Grease filter

a filter and filter body technology, applied in the field of filtering, can solve the problems of reducing the energy efficiency of ventilation apparatus, affecting and causing pressure loss inside the flow field, so as to reduce the flow resistance of air, reduce the loss, and enhance the efficiency of oil capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

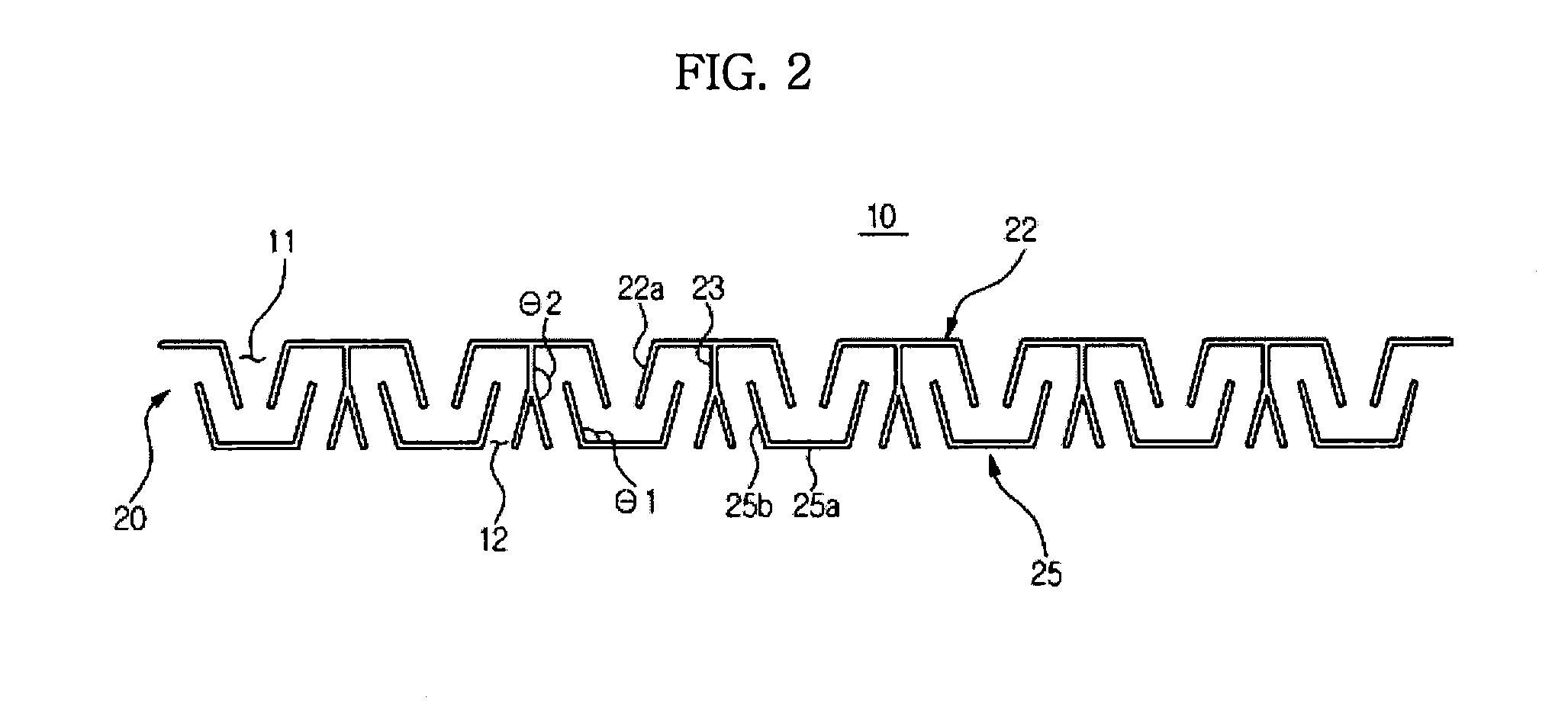

[0040]Reference will now be made in detail to the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout.

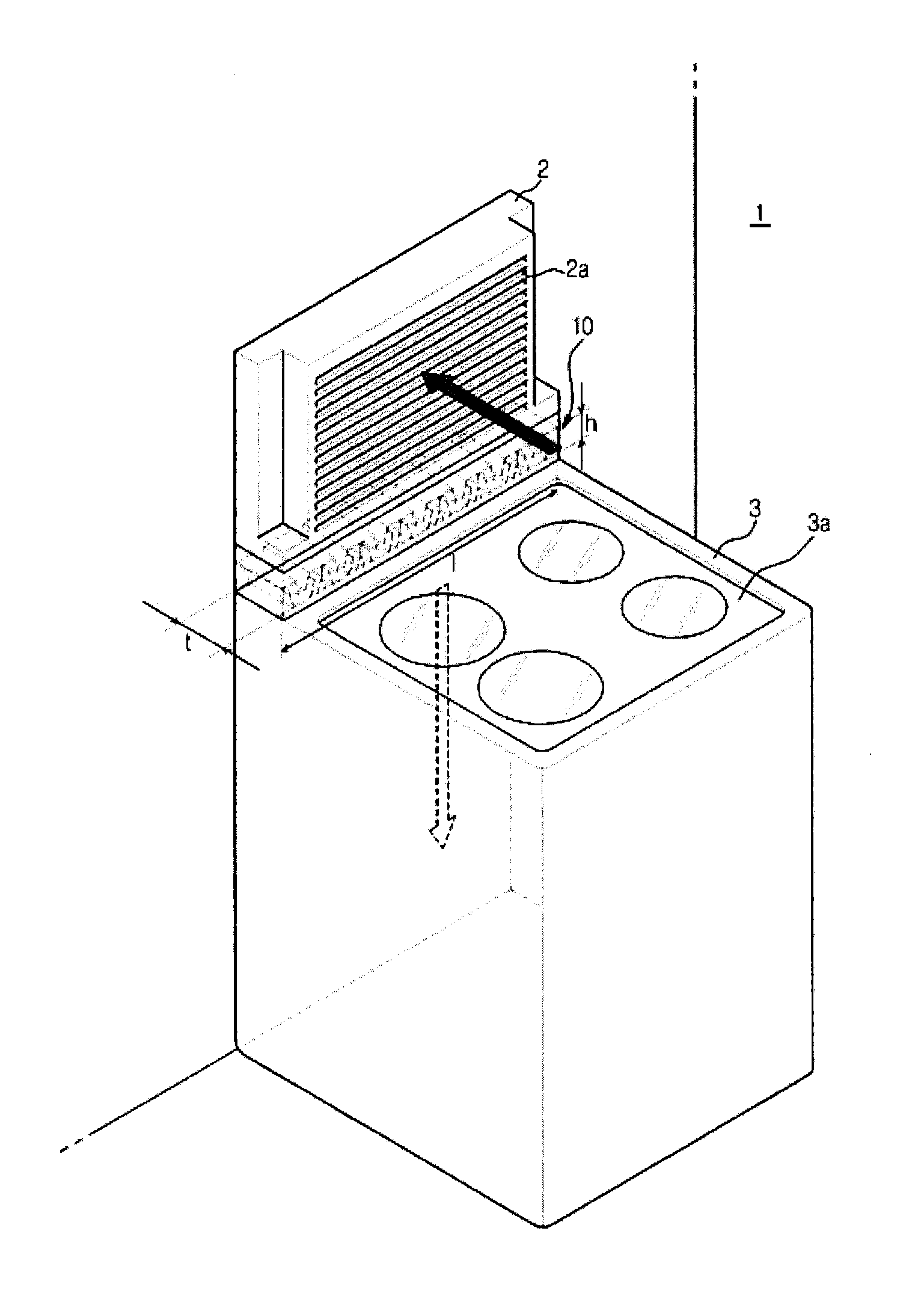

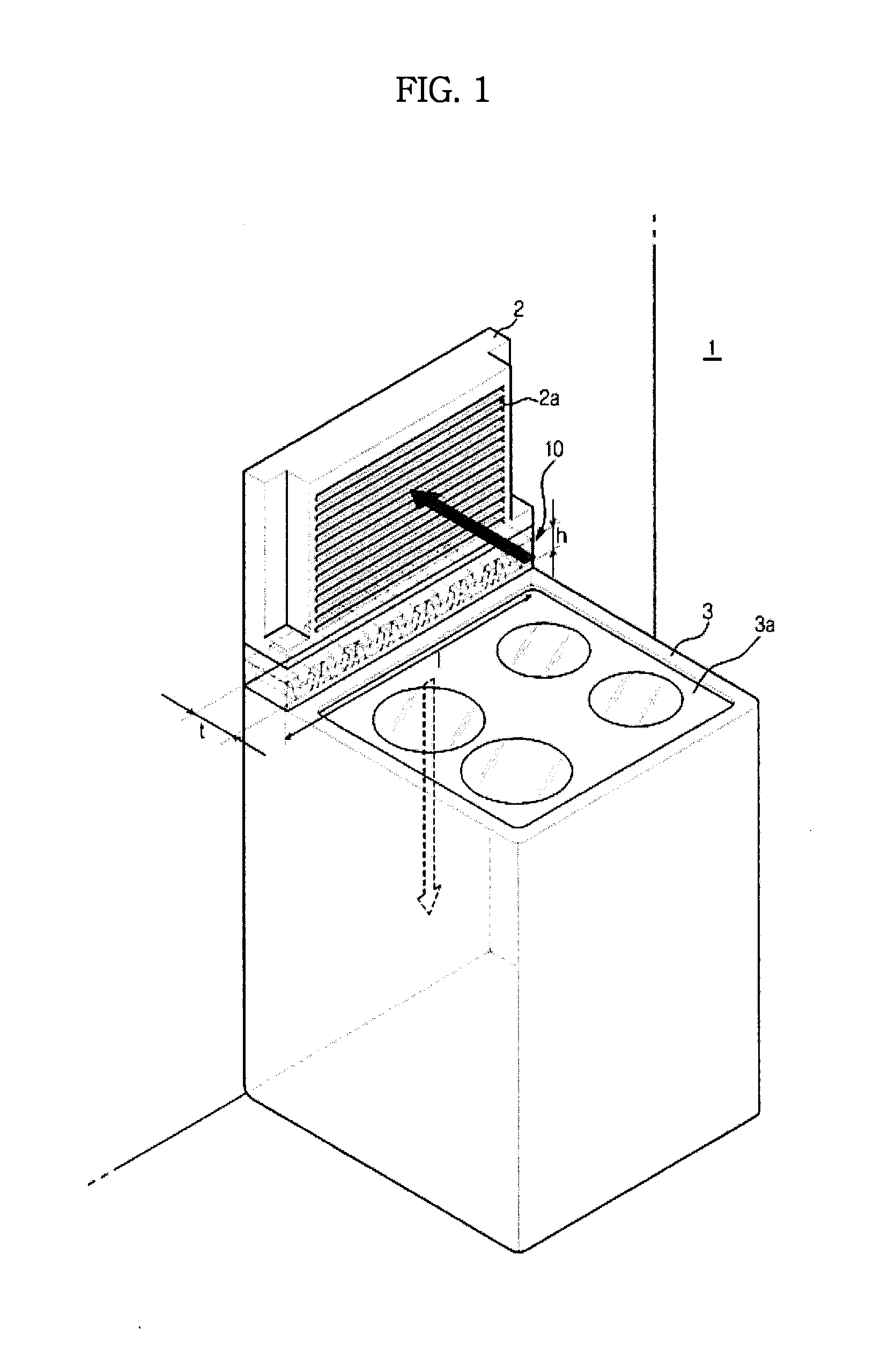

[0041]Referring to FIG. 1, a cooking apparatus 1 includes a body 3 forming an exterior, a heating apparatus 3A provided at an upper side of the body 3, and a suction portion 2 provided on an edge of a side of the body 3.

[0042]The heating apparatus 3A is provided to apply heat directly to a food or a cookware containing food by generating high-temperature heat.

[0043]Although an electric range, an upper portion of which is provided in a flat shape and disposed at an upper surface thereof, is illustrated as the heating apparatus 3A of the embodiment of the present invention, a gas range or an apparatus configured to perform a cooking by applying heat on a food may also be used as the heating apparatus 3A.

[0044]The suction portion 2 may be protrudedly formed from an upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com