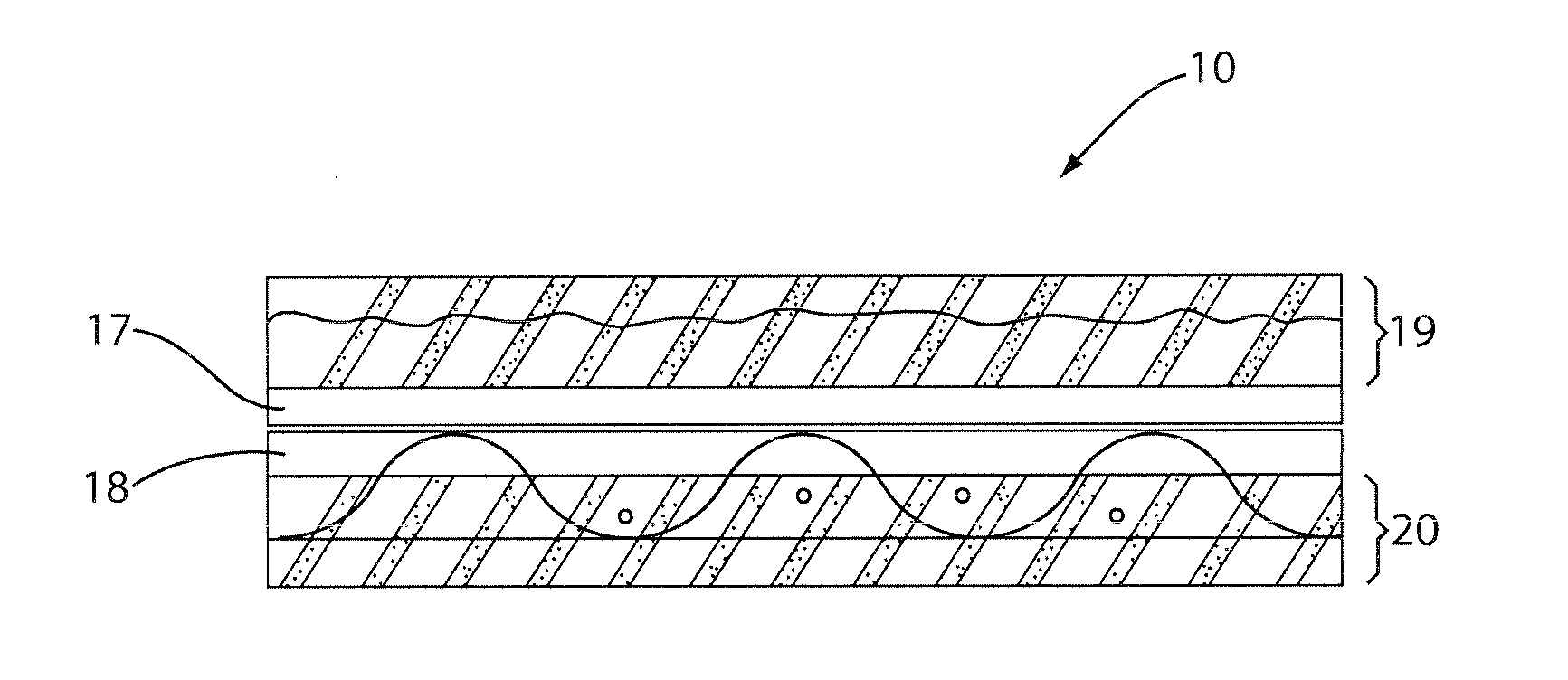

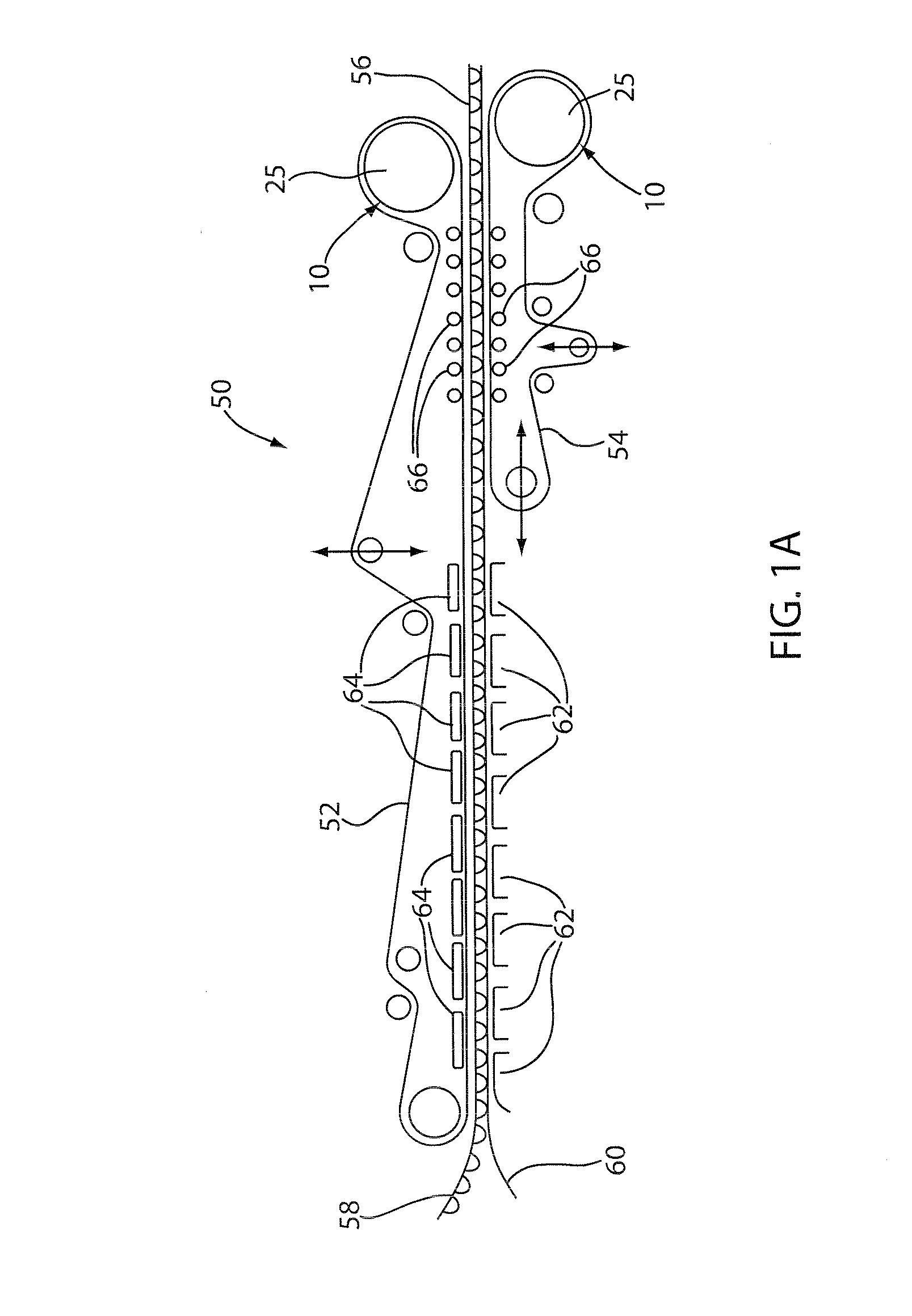

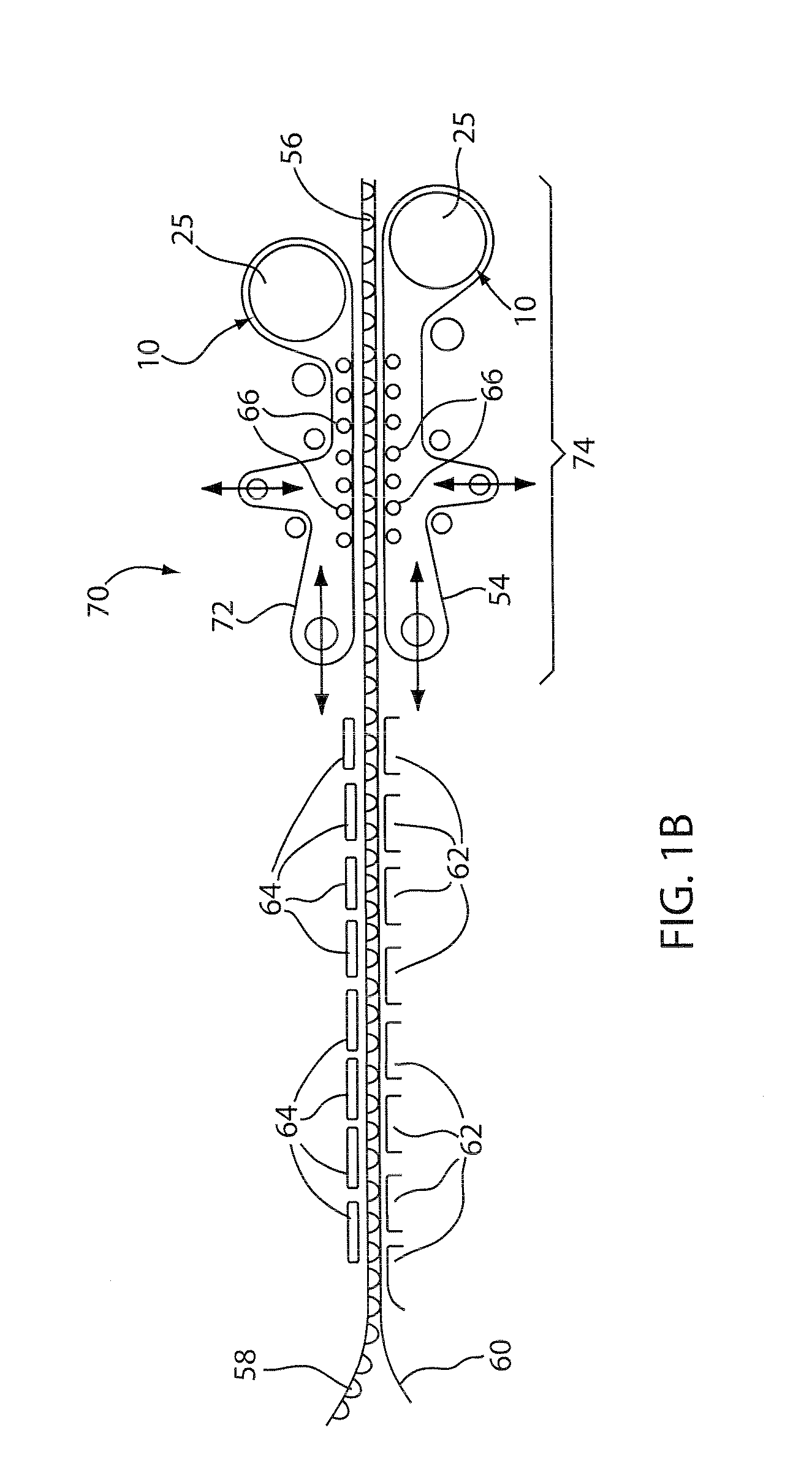

[0023]FIGS. 1A and 1B are schematic views of a typical belted section of a corrugator machine. A corrugator machine 50 in FIG. 1A has an upper corrugator belt 52 and a lower corrugator belt 54 which together support and pull a corrugated paper product 56 therethrough. After passing over hot plates 62, the upper and lower belts 52, 54 together pull the corrugated paper product 56 between them, maintaining the speed of the operation and cooling the paper product 56. Weighted rollers 66 apply pressure from within the endless loops formed by belt 52 and belt 54 toward one another, so that corrugat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com