Honing tool for honing blind bores

a technology for honing tools and blind bores, applied in the field of honing tools, can solve the problems of limited idle travel, and achieve the effects of reducing wear and tear, keeping the bore straight, and not so fas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

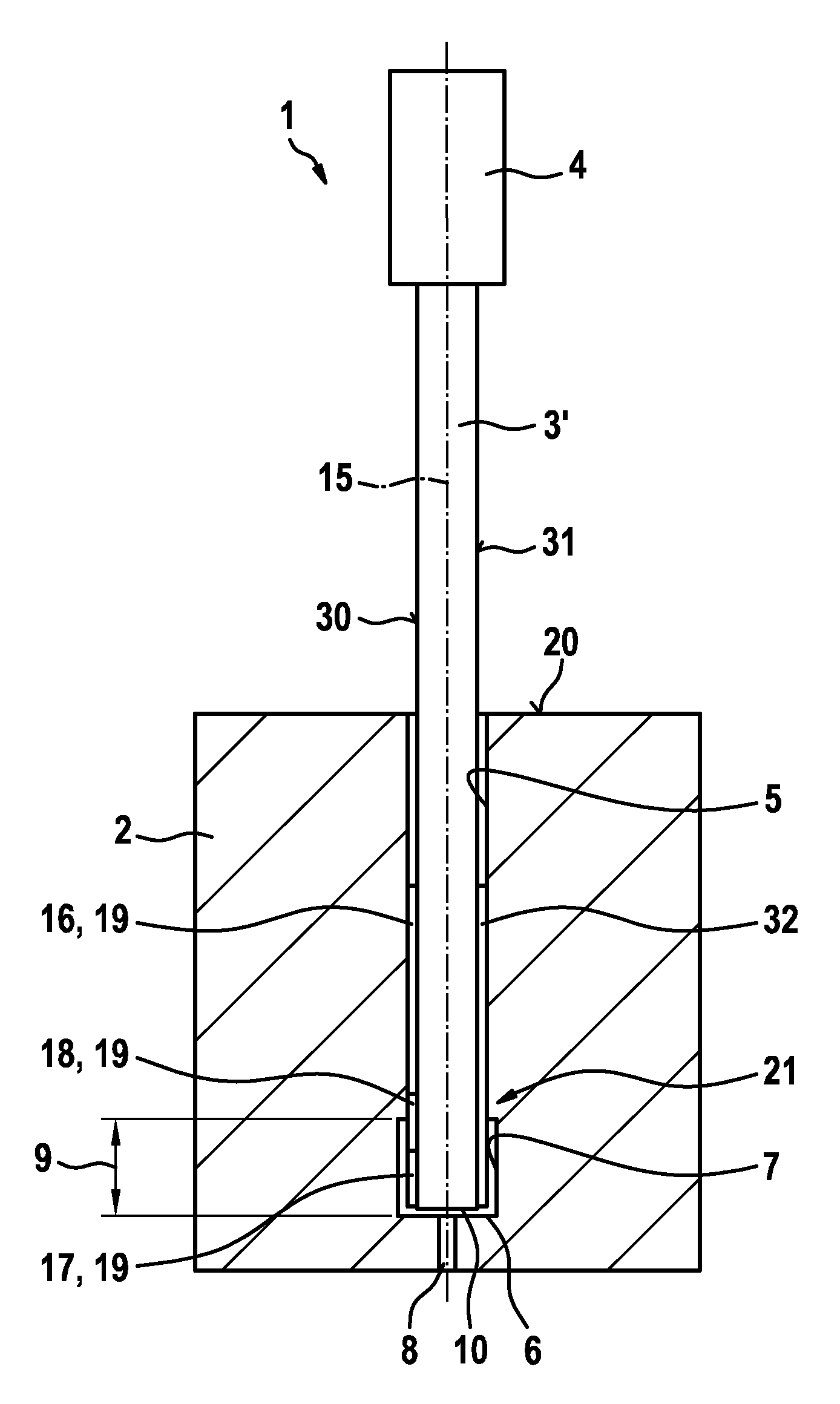

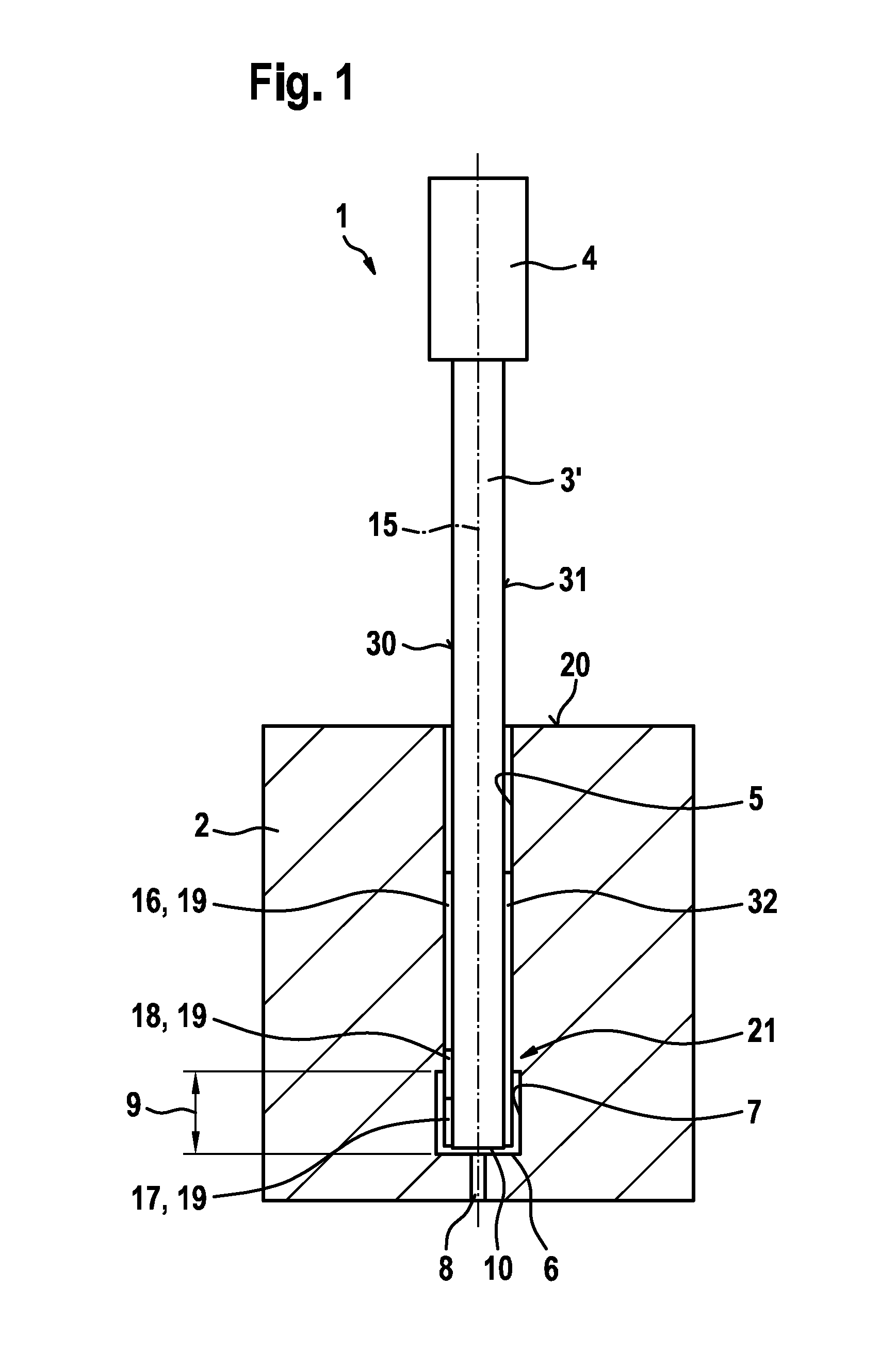

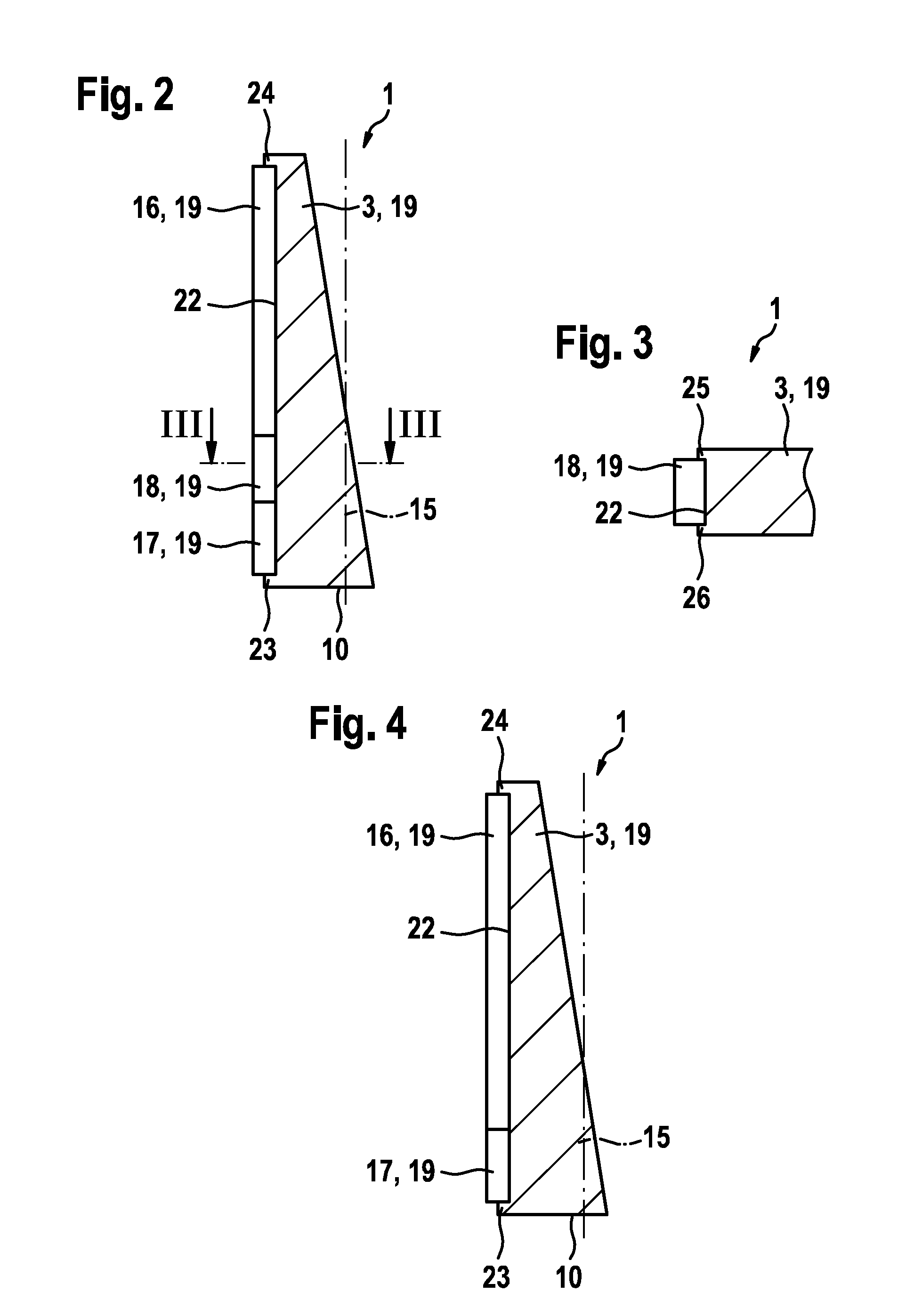

[0019]FIG. 1 shows a honing tool 1 and a work piece 2 in a schematic depiction according to a first exemplary embodiment of the invention.

[0020]The honing tool 1 comprises a stone carrier 3 (FIG. 2), a honing tool body 3′ and a cylindrical section 4, on which the honing tool 1 can be clamped into a chuck of a machine. By way of illustration, the honing tool 1 is introduced into a bore 5, which is configured as a blind bore 5. In this case, the blind bore 5 has an expanded section 7 at a lower end 6. In addition, provision is made for a bore 8 with reduced diameter, which opens out into the expanded section 7.

[0021]The expanded section 7 specifies a limited idle travel 9 for machining the bore using the honing tool 1. The limited idle travel 9 is hereby limited by a lower end of the honing tool body 3′ striking against the lower end 6 of the expanded section 7.

[0022]The honing tool 1 has a longitudinal axis 15. In order to machine the bore 5, the honing tool 1 is displaced in the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com